3

Contents

Introduction................................................1

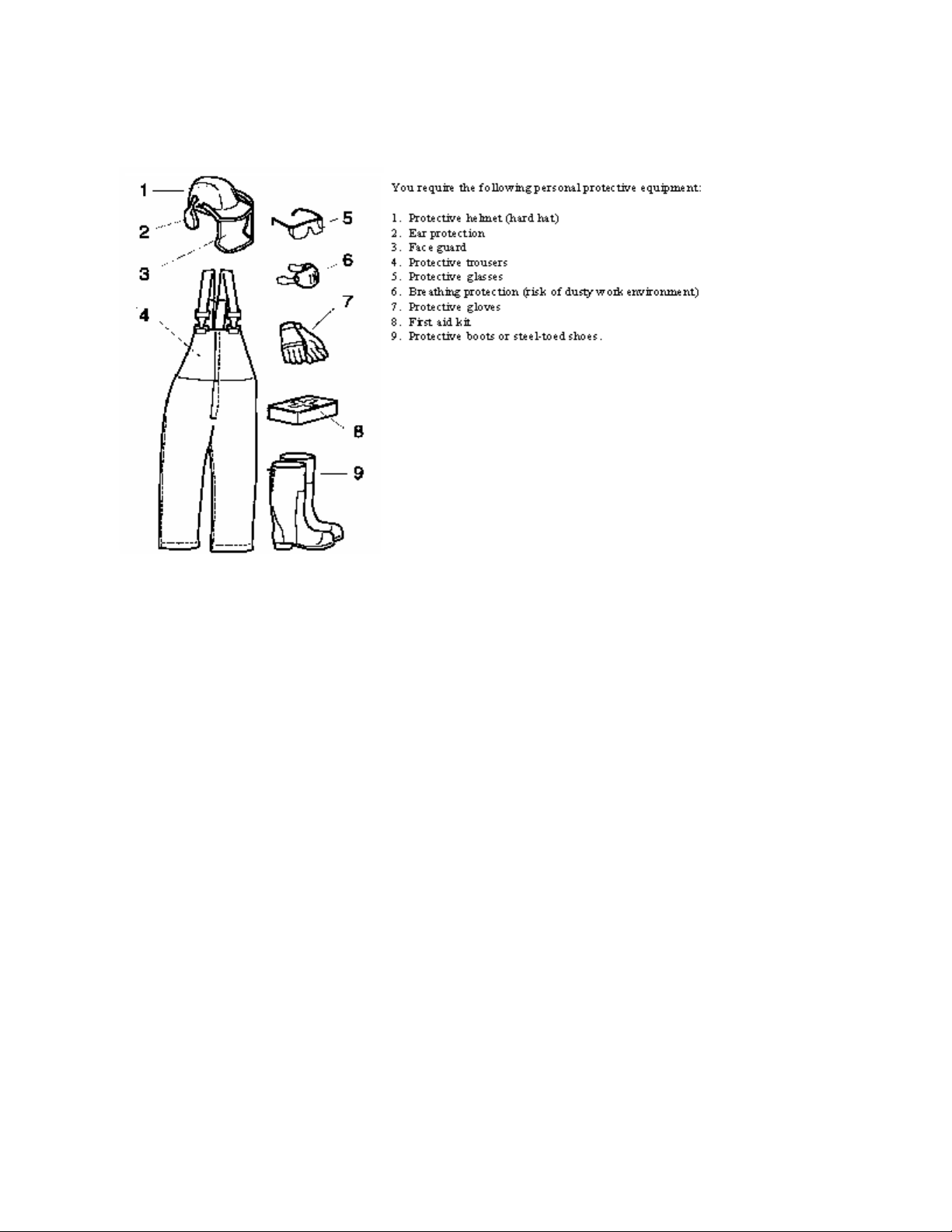

Safety...........................................................4

Safe Operating Practices .........................4

Training...................................................4

Preparation...............................................4

Operating.................................................5

Slope Operation.......................................6

Maintenance and Storage ........................6

Safety and Instructional Decals................8

Controls.......................................................9

Throttle....................................................9

Safety Bail...............................................9

Parking Brake..........................................9

Hour Meter..............................................9

Specifications............................................10

Operating..................................................11

Before you Start.....................................11

Adding Fuel ..............................................12

Using Stabilizer/Conditioner.................13

Filling the Fuel Tank.............................13

Checking the Engine Oil Level...............14

Starting and Stopping the Engine .........15

Starting the Engine................................15

Stopping the Engine ..............................16

Grinding the Stump.................................16

Maintenance.............................................19

Recommended Maintenance Schedule..19

Cleaning the Cyclone Air Filter ............20

Replacing the Air Filter.........................21

Changing the Engine Oil.......................23

Changing the Oil ...................................23

Cleaning the Sediment Cup...................24

Servicing the Spark Plug.......................25

Removing the Spark Plug......................25

Installing the Spark Plug .......................25

Cutting Blade.........................................26

Replacing Cutting Blades......................26

Parking Brake Adjustment ....................27

Cleaning and Washing...........................27

Lubricating the Bearings.......................27

Drive Belt..............................................28

Belt Drive Adjustment...........................28

Storage ......................................................29

Troubleshooting.......................................30

Warranty ................................. Back Cover