Contents

Safety.......................................................................4

GeneralSafety...................................................4

SafeOperatingPractices....................................4

AeratorSafety....................................................6

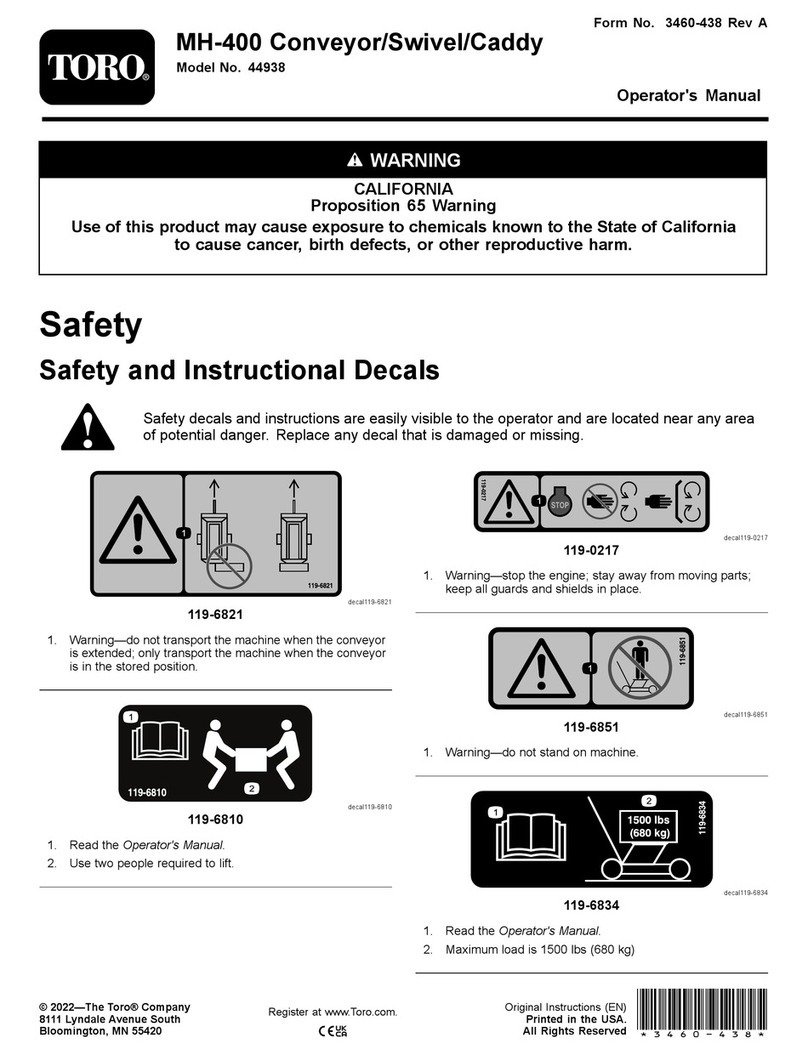

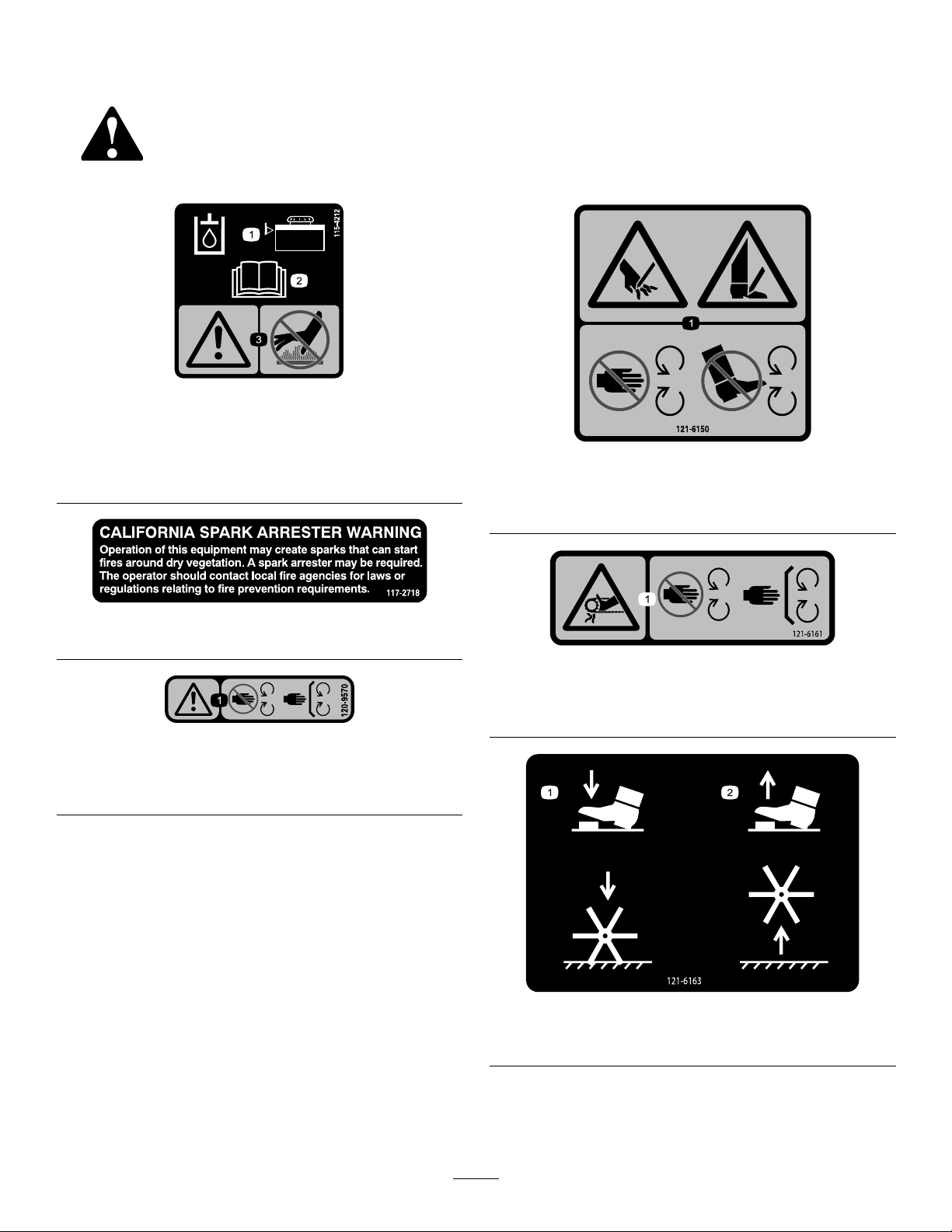

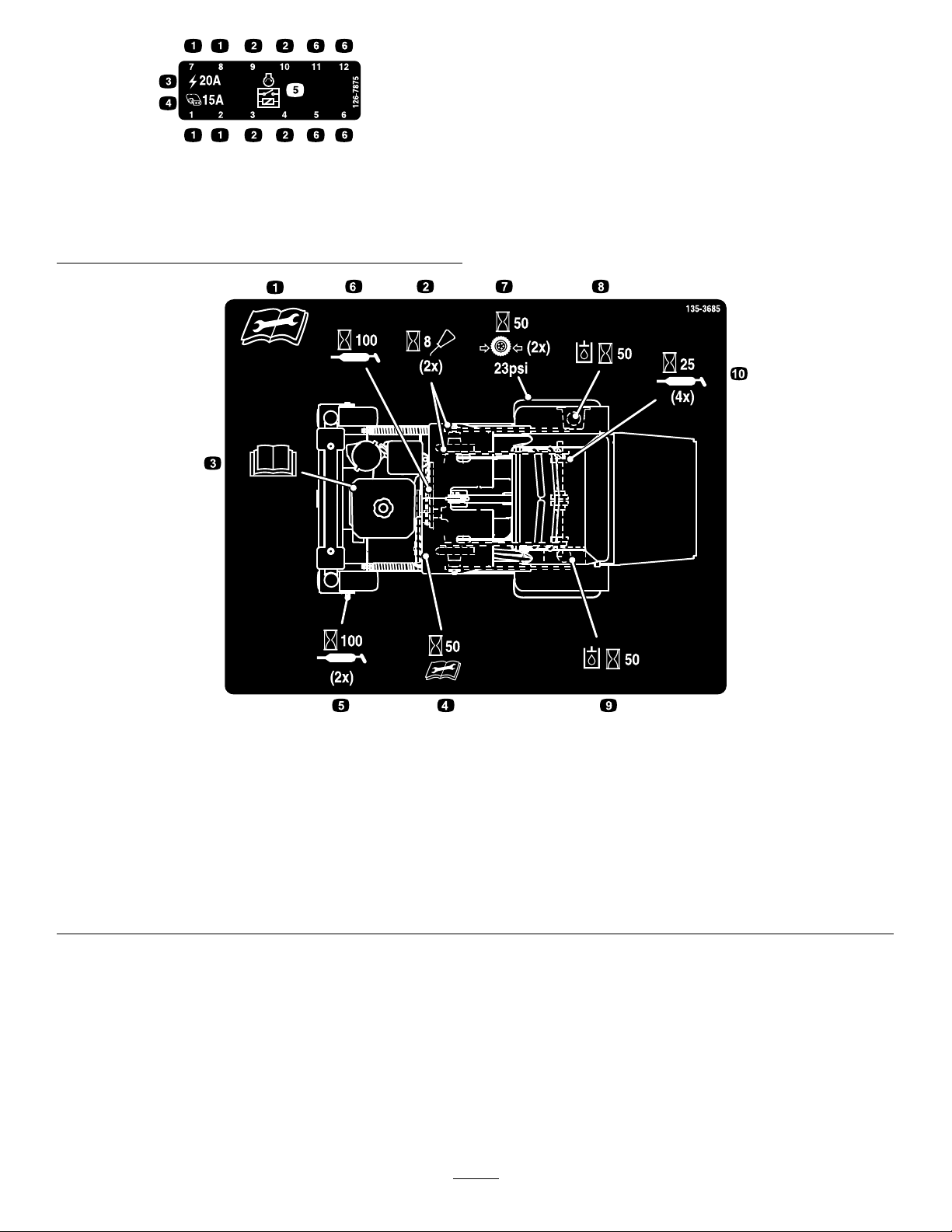

SafetyandInstructionalDecals..........................8

Setup......................................................................12

1CheckingTireAirPressure............................12

2ServicingtheEngineOil.................................12

3CheckingtheBatteryCharge.........................12

4CheckingtheTransmissionFluid...................13

5ChecktheAuxiliaryHydraulicFluid

Level.............................................................13

ProductOverview...................................................14

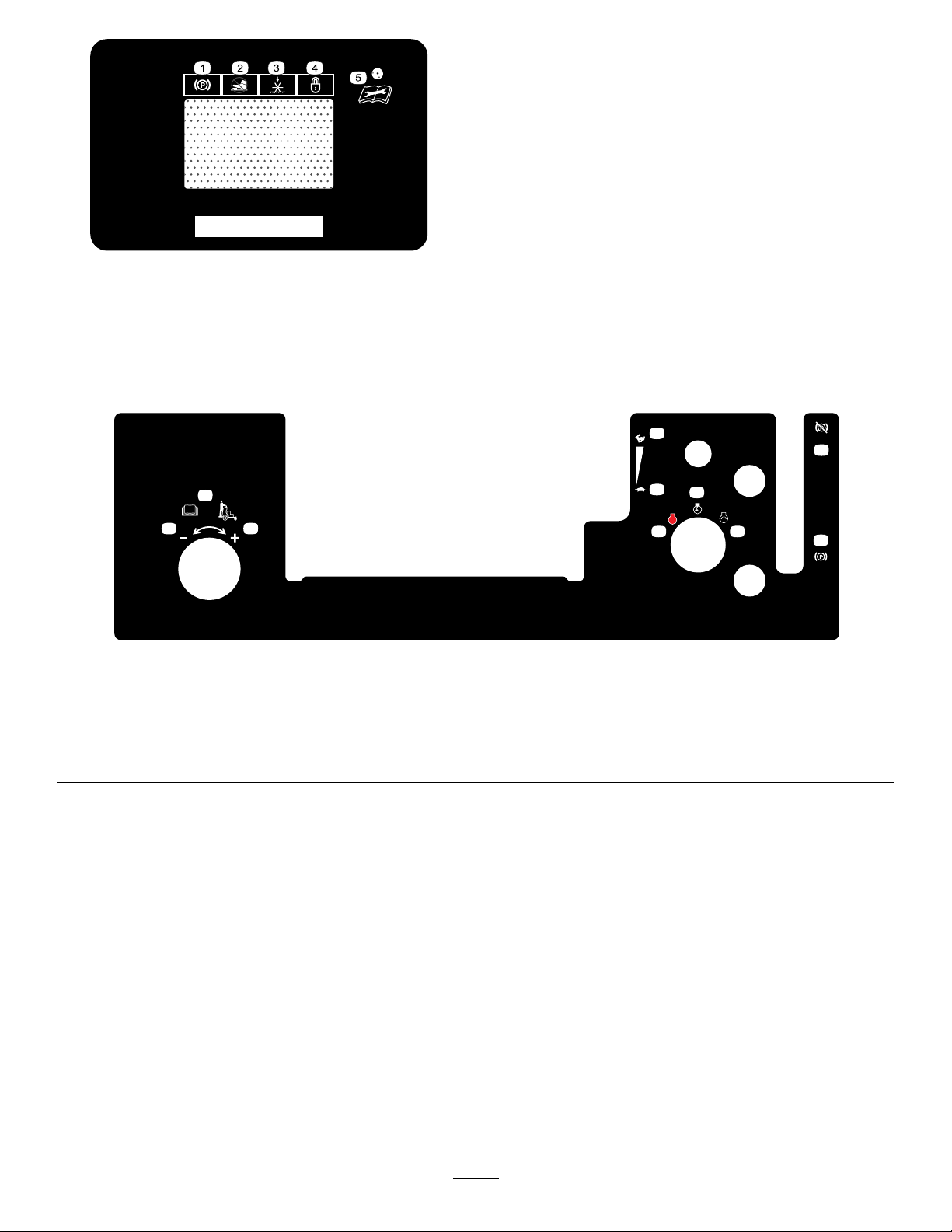

Controls...........................................................14

Specications..................................................21

Operation................................................................21

AddingFuel......................................................21

OpeningandClosingtheFuelShutoff

Valve.............................................................22

StartingtheEngine...........................................22

CheckingtheSafetyInterlock...........................23

LoweringtheTines...........................................23

ChangingtheTineDepthSetting......................23

Locking/UnlockingtheTineDepth

Setting...........................................................23

AdjustingtheOperatorWeightControl

Valve.............................................................23

RaisingtheTines..............................................24

ShuttingOfftheEngine.....................................24

DrivingtheMachine..........................................24

PositioningtheAir-CleanerCoverforColdor

WarmAirT emperature..................................25

AdjustingtheFrontReference/Speed

ControlBar....................................................26

LoadingtheMachine........................................26

TransportingtheMachine.................................26

Maintenance...........................................................28

MaintenanceSafetyInformation.......................28

RecommendedMaintenanceSchedule(s)...........30

Pre-MaintenanceProcedures..............................31

PreparingforMaintenance...............................31

Lubrication..........................................................31

LubricatingtheChains......................................31

LubricatingtheGreaseFittings.........................32

EngineMaintenance...........................................32

ServicingtheAirCleaner..................................32

ServicingtheEngineOil....................................33

ServicingtheSparkPlug...................................35

CheckingtheSparkArrester.............................36

ElectricalSystemMaintenance...........................36

JumpStartingtheMachine...............................36

ServicingtheBattery.........................................37

DriveSystemMaintenance..................................38

CheckingtheDriveTireAirPressure.................38

CheckingtheWheelHubBolts..........................38

CheckingtheT orqueoftheWheelLug

Nuts..............................................................38

CheckingtheConditionoftheChains...............39

CheckingtheSprocketCondition......................39

MaintainingtheChain.......................................39

CheckingtheT orqueoftheTransmission

OutputShaftNut...........................................39

AdjustingtheMotionControlLinkage................40

AdjustingtheMotionControlTracking...............40

CheckTransmissionMountBoltTorque............41

BrakeMaintenance.............................................41

AdjustingtheParkingBrake..............................41

BeltMaintenance................................................42

CheckingtheConditionandT ensionofthe

Belts..............................................................42

AdjustingtheAuxiliaryPumpDrive

Belt................................................................42

CheckingtheTransmissionDriveBelt

Tension.........................................................42

HydraulicSystemMaintenance...........................43

AuxiliaryHydraulicFluidSpecication..............43

CheckingtheAuxiliaryHydraulicFluid

Level.............................................................43

ChangingtheAuxiliaryHydraulicReservoir

FluidandFilter..............................................43

TransmissionFluidSpecication......................45

CheckingtheTransmissionFluidLevel.............45

ChangingtheHydraulicTransmissionFilters

andFluid.......................................................45

TineMaintenance.................................................47

CheckingtheTines...........................................47

AdjustingtheTineDriveChain..........................47

AdjustingtheReturn-to-UpSpring....................48

ChassisMaintenance...........................................48

CheckforLooseHardware...............................48

Cleaning..............................................................49

CleaningtheEngineandtheExhaust

SystemArea.................................................49

RemovingtheEngineShroudsandCleaning

theCoolingFins............................................49

CleaningtheDebrisfromtheMachine...............49

DisposingofWaste...........................................49

Storage...................................................................50

Troubleshooting......................................................51

3