Contents

Safety.......................................................................3

GeneralSafety...................................................3

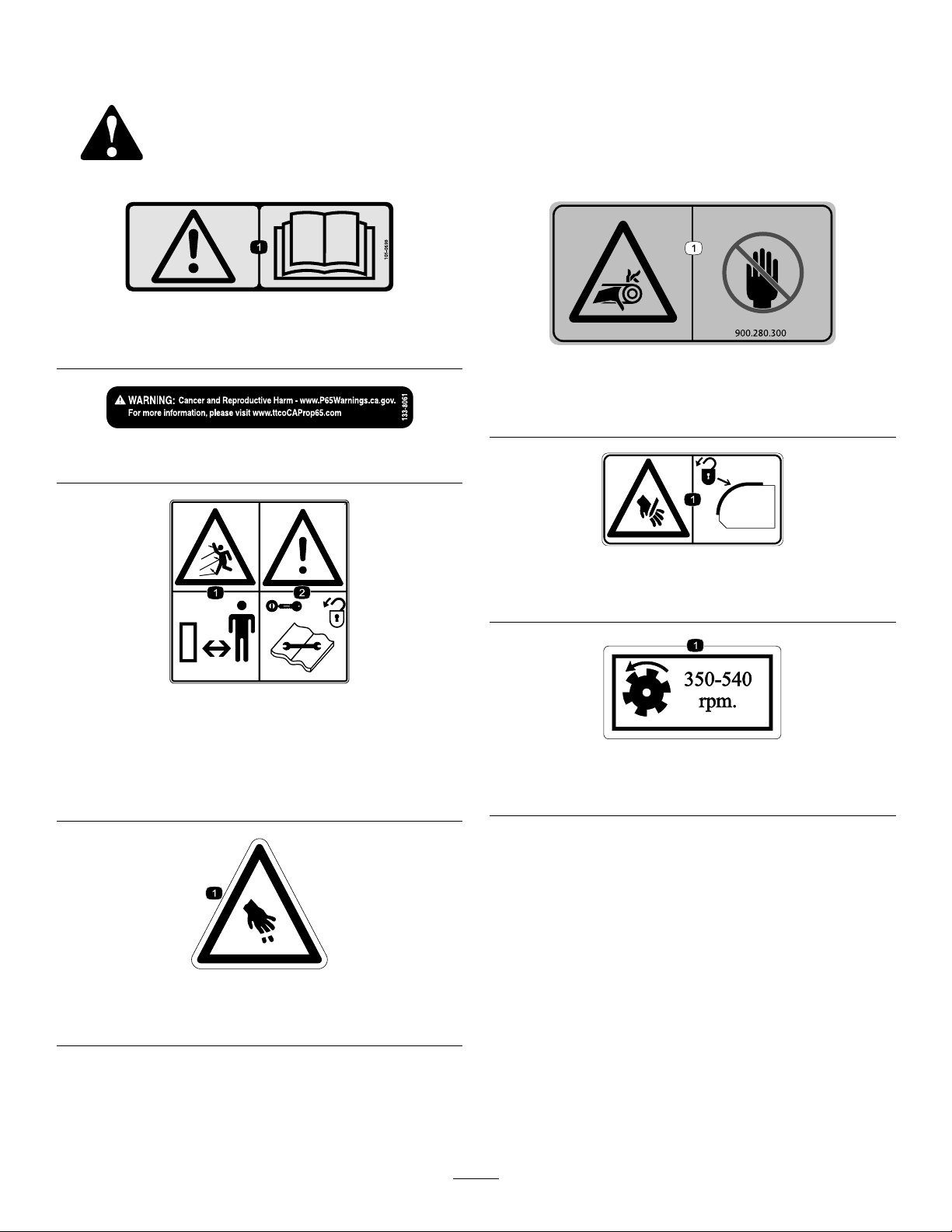

SafetyandInstructionalDecals..........................4

Setup........................................................................6

InspectingtheMachine.......................................6

ProductOverview.....................................................7

Specications....................................................7

Attachments/Accessories...................................7

BeforeOperation...................................................8

BeforeOperationSafety.....................................8

UnderstandingtheTractionUnitControls............8

PracticingtheOperatingProcedures..................8

Connectingtoa3-PointHitch..............................8

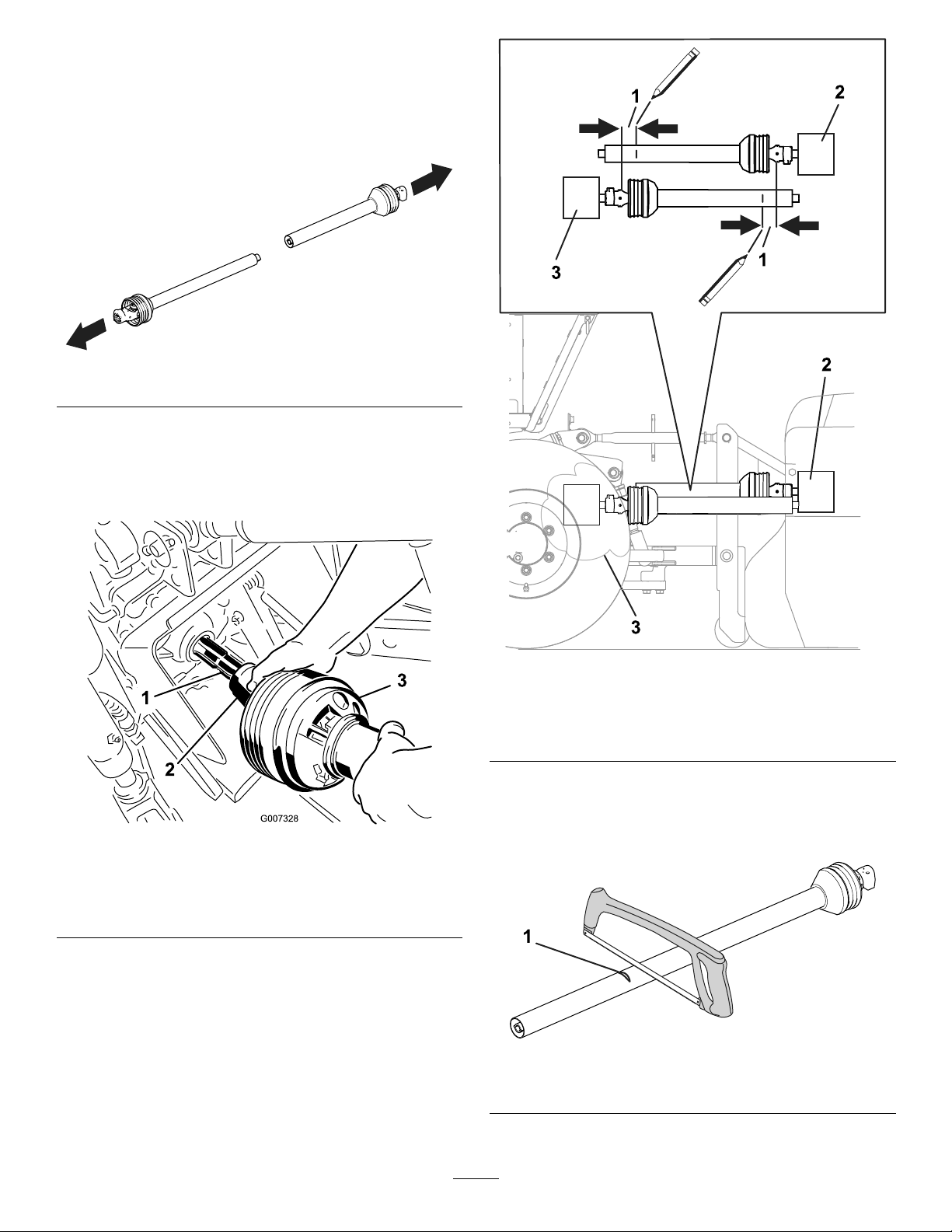

ConnectingthePTODriveshaft..........................9

ConnectingtheHydraulicHoses.......................13

AdjustingtheWorkingDepth.............................13

TransportingtheMachine.................................14

DuringOperation.................................................14

DuringOperationSafety...................................14

SlopeSafety.....................................................15

OperatingtheAttachment.................................15

OperatingTips.................................................18

AfterOperation....................................................18

AfterOperationSafety......................................18

RemovingtheAttachment................................18

Maintenance...........................................................20

RecommendedMaintenanceSchedule(s)...........20

MaintenanceSafety..........................................20

GreasingtheAttachment..................................21

CheckingtheGearboxLubrication....................21

ChangingtheGearboxLubrication...................22

InspectingtheBelts..........................................22

AdjustingtheV-BeltT ension.............................22

AdjustingtheConveyorBeltAlignment.............23

CleaningtheMachine.......................................24

InstallingtheCutterKnives...............................24

InstallingScarifyingKnives...............................25

Storage...................................................................29

StorageSafety..................................................29

PreparingtheMachineforStorage...................29

Troubleshooting......................................................30

Safety

GeneralSafety

Thisproductiscapableofcausingpersonalinjury.

Alwaysfollowallsafetyinstructionstoavoidserious

personalinjury.

•Readandunderstandthecontentsofboththis

Operator’sManualandtheoperator’smanualof

thetractionunitbeforeusingthismachine.Ensure

thateveryoneusingthisproductknowshowtouse

thismachineandthetractionunitandunderstands

thewarnings.

•Useyourfullattentionwhileoperatingthe

machine.Donotengageinanyactivitythat

causesdistractions;otherwise,injuryorproperty

damagemayoccur.

•Donotputyourhandsorfeetnearmoving

componentsofthemachine.

•Donotoperatethemachinewithoutallguards

andothersafetyprotectivedevicesinplaceand

workingonthemachine.

•Keepthemachineawayfrombystanderswhileit

ismoving.

•Keepchildrenoutoftheoperatingarea.Never

allowchildrentooperatethemachine.

•Stopthemachine,shutofftheengine,engage

theparkingbrakeofthetractionunit,removethe

key,andwaitforallmovingpartstostopbefore

servicing,fueling,oruncloggingthemachine.

Improperlyusingormaintainingthismachinecan

resultininjury.Toreducethepotentialforinjury,

complywiththesesafetyinstructionsandalways

payattentiontothesafety-alertsymbol,which

meansCaution,Warning,orDanger—personalsafety

instruction.Failuretocomplywiththeseinstructions

mayresultinpersonalinjuryordeath.

3