Toro 03662 User manual

Other Toro Lawn And Garden Equipment manuals

Toro

Toro Multi Pro 5700-D User manual

Toro

Toro GreensPro 1240 User manual

Toro

Toro multi-pro 1200 User manual

Toro

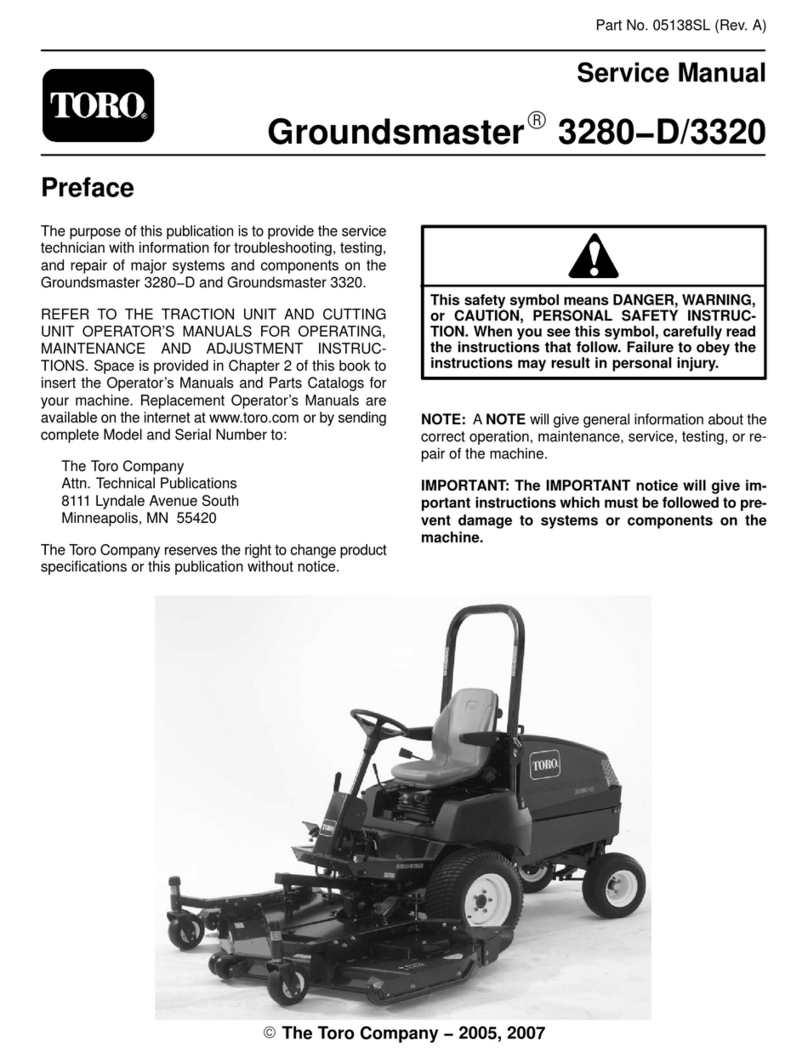

Toro Groundsmaster 3280-D User manual

Toro

Toro Greensmaster TriFlex 3300 User manual

Toro

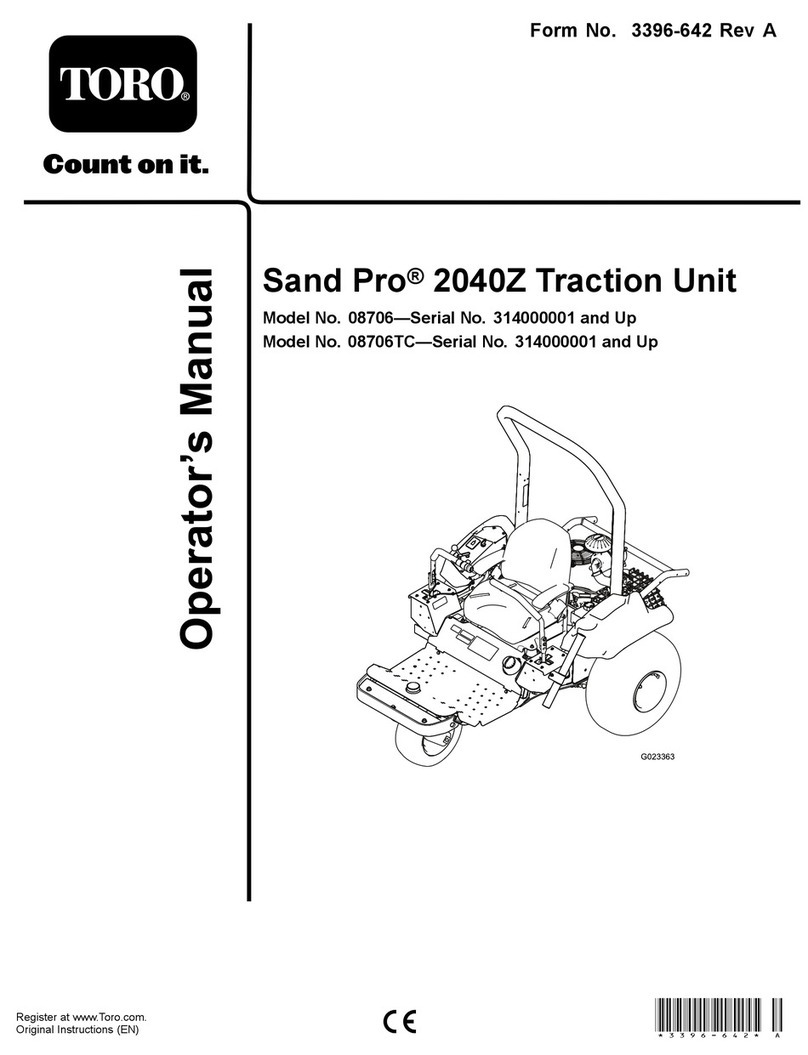

Toro Sand Pro 2040Z User manual

Toro

Toro Bullseye QuickGroom 550 User manual

Toro

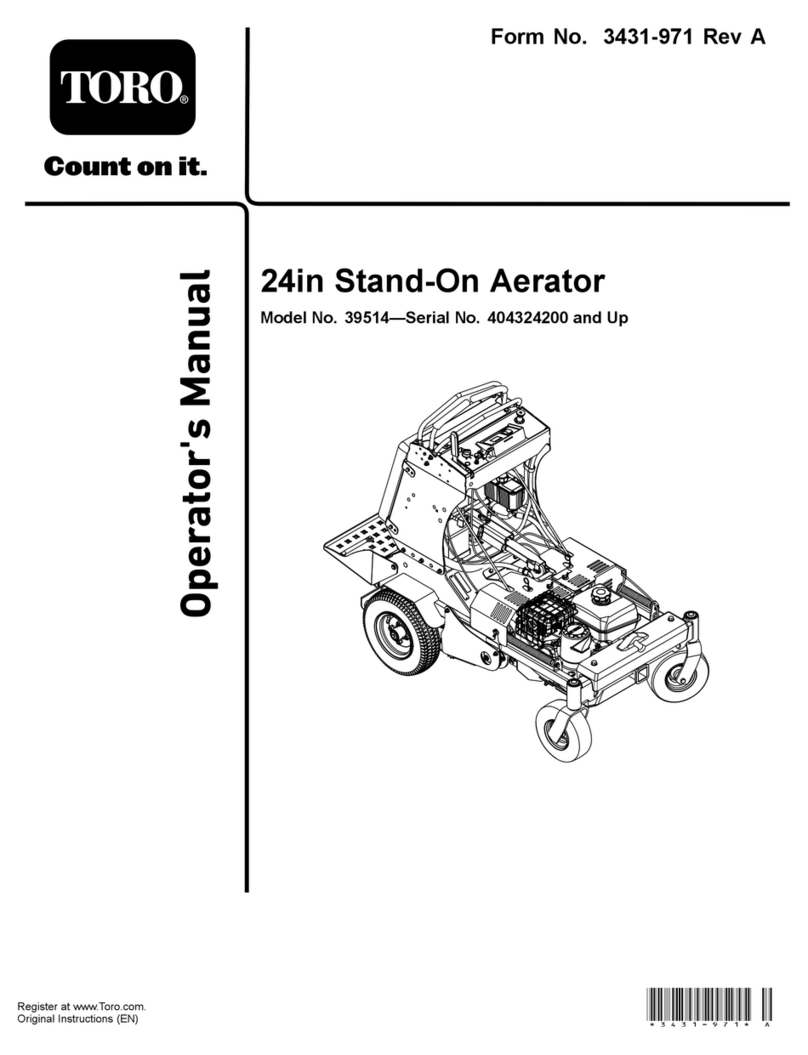

Toro 39514 User manual

Toro

Toro 58630 User manual

Toro

Toro ProCore User manual

Toro

Toro Bullseye QuickGroom 710 User manual

Toro

Toro T7 Series User manual

Toro

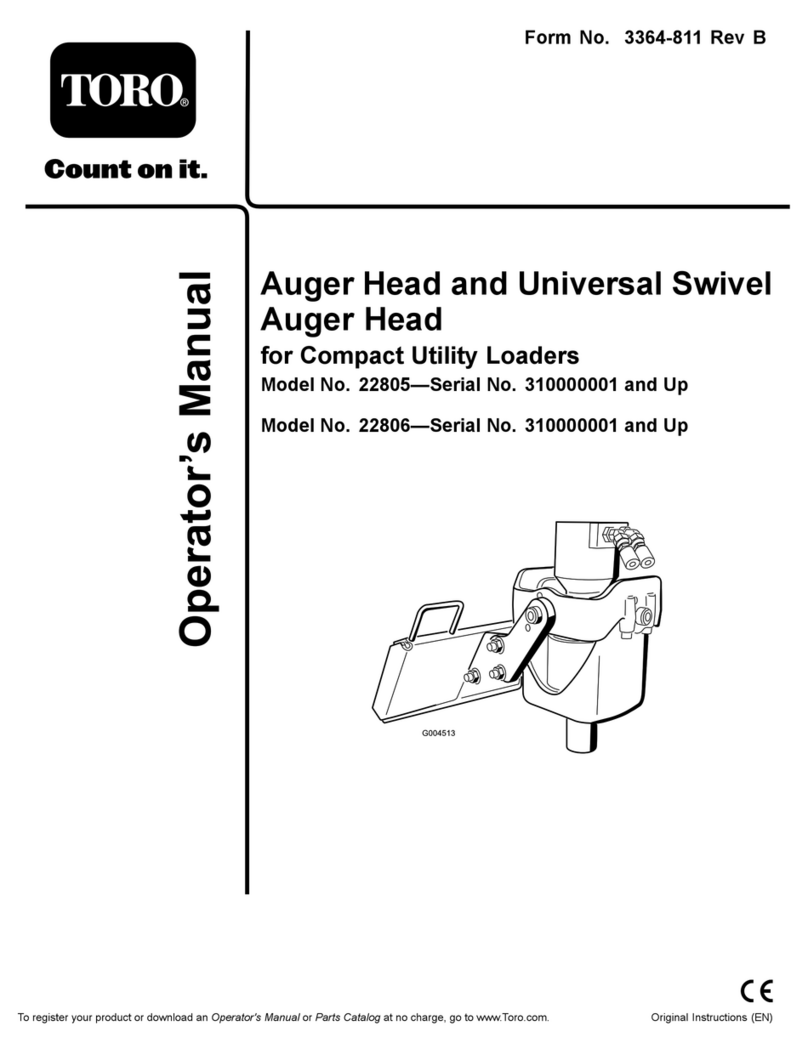

Toro 22805 User manual

Toro

Toro 135-7423 User manual

Toro

Toro eS3000SD 72V User manual

Toro

Toro Sand Pro 3040 User manual

Toro

Toro 04475 User manual

Toro

Toro VS-70 User manual

Toro

Toro 09830 User manual

Toro

Toro 22368 User manual

Popular Lawn And Garden Equipment manuals by other brands

Vertex

Vertex 1/3 HP Maintenance instructions

GHE

GHE AeroFlo 80 manual

Millcreek

Millcreek 406 Operator's manual

Land Pride

Land Pride Post Hole Diggers HD25 Operator's manual

Yazoo/Kees

Yazoo/Kees Z9 Commercial Collection System Z9A Operator's & parts manual

Premier designs

Premier designs WindGarden 26829 Assembly instructions

AQUA FLOW

AQUA FLOW PNRAD instructions

Tru-Turf

Tru-Turf RB48-11A Golf Green Roller Original instruction manual

BIOGROD

BIOGROD 730710 user manual

Land Pride

Land Pride RCF2784 Operator's manual

Makita

Makita UM110D instruction manual

BOERBOEL

BOERBOEL Standard Floating Bar Gravity Latch installation instructions