Thismanualidentiespotentialhazardsandhas

safetymessagesidentiedbythesafety-alertsymbol

(Figure2),whichsignalsahazardthatmaycause

seriousinjuryordeathifyoudonotfollowthe

recommendedprecautions.

g000502

Figure2

Safety-alertsymbol

Thismanualuses2wordstohighlightinformation.

Importantcallsattentiontospecialmechanical

informationandNoteemphasizesgeneralinformation

worthyofspecialattention.

Contents

Safety.......................................................................4

GeneralSafety...................................................4

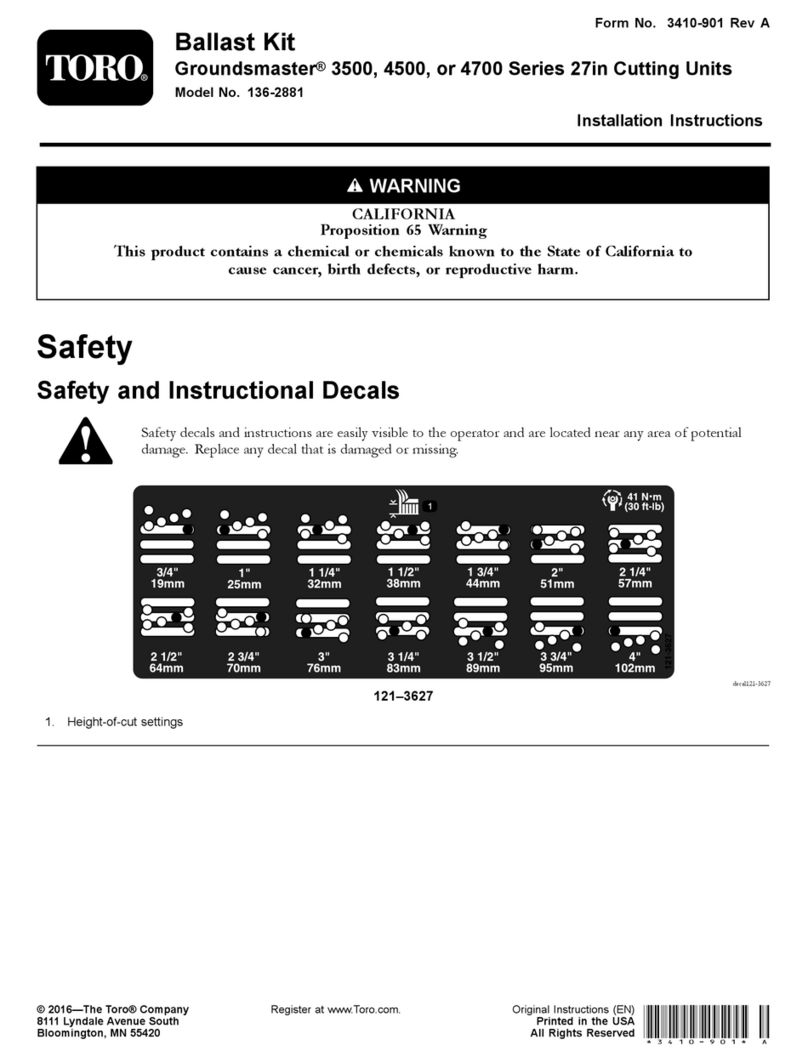

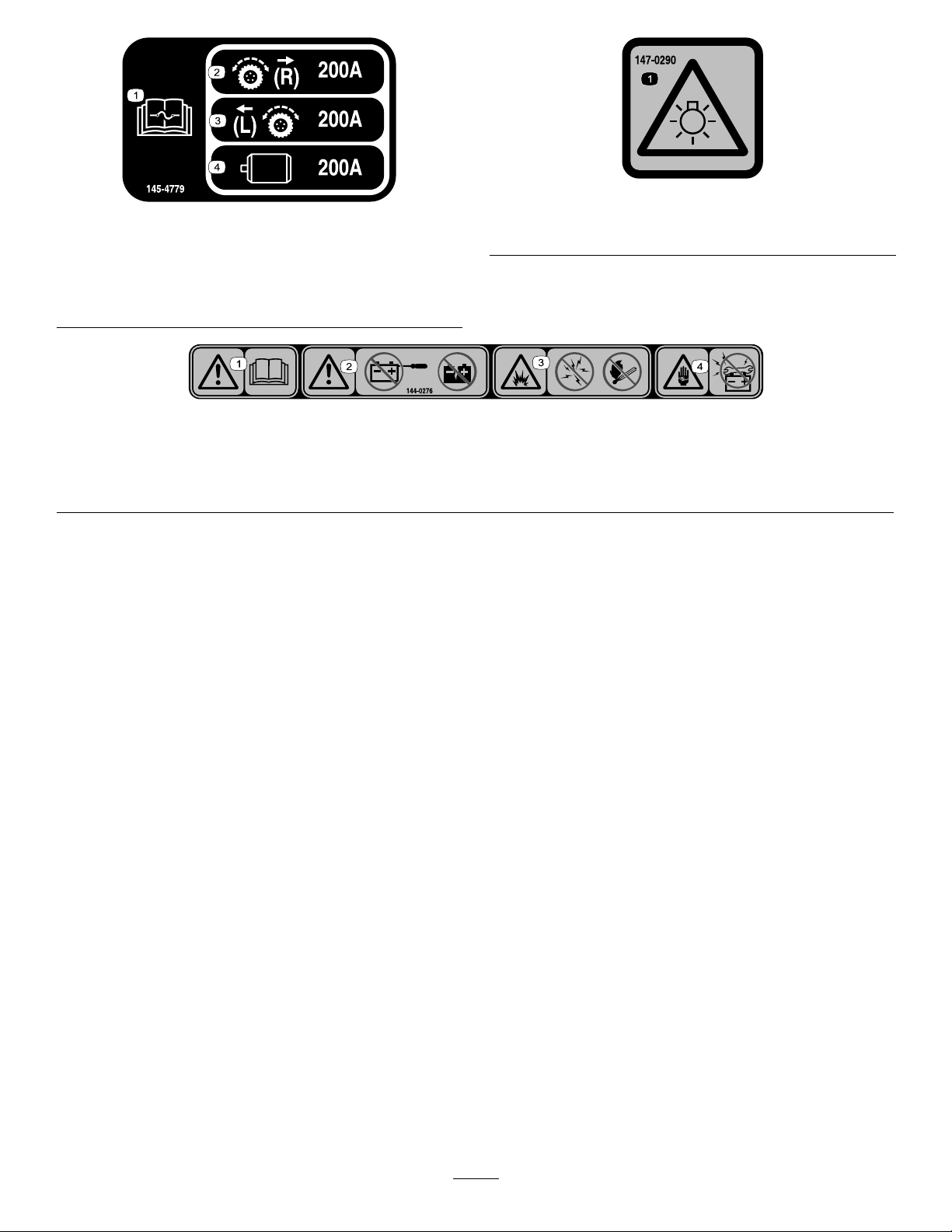

SafetyandInstructionalDecals..........................5

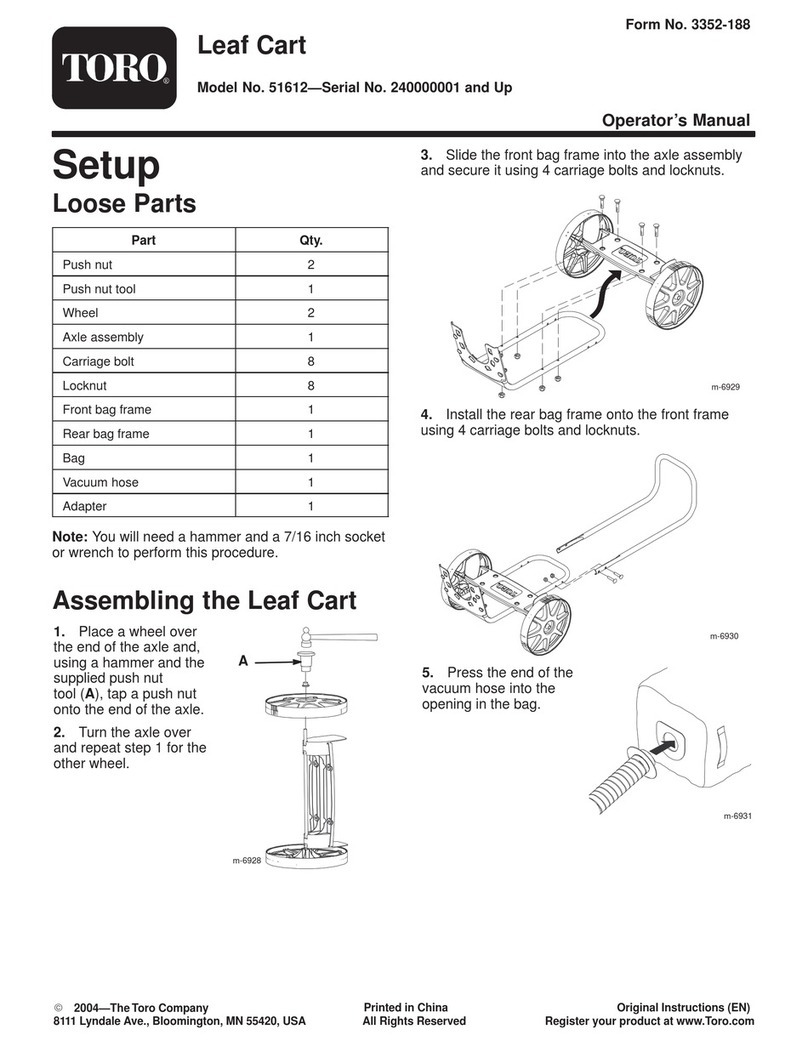

Setup......................................................................10

1CheckingtheHydraulicFluidLevel................10

2ChargingtheBatteries...................................10

ProductOverview....................................................11

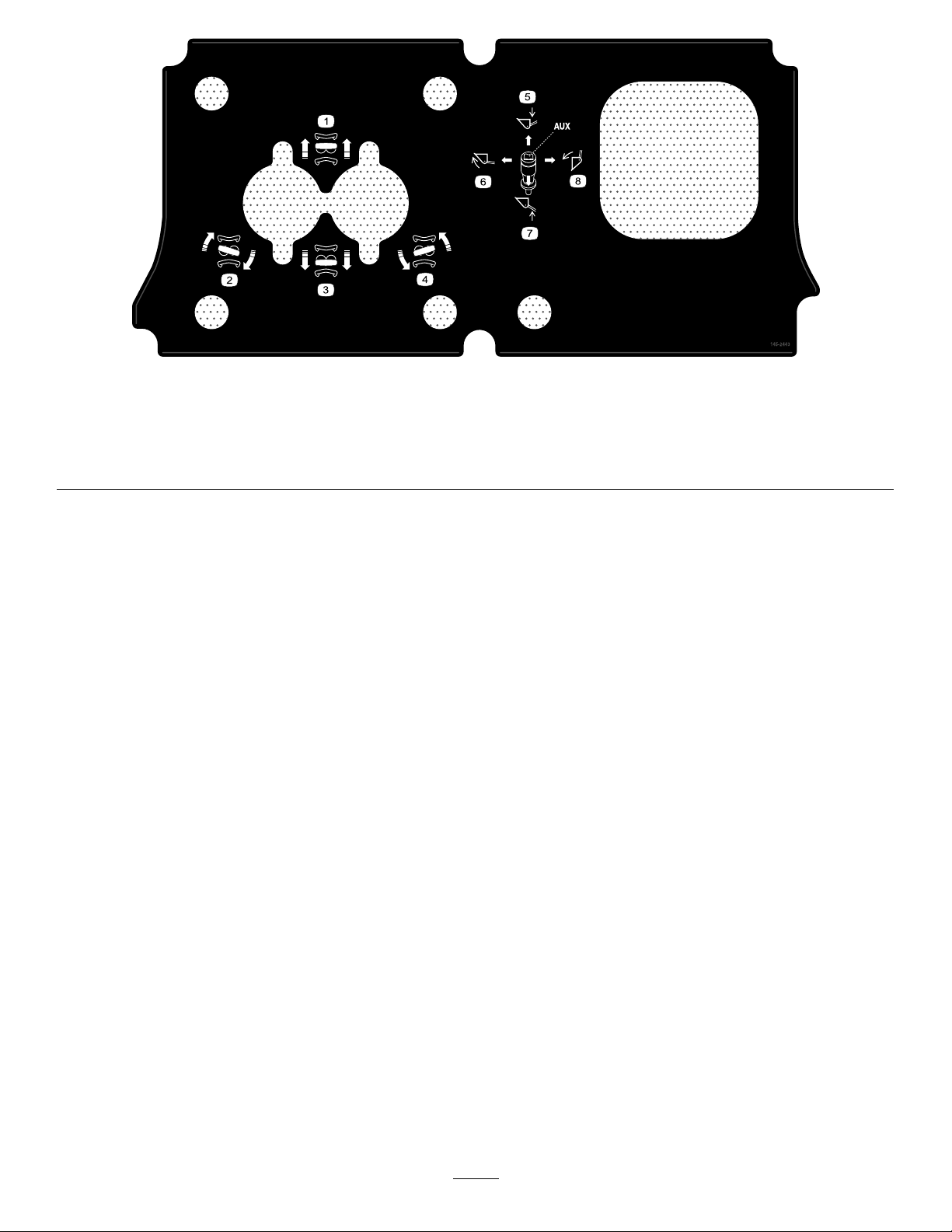

Controls............................................................11

InfoCenterDisplay........................................13

Specications..................................................15

Attachments/Accessories.................................15

BeforeOperation.................................................16

BeforeOperationSafety...................................16

PerformingDailyMaintenance..........................16

DuringOperation.................................................16

DuringOperationSafety...................................16

StartingtheMachine.........................................18

ShuttingOfftheMachine..................................18

SleepMode......................................................18

UsingAttachments...........................................18

ChangingtheAttachmentMode........................20

AfterOperation....................................................20

AfterOperationSafety......................................20

MovingaNon-FunctioningMachine..................21

LiftingtheMachine...........................................22

HaulingtheMachine.........................................22

TransportingtheLithium-IonBatteries..............24

ChargingtheBatteries......................................24

Maintenance...........................................................25

MaintenanceSafety..........................................25

RecommendedMaintenanceSchedule(s)...........26

Pre-MaintenanceProcedures..............................27

UsingtheCylinderLocks..................................27

AccessingInternalComponents.......................28

RemovingtheLowerFrontCover.....................28

Lubrication..........................................................29

GreasingtheMachine.......................................29

ElectricalSystemMaintenance...........................29

ElectricalSystemSafety...................................29

UsingtheBattery-DisconnectSwitch................29

ReplacingtheStaticStrap................................30

ServicingtheBatteries......................................30

MaintainingtheLithium-IonBatteries................30

MaintainingtheBatteryCharger.......................31

ServicingtheFuses..........................................31

DriveSystemMaintenance..................................31

CheckingtheTireTreads..................................31

CheckingtheWheel-LugNuts..........................31

Drive-MotorGearOilSpecications..................31

ChangingtheDrive-MotorGearOil...................32

ControlsSystemMaintenance.............................33

AdjustingtheControls.......................................33

HydraulicSystemMaintenance...........................33

HydraulicSystemSafety...................................33

RelievingHydraulicPressure............................33

HydraulicFluidSpecications...........................34

CheckingtheHydraulic-FluidLevel...................35

ReplacingtheHydraulicFilter...........................36

ChangingtheHydraulicFluid............................36

Cleaning..............................................................37

RemovingDebris..............................................37

WashingtheMachine.......................................37

Storage...................................................................38

StorageSafety..................................................38

StoringtheMachine..........................................38

BatteryStorageRequirements.........................38

Troubleshooting......................................................39

3