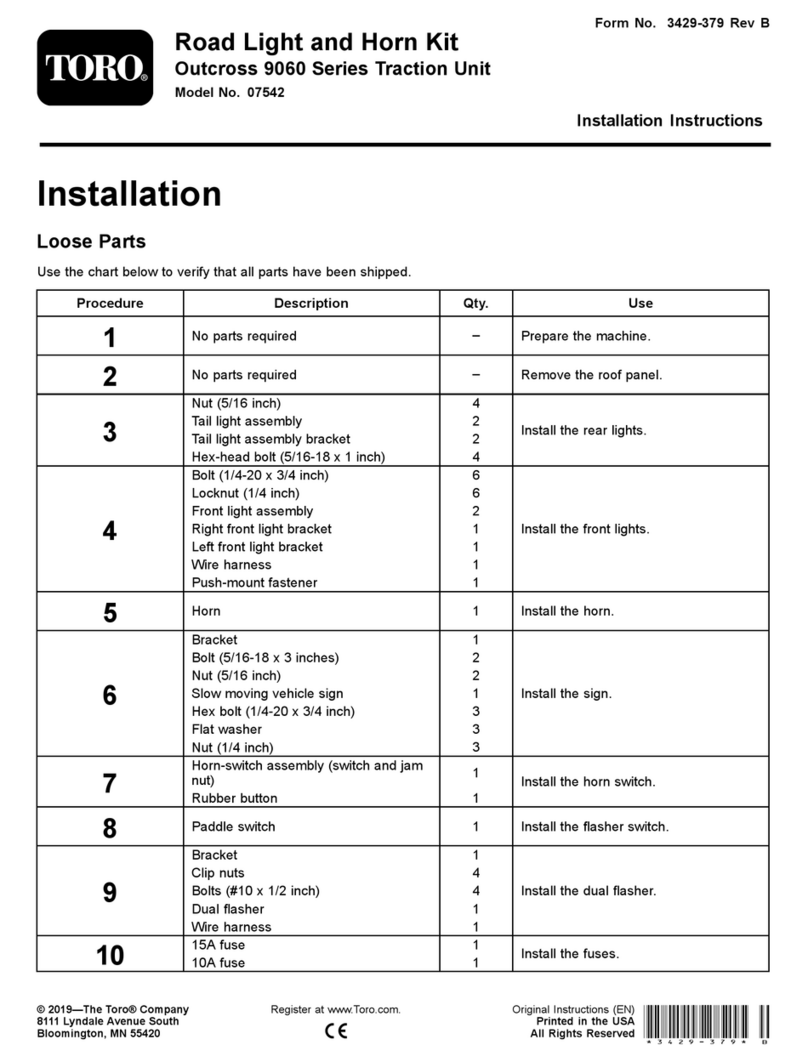

g229104

Figure4

1.Plug2.Spout

6.Positionthehydraulictankontothemachine

frameandensurethattheclearancebetween

thehydraulictankandthefueltankis3.2to9.5

mm(1/8to3/8inch).

7.Applyanti-seizelubricanttothethreadsofthe

3capscrews.Securethehydraulictanktothe

machineframewith3capscrews,atwashers,

andbushings.T orquethecapscrewsfrom3.4to

6.7N∙m(30to60in-lb).

8.Usingyournotestakenduringtheremovalof

theexistingtank,connectthehydraulichosesto

thetankttings.Tightenthehoseconnections.

9.Greensmaster3150machines:Connectthe

machinewireharnesstooil-levelsensor.

5

InstallingtheLeak-Detector

Tank

Greensmaster3150MachinesOnly

NoPartsRequired

Procedure

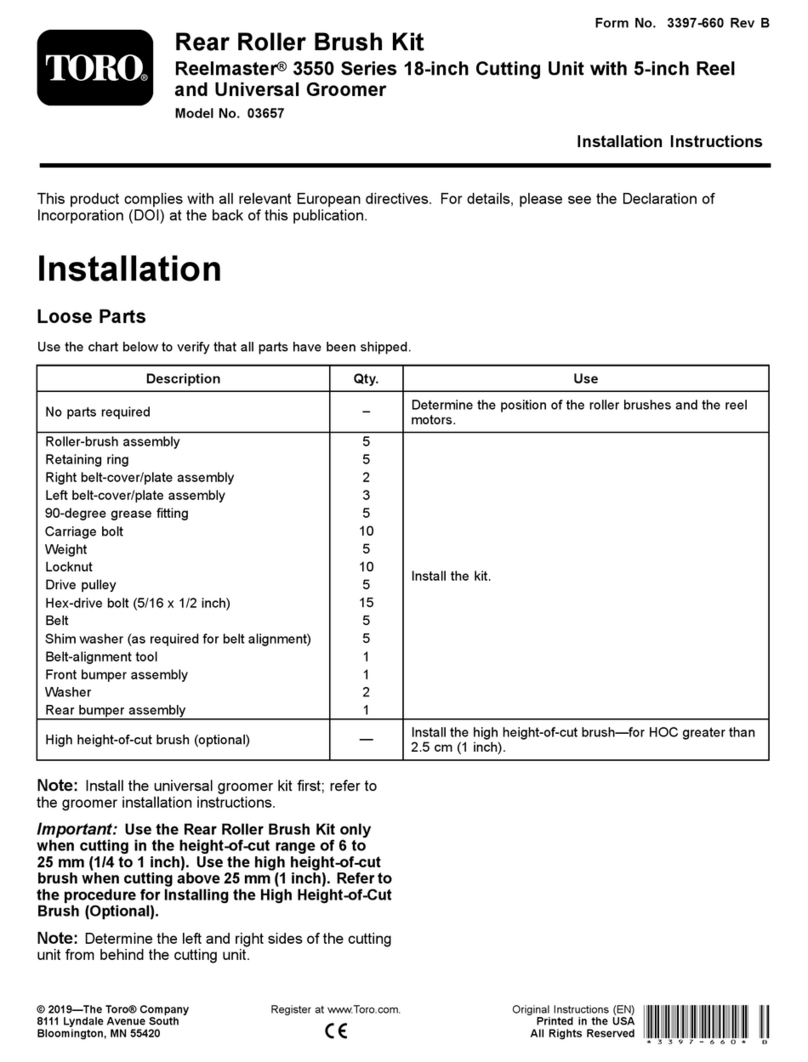

1.Positiontheleak-detectortankontothehydraulic

tank.

2.Usethecapscrewsandthelockwashersto

securethesolenoid-valveassemblytothe

hydraulictank

3.Connecttheoverowhosetothehydraulic-tank

spoutandsecureitwithahoseclamp.

4.Positionthecarboncanisterandbracketonto

theleak-detectortank.

5.Performthefollowingstepstosecurethe

leak-detectortanktothehydraulictank:

A.Applyanti-seizelubricanttothethreadsof

thecapscrews.

B.Usethecapscrews,atwashers,neoprene

washers,andspacerstosecurethe

leak-detectortankandcarboncanisterto

thehydraulictank.

C.Torquethecapscrewsto3.4to6.7N∙m(30

to60in-lb).

Important:Donotovertightenthe

capscrews.Ifyouovertightenthescrews,

thethreadsinthehydraulictankmay

becomedamaged.

6.Connecttheleak-detector-solenoidcoiltothe

machinewireharness.

7.Securethepump-inlethosetothehydraulic

pumpwithahoseclamp;refertoFigure2.

6

CompletingtheInstallation

NoPartsRequired

Procedure

1.Fillthehydraulictankwithnewhydraulicuid;

refertoyourmachineOperator’sManual.

2.Ifyourmachineisequippedwithaleak-detector

tank:

A.Connecttheoil-level-sensorwireconnector

tothemachinewireharness.

B.Connectthebattery;refertoyourmachine

Operator’sManual.

C.Ensurethattheleak-detectorsystemis

operating;refertoyourmachineOperator’s

Manual

3.Usethedipsticktomonitorthehydraulic-uid

level.

Note:Asairisremovedfromthehydraulic

circuit,youmayneedtoadjustthehydraulic-uid

levelafteryouinitiallyllthetank.

4