Maintenance

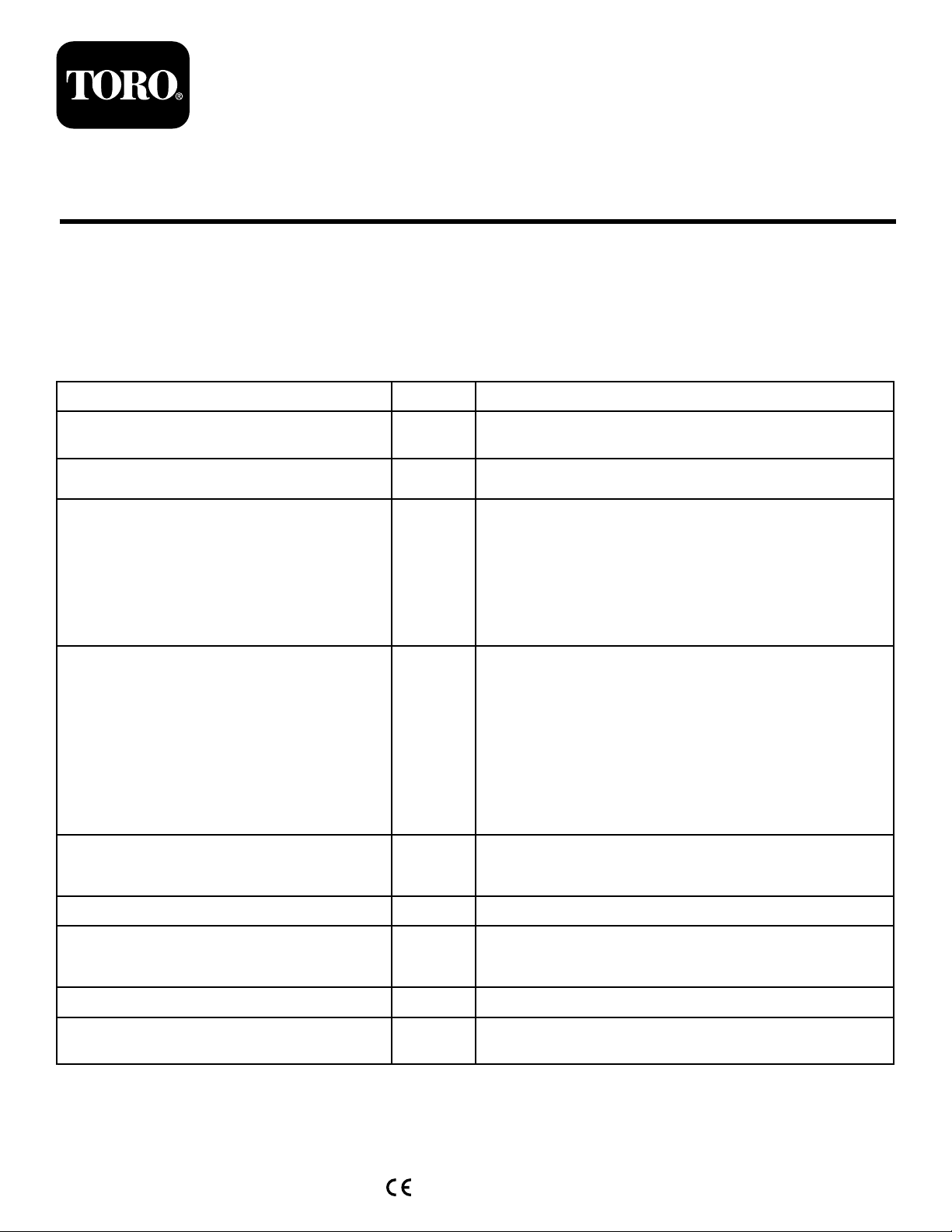

•Ensurethatthebrushisparalleltotherollerwith

1.5mm(0.060inch)clearancetolightcontact.

•Greasethettingsevery50hoursandafterevery

washing.

•Whenreplacingarollerbrush,torquetheJ-bolts

to2to3N∙m(20to25in-lb).

•Whenreplacingthebrush-shaft-drivenpulley,

torquethenutto36to45N∙m(27to33ft-lb).

•Whenreplacingthebrush-drivepulley,apply242

Loctite(blue)andtorquetheboltto20to26N∙m

(15to19ft-lb).

Note:Therollerbrush,theidlerbearing,andthebelt

areconsideredconsumableitems.

CheckingthePulley

Alignment

Important:Ensurethatthebeltisproperly

tensionedpriortocheckingthealignment.

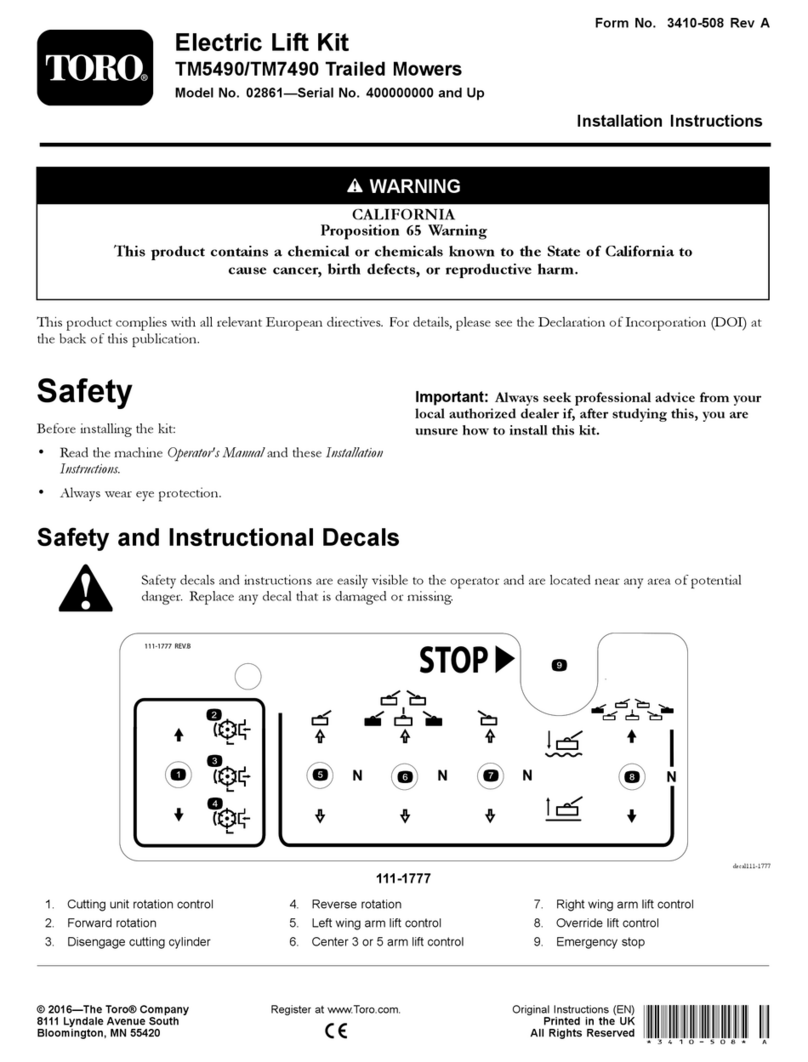

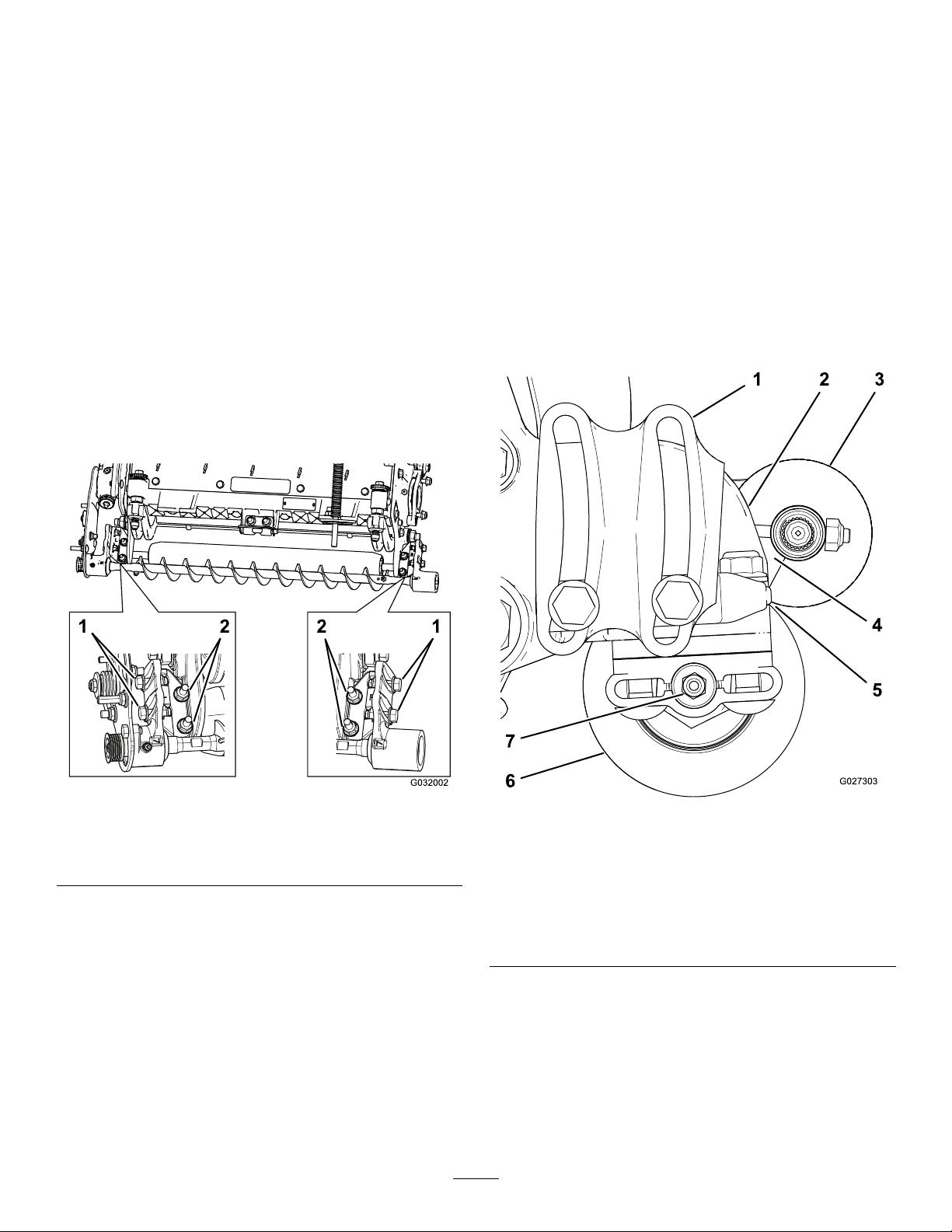

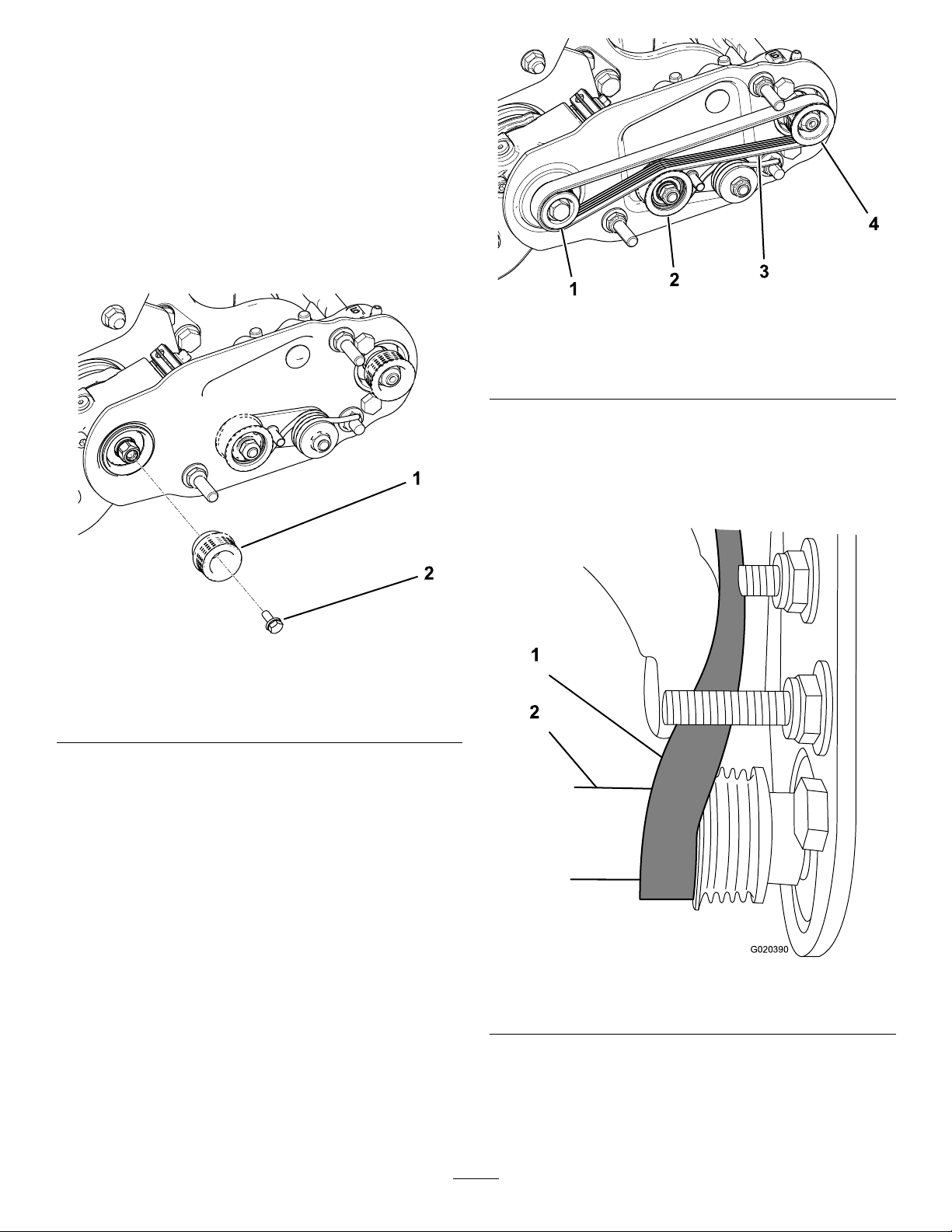

1.Layastraightedgealongtheouterfaceofthe

drivepulley(Figure21).

Important:Onlylaythestraightedgeacross

thedrivepulley,donotlayitacrossthedrive

andthedrivenpulley.

2.Ensurethattheouterfacesofthedrivepulley

andthedrivenpulleyareinlinewithin0.76mm

(0.030inch).

Important:Donotusetheidlerpulleyto

checkthealignment.

3.Ifthepulleysarenotaligned,refertoAdjusting

thePulleyAlignment(page10).

Important:Thebeltmayfailprematurelyif

thepulleysarenotproperlyaligned.

g192350

Figure21

AdjustingthePulley

Alignment

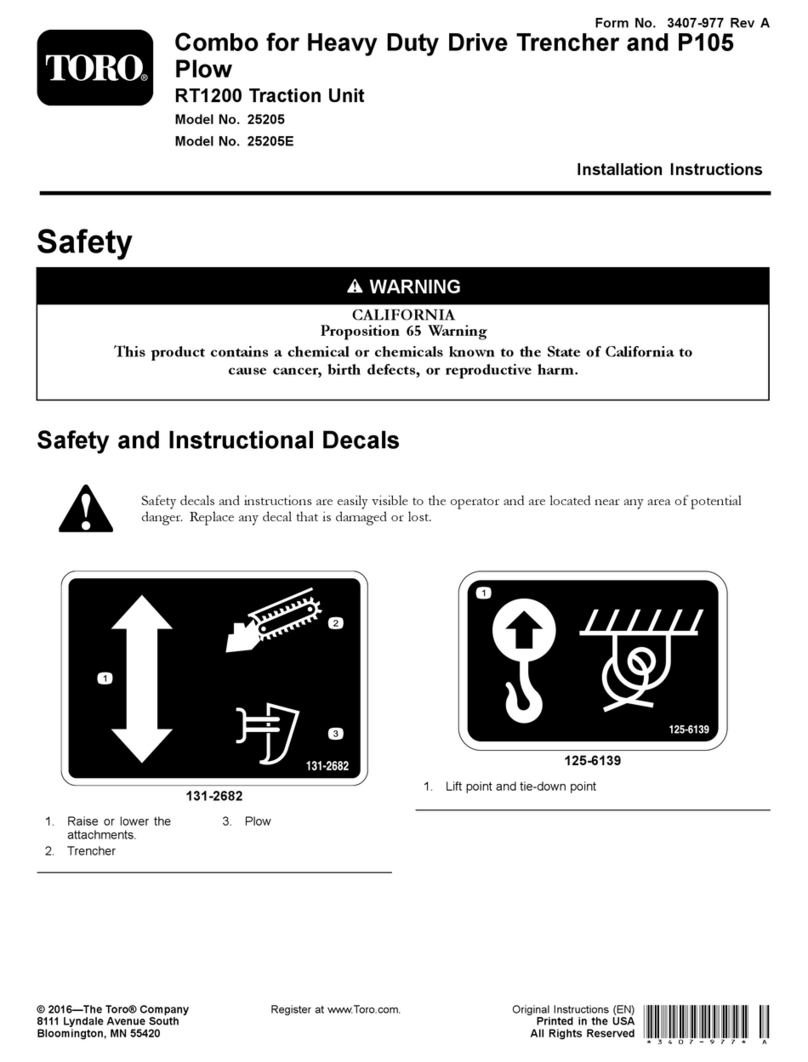

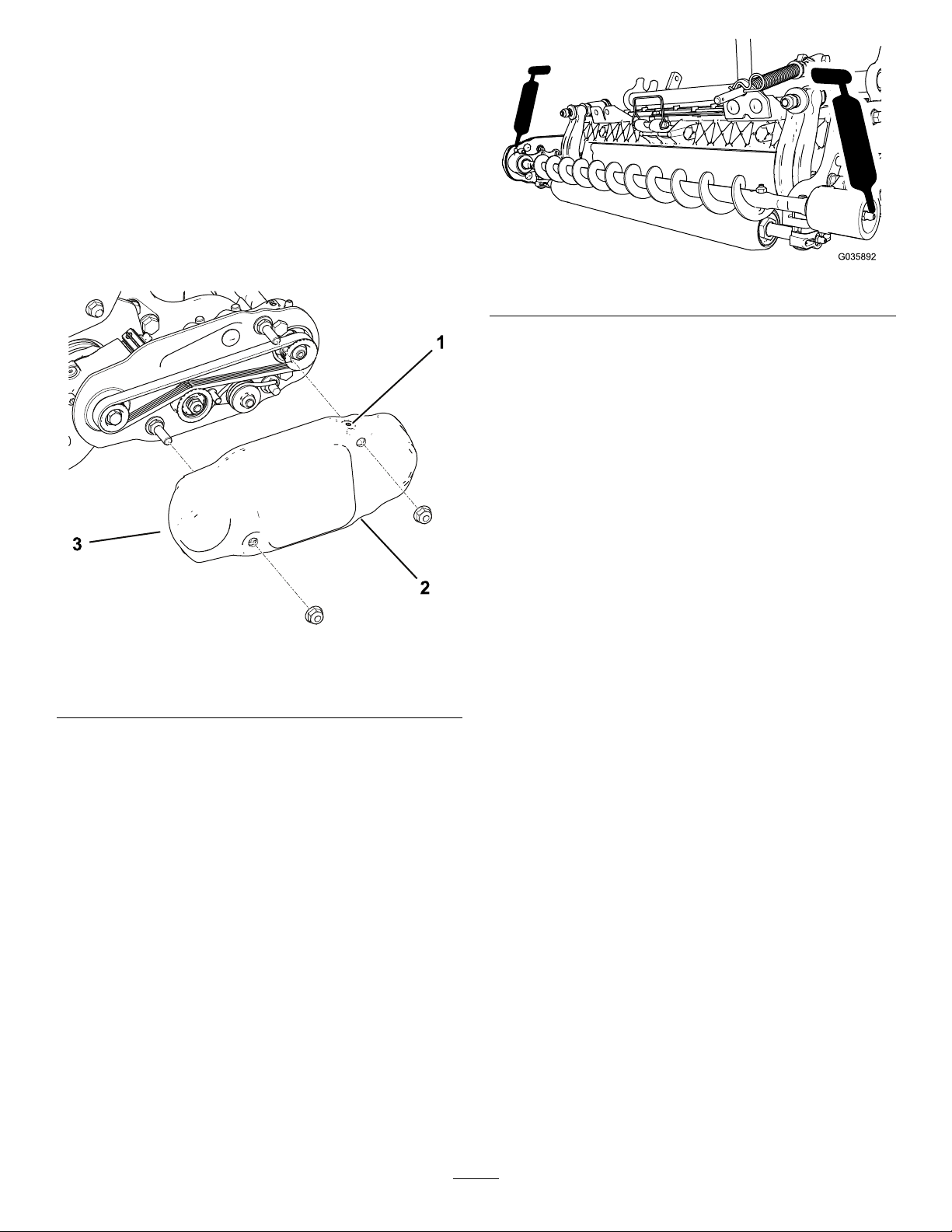

1.Thedrivenpulley(attheroller-brushshaft)can

moveinorout(Figure22).

Note:Makenoteofwhichwaythepulleyneeds

tomovewhencheckingthebeltalignment;refer

toCheckingthePulleyAlignment(page10).

g193169

Figure22

1.Drivepulley3.Drivenpulley

2.Idlerpulley4.Driven-pulleynut

2.Whilerotatingthereel,whichrotatesthedrive

pulley,prythebeltoffthedrivepulley(Figure22

Important:Wearapaddedgloveorusea

heavyragtorotatethereel.

3.Removethelocknutsecuringthedrivenpulley

tothebrushshaft(Figure22orFigure23).

Note:Usea1/2-inchwrenchontheroller-brush

shaftatstokeepitfromrotating.

4.Removethedrivenpulleyfromtheshaft(Figure

23).

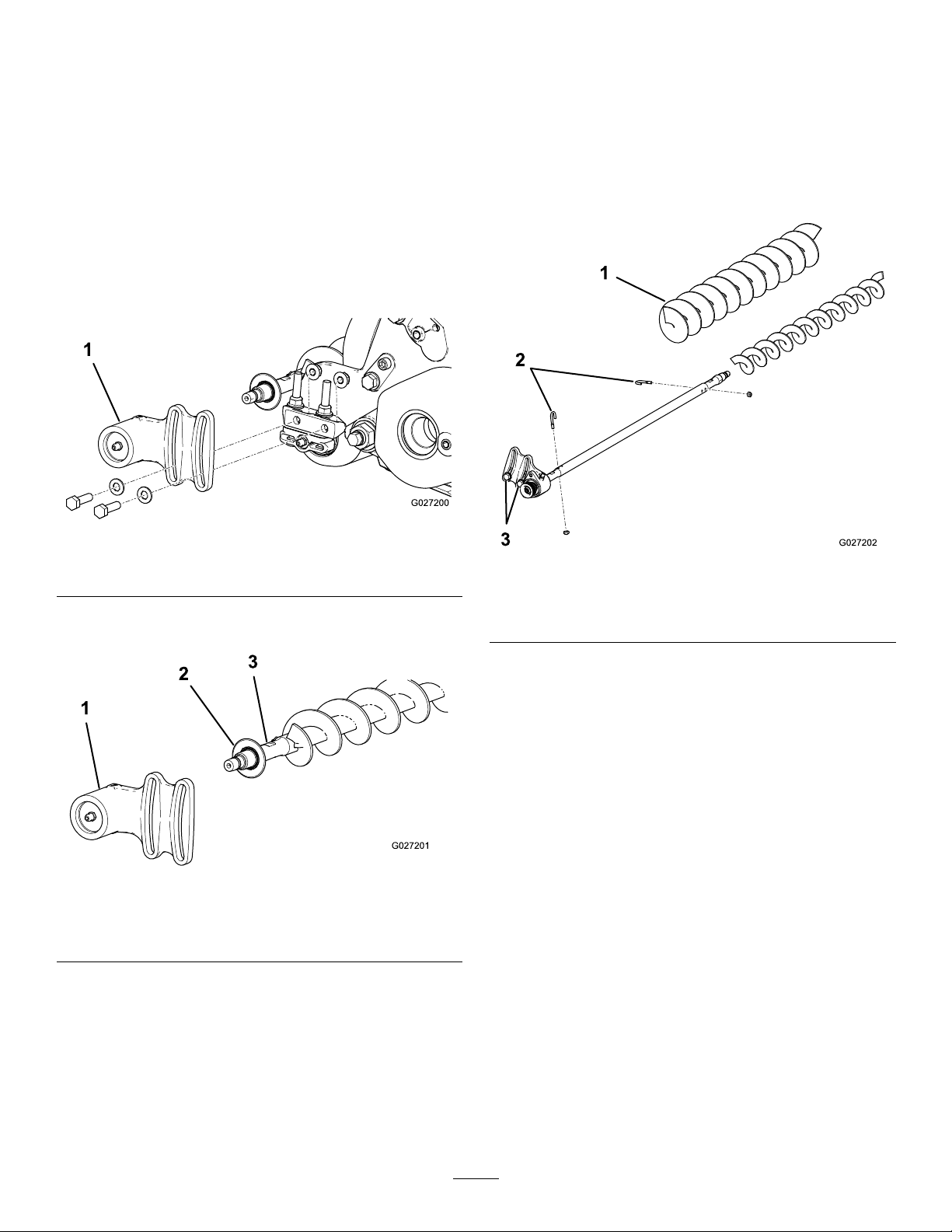

5.Ifthepulleyneedstomoveout,adda0.8mm

(0.032inch)thickwasher(Figure23).

Note:Ifthepulleyneedstomovein,remove

theexisting0.8mm(0.032inch)thickwasher.

6.InstallthepulleyasshowninFigure23.

10