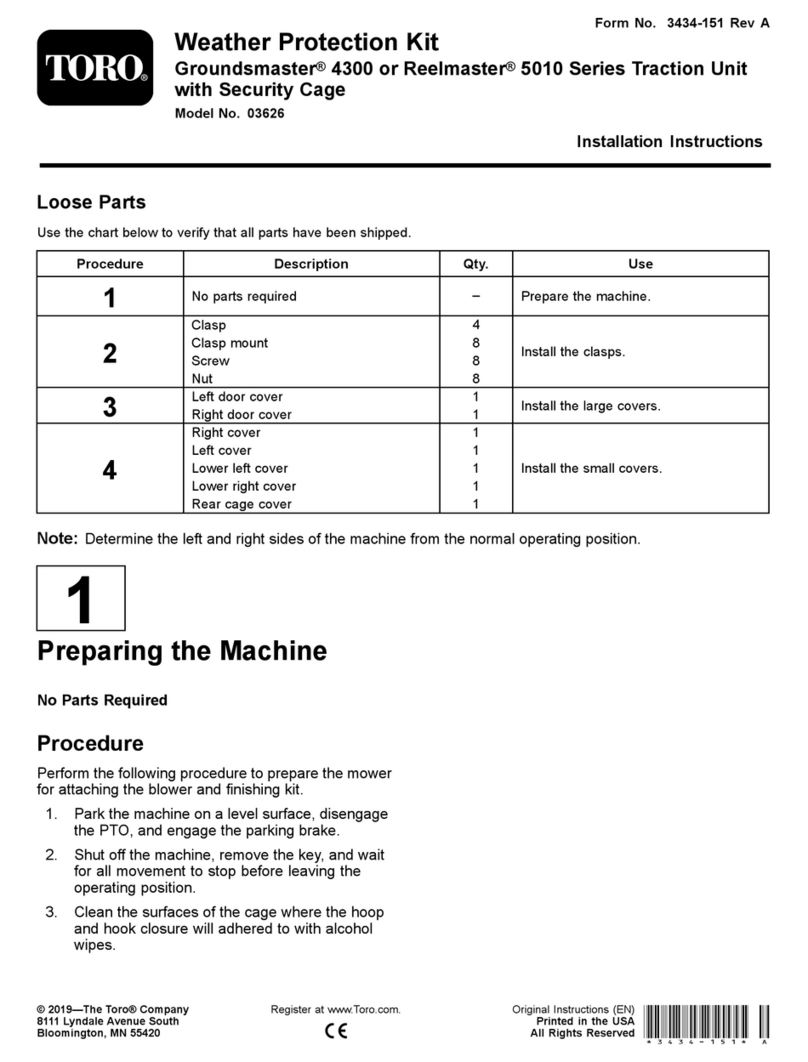

2.Installtheoor-platelatchtotheframeusing2

carriagebolts(1/4x3/4inch)and2locknuts

(1/4inch)(Figure6).

3.Removethe2lockingnutsfromthelock

assembly.

4.Insertthelockassemblyintotheholeintheoor

platewiththecatchfacingtotheleft.

5.Installthelockingnutsontothebottomofthe

lockassemblytosecureitinplace.

Note:Themountingholesinthelatchare

slottedsothatyoucanadjustthelockassembly.

5

InstallingtheHoodHandle

Partsneededforthisprocedure:

1Hoodhandle

2Bolt(1/4x1-1/8inch)

2Washer(5/16inch)

1Clamp

Procedure

1.Locatethehoodsupportrailontheinsideofthe

leftsideofthehood.

2.Measurealongtherail,fromthesupportedge,

3.8cm(1-1/2inches)asshowninFigure7.

3.Installtheclamparoundtherailatthislocation.

4.Usingtheclampasatemplate,markanddrillan

8-mm(5/16inch)diameterhole.

5.Installawasher(5/16inch)andbolt(1/4x1-1/8

inch)throughtheclampanddrilledholeinthe

hoodandintothehoodhandle.

6.Withthehoodhandleintheapproximateposition

showninFigure7,markthesecondholetodrill.

Note:Thesecondholeis12.2cm(4-13/16

inch)fromthersthole.

7.Swingthehoodhandleoutofpositionanddrilla

5/16inchdiameterholeatthemarkedlocation.

8.Installawasherontotheotherbolt(1/4x1-1/8

inch)andthroughthehood.

9.Securethehandletothehoodusingtheother

washer(5/16inch)andbolt(1/4x1-1/8inch)

asshowninFigure7.

Note:Tightenthebolts.

7