g016235

Figure24

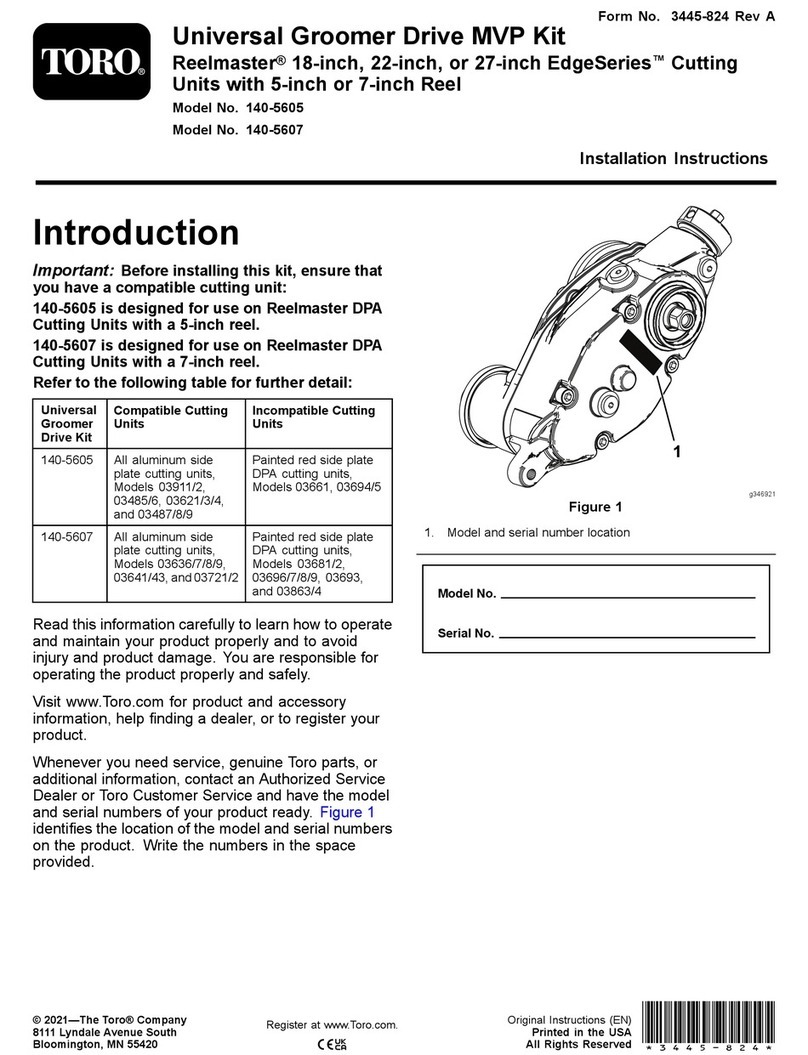

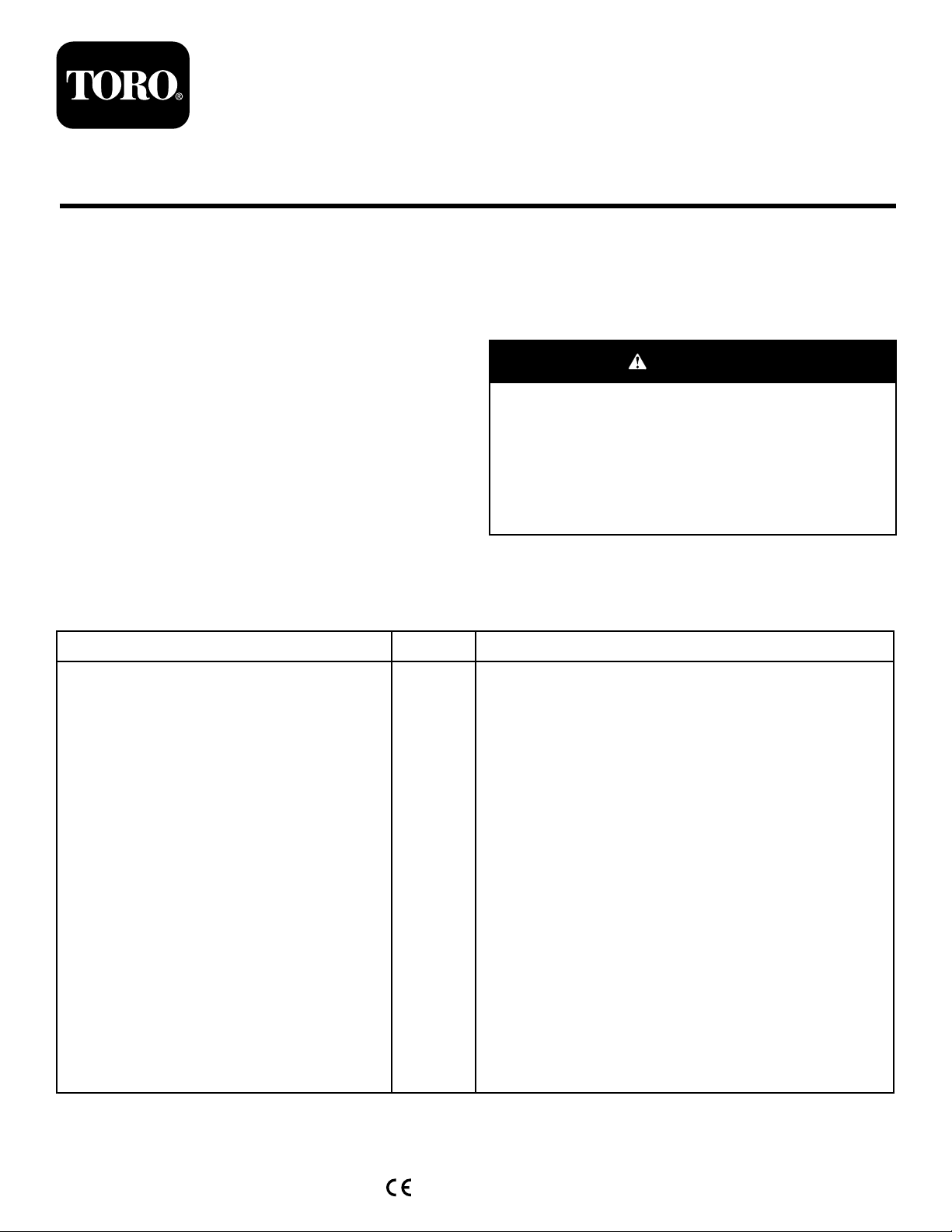

5.On1endofgroomershaft,measurethedistance

fromthelowesttipofagroomerbladetowork

surface.Turnthegroomerheightadjustingknob

(Figure25)toraiseorlowerbladetiptothe

desiredgroomingheight.Eachnotchonthe

adjustingknobisapproximatelyequalto0.08

mm(0.003inch)ofgroomerdepth.

g016236

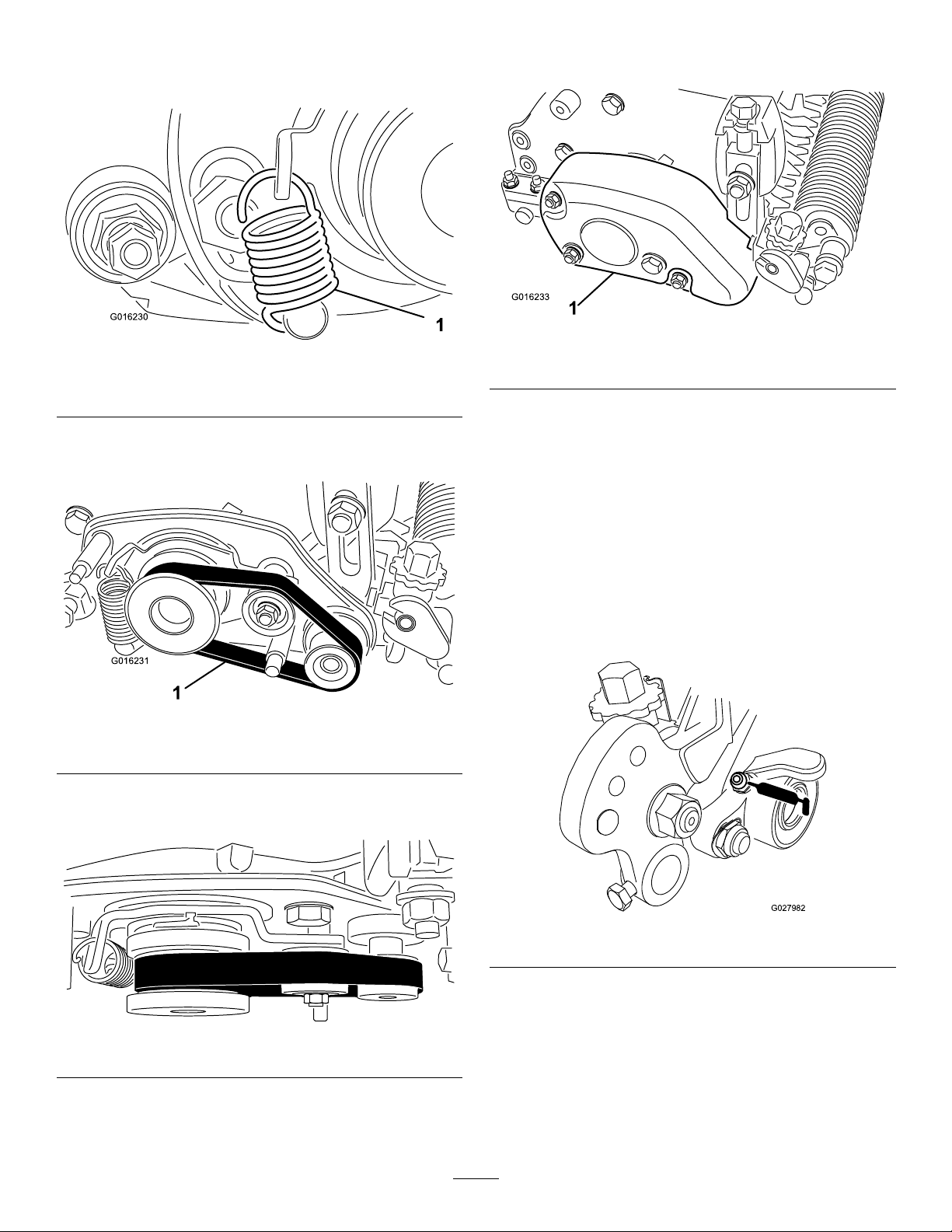

Figure25

1.Groomerheightadjustingknob

6.Repeatthisprocedureontheoppositeendof

thegroomer,thencheckthesettingonrstside.

Adjustasrequired.

7.Ifyouarenotusingthegroomingmode,raise

thegroomingreelfromAtoBorfromBtoC.

Note:Athighergroomingheights,thegrooming

reelmayhavetobesetintheCposition,making

theraise/lowerfeatureunavailable.

TestingthePerformanceof

theGroomer

Important:Improperorover-aggressiveuseof

thegroomingreel(i.e.,toodeeportoofrequent

grooming)maycauseunnecessarystressonthe

turfleadingtoseveregreensdamage.Usethe

groomercautiously.

Itisimportanttodeterminetheperformanceof

thegroomerbeforeputtingitintoregularuseon

greens.Westronglysuggeststhatyouuseaformal

testprocedure.Thefollowingisapracticalwayof

determiningtheproperheight/depthsetting:

1.Setthecuttingreeltotheheight-of-cutthatyou

wouldnormallyusewithoutthegroomingreel.

UseaWiehlerollerandscraperforthefront

roller.

2.Setthegroomerreel1/2theheight-of-cutsetting

abovetheground(e.g.,for3.2mm(1/8inch)

height-of-cutsetting,setthegroomerat1.6mm

(1/16inch)abovetheground).

Note:Ifyouareusingthegroomerbrush,set

itattheheight-of-cutsettingabovetheground

(e.g.for3.2mm(1/8inch)height-of-cutsetting,

setthegroomerat3.2mm(1/8inch)abovethe

ground).

3.Makeapassoverthetestgreen,thenlower

thegroomerushwiththerollerlevelandmake

anotherpassoverthetestgreen.

Note:Ifyouareusingthegroomerbrush,

loweritto1/2theheight-of-cutsettingabovethe

ground(e.g.for3.2mm(1/8inch)height-of-cut

setting,setthegroomerat3.2mm(1/8inch)

abovetheground).

4.Comparetheresults.Therstgroomedarea

whenthesettingwas1/2theheight-of-cutsetting

abovethegroundwillhaveremovedsignicantly

lessgrassandthatchthanthesecondsetting.

Checkthetestgreen2or3daysaftertherst

groomingforgeneralcondition/damage.Ifthe

groomedareasareturningyellow/brown,and

thenon-groomedareasaregreen,thenthe

groomingwastooaggressive.

Note:Thecolorofthegrasswillchangewhen

youusethegroomingreel.Anexperienced

greenssuperintendentcanjudgebythecolor

oftheturf(alongwithcloseexamination)ifthe

currentgroomingpracticeisappropriateforthe

particulargreen.Becausethegroomingreel

standsupmoregrassandremovesthatch,the

qualityofthecutwillnotbethesameaswithout

thegroomer.Thiseffectismostnoticeablethe

rstfewtimesyouuseagroomeronagreen.

10