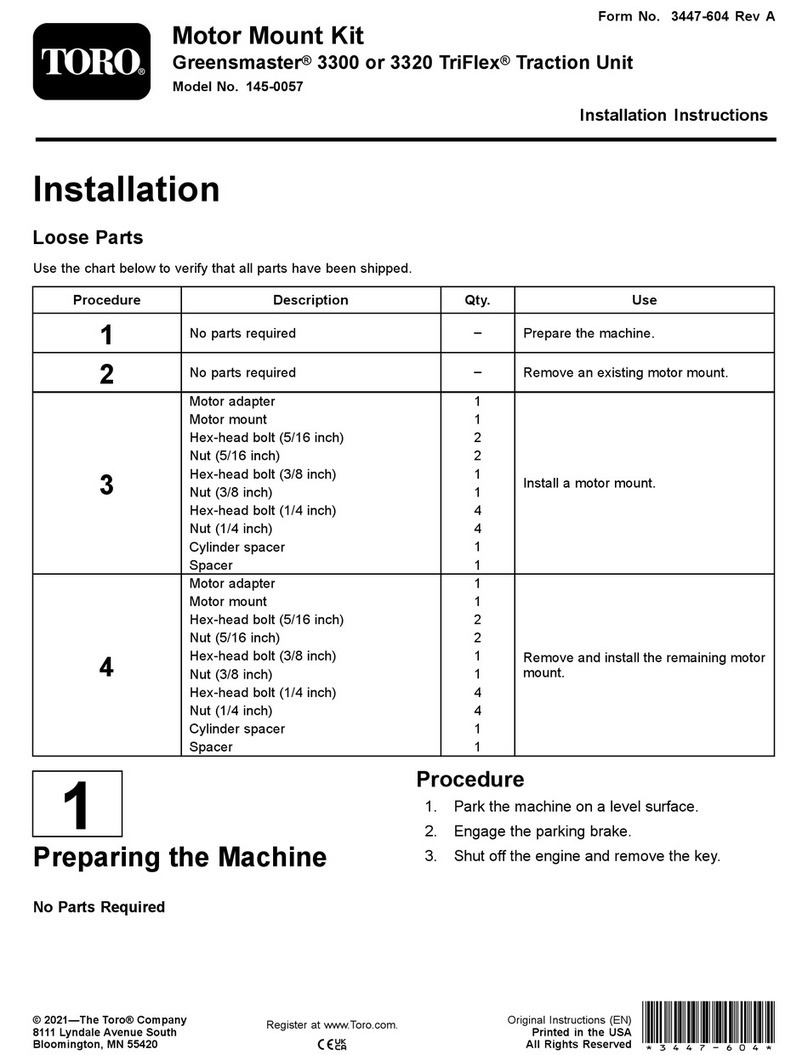

3

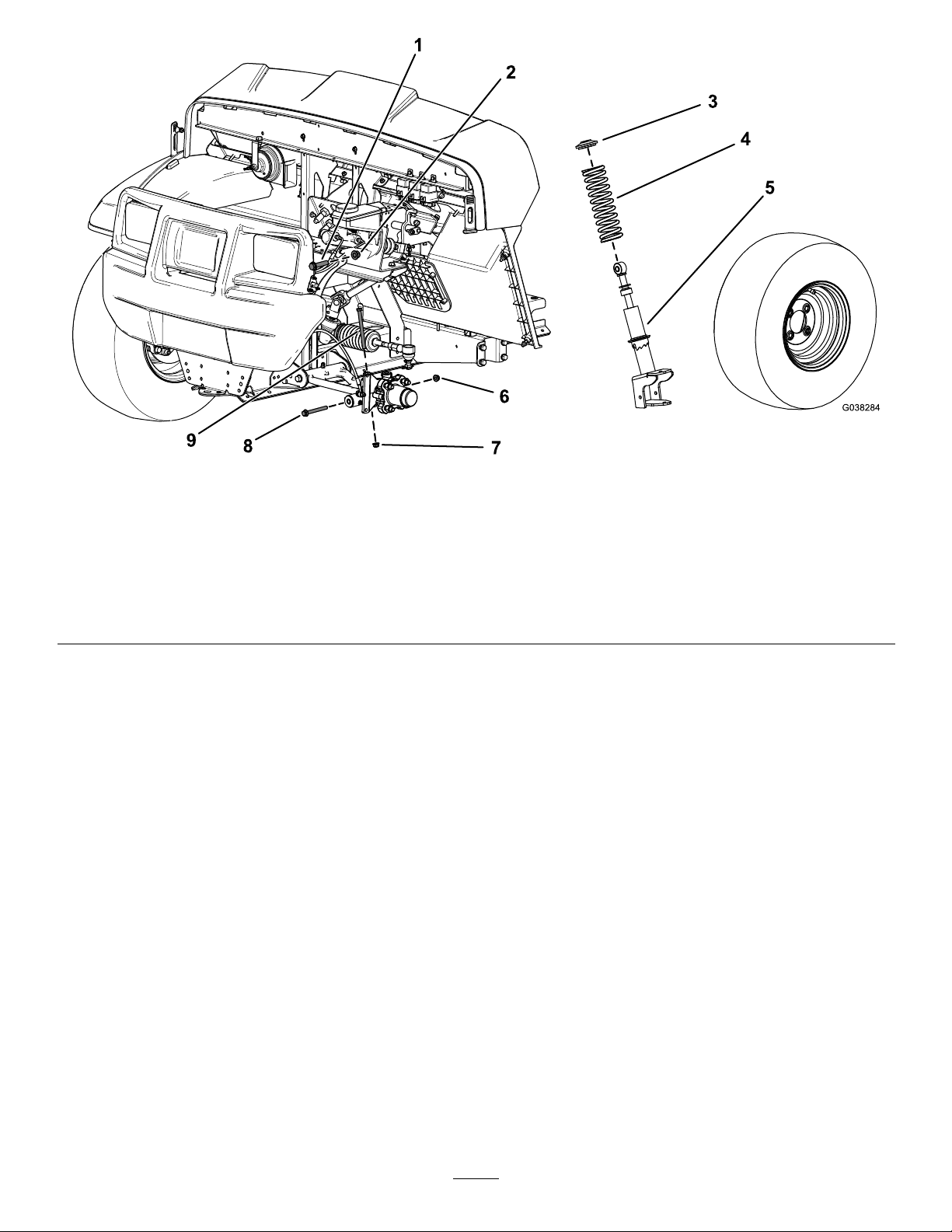

Installing the Springs

For Machines with Serial No.

403448001 and Before Only

Parts needed for this procedure:

2

Spring

Procedure

Use an approved T oro spring-compression tool to

remove and install springs of the strut assembly .

Contact your authorized T oro distributor .

1. Place the strut assembly into the compression

tool and use the tool to compress the spring.

2. While the spring is compressed, remove the

collar .

3. Remove the spring from the strut assembly

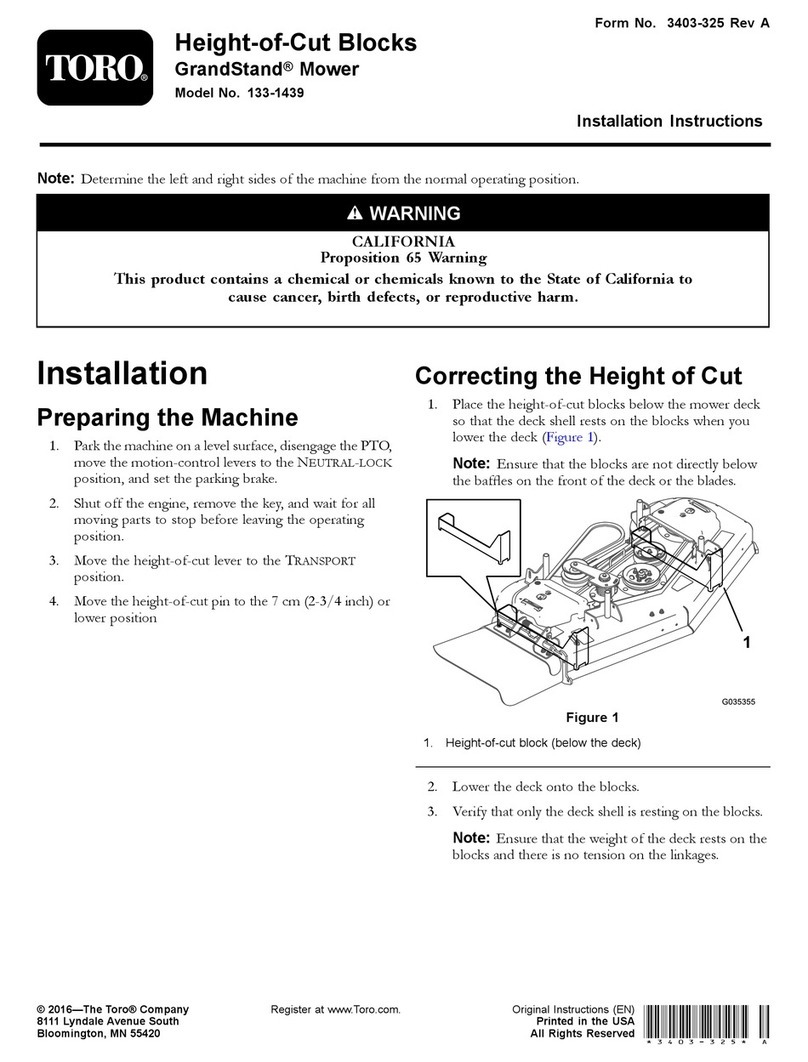

(Figure 1 ).

4. Install the new spring over the existing strut

assembly ( Figure 1 ).

5. Using the T oro spring-compression tool,

compress the spring.

6. While the spring is compressed, install the collar .

7. Carefully release pressure on the spring,

allowing it to seat on the collar .

8. Remove the strut assembly from the

compression tool.

Note: Repeat this procedure for the other side of the

machine.

4

Installing the Strut

Assembly

For Machines with Serial No.

403448001 and Before Only

No Parts Required

Procedure

1. Install strut assembly to the machine.

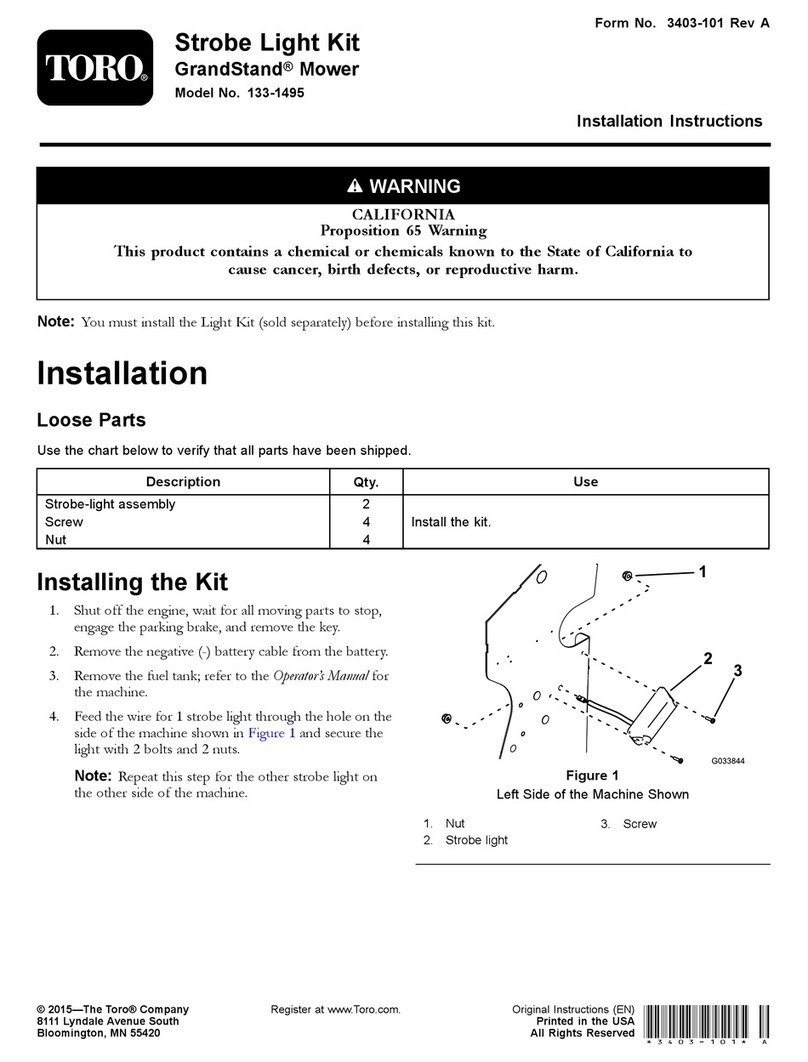

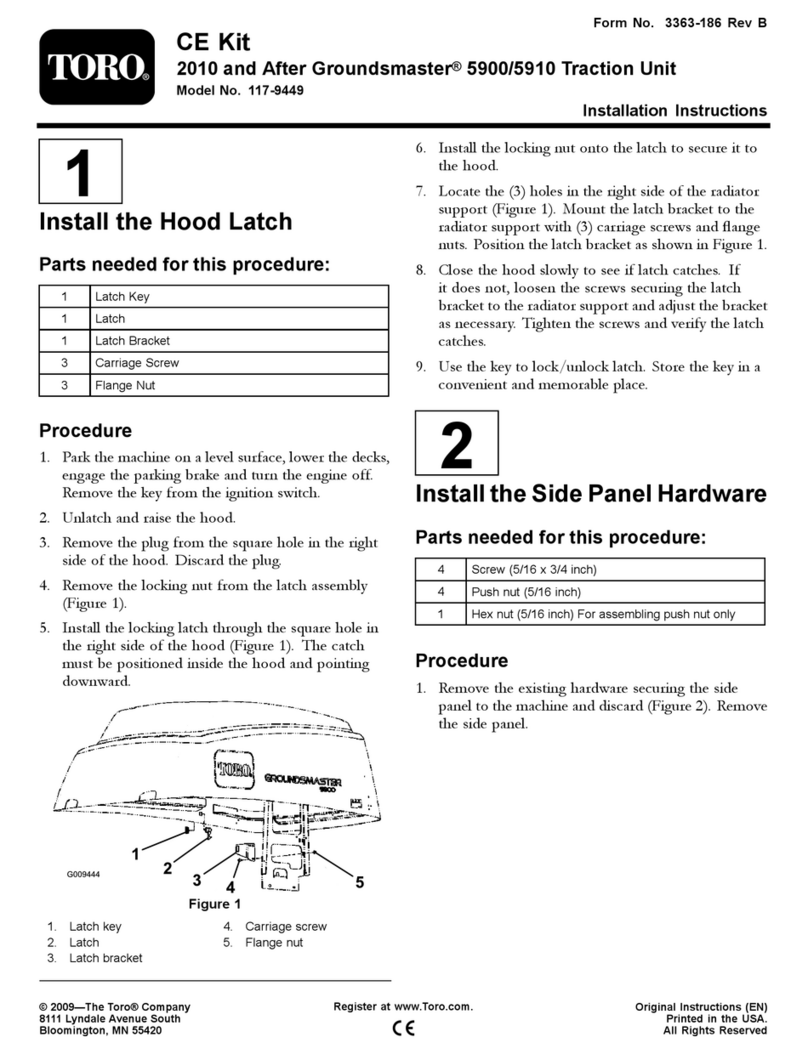

2. Secure the upper portion of the strut assembly

to the frame using the upper , hex-head bolt (1/2

x 2-1/4 inches) and locknut (1/2 inch) as shown

in Figure 1 .

3. T orque the hex-head bolt (1/2 x 2-1/4 inches) to

91 to 1 13 N∙m (67 to 83 ft-lb).

4. Install the hex-head bolt (3/8 x 4-3/4 inches) and

ange nut (3/8 inch) to the spindle ( Figure 1 ).

5. T orque the hex-head bolt (3/8 x 4-3/4 inches) to

37 to 45 N∙m (27 to 33 ft-lb).

6. Secure the lower portion of the strut assembly

to the control arm using the hex-head bolt (3/8 x

3-1/2 inches) and ange nut (3/8 inch) as shown

in Figure 1 .

7. T orque the hex-head bolt (3/8 x 3-1/2 inches) to

37 to 45 N∙m (27 to 33 ft-lb).

8. Install the front wheel.

Note: Repeat this procedure for the other side of the

machine.

6