8.Plugthegeneratorinterfaceontheharnessintothe

terminalonthegenerator,neartheengine.

Note:OnModel04530(gasolineengine),the

generatorislocatedinthecenterofthemachine

frame(Figure6);onModel04540(dieselengine),the

generatorislocatedoutsidethemachineframe(Figure

7).

Figure6

Model04530

1.Frame3.Terminal

2.Generator

Figure7

Model04540

1.Frame3.Terminal

2.Generator

9.Slowlyturntheringonthegeneratorinterface

connectorclockwisetoaligntheotherconnectorand

securetheconnection.

Important:Ensurethattheterminalsarefully

connected.Alooseconnectionmaycauseexcess

heatfromtheelectricalcurrent,leadingtoproduct

damage.

10.Connecttheappropriateterminalstothereelmotors.

Note:Ensurethattheconnectorsclicktogetherso

thattheyaresecure.

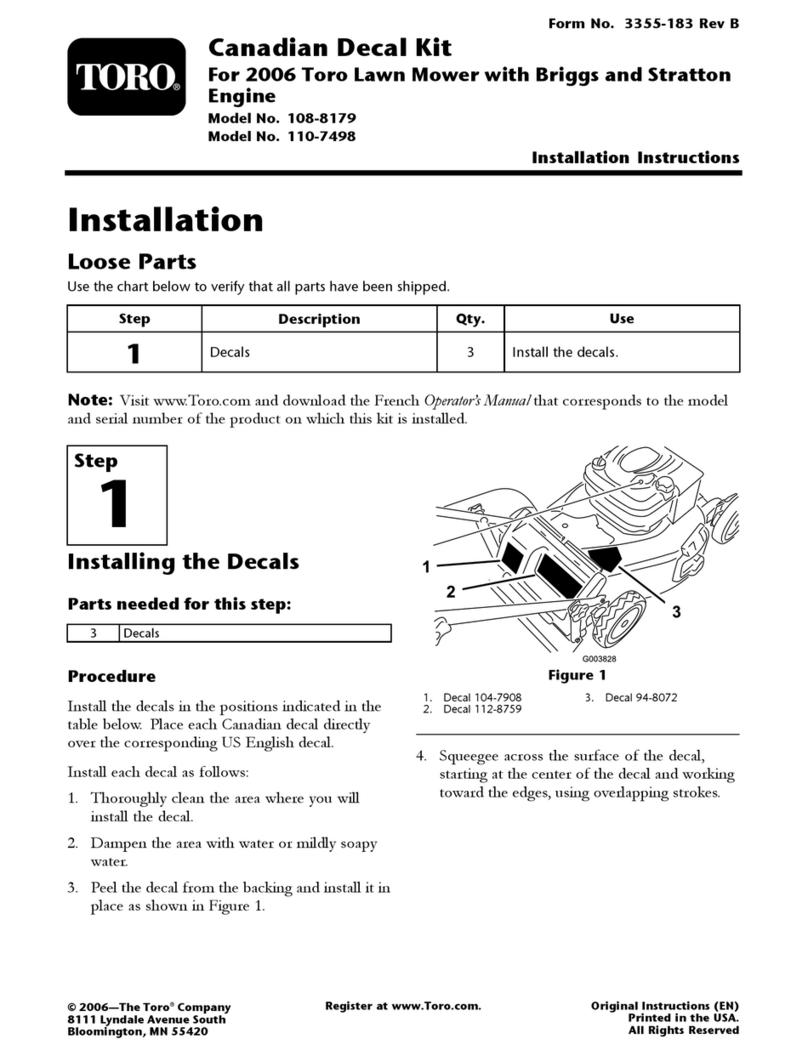

11.Removeanddiscardthecapfromthe10A58-voltfuse

(aredwireandayellowwire);refertoFigure8.

Figure8

1.Groundblock9.E-reelsCANdiagnostic

port

2.E-reelsenablerelay10.Protectiondiode

3.E-reelsfuse(60A-58V),

existing

11.IDmodule

4.Battery-sidepower(boot

notshown)

12.Harnessground

5.Maincontactorcoil

connector(white)

13.Harnessground

6.Maincontactorcoil

connector(brown)

14.CANinterfacemodule

(P10)

7.Switched-sidepower(boot

notshown)

15.E-reelsbatteriesground

8.48VDCcontactor16.10A58-voltfuse

12.Inserttheterminalwiththe10A58-voltfuseintothe

existingcapmountedontheframeofthemachine.

13.ConnecttheE-Reelsenablerelayconnector(P07).

14.Connectthe90-degreeswitchedside(J07)connector

ontheharnesstotherearterminalonthe48VDC

contactor,andsecureittotheterminal.

15.Routethewireundertheangeonthe48VDC

contactor.

16.Connectthe2maincontactorcoilconnectorstothe

48VDCcontactor.

17.Connectthewiremarked“BatterySide”andthe

battery-disconnectwiretothefrontterminalofthe

48VDCcontactor.

18.Slidetheinsulatorbootsfortheswitched-sidepower

connectorandthebattery-sideconnectoroverthe

terminalstocoverthem.

19.ConnecttheIDmodule(P08).

20.ConnecttheCANinterfacemodule(P10).

21.Connectthe2terminals(CANbusinterconnectand

interfacetomainharness)onthenewharnesswith

the2terminalsonthemainmachineharnessunder

theseat.

22.Installthefuseblock,withtheharnessroutedbehind

thebracket(Figure9).

3