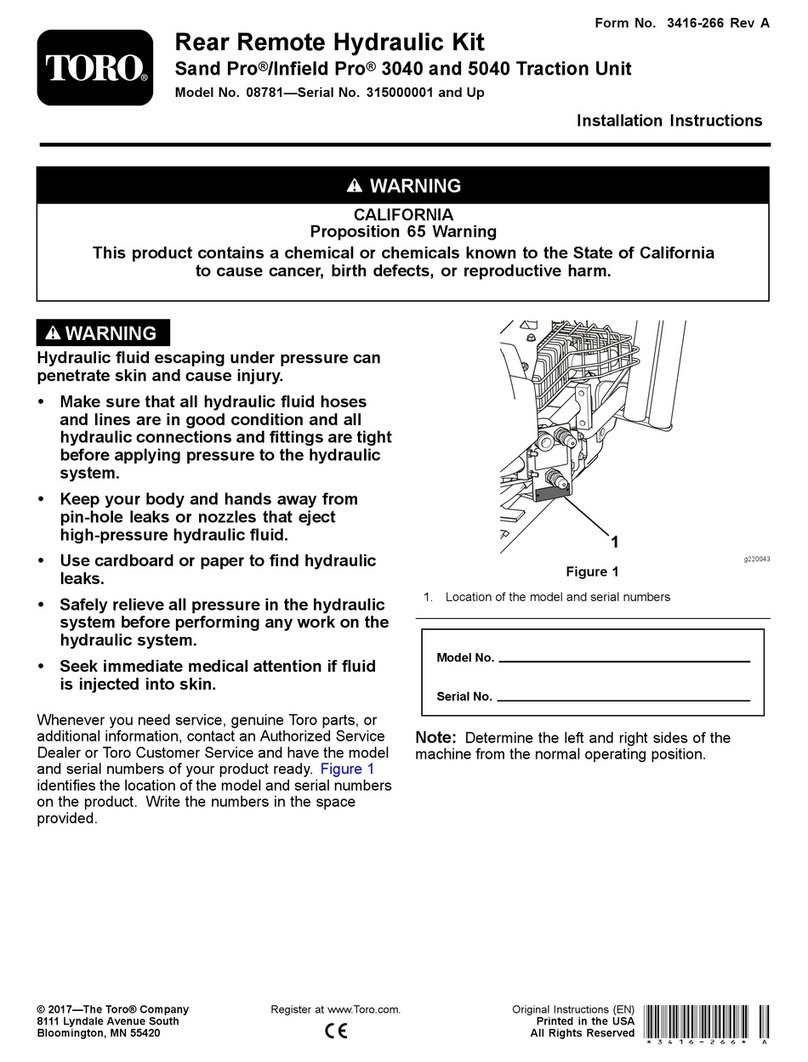

g352162

Figure15

1.Driveshaft3.Drivepulley

2.Spacer4.Bolt—Torqueto47to54

N-m(35to40ft-lb)

22.Installthebeltontothepulleysasfollows:

•Loopthebeltaroundthedrivenpulleyand

thenoverthetopoftheidlerpulley(Figure

16).

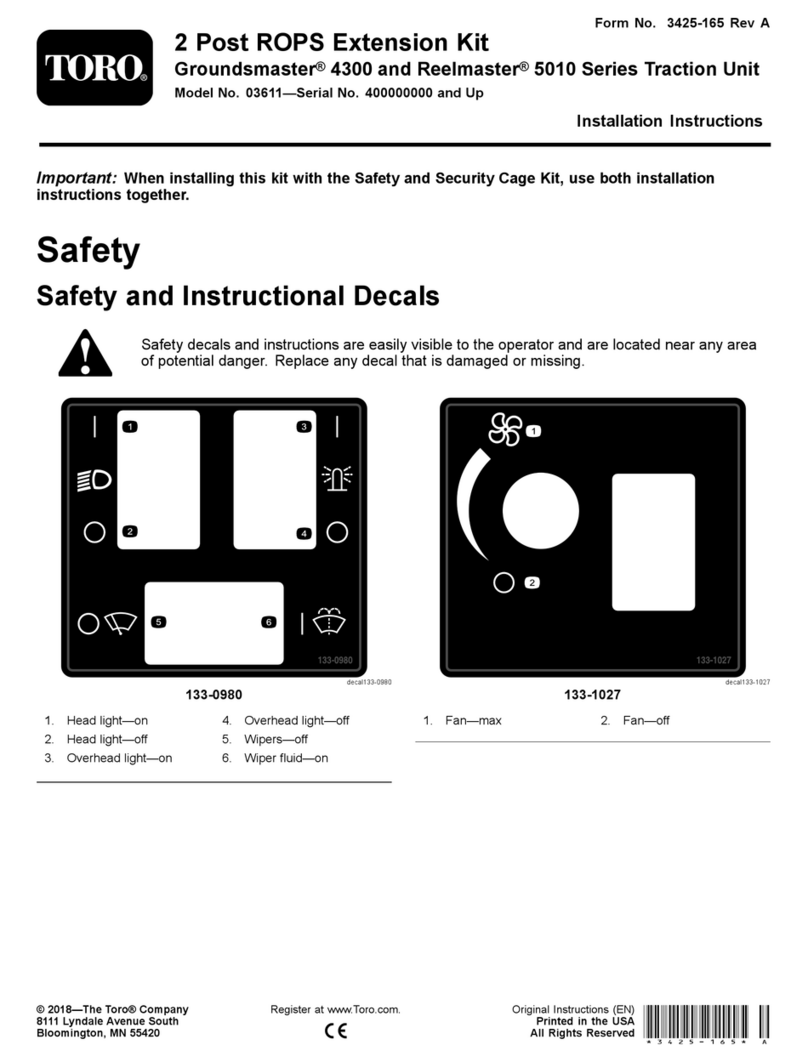

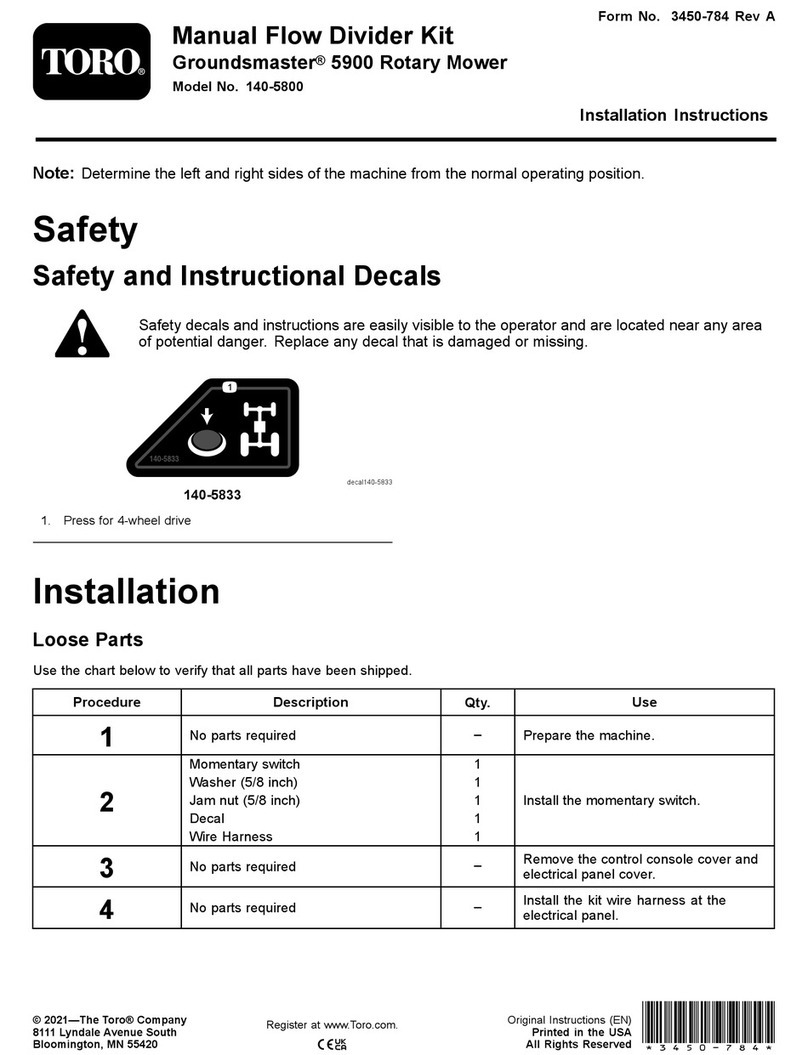

g352173

Figure16

1.Drivepulley3.Drivenpulley

2.Idlerpulleyassembly4.Belt

•Startthebeltonthedrivepulley(Figure16).

•Whileguidingthebeltontothedrivepulley,

rotatethereelforwardtodrawthebeltonto

thedrivepulley.

Note:Wearapaddedgloveoruseaheavy

ragtorotatethereel.

Important:Makesurethattheribsonthe

beltareproperlyseatedinthegroovesin

eachpulley.Also,makesurethebeltisin

thecenteroftheidlerpulley.

23.Pushdownontheidlerpulleytoensurethatthe

idlerpulleyassemblypivotsfreely.

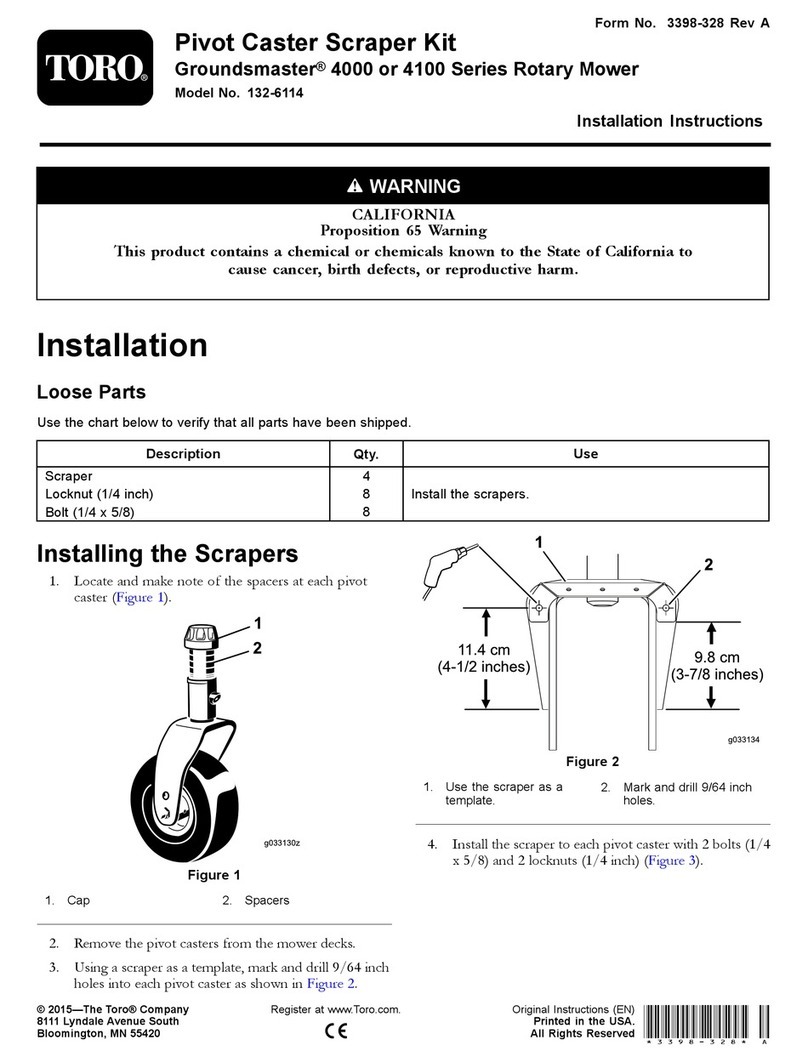

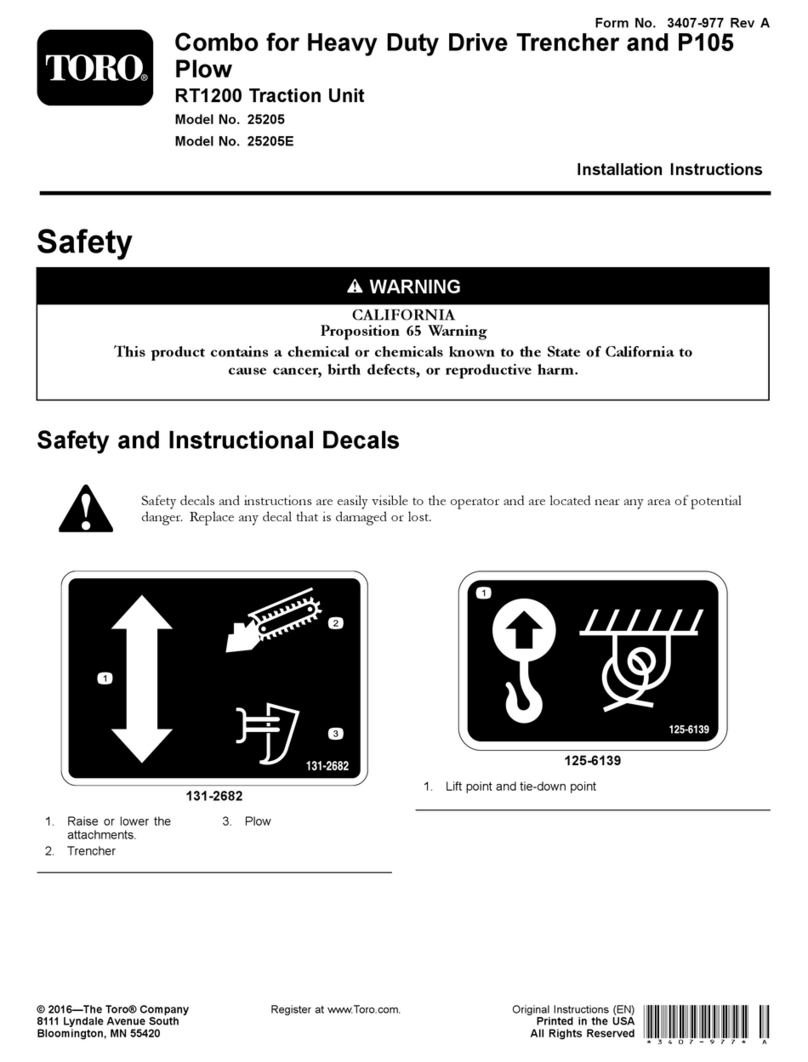

24.Checkthealignmentofthebelt/pulleysas

follows:

•Thebeltmustbeproperlytensioned

(installed)priortocheckingalignment.

•Layastraightedgealongtheouterfaceof

thedrivepulley(Figure17).Donotlay

thestraightedgeacrossboththedriveand

drivenpulleys.

•Theouterfacesofthedriveanddriven

pulleysshouldbeinlinewithin0.76mm

(0.030inches).

•Ifthepulleysarenotaligned,RefertoPulley

Alignment(page15).

•Ifthepulleysarealigned,continuewiththe

installation.

•Donotusetheidlerpulleytocheck

alignment.

Important:Thebeltmayfailprematurely

ifthepulleysarenotproperlyaligned.

g352174

Figure17

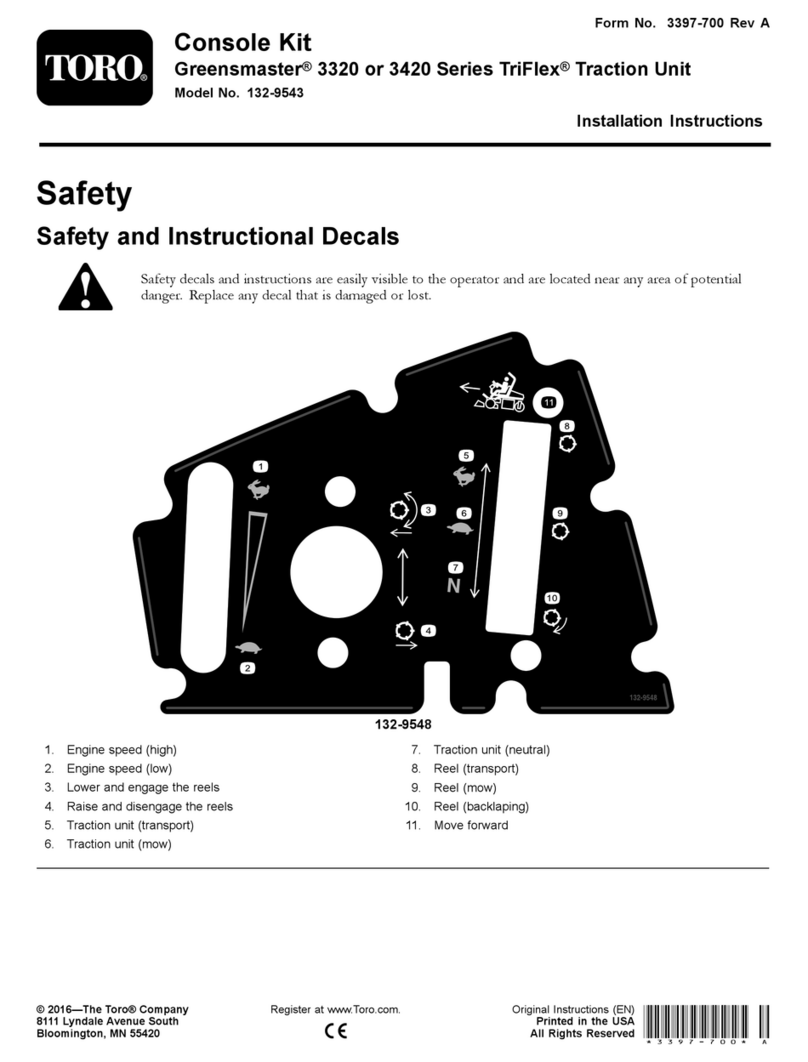

25.Slidethebeltcoverontothemountingboltsand

securewith2angenuts(Figure18).

Important:Donotovertightenthenutsas

damagetothecovermayoccur.

g352176

Figure18

1.Beltcover

26.Lubricatethegreasettingsoneachoftheroller

brushbearinghousingsandontheremainder

ofthecuttingunitwithNo.2general-purpose,

8