Toro 30506 User manual

Other Toro Lawn Mower Accessories manuals

Toro

Toro TransPro 80 series User manual

Toro

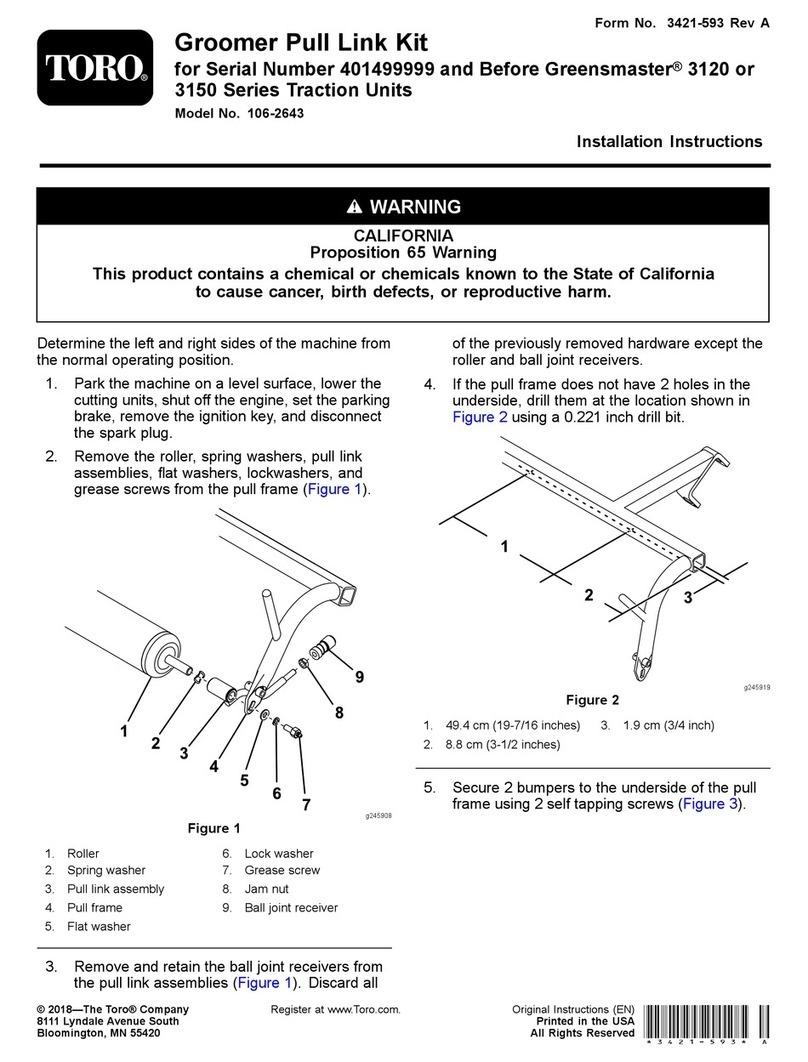

Toro 106-2643 User manual

Toro

Toro 161-4450 User manual

Toro

Toro HoverPro 450 User manual

Toro

Toro Maxi Sneaker 370 User manual

Toro

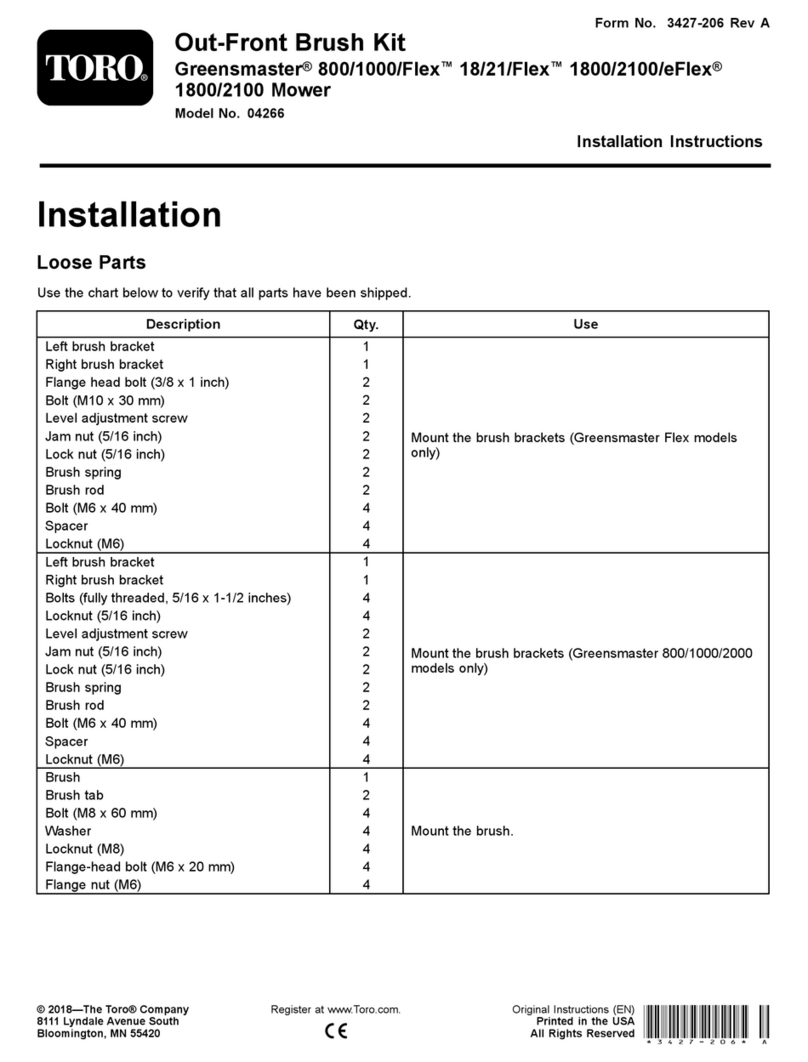

Toro 04266 User manual

Toro

Toro Reelmaster 03485 User manual

Toro

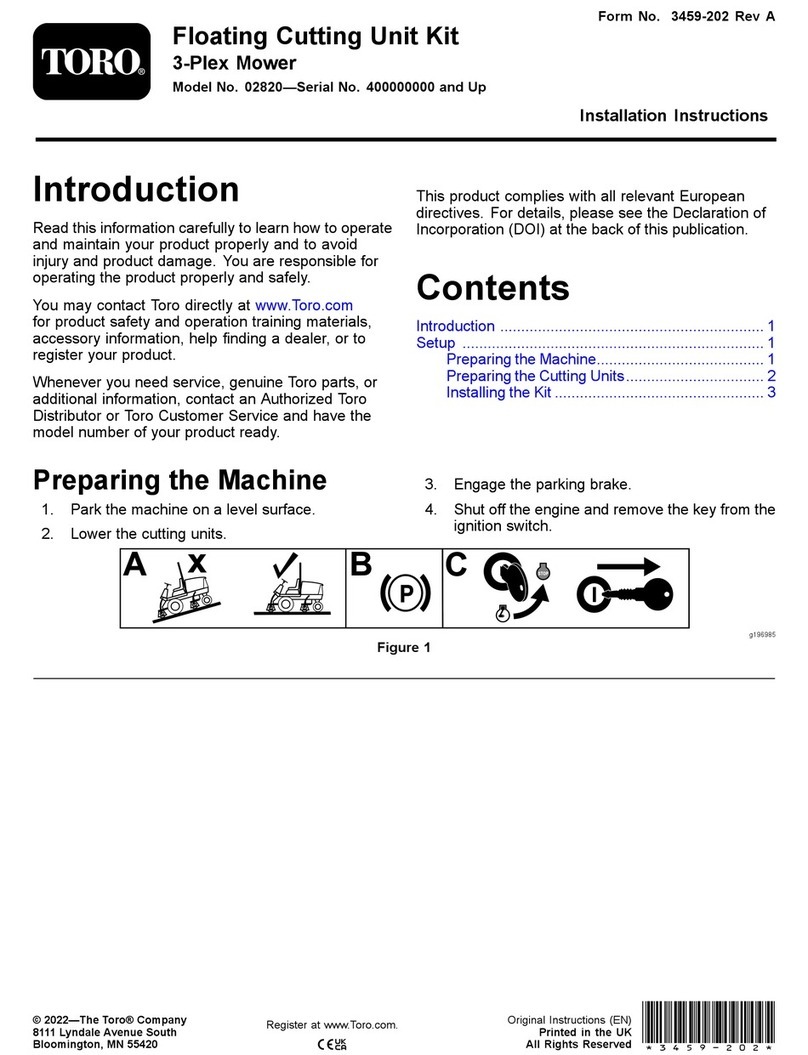

Toro 02820 User manual

Toro

Toro 139-6655 User manual

Toro

Toro 23508 Installation and operating manual

Toro

Toro 23126 User manual

Toro

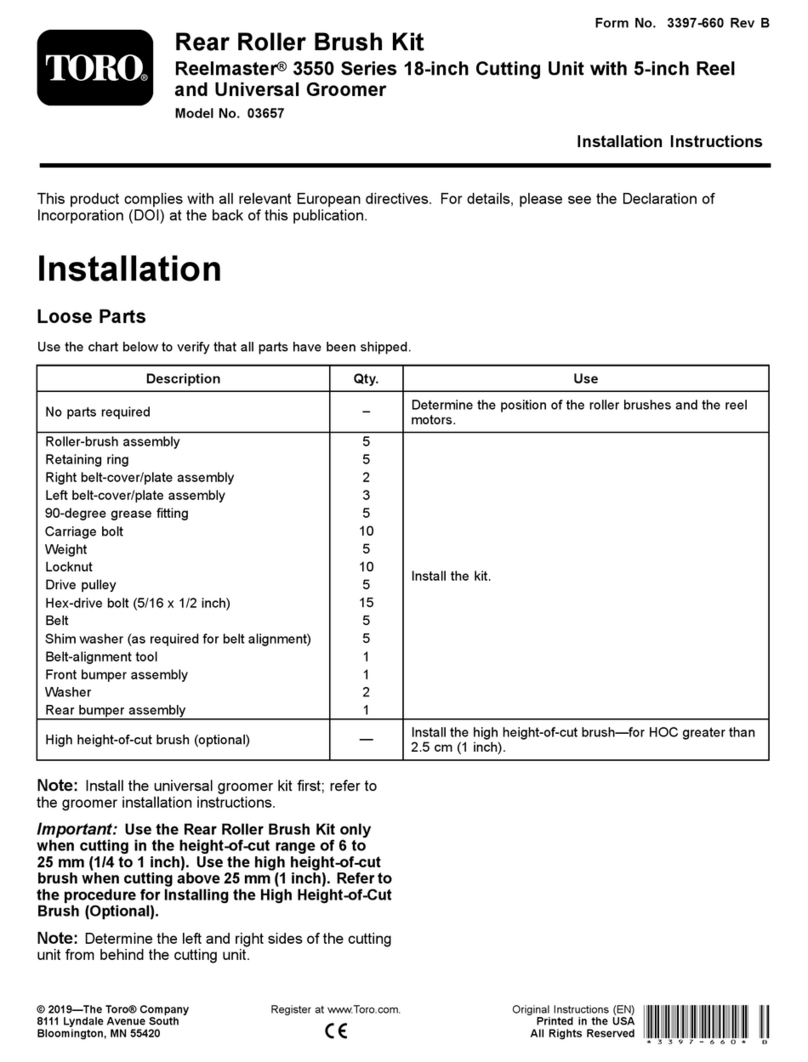

Toro Reelmaster 03657 User manual

Toro

Toro 137-6946 User manual

Toro

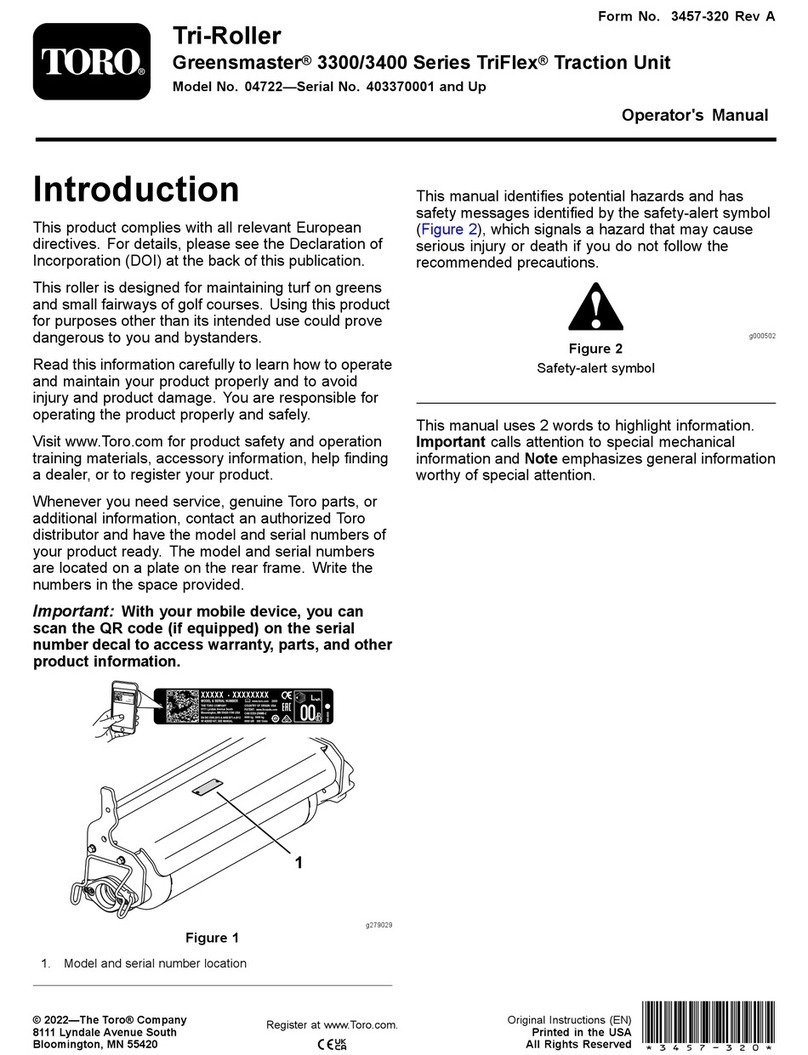

Toro Greensmaster TriFlex 3300 User manual

Toro

Toro 78490 User manual

Toro

Toro 03713 User manual

Toro

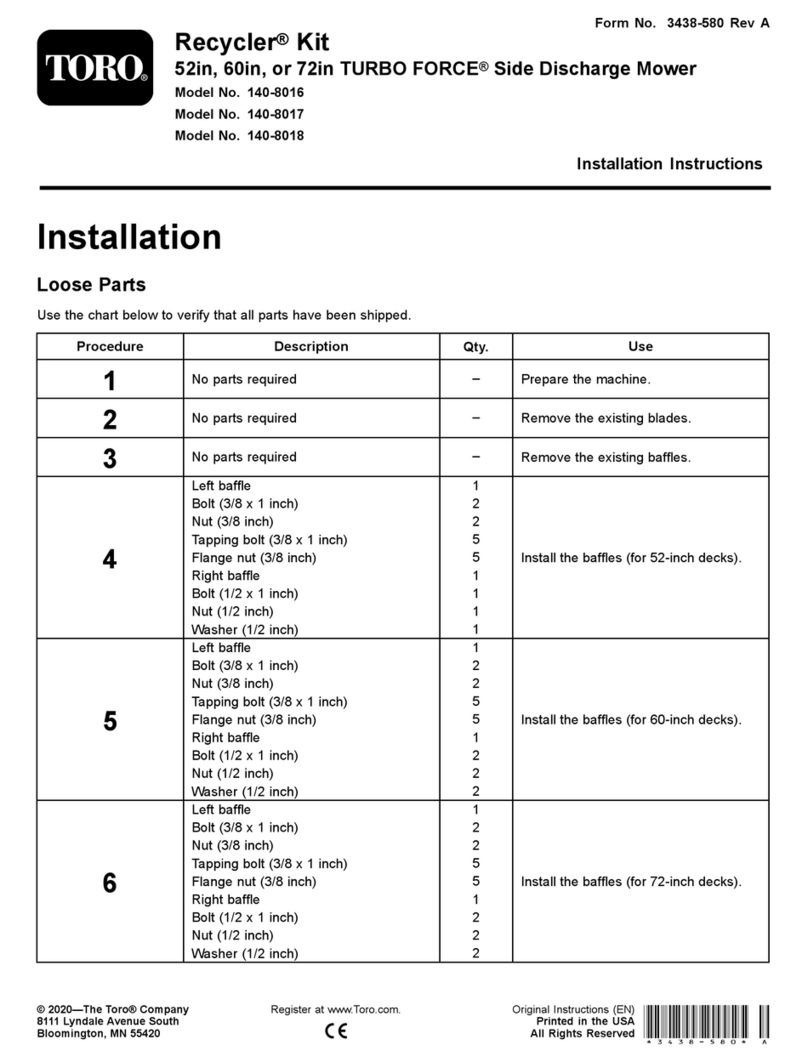

Toro 140-8016 User manual

Toro

Toro 78555 User manual

Toro

Toro Groundsmaster 5900 Series User manual

Toro

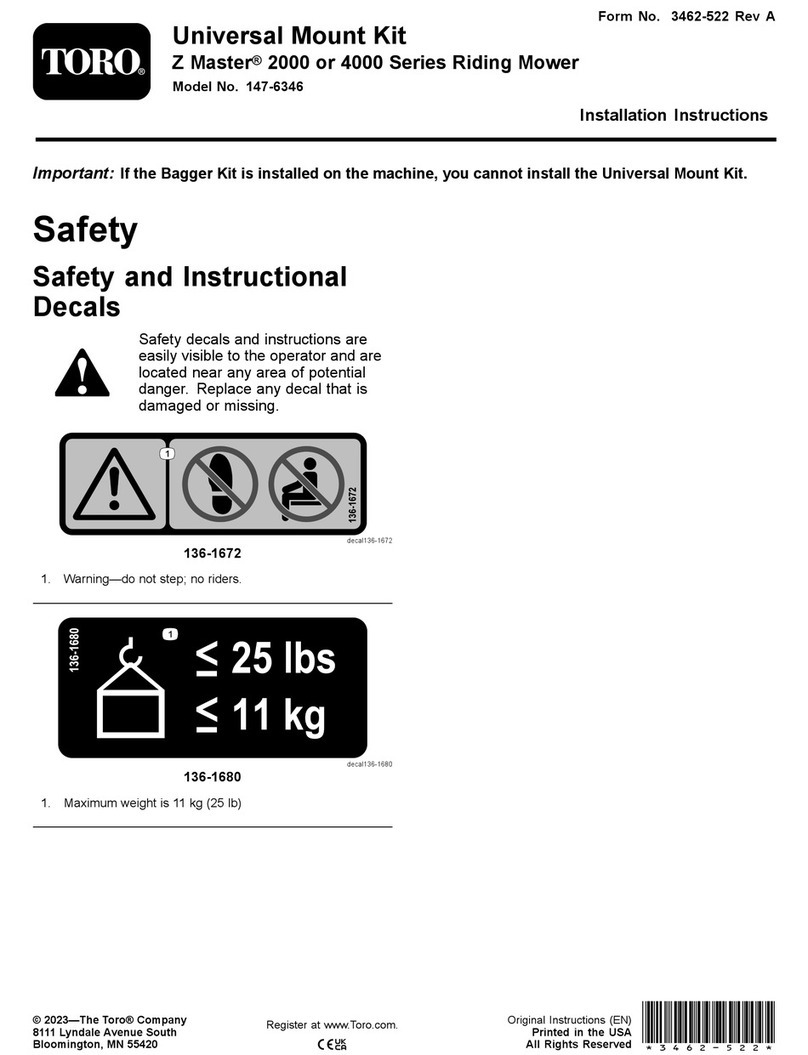

Toro 147-6346 User manual