FormNo.3329-829RevB

CrosscutPositionKit

ForGroundsmaster4500-D

ModelNo.30832

InstallationInstructions

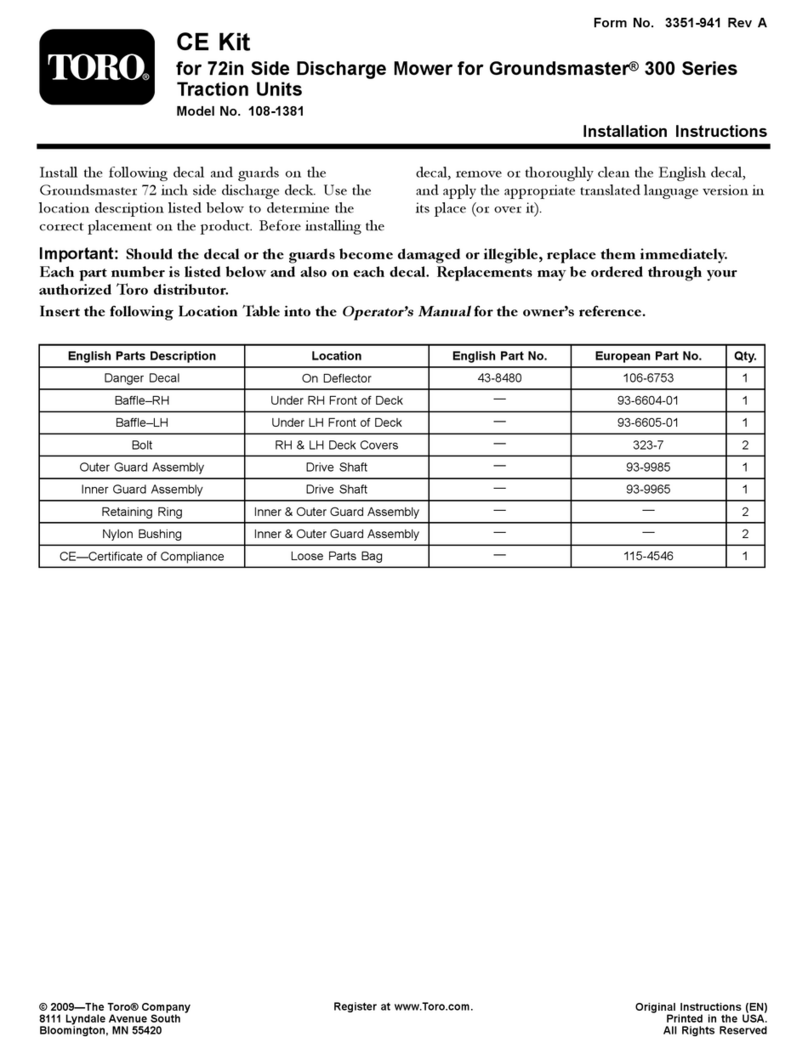

Installation

1.Positionthemachineonalevelsurface,lowerthe

cuttingdeckstotheoor,shuttheengineoffand

engagetheparkingbrake.

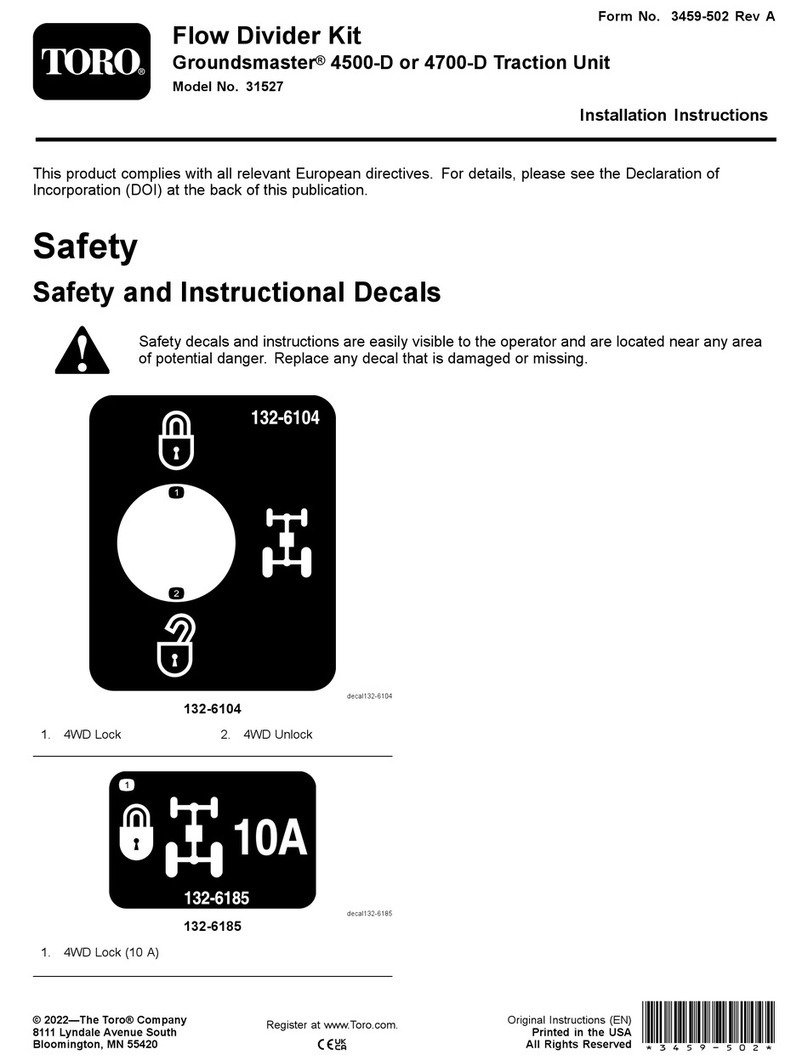

2.Removethe(4)5/16inchx5/8inchangebolts

securingtheoorplatetotheframe(Figure1).

Removetheoorplate.

Figure1

1.Floorplate

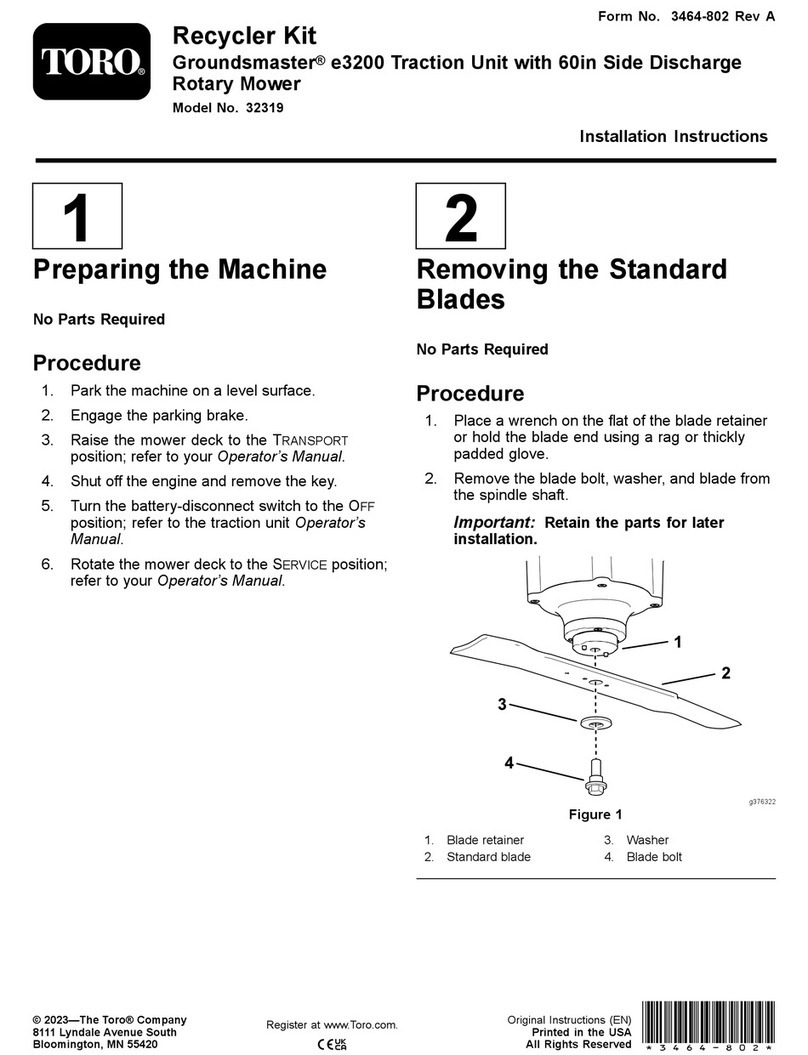

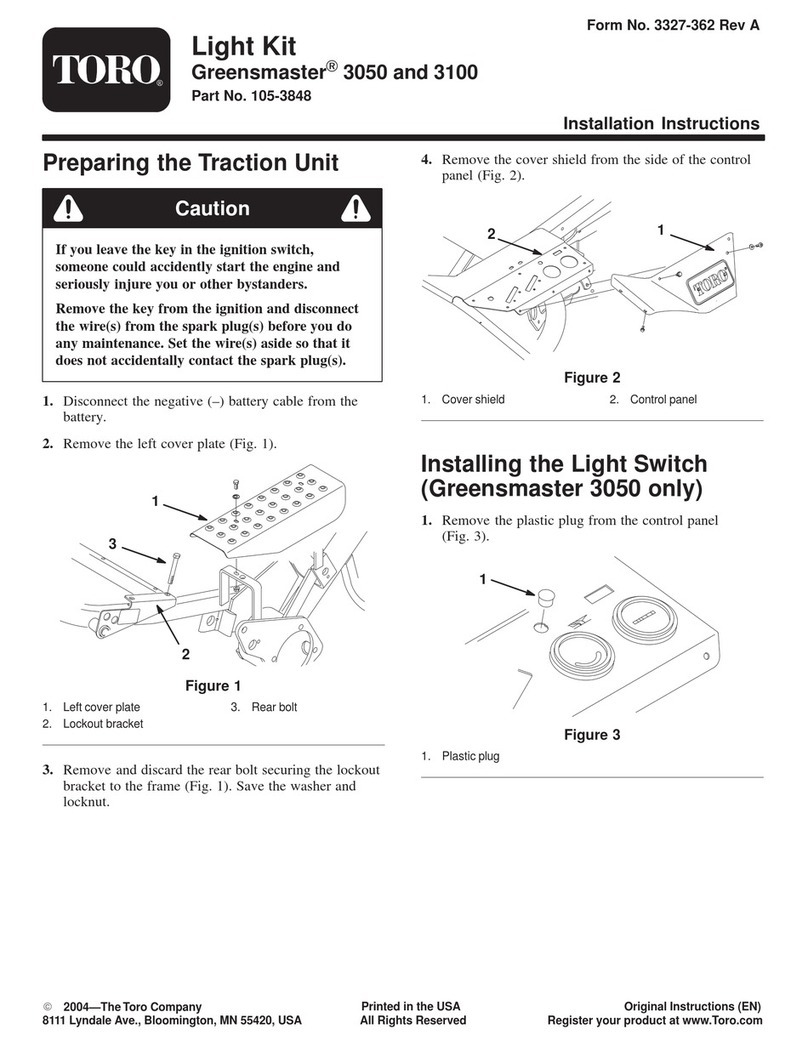

3.UsingthedimensionsshowninFigure2,locate,

markanddrilla13/16inchdiameterholethrough

theoorplateandfoottread.

Figure2

1.4–1/2inches3.13/16inchdiameterhole

2.15–7/8inches

4.Removethefrontcenterdeckfromthetractionunit

asfollows:

A.Disconnectandremovethehydraulicmotor

fromthedeck.Coverthetopofthedeckspindle

toprotectitfromcontamination.

B.Removethelynchpinsecuringthedeckcarrier

frametotheliftarmpivotpin.

C.Rollthecuttingdeckawayfromthetractionunit.

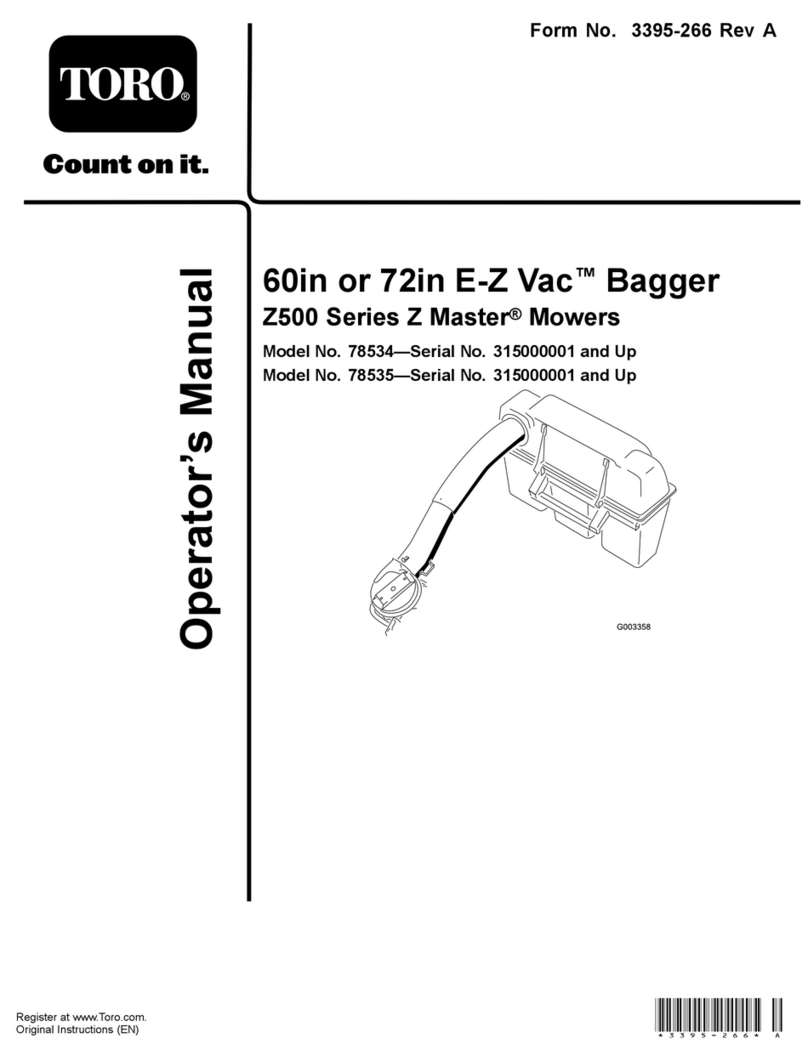

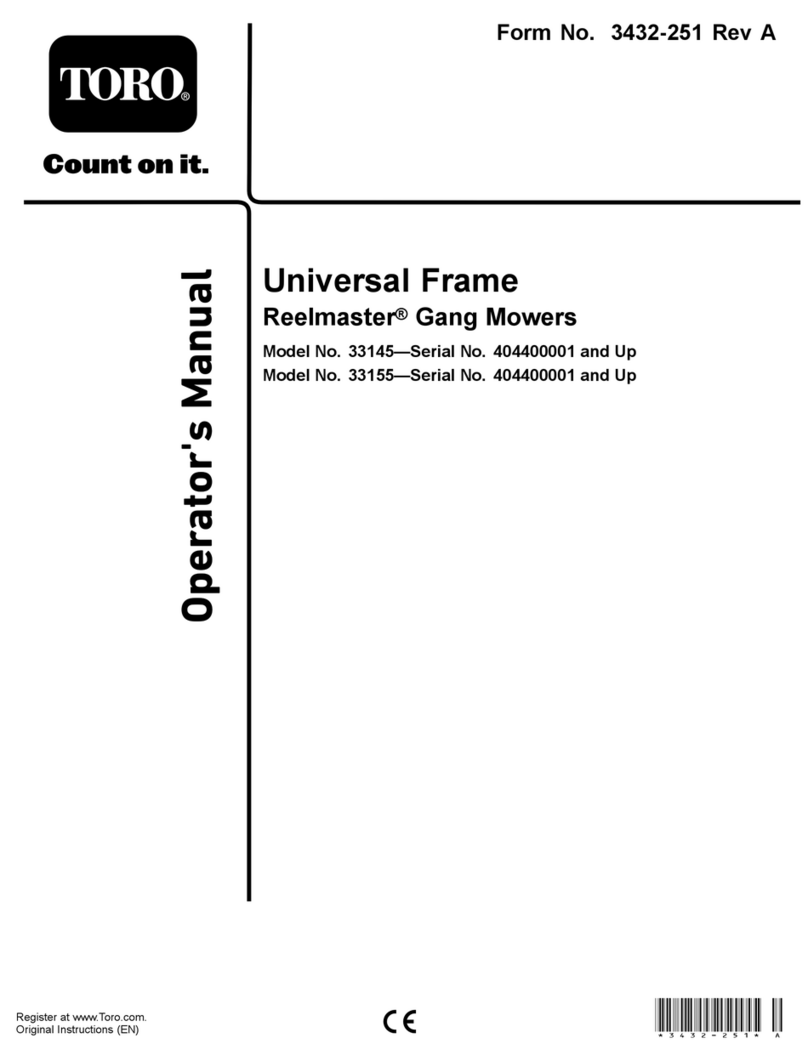

5.UsingthedimensionsshowninFigure3,locate,

markanddrill(2)7/32inchdiameterholesinthe

topofthefrontframetube.

Figure3

1.4–53/64inches3.1–3/8inches

2.7/16inch4.7/32inchdiameter

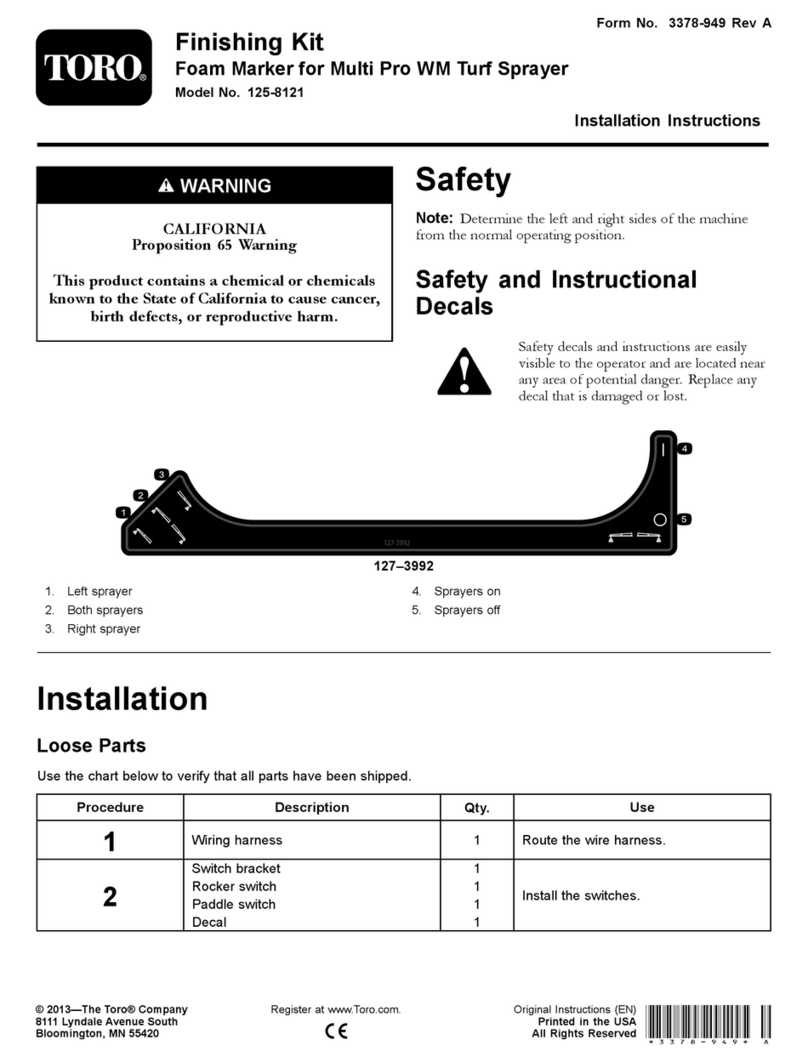

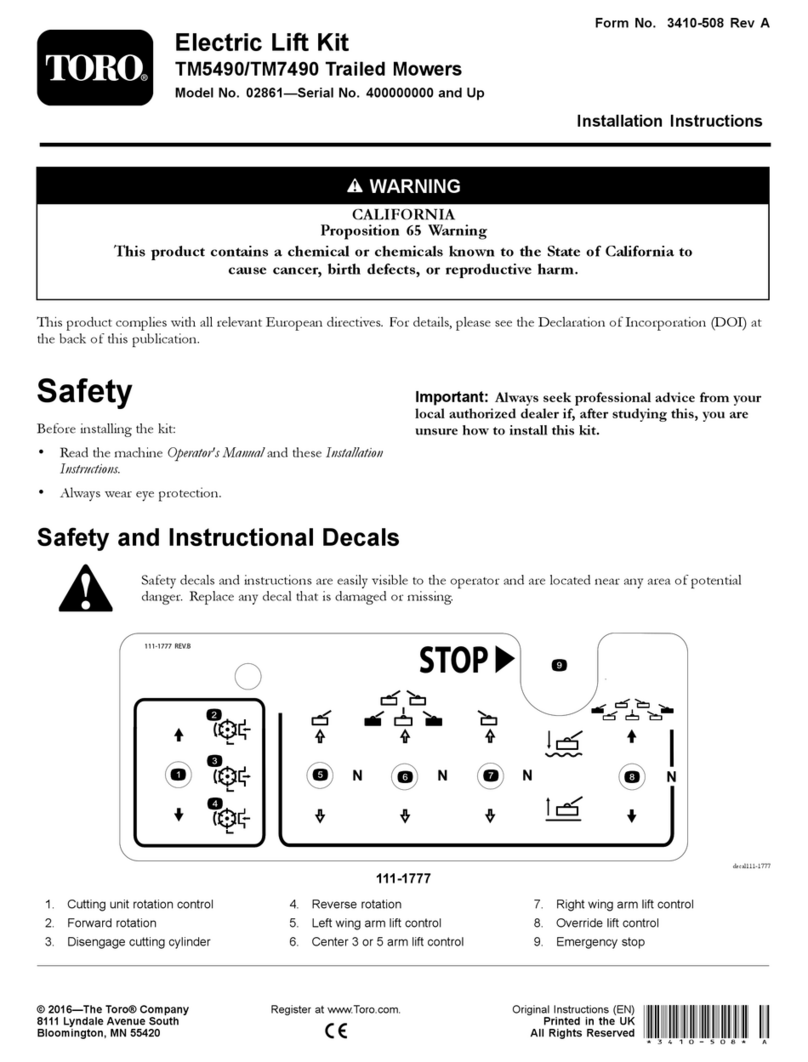

6.Mountthespringbrackettothetopoftheframe

tubewith(2)¼inchselftappingangebolts

(Figure4).

Figure4

1.Springbracket2.Selftappingbolt

©2008—TheToro®Company

8111LyndaleAvenueSouth

Bloomington,MN55420

Registeratwww.Toro.com.OriginalInstructions(EN)

PrintedintheUSA.

AllRightsReserved