4.Rotatethereelsothatabladecrossesthe

bedknifeapproximately25mm(1inch)infrom

theendofthebedknifeontherightsideofthe

cuttingunit.

Note:Putanidentifyingmarkonthisbladeto

makesubsequentadjustmentseasier.

5.Insertthe0.05mm(0.002inch)shimbetween

themarkedreelbladeandthebedknifeatthe

pointwherethebladecrossesthebedknife.

6.Turntherightbedbaradjusterclockwiseuntil

youfeellightpressure(i.e.drag)ontheshim,

thenbackoffthebedbaradjuster2clicksand

removetheshim.

Note:Adjusting1sideofthecuttingunitaffects

theotherside,the2clickswillprovideclearance

forwhentheothersideisadjusted.

Note:Ifstartingwithalargegap,bothsides

shouldinitiallybedrawncloserbyalternately

tighteningtherightandlefthandsides.

7.Slowlyrotatethereelsothatthesameblade

thatyoucheckedontherightsideiscrossing

thebedknifeapproximately25mm(1inch)in

fromtheendofthebedknifeontheleftsideof

thecuttingunit.

8.Turntheleftbedbaradjusterclockwiseuntilthe

shimcanbeslidthroughthereeltobedknife

gapwithlightdrag.

9.Returntotherightsideandadjustasnecessary

togetlightdragontheshimbetweenthesame

bladeandbedknife.

10.Repeatsteps8and9untiltheshimcanbeslid

throughbothgapswithslightdrag,butoneclick

inonbothsidespreventstheshimfrompassing

throughonbothsides.

Note:Thebedknifeisnowparalleltothereel.

Note:Thisprocedureshouldnotbeneeded

ondailyadjustments,butshouldbedoneafter

grindingordisassembly.

11.Fromthisposition(i.e.,1clickinandshimnot

passingthrough)turnthebedbaradjusters

clockwise1clickeach.

Note:Eachclickturnedmovesthebedknife

0.022mm(0.0009inch).Donotovertighten

theadjustingscrews.

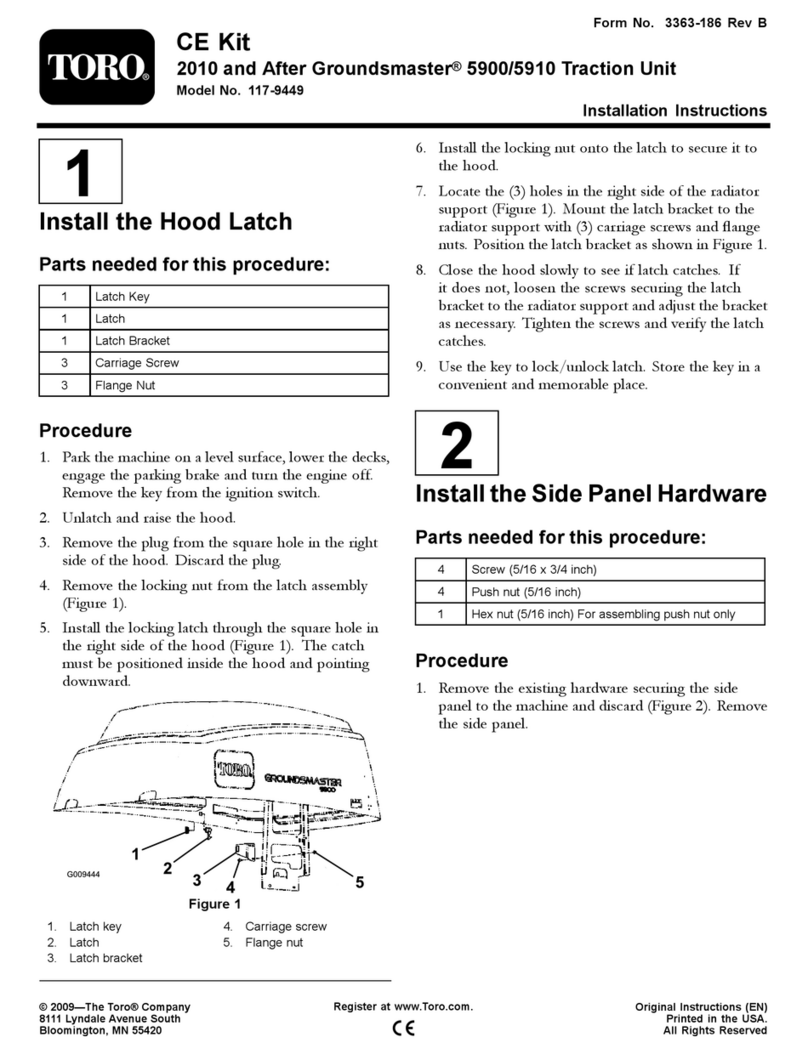

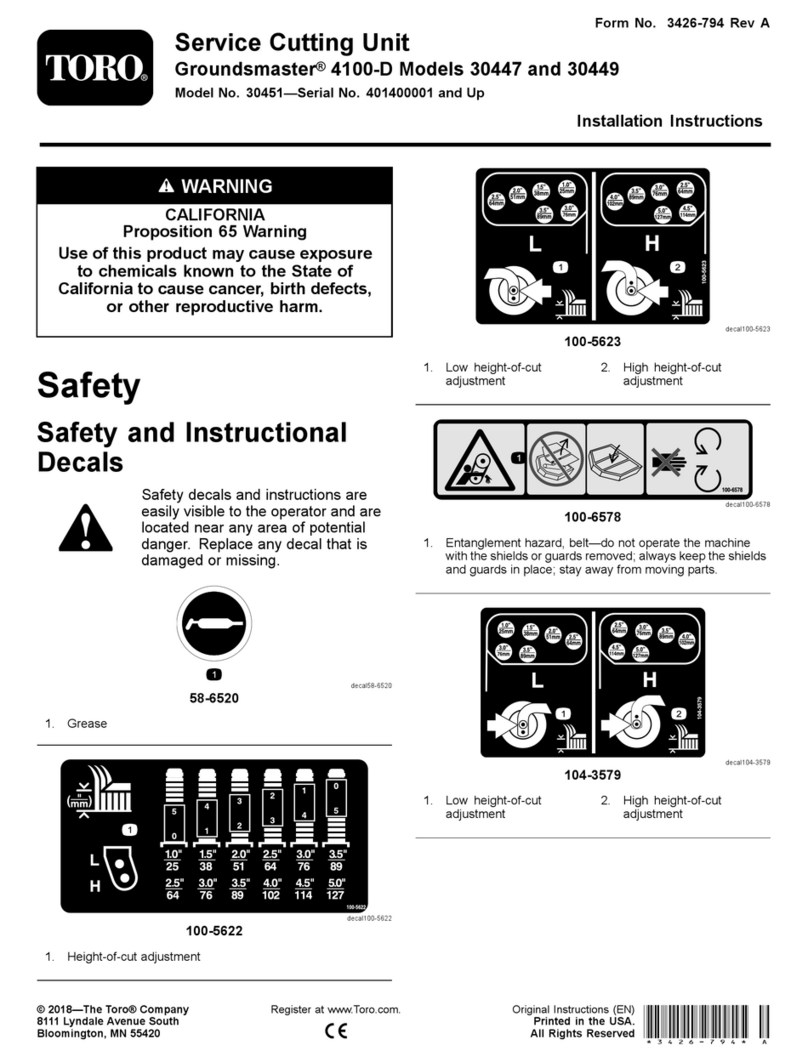

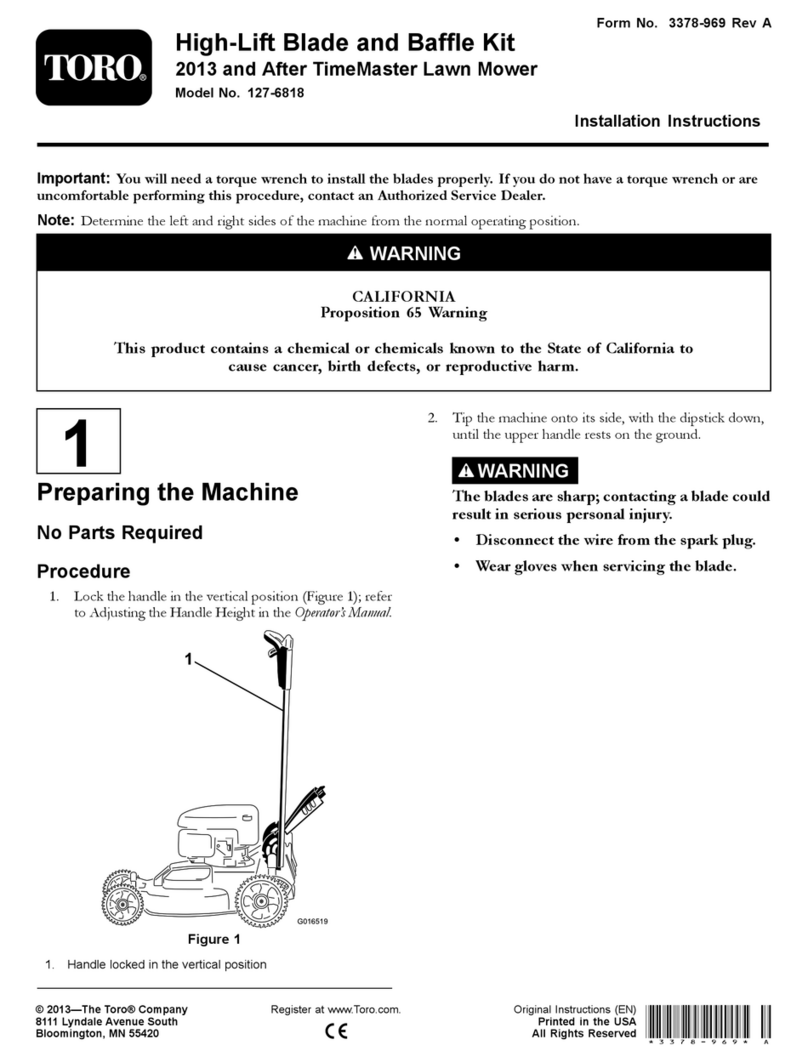

12.Testthecuttingperformancebyinsertingalong

stripofTorocuttingperformancepaperbetween

reelandbedknife,perpendiculartothebedknife

(Figure10).

Note:Slowlyrotatethereelforward;itshould

cutthepaper.

g027166

Figure10

Note:Ifexcessivereeldragoccurseither

backlaporgrindthecuttingunittoachievethe

sharpedgesneededforprecisioncutting.

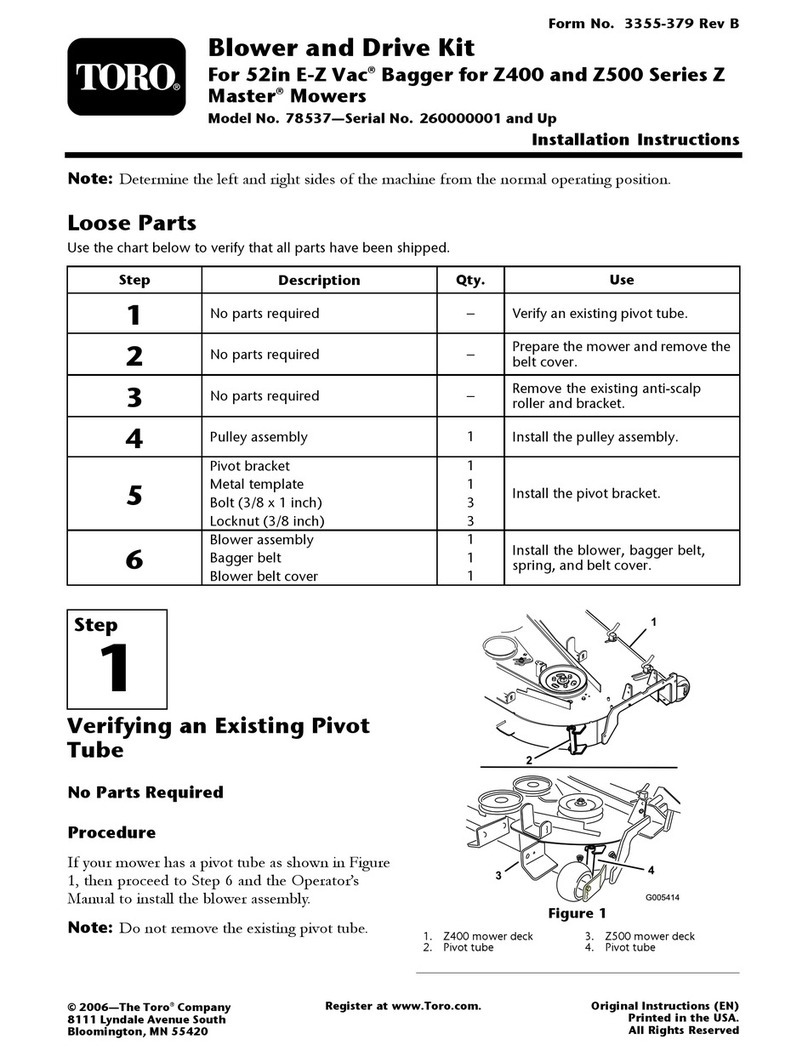

AdjustingtheRearRoller

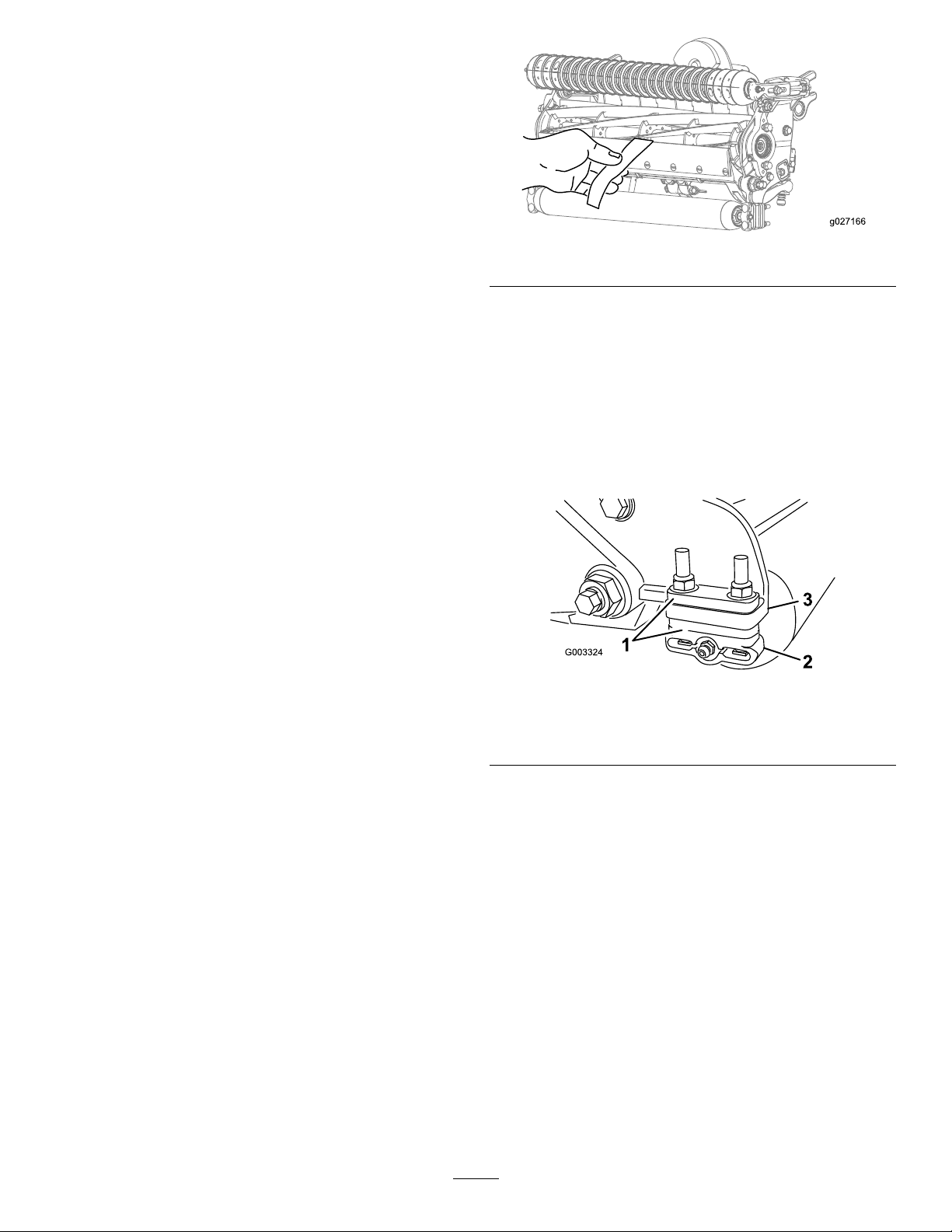

1.Adjusttherearrollerbrackets(Figure11)tothe

desiredheight-of-cutrangebypositioningthe

requiredamountofspacersbelowtheside-plate

mountingange(Figure11)pertheHOCChart.

g003324

Figure11

1.Spacer3.Side-platemountingange

2.Rollerbracket

2.Raisetherearofthecuttingunitandplacea

blockunderthebedknife.

3.Removethe2nutssecuringeachrollerbracket

andthespacertoeachside-platemounting

ange.

4.Lowertherollerandthescrewsfromthe

side-platemountingangesandspacers.

5.Placethespacersontothescrewsontheroller

brackets.

6.Re-securetherollerbracketandthespacersto

undersideoftheside-platemountinganges

withthenutspreviouslyremoved.

7.Verifythatthebedknife-to-reelcontactiscorrect.

Tipthemowertoexposethefrontandrear

rollersandthebedknife.

Note:Thepositionoftherearrollertothereel

iscontrolledbythemachiningtolerancesofthe

9