Toro 110-2626 User manual

Other Toro Utility Vehicle manuals

Toro

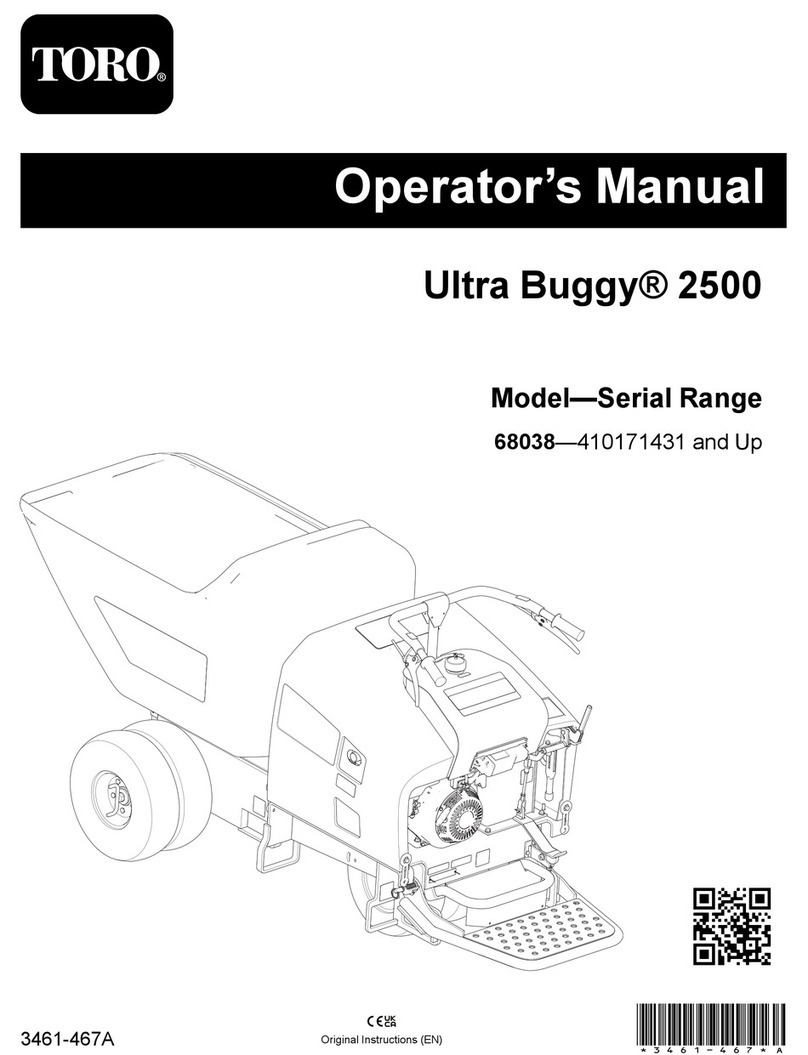

Toro Ultra Buggy 2500 User manual

Toro

Toro 07277 Workman 2110 User manual

Toro

Toro 12004 User manual

Toro

Toro 7383 User manual

Toro

Toro 09833 User manual

Toro

Toro 07352 User manual

Toro

Toro Workman HDX Series User manual

Toro

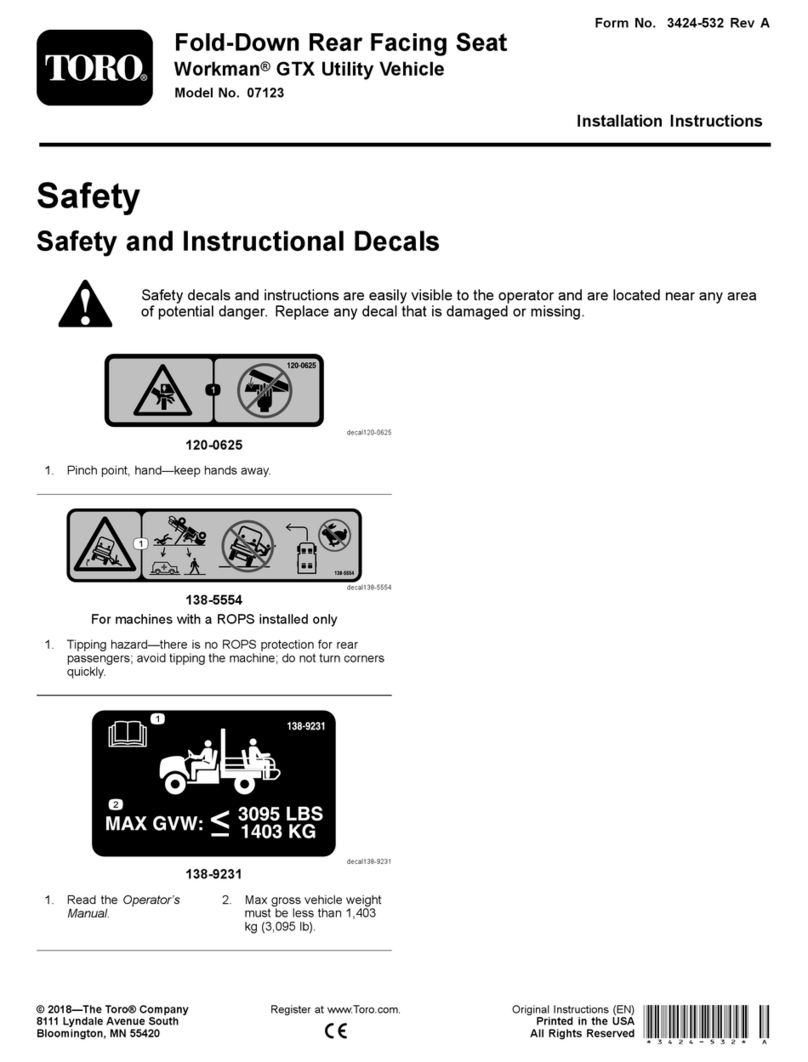

Toro Workman GTX User manual

Toro

Toro 7220 User manual

Toro

Toro 07385 Workman HDX-D User manual

Toro

Toro 07413LT User manual

Toro

Toro 7363 User manual

Toro

Toro 07252TC Workman 1100 User manual

Toro

Toro 07252 Workman 1100 User manual

Toro

Toro 7266 User manual

Toro

Toro Workman 07369 User manual

Toro

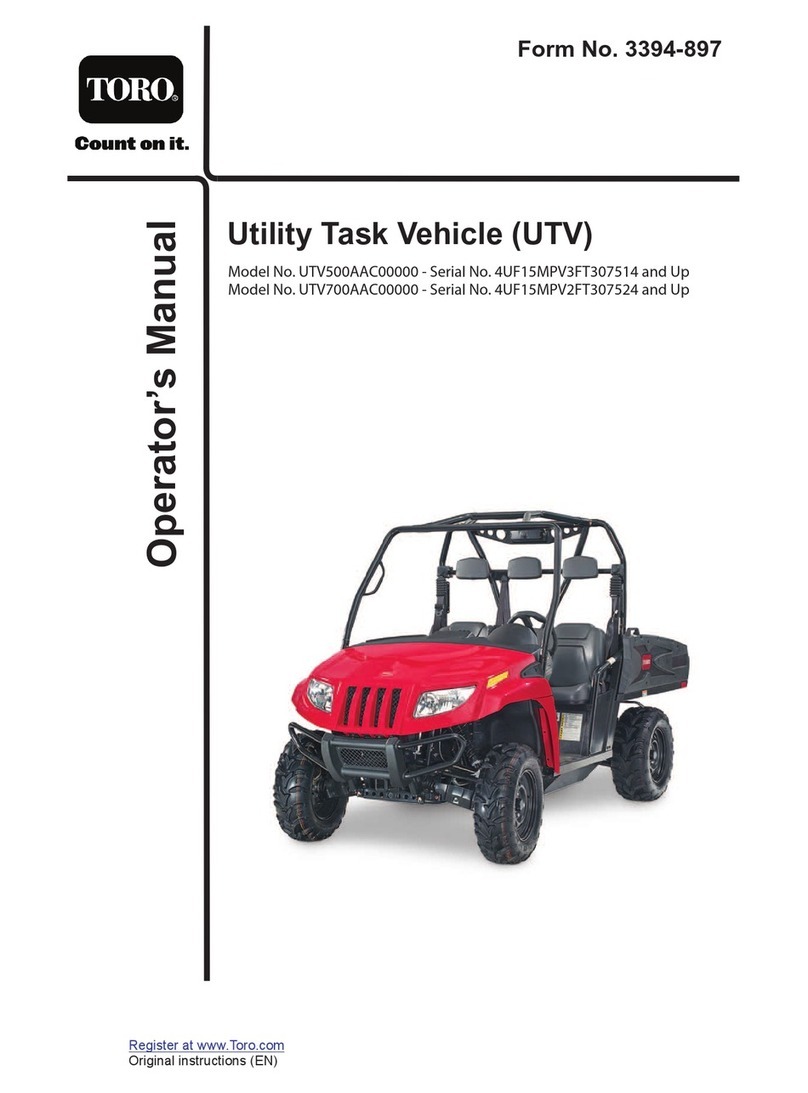

Toro UTV500AAC00000 User manual

Toro

Toro Workman MD User manual

Toro

Toro 7205 User manual

Toro

Toro 07411EX User manual

Popular Utility Vehicle manuals by other brands

Range Road

Range Road RR608 Assembly manual

Landoll

Landoll 900D Series Operator's manual

SSI SCHAEFER

SSI SCHAEFER WEASEL LITE user manual

Club Car

Club Car TURF 272 2005 Maintenance service manual

pronovost

pronovost PUMA-10000 Operator's manual

Cushman

Cushman Turf Truckster 84069 Parts & maintenance manual