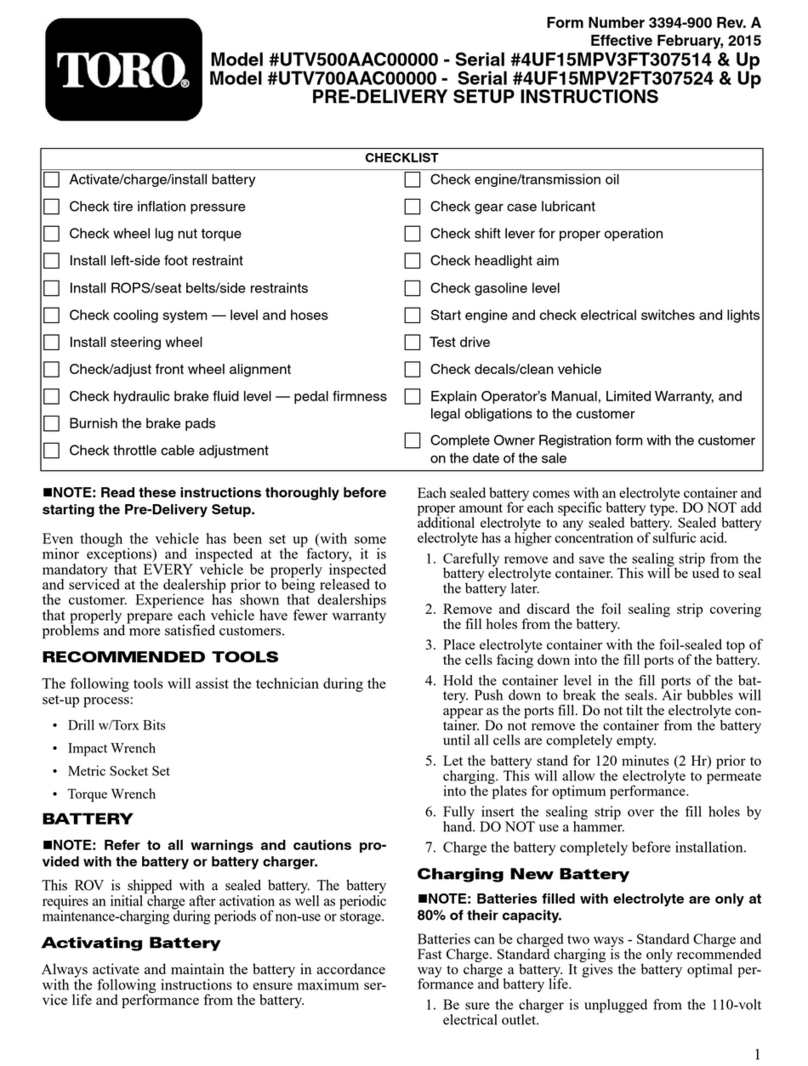

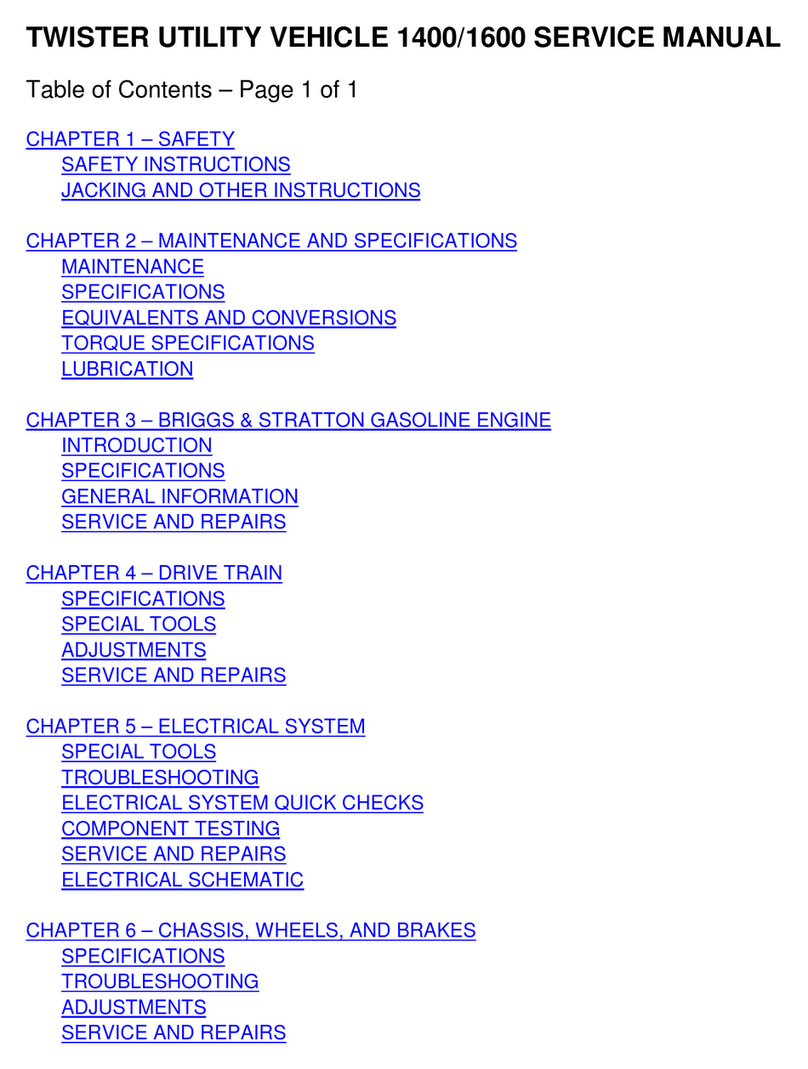

Contents

Safety.......................................................................4

GeneralSafety...................................................4

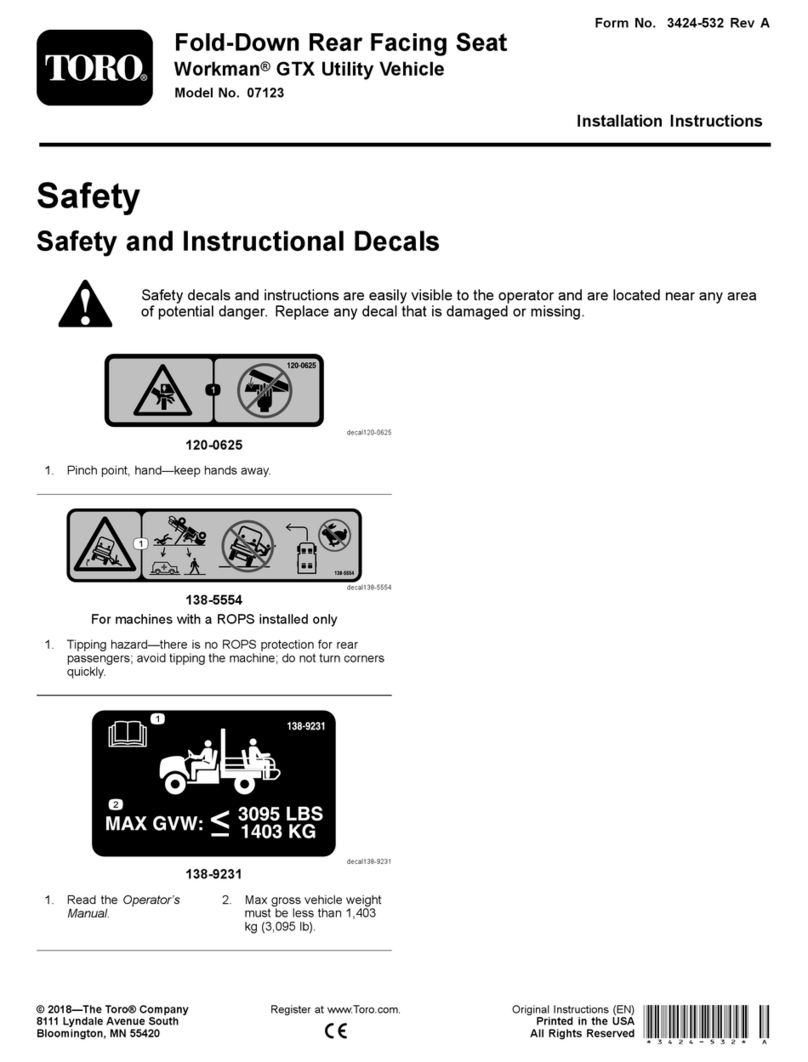

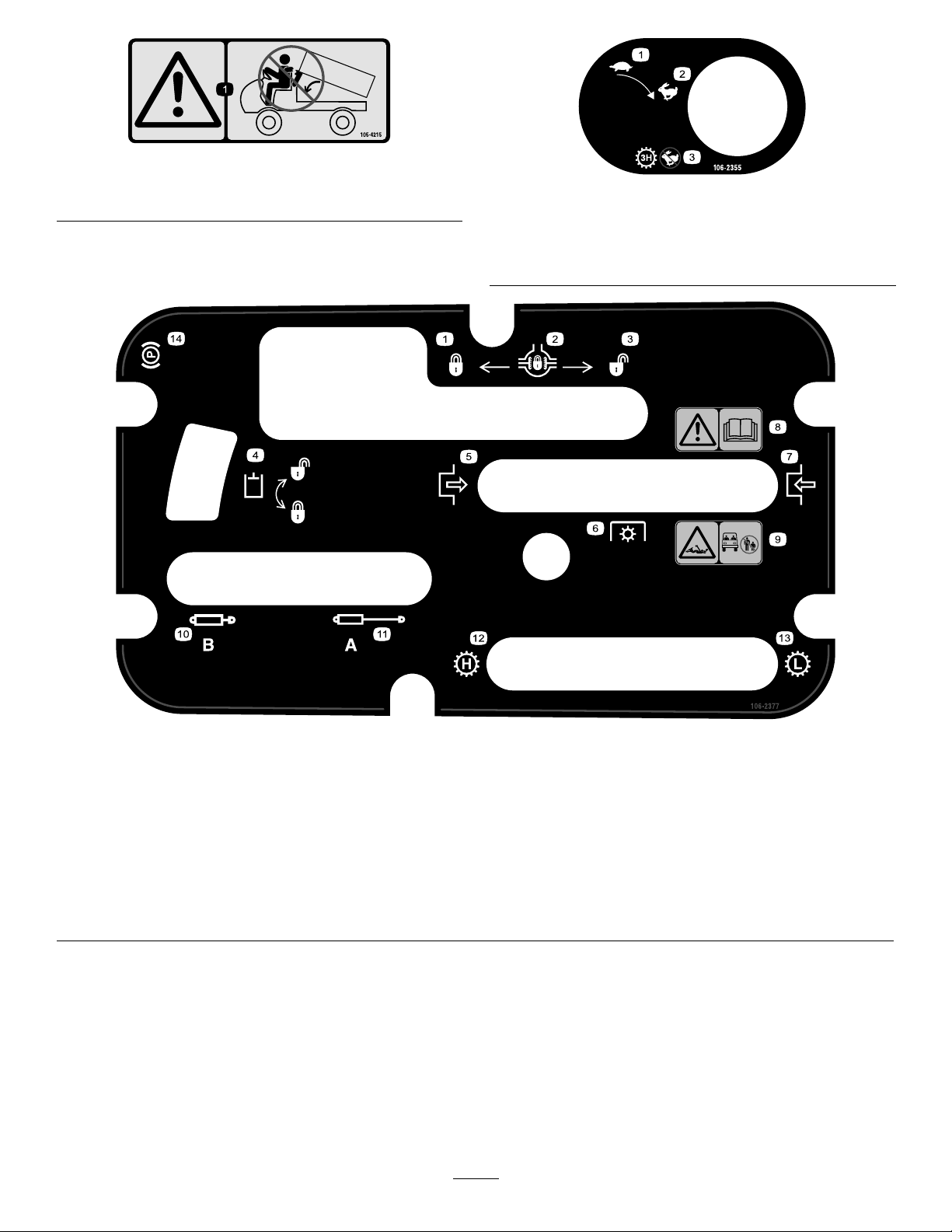

SafetyandInstructionalDecals..........................5

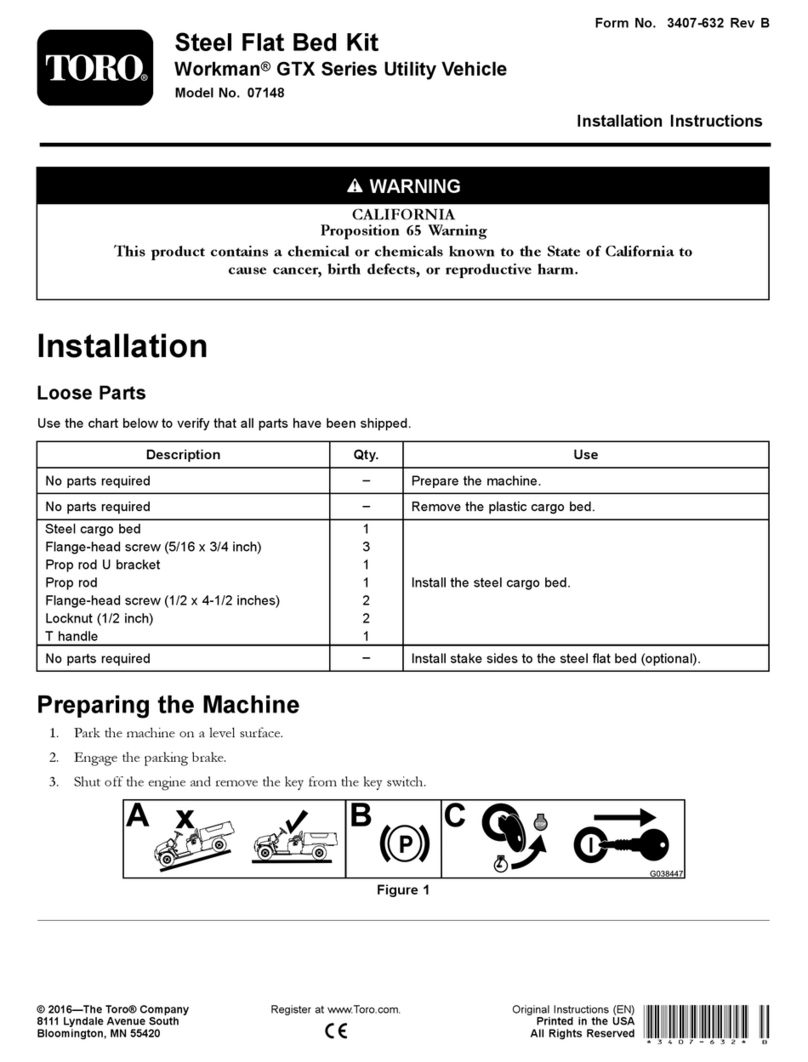

Setup.......................................................................11

1CheckingtheFluidLevelsandTire

Pressure........................................................11

2InstallingtheRollBar.....................................12

3BurnishingtheBrakes....................................12

ProductOverview...................................................13

Controls...........................................................13

Specications..................................................18

Attachments/Accessories.................................18

BeforeOperation.................................................19

BeforeOperationSafety...................................19

PerformingDailyMaintenance..........................19

CheckingtheTirePressure...............................19

AddingFuel......................................................20

BreakinginaNewMachine..............................20

CheckingtheSafety-InterlockSystem..............21

DuringOperation.................................................21

DuringOperationSafety...................................21

OperatingtheCargoBed..................................23

StartingtheEngine...........................................24

DrivingtheMachine..........................................24

StoppingtheMachine.......................................24

ShuttingOfftheEngine.....................................24

UsingtheDifferentialLock................................25

UsingtheHydraulicControl..............................25

AfterOperation....................................................27

AfterOperationSafety......................................27

HaulingtheMachine.........................................28

TowingtheMachine..........................................28

TowingaTrailer................................................28

Maintenance...........................................................29

MaintenanceSafety..........................................29

RecommendedMaintenanceSchedule(s)...........29

MaintainingtheMachineunderSpecial

OperatingConditions....................................31

Pre-MaintenanceProcedures..............................32

PreparingtheMachineforMaintenance............32

UsingtheBedSupport......................................32

RemovingtheFullBed......................................33

InstallingtheFullBed........................................33

RaisingtheMachine.........................................34

RemovingandInstallingtheHood....................35

Lubrication..........................................................36

GreasingtheBearingsandBushings................36

EngineMaintenance...........................................38

EngineSafety...................................................38

ServicingtheAirCleaner..................................38

ServicingtheEngineOil....................................39

ServicingtheSparkPlugs.................................41

FuelSystemMaintenance...................................41

InspectingFuelLinesandConnections.............41

InspectingtheCarbonCanisterAir

Filter..............................................................41

ReplacingtheFuelFilter...................................42

ElectricalSystemMaintenance...........................42

ElectricalSystemSafety...................................42

ServicingtheFuses..........................................42

Jump-StartingtheMachine...............................43

ServicingtheBattery.........................................44

DriveSystemMaintenance..................................44

AdjustingtheShiftCables.................................44

AdjustingtheHigh-LowCable...........................44

AdjustingDifferential-LockCable......................45

InspectingtheTires..........................................45

CheckingtheFrontWheelAlignment................46

TorquingtheWheelLugNuts............................47

CoolingSystemMaintenance..............................47

CoolingSystemSafety.....................................47

CleaningtheEngine-CoolingAreas..................47

BrakeMaintenance.............................................48

CheckingtheBrake-FluidLevel........................48

AdjustingtheParkingBrake..............................49

AdjustingtheBrakePedal.................................49

BeltMaintenance................................................50

CheckingthePump-BeltTension......................50

AdjustingthePump-DriveBelt..........................50

ControlsSystemMaintenance.............................51

AdjustingtheClutchPedal................................51

AdjustingtheAccelerator..................................52

AdjustingtheChoke..........................................52

HydraulicSystemMaintenance...........................53

HydraulicSystemSafety...................................53

ServicingtheTransaxle/Hydraulic

System..........................................................53

RaisingtheCargoBedinanEmergency...........55

Cleaning..............................................................56

WashingtheMachine.......................................56

Storage...................................................................57

StorageSafety..................................................57

StoringtheMachine..........................................57

Troubleshooting......................................................58

3