•Neverremovethefuelcaporaddfuelwiththe

enginerunning.

•Allowenginetocoolbeforerefueling.

•Neverrefuelthemachineindoors.

•Neverstorethemachineorfuelcontainerwhere

thereisanopename,spark,orpilotlight,such

asonawaterheateroronotherappliances.

•Removeequipmentfromthetruckortrailerand

refuelitontheground.Ifthisisnotpossible,then

refuelsuchequipmentwithaportablecontainer

ratherthanfromafuel-dispensernozzle.

•Iffuelisspilledonclothing,changeclothing

immediately.

•Neveroverllthefueltank.Replacethefuelcap

andtightenitsecurely.

Operation

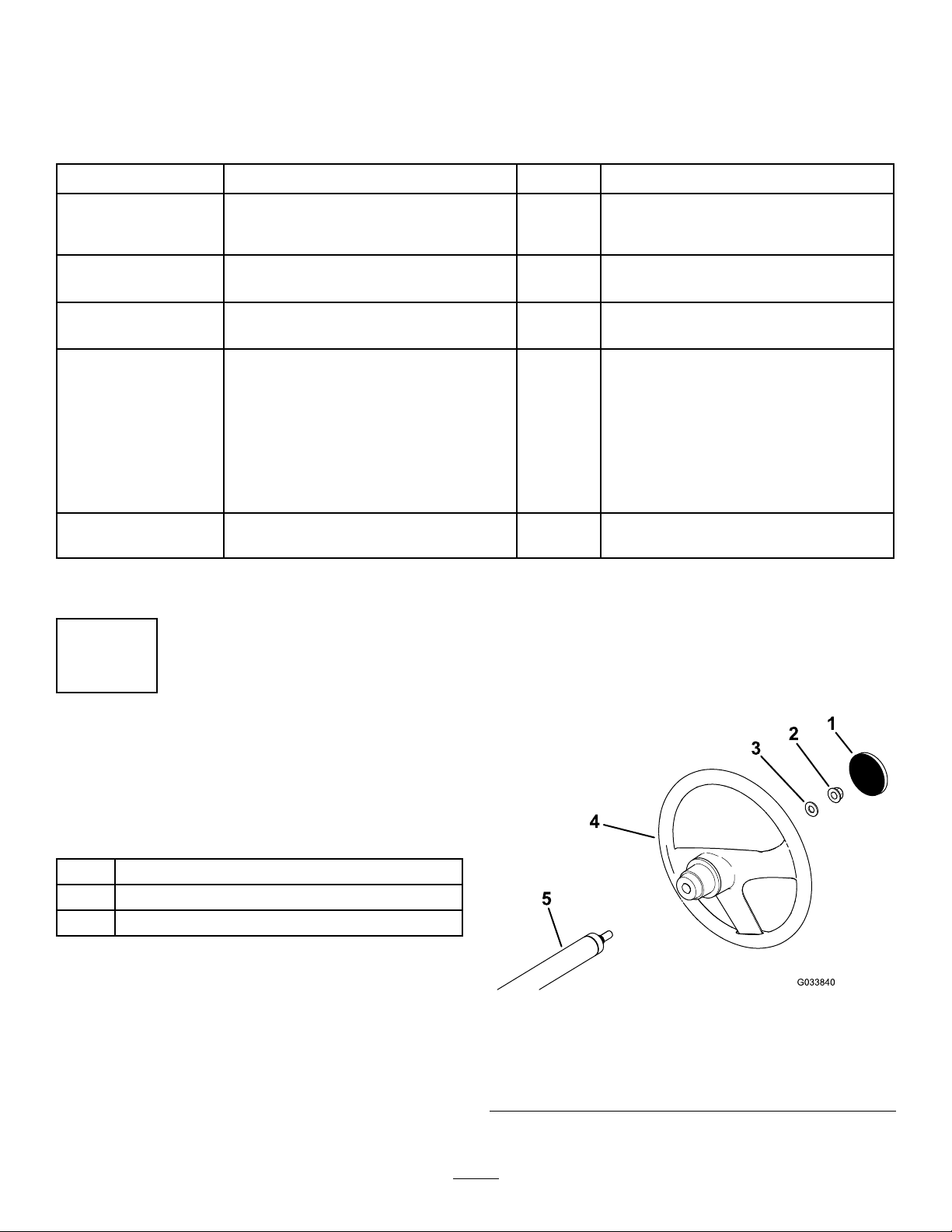

•Theoperatorandpassengershouldremainseated

wheneverthemachineisinmotion.Theoperator

shouldkeepbothhandsonthesteeringwheel,

wheneverpossible,andthepassengershould

usethehandholdsprovided.Keeparmsandlegs

withinthemachinebodyatalltimes.

•Driveslowerandturnlesssharplywhenyouare

carryingapassenger.Rememberyourpassenger

maynotbeexpectingyoutobrakeorturnand

maynotbeready.Nevercarrypassengersinthe

boxoronattachments.

•Neveroverloadyourmachine.Thenameplate

(locatedunderthemiddleofthedash)shows

theloadlimitsforthemachine.Neveroverll

attachmentsorexceedthevehiclemaximumgross

vehicleweight(GVW).

•Failuretooperatemachinesafelymayresultin

anaccident,tipoverofthemachine,andserious

injuryordeath.Drivecarefully.Topreventtipping

orlossofcontrol,takethefollowingprecautions:

–Useextremecaution,reducespeed,and

maintainasafedistancearoundsandtraps,

ditches,creeks,ramps,anyunfamiliarareas,

orotherhazards.

–Watchforholesorotherhiddenhazards.

–Usecautionwhenoperatingthemachine

onaslope.Normally,travelstraightupand

downslopes.Reducespeedwhenmaking

sharpturnsorwhenturningonhillsides.Avoid

turningonhillsideswheneverpossible.

–Useextracautionwhenoperatingthemachine

onwetsurfaces,athigherspeeds,orwitha

fullload.Stoppingtimewillincreasewithafull

load.

–Avoidsuddenstopsandstarts.Donotgo

fromreversetoforwardorforwardtoreverse

withoutrstcomingtoacompletestop.

–Donotattemptsharpturnsorabrupt

maneuversorotherunsafedrivingactionsthat

maycausealossofcontrolofthemachine.

–Whendumping,donotletanyonestandbehind

machineanddonotdumptheloadonanyone’s

feet.Releasethetailgatelatchesfromtheside

ofbox,notfrombehind.

–Keepallbystandersaway.Beforebacking

up,looktotherearandensurethatnooneis

behindthemachine.Backupslowly.

–Watchoutfortrafcwhennearorcrossing

roads.Alwaysyieldtherightofwayto

pedestriansandothermachines.Always

signalyourturnsorstopearlyenoughsoother

personsknowwhatyouplantodo.Obeyall

trafcrulesandregulations.

–Neveroperatethemachineinornearanarea

wherethereisdustorfumesintheairwhich

areexplosive.Theelectricalandexhaust

systemsofthemachinecanproducesparks

capableofignitingexplosivematerials.

–Alwayswatchoutforandavoidlowoverhangs

suchastreelimbs,doorjambs,overhead

walkways,etc.Makesurethereisenough

roomoverheadtoeasilyclearthemachine

andyourhead.

–Ifyouareeverunsureaboutthesafeoperation

ofthemachine,stopyourworkandaskyour

supervisor.

•Beforegettingofftheseat:

–Stopthemachine.

–Lowerthebed.

–Shuttheengineoffandwaitforallmovement

tostop.

–Engagetheparkingbrake.

–Removethekeyfromthekeyswitch.

•Donottouchtheengine,transmission,radiator,

muferormufermanifoldwhiletheengineis

runningorsoonafterithasstoppedbecausethese

areasmaybehotenoughtocauseburns.

•Ifthemachineevervibratesabnormally,stopthe

machineimmediately,shutoffthemachine,wait

forallmotiontostopandinspectfordamage.

Repairalldamagebeforeresumingoperation.

•Lightningcancausesevereinjuryordeath.If

lightningisseeninthearea,donotoperatethe

machine;seekshelter.

Braking

•Slowdownthemachinebeforeyouapproachan

obstacle.Thisgivesyouextratimetostoporturn

away.Hittinganobstaclecaninjureyouandyour

passenger.Inaddition,itcandamagethemachine

anditscontents.

5