bellow. How ever there are some tricks, which can prolong the life of some parts, such as: the

silicone felt cleaning roller, the aligning roller, the paper pick up and feed rollers. For example:

given the machine is maintained properly the OPC drum can easily make twice the normal copies

recommended by the manufacturer. After the 400 000 to 600 000 period it is possible to encounter a

variety of defects in certain modules such as the fuser, developer, feeding and drive system modules.

How ever there is nothing to worry – there will be a special article dedicated only to defects not

mentioned in the service manual.

As I always mention: most of the defects in copiers that are still under 400 000 copies are

due to poor maintenance and cleaning.

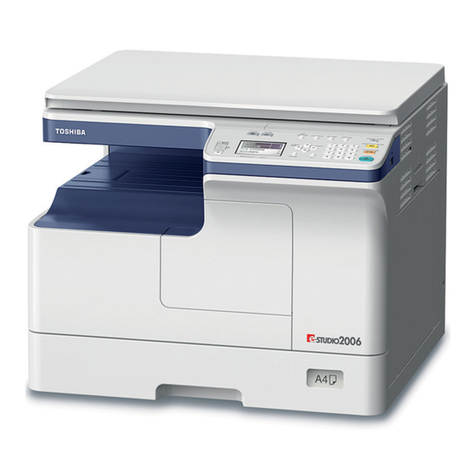

1. PERIODICAL MAINTENANCE – USEFUL PRACTICES (TOSHIBA 2060/2860)

Inspection every 80,000 Copies

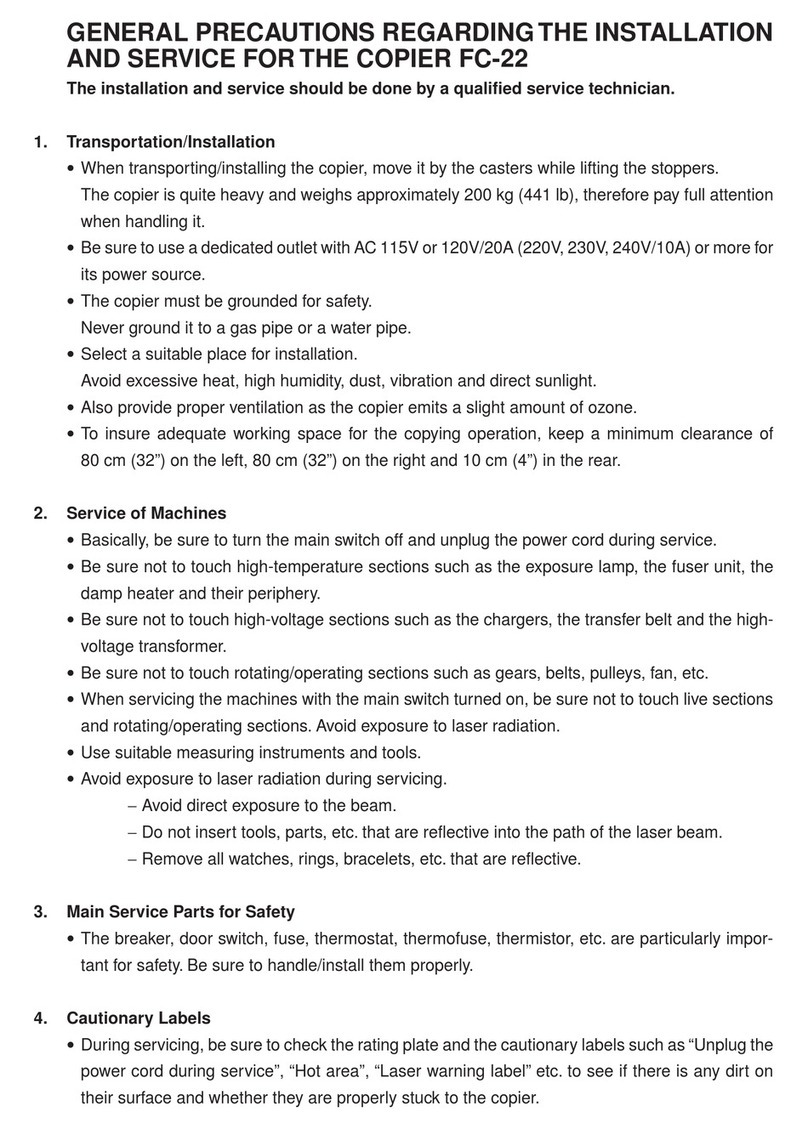

(1) Preparation

1 Ask the key operator about the present machine conditions and note them down.

2 Before starting the maintenance work, make and retain a few sample copies for later comparison.

3 Turn off the power switch and disconnect the power cord plug.

(2) The periodic inspection should be conducted in accordance with the Periodic Inspection Check

List shown below. Perform the inspection by referring to the figures, as well as to the explanations

in the Service Manual when necessary.

(3) After the inspection has been completed, plug in the machine and turn the power switch on, and

confirm the general operation of the machine by making a few copies and comparing them to those

made previously.

Inspection and Overhaul every 240,000 Copies

(1) Replace all the consumables.

(2) Check to see if there is any damage to the parts of driving section (gear, pulley, timing belt, etc.).

Replace parts on principle if damaged.

(3) Check to see if there is any damage or peeling of adhered parts (tape, Mylar sheet, etc.). Replace

any affected parts.

(4) Check to see if all the switches and sensors operate properly. Replace them if they are not

operating properly.

(5) Clean the inside of the machine thoroughly.

Periodic Inspection Check List

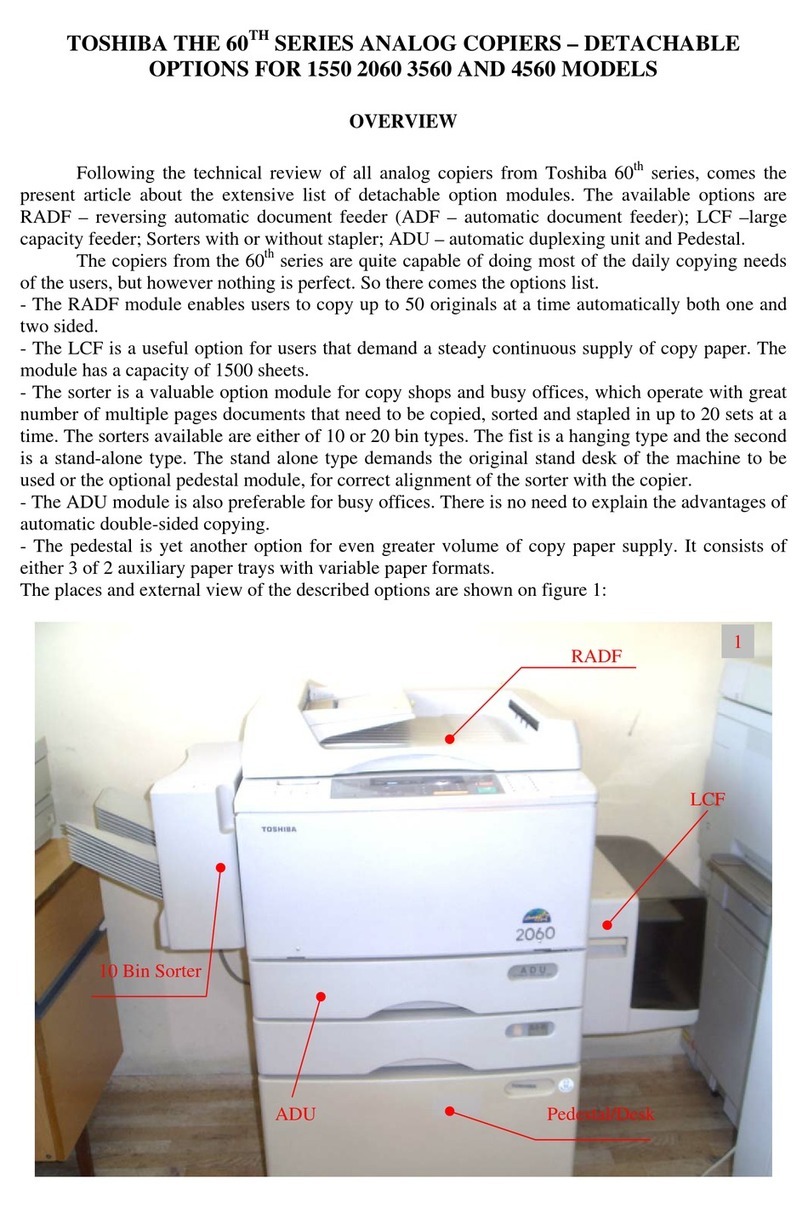

On figure 2 and 3 you can see the actual position of item numbers in the list bellow: