E6581810

Safety precautions

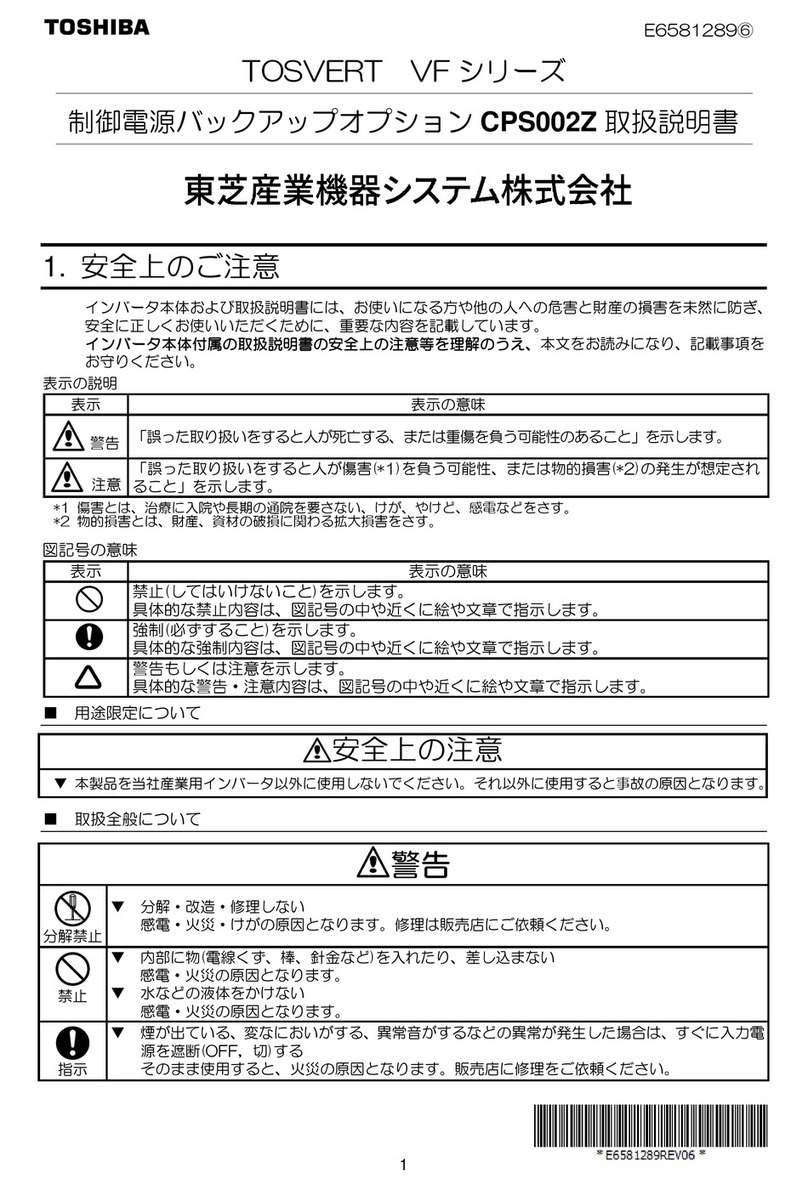

Warning

・ Read and understand the instruction manual entirely before installing or operating the VF-AS1 or

VF-PS1 inverters. Electrical construction work must be done by a qualified expert.

・ Do not short across terminal PA/+ and PC/- or across the DC bus capacitors.

・ Do not touch unshielded components or terminals because the unit contains many high voltage

parts.

・ Ground must be connected securely.

・ Before installing conduit box kit to an inverter, be certain to follow the items below.

① Turn off all power, including external control power.

② Place a “DO NOT TURN ON” label on every power switch.

③ Lock all power switches in their open positions.

④ Wait at least 15 minutes and make sure that the charge lamp is no longer lit.

⑤ Use a tester to make sure that the voltage to the DC main circuits (between PA/+ and PC/-) is

45 V or less. Refer to “DC voltage test procedure” below for details.

・Close all covers before turning on power or starting an inverter.

* Failure to follow these instructions will result in death or serious injury.

DC voltage test

Please use a tester with a DC voltage range of 800 VDC or more to measure DC voltage.

Test procedure:

1. Turn off the inverter’s power supply.

2. Wait at least 15 minutes and make sure that the charge lamp is no longer lit.

3. Measure the voltage of DC bus between the PA/+ and the PC/- terminals to verify the voltage is less

than 45 Vdc.

4. If the DC bus capacitors do not discharge completely, contact your local sales agency. Do not operate it

or attempt to replace component.

- 1 -