Visit www.trailfx.com or 1 (866) 638-4870 for Warranty Information / Tech Support / Product Updates

2021 Keystone Automotive Operations Inc. All Rights Reserved. 03/29/2022-R01 Page-2-6

INSTALLATION PROCEDURE:

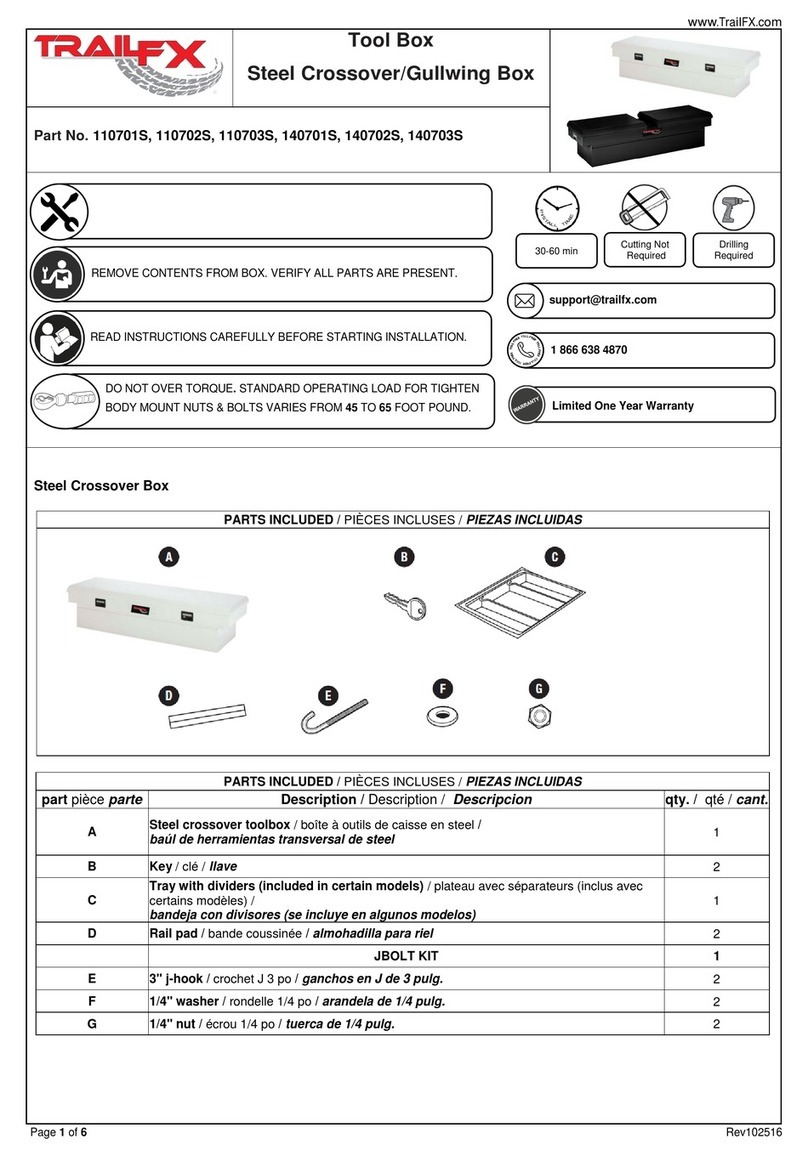

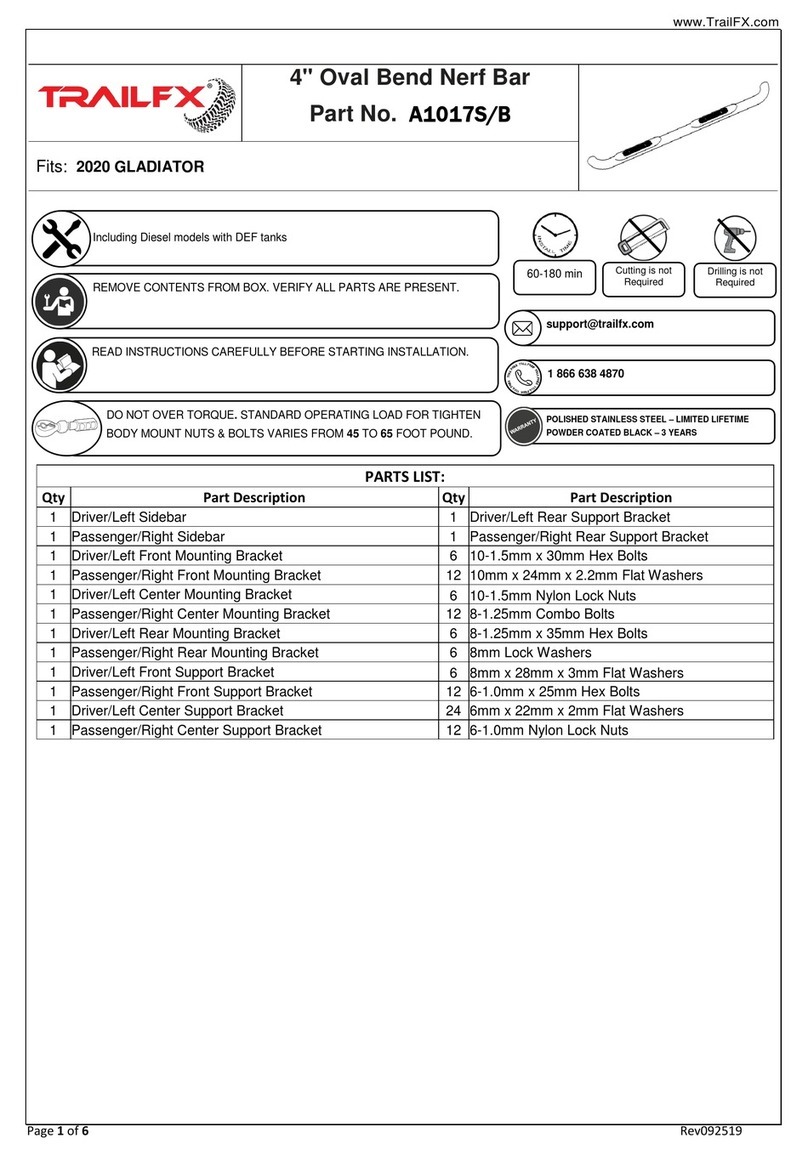

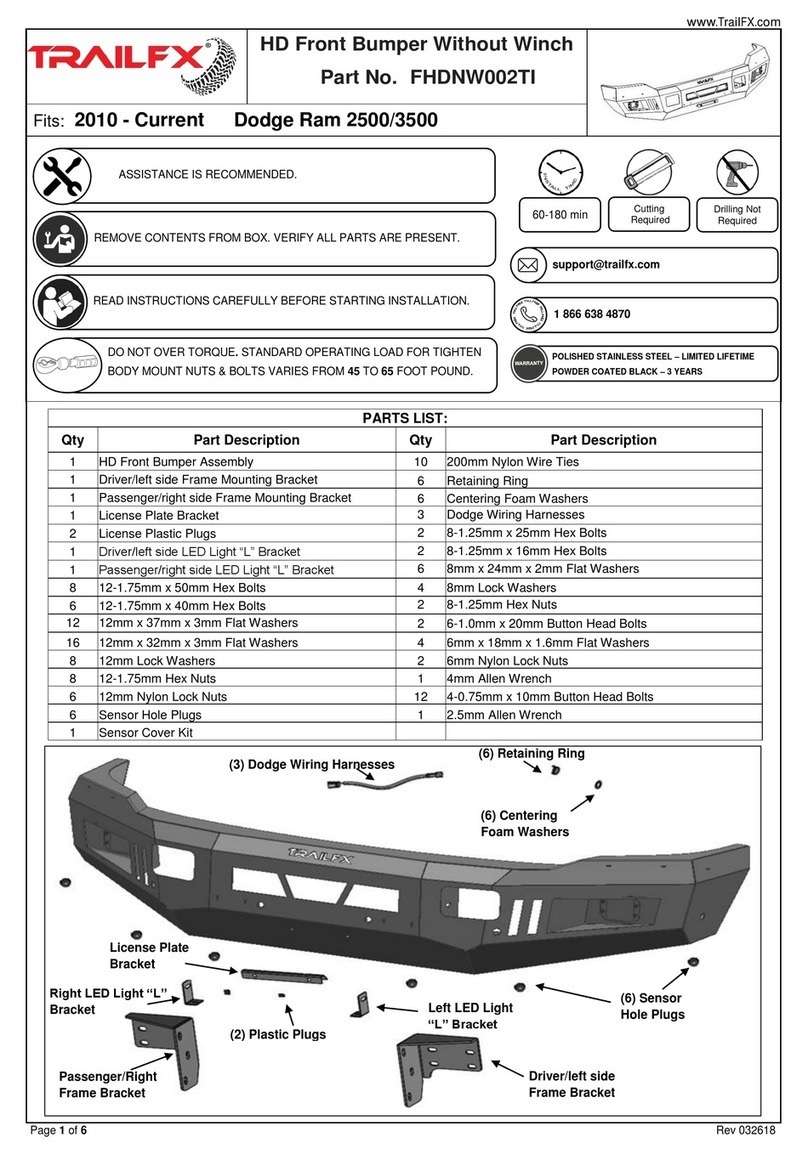

REMOVE CONTENTS FROM BOX. VERIFY ALL PARTS ARE PRESENT. READ INSTRUCTIONS CAREFULLY BEFORE

STARTING INSTALLATION. DRILLING IS REQUIRED. ASSISTANCE IS RECOMMENDED.

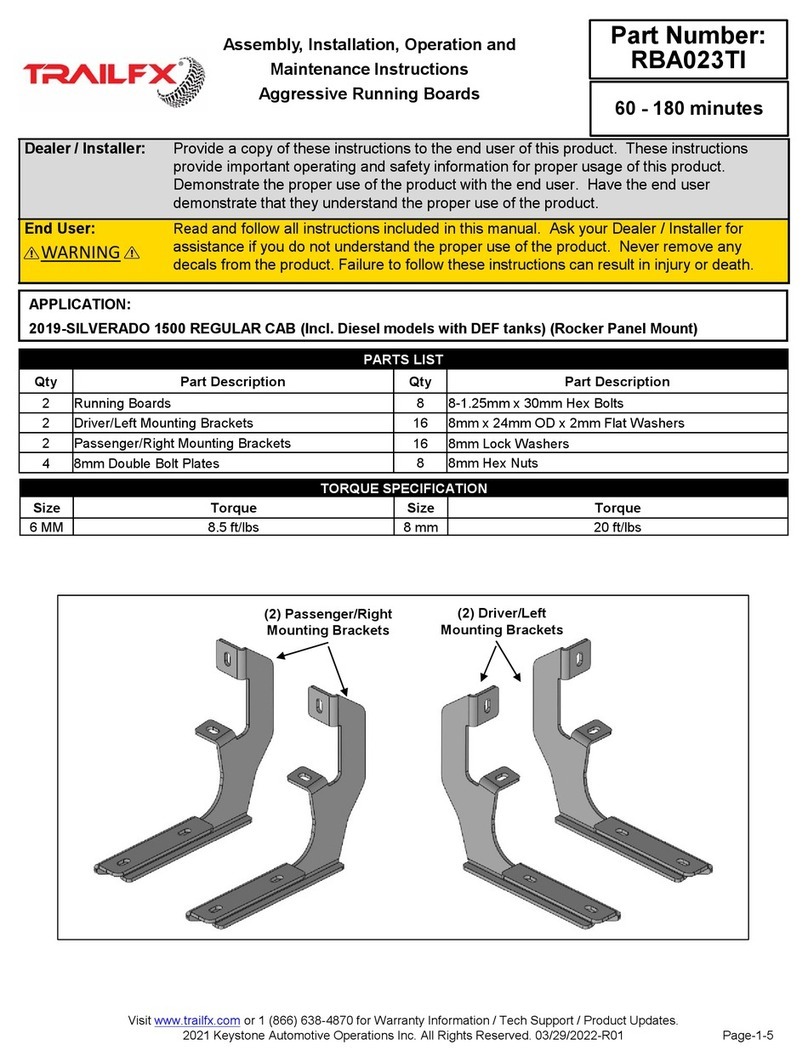

1. Start the installation under the passenger side of the vehicle. Locate the rubber plugs covering the factory holes in the

bottom of the outer body panel below the sliding door, (Figures 2 & 5). IMPORTANT: Rubber plugs may be covered with

heavy undercoating. Remove excess undercoating and/or sealant from all mounting locations so that Brackets will install

flat against body panel and pinch weld. NOTE: Mounting locations for the 136in wheelbase models are similar but slightly

different from the 159in wheelbase models, (Figures 1, 2, 3 & 5).

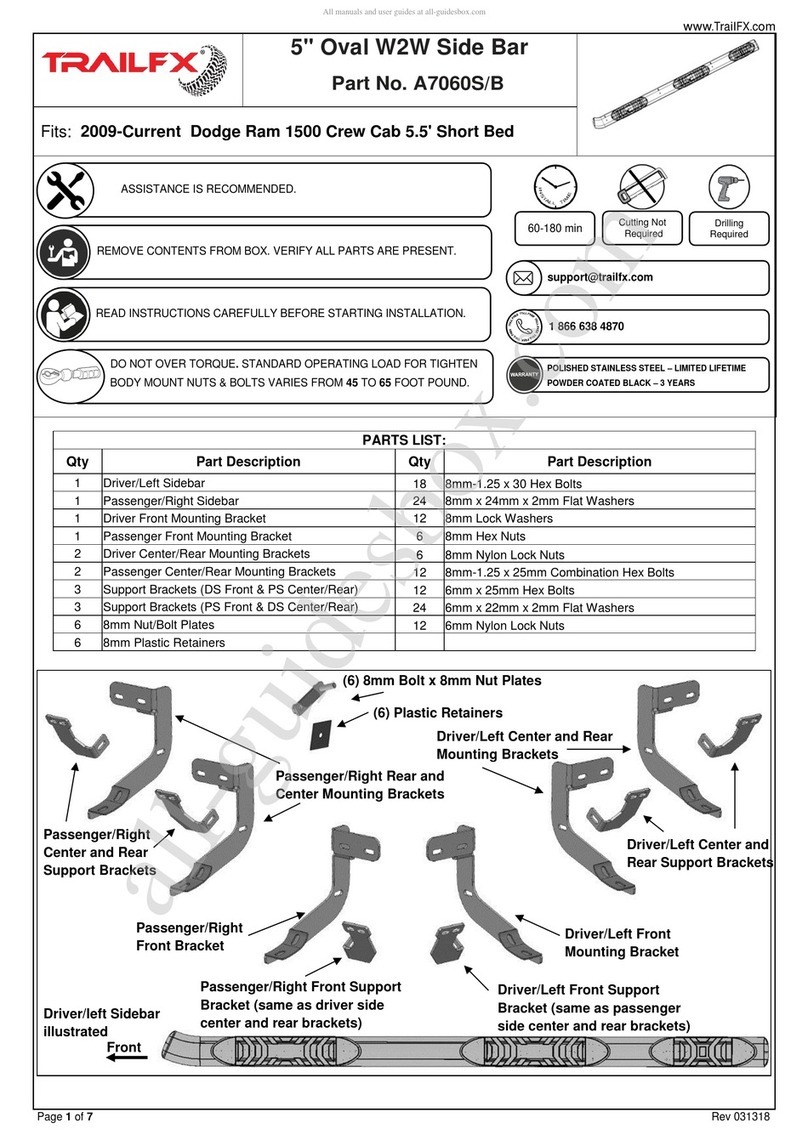

2. Move to the front mounting location, (Figures 1, 2, 3 & 5). Select (1) 8mm Bolt Plate and (1) 8mm Plastic Retainer, (Figure

4). Thread the Retainer part way onto the Bolt Plate. Insert the Bolt Plate into the hole and tighten the Retainer against the

body panel, (Figure 5). IMPORTANT: The Plastic Retainer is designed to prevent the Bolt Plate from pushing up into the

body panel and to aid in Bracket installation. Use of Retainer is not mandatory for installation.

3. Select (1) Mounting Bracket, (Figure 6). Attach the Bracket to the Bolt Plate with (1) 8mm x 28mm Large Flat Washer, (1)

8mm Lock Washer and (1) 8mm Hex Nut, (Figures 6 & 7). Leave hardware loose at this time.

4. Select (1) Support Bracket, (Figure 6). Attach the Support Bracket to the front of the Mounting Bracket with (1) 8mm x

25mm Hex Bolt, (2) 8mm x 16mm Small Flat Washers and (1) 8mm Nylon Lock Nut. Line up the top of the Support Bracket

with the back of the pinch weld, (Figure 7). Scrape off excess sealant as necessary to attach Support Bracket flat against

body panel. Snug but do not fully tighten hardware at this time.

5. Move to the center mounting location. Locate the hole in the bottom of the floor panel, (Figures 1, 2, 3 & 5). Repeat Steps

1—4 to attach the center mounting Bracket and Support Bracket, (Figure 12).

6. Continue along the vehicle to the next/rear mounting location, (Figures 1, 2, 3 & 5). Repeat previous Steps to install the rear

Mounting Bracket and Support Bracket.

7. Carefully unwrap the Running Board. Place the Running Board on top of the (3) Brackets. Select (3) 8mm Double Bolt

Plates, (Figure 8). Locate the channels in the bottom of the Running Board. Insert the Bolt Plates into the channels closest

to the Brackets. Lift the Running Board up and guide the studs down through the Brackets.

8. Attach the Running Board to the Brackets with (6) 8mm x 24mm STD Flat Washers, (6) 8mm Lock Washers and (6) 8mm

Hex Nuts, (Figure 9). NOTE: The Running Board is designed to fit close to the vehicle. It may be necessary to loosen the

Bracket hardware and tilt the Brackets downward to insert the Running Board between the Brackets and the body. Do not

tighten hardware at this time.

9. Level and adjust the Running Board and tighten the Bracket to Bolt Plate hardware only. Adjust the Support Brackets as

necessary to move the top of the Brackets up to touch the bend in the pinch weld. Scrape off excess sealant as required.

Mark the location of the (3) slots in the Support Brackets onto the back of the pinch weld, (Figure 10).

10. Use a 1/4” drill bit to drill (3) holes through the pinch weld for the (3) Support Brackets. NOTE: Drill the holes as far up from

the bottom edge of the pinch weld as possible. IMPORTANT: Do not drill through the welds in the pinch weld if possible. If

necessary, temporarily remove the Support Brackets and/or Running Board for additional room to drill holes for Support

Brackets.

11. Reinstall the Support Brackets if removed. Attach the top of each Support Bracket to the back of the pinch weld with (1)

6mm x 25mm Hex Bolt, (2) 6mm Flat Washer, (1) 6mm Lock Washer and (1) 6mm Hex Nut, (Figures 11 & 12). Reinstall

the Running Board. Level, adjust and tighten all hardware.

12. Reinstall the Running Board if removed. Level and adjust the Running Board and tighten all hardware.

13. Do periodic inspections to the installation to make sure that all hardware is secure and tight.

To protect your investment, wax this product after installing. Regular waxing is recommended to add a protective layer over the finish. Do

not use any type of polish or wax that may contain abrasives that could damage the finish.

Mild soap may be used also to clean the Running Board.

IMPORTANT! Any cutting or drilling tool may break or shatter. Government regulations require safety glasses & equipment

at all times when cutting or drilling.