Trek 2021 E-CALIBER Operating manual

2021 E-CALIBER

SERVICE MANUAL SUPPLEMENT

2021 E-Caliber Service Manual

1

Contents

Safety 1

Headset with Knock Block 2

Frame and drive system guards 3

Rear triangle and chainstay bridge 4

Main pivot 6

Dérailleur hanger 7

Cabling overview 8

IsoStrut remote lockout cable 9

IsoStrut 10

Air volume spacer 11

Carriage wiper seals and bushings 14

Fazua system 19

Specications 20

Suspension 21

Safety

WARNING

Alwaystightenhardwaretothespeciedtorque.

Over-tightening hardware could deform or break the

hardwareorcomponents.Under-tighteninghardware

couldcausehardwareorcomponentstobecomeloose.

Either situation could damage the bicycle and result in

injurytotherider.

WARNING

All reused-fasteners with a pre-applied threadlocker

must be cleaned with isopropyl alcohol and have new

threadlockerappliedbeforere-assembly.Ifathreadlock-

er is not applied, the fasteners may loosen, which could

damagethebicycleandresultininjurytotherider.

Copyright 2021 Trek Bicycle Corporation All Rights Reserved

2021 E-Caliber Service Manual

2

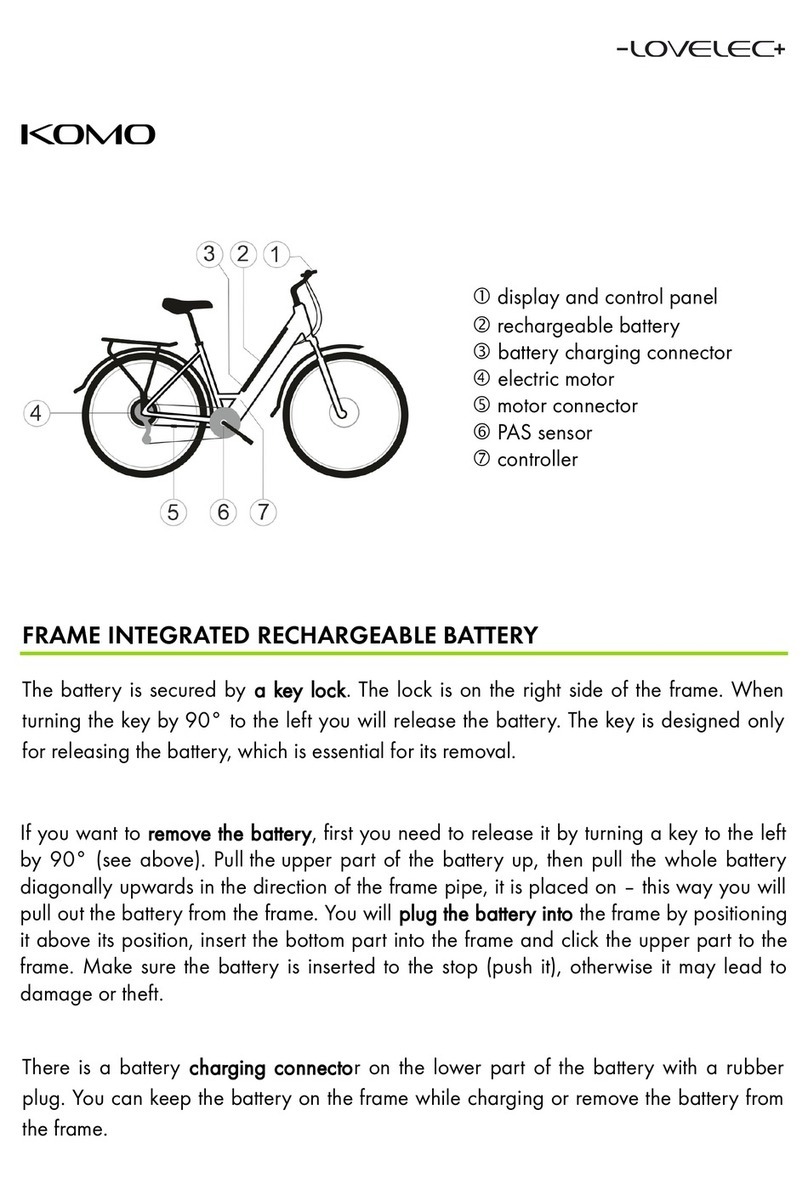

Headset with Knock Block

1

2

3

4

5

6

7

Item Description

Quantity in

Assembly Part Number Torque (Nm)

1 Upperbearingcover 1

5252159

—

2 Knock Block chip bolt 1 2

3 Knock Block chip, 62 degrees 1 —

4 Compression ring 1 —

5 Upperbearing 1 —

6 Lower bearing 1 5252158 —

7 Crown race 1 —

Tools

• 2.5mmhextool

• Torquewrenchwith2.5mmhexbit

• Headset tools

• Grease

1. Inspectthecomponentsfordamageorexcessive

wear.

• Knock Block chip (3)

• Undersidechanneloftheupperbearingcover(1)

• Interlocking keys of the upper bearing cover (1)

and the stem

2. Replaceanydamagedorworncomponents.

3. Apply grease to:

• Upperandlowerheadtubebearingbores.

• Inside of the bearing seats of the compression

ring(4)andthecrownrace(7).

4. Install the crown race (7), then the lower the bearing

(6)ontothesteerertube.

5. Insert the steerer tube into the bottom of the head

tube.

6. Install the upper bearing (5), then the compression

ring(4)ontothesteerertube.

7. Insert the Knock Block chip (3) and bolt (2) into the

frame,butdonottightenit.

8. Installtheupperbearingcover(1).

9. Installspacersasneeded.

10. TorquetheKnockBlockchipbolt(2)to2Nm.

2021 E-Caliber Service Manual

3

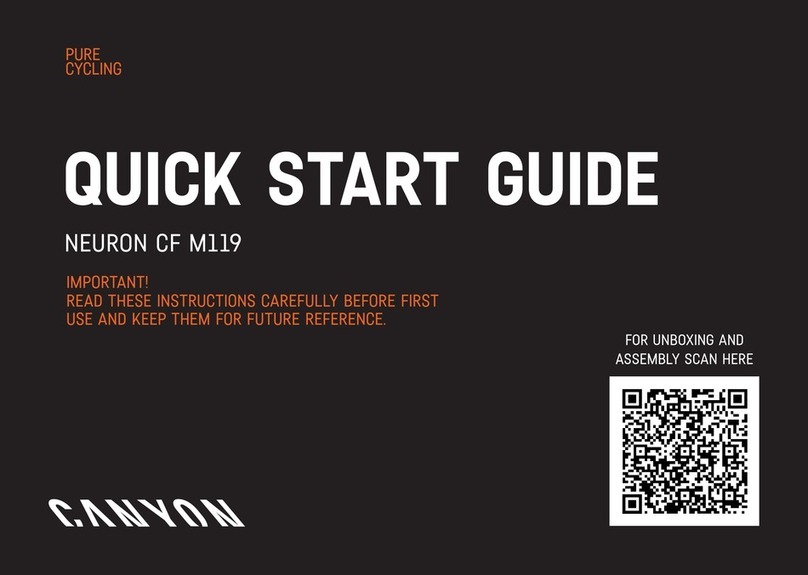

Frame and drive system guards

1

3

4

3

2

Item Description

Quantity in

Assembly Part Number Torque (Nm)

1 Chainstay guard 1 W582883 —

2 Down tube guard 1 W582884 —

3 Drive unit guard fasteners 4 5269023 3

4 Drive unit guard 1 W1040440 —

Chainstay and down tube guards

Useisopropylalcoholtocleantheframesurfacewherethe

guardsattach.Waitforthealcoholtodrybeforeapplying

theguards.

Notice: Do not clean the entire frame with isopropyl

alcohol.Isopropylalcoholcoulddamagethepaint.

2021 E-Caliber Service Manual

4

Rear triangle and chainstay bridge

1

3

2

4

4

5

Item Description

Quantity in

Assembly Part Number Torque (Nm)

1 RearIsoStrutaxle 1 591626 10

2 End cap bolt 1 —

3 Front IsoStrut bolt and washer 2 W584485 5

4 Chainstay bridge bolt 4 5265697 8

5 Chainstay bridge, charcoal colour 1 5266755 —

Tools

• Bike repair stand

• Torquewrenchwith6mmhexbit,T25andT30

Torxbits

• Grease

Important: You must have the main pivot bearing and

sleeve (See the Main pivot section on page 6) and the

IsoStrut (See the IsoStrut section on page 10) installed

on the rear triangle before attaching the rear triangle to

theframe.

1. Puttheseatpostintoabikerepairstand.

2. Fitthereartriangleintothemainframe.

3. InstallthetwofrontIsoStrutboltsandwashers(3).

Important: Donottorquetheboltsatthistime.

4. Apply greasetotheIsoStrutrearaxle(1).

5. InstalltheIsoStrutrearaxle(1)andendcapbolt(2).

Important: Donottorquetheboltsatthistime.

6. Applygreasetotheatsurfacesofthechainstay

bridge(5).

2021 E-Caliber Service Manual

5

Rear triangle and chainstay bridge (continued)

7. Insert the chainstay bridge (5) inside the rear

triangle.

4

4

5

8. Install the four bridge bolts (4) to attach the bridge to

thereartriangle.

9. If applicable, install the main pivot hardware before

torquingthebridgebolts(4).SeetheMain pivot

section on page 6.

10. Torque:

• Chainstaybridgebolts(4)to8Nm.

• IsoStrutrearaxle(1)to10Nm.

• FrontIsoStrutbolts(3)to5Nm.

2021 E-Caliber Service Manual

6

Main pivot

1

234

3

2

5

Item Description Quantity in

Assembly

Part Number Torque (Nm)

1 Main pivot nut 1 W584134 —

2 Washer 2 W440921 —

3 Main pivot bearing 2 W302025" —

4 Main pivot sleeve 1 W600642 —

5 Main pivot bolt 1 W600628 30

Tools

• Bearing press

• 8mmhextool

• Torquewrenchwith8mmhexbit

• Grease

1. Pressinthedrive-sidebearing(3).

2. Insertthesleeve(4)fromthenon-driveside.

3. Pressinthenon-drive-sidebearing(3).

4. Position the chainstay over the seat tube, ensuring

thatthemainpivotholesarealigned.

Tip: Slidethelongarmofthehextoolfromthenon-

drive-sideandthroughthealignedpivotholes.For

eachstep,slidethecomponentontothehextoolto

alignthecomponentsoneachsideofthemainpivot.

5. Apply grease to the shoulder of the main pivot

bolt(5).

6. Insert the drive-side washer (2) between the bearing

thechainstay.

7. Partially insert the main pivot bolt (5) from the drive

side.

8. Insert the non-drive-side washer (2) between the

bearingandthechainstay.

9. Fullyinsertthemainpivotbolt(5).

10. Installthenut(1).

11. Torquethemainpivotbolt(5)to30Nm.

2021 E-Caliber Service Manual

7

Dérailleur hanger

1

2

Item Description Quantity in

Assembly

Part Number Torque (Nm)

1 Thruaxle,M12X1.0X15MM 1 W600321 10

2 Dérailleur hanger 1

W600660

—

Hanger bolt, left-handed thread 1 25

Washer, 25mm 1 —

ThisbicycleframeisdesignedtouseaUniversalDerailleur

Hanger(UDH).

NOTICE: ThethruaxlemustbecompatiblewithaUDH

andmustbeM12x1.0witha12.7mmthread.

NOTICE: Thewasherisframe-specic.Installonlythe

washercompatiblewithyourframe.

WARNING

Donotapplygreasetothederailleurhangerorbolt.Only

applygreasetothethruaxle.

1. Insert the hanger on the inside of the drive-side

chainstay.

2. Installthewasheronthederailleurhangerbolt.

3. Inserttheboltintotheframe.

4. Makesurethehangerispositionedasshownbelow.

5. Torquethehangerboltto25Nm.

NOTICE: Donotover-tighten.Over-tighteningthebolt

couldcausethehangertobreak.

ForadditionalinformationabouttheUDH,refertothe

SRAM user manual at sram.com.

2021 E-Caliber Service Manual

8

Cabling overview

1

4

5

6

9

10

11

12

7

8

2

3

Item Description Quantity in

Assembly

Part Number Torque (Nm)

1 Bolt 1 W562831 3

2 Speed sensor 1 W581396 —

3 Rear brake cable 1 — —

4 Speed sensor cable 1 — —

5 Dropper post cable 1 — —

6 IsoStrut lockout cable 1 — —

7 Head tube cable guide 2 W519232" —

8 Head tube cable guide fastener 2 W532763 1

9 Controller cable 1 — —

10 Down tube cable guide 3 W591416 —

11 Rear derailleur cable 1 — —

12 Grommet, for use with wireless derailleur only 1 5259425 —

Zip tie location 4 — —

Routeandziptiethecablesasshownintheillustrationabove.

Dropper cable

• For detailed dropper remote instructions, please refer

to the Drop Lock Remote manual at trekbikes.com/

manuals.

IsoStrut cable

• See the IsoStrut remote lockout cable section on

page 9.

2021 E-Caliber Service Manual

9

IsoStrut remote lockout cable

Tools

• Cable cutter

• Torquewrenchwith2mmhexbit

1. Installthecableintheremotelockout.

2. Route the cable through the hole in the bottom of the

top tube just in front of the IsoStrut and out the drive

sideoftheheadtubehole.

3. Attheheadtube,routethewirethroughthecable.

4. AttheIsoStrut,slidetheferruleonthewire.

5. Guidethewirethroughtheslotinthecablestop.

6. Route the wire around the lockout spool and install

thesetscrew.Torqueto1Nm.

Drive side Non-driveside

7. Testthatthemechanismworkssatisfactorily.

8. Cut the wire to the appropriate length (20-30 mm)

andcrimpanendcaponit.

2021 E-Caliber Service Manual

10

IsoStrut

6

1

2

3

4

3

2

5

7

8

9

10

Item Description Quantity in

Assembly

Part Number Torque (Nm)

1 Damper body nut 1

W580727

—

2 O-ring 2 —

3 Guide bushing 2 —

4 Damper body sleeve 1 —

5 Damper body bolt 1 7

6 Foxshock,performance,black 1 W587198 —

Foxshock,performance,kashima W587197 —

7 Compression sleeve 1 591626 —

8 Shock oil plug 1 W580727

9 End cap bolt 1 591626 —

10 RearIsoStrutaxle 110

Tools

• Torquewrenchwith5mmhexbit

1. Assemble the body bolt (5), body sleeve (4), one

o-ring(2)andoneguidebushing(3)asshownbelow.

2. Inserttheassemblyintothebottomofthecarriage.

3. Installtheupperguidebushing(3)intothecarriage.

4. Installtheo-ring(2)ontothedamperbodynut(1).

5. Install damper body nut (1) with o-ring (2) into the

carriage.

6. Torquethedamperbodybolt(5)to7Nm.

2021 E-Caliber Service Manual

11

Air volume spacer

Item Description Part Number

1 Foxairvolumespacerkit 595583

Tools

• BSA30 Open-ended bottom bracket tool

• Spanner pliers

• Loctite Blue 243 threadlocker or similar

• Parallel jaws pliers

• T25torxdrivewrench

• Torquewrench

• Shock pump

• Spacers

• Soft cloth

• Grease

Note: This procedure should be performed with the

IsoStrutinstalledonthebike.

Note the current air pressure

1. Useashockpumptochecktheairpressureinthe

shock.Makeanoteofthecurrentairpressuresoyou

canre-inatetheshockafterchangingtheairspacer.

2. Graduallybleedtheairfromtheairvalve.

Tip: You do not need to compress the shock because

youwillneedsomeairinthenegativeairspring.

Release the shock from the carriage

1. Remove the two bolts and washers at the front of the

shock.

2. Loosen,butDONOTREMOVEtherearaxle.

3. Turnthelockoutleveranti-clockwisetotheopen/

unlockedposition.

2021 E-Caliber Service Manual

12

Air volume spacer (continued)

4. Sitontheseattocompressthesuspension.Thefront

of the IsoStrut will move away from the top tube to

provideclearancefortheBSA30wrench.

5. Position your body on the seat to keep the shock

compressed, and use the BSA30 wrench to break the

lockringlooseandunthreaditfromthecarriage.

NOTICE: Useasoftclothtoprotectthetoptube

fromscratchesthattheBSA30wrenchmaycause.

6. Once the ring is unthreaded from the shock, the front

endoftheshockwillextendforwardstorevealan

o-ring,aroundmetalplateandtheairspacer.

1 2 3

Item Description

1 O-ring

2 Round metal plate

3 Air spacer

Replace the air spacer

1. Clean off any dirt or residue from the threads and the

lockring.

2. Movetheroundmetalplatetowardstheo-ring.Usea

spannerplierstoremovetheairvolumespacer.

3. Putanewspacerinplacearoundthedampershaft.

Tip: Depending on the size of the spacer, it may be

helpful to use the spanner pliers or a parallel jaws

plierstotthespacerinplace.

4. You should hear a ‘snap’ when the spacer snaps into

the front end of the shock.

2021 E-Caliber Service Manual

13

Air volume spacer (continued)

Tighten the lock ring

1. Add Loctite Blue 243 threadlocker or similar to

a minimum of two threads, covering 60-90°of

threads.

2. Standbehindtheseatandpulltheseatuptoextend

thesuspension.Thiswillbringthelockringincontact

withthestrut.

3. UsetheBSA30wrenchtoturnthelockringontothe

strut.

Tip: For the best results, sit on the rear tyre for this

steptobalancethebike.

4. As you tighten the lock ring, orientate the upper air

capasshownbelow.

Size small frame: theairllvalvealignswiththe

mountingtab.

Size medium, large and extra large frames: the

cablehangeralignswiththemountingtab.

5. PlacethetorquewrenchintheholeintheBSA30

wrench.Torquethelockringto17Nm.

6. Verifythattheshockispositionedtoacceptashock

pumptotheairvalve.Ifthereisinterference,reposi-

tiontheshock.

7. Install the washers and bolts at the front of the

shock.Torquetheboltsto5Nm.

8. Torquetherearshockaxleto10Nm.

9. Usetheshockpumptore-inatetheshockairpres-

sure to the PSI noted prior to beginning the air spacer

procedure.

10. Perform the sag procedure to determine the proper

ridersettingforthestrut.

2021 E-Caliber Service Manual

14

Carriage wiper seals and bushings

1

2

3

2

4

1

3

Item Description

Quantity in

Assembly Part Number Kit

1 Carriage wiper seal 2 — 592550

2 Carriage wiper bushing 2 595247

3 Foam block 2 —

4 Foam ring 1 —

Tools for replacing the seals

• IsoStrutsealandbushingpresstoolset.Available

aspartnumber593490.

• Delrinrod,1inch(25.4mm)

• Headset press

• Fork bath oil, 10 wt

Tools for replacing the bushings

• Slide hammer

• 30-36Expandingcollet

• IsoStrutsealandbushingpresstoolset.Available

as part number 593490

• Bushing sizer

• Clean, dry cloth

NOTICE: Inspect all tools prior to use to make sure

theyareclean.Dirtytoolscoulddepositgritinto

the shock which could mar surfaces and create

frictionthatcoulddamagetheshock.

Remove the shock from the carriage

1. RemovetheIsoStruthardware.SeeIsoStrut section

on page 10.

2. Removetheshockfromthecarriage.

2021 E-Caliber Service Manual

15

Carriage wiper seals and bushings (continued)

Remove the carriage seals

1. UsetheDelrinrodtopulloutthefrontseal.

Tip: You may need to move the rod around the car-

riagetoremovetheseal.

2. Pulloutthefoamring.Thisistheonlyfoamringinthe

carriage.

3. UsetheDelrinrodtopullouttherearseal.

If you are replacing only the seals, jump to Carriage wiper

seals and bushings (continued) section on page 17.

If you are replacing both the seals and the bushings, con-

tinue with the Replace the bushings section on page 15.

Replace the bushings

NOTICE: Donotapplygreasetothebushings.

1. Put the slide hammer with the collet attached inside

thefrontendofthecarriage.

NOTICE: Take care to engage only the bushing,

andNOTtheinteriorofthecarriage.Engagingthe

carriagecoulddamagethecarriage.

2. Thread the collet to engage the bushing lip.

Tip: Be careful not to engage the lip inside the car-

riage.Engagethebushingonly.

3. Usetheslidehammertoremovethebushing.

4. Repeatsteps1to3toremovetherearbushing.

5. Wipe the bushing bores with a clean, dry cloth to

removeanydebris.

2021 E-Caliber Service Manual

16

Carriage wiper seals and bushings (continued)

6. Load a new bushing onto each bushing installation

tool.

Bushing

Usethissideofthetoolforpressingin

bushings.

Seal

Usethissideofthetoolforpressingin

seals.

NOTICE: Do not use grease when installing the

bushings.Usinggreasecouldcausethebushings

toslipoutofplace.

7. Put one tool with one bushing into the front of the

carriage, and the other tool with the other bushing

intotherearofthecarriage.

8. Insert the upper half of the headset press into the

frontofthecarriage.

9. Insert the lower half of the headset press into the

rearendofthecarriageandlockitintoplace.

10. Spin the headset press until it is snug against the

bushingtool.Checkforthecorrectalignmentofthe

press,toolsandbushings.Rotatethepresstopush

thebushingsintoplace.It’snormaltohavedifferent

gapsatthefrontandrearofthecarriage.

11. Tightenthepressuntilyoufeelresistance.Onceyou

feelresistance,removethepressandbothtools.

12. Inspect the bushings to verify that they are pressed

deepenoughintothecarriage.Fromthetopofthe

bushing to the step above the bushing, the measure-

ments should be:

Front=16.9mm Rear=10.5mm

13. From the front of the carriage, use the bushing sizer

tosizethebushing.Thesizercanberotatedtothe

leftortotheright.

14. Repeat step 13 three to four times, alternating be-

tweenthefrontandrearbushings.

2021 E-Caliber Service Manual

17

Carriage wiper seals and bushings (continued)

Replace the wiper seals

1. Wipe the seal surface inside the carriage to remove

debris.

2. Loadanewsealontoeachsealinstallationtool.

Seal

Usethissideofthetoolforpressingin

seals.

Bushing

Usethissideofthetoolforpressingin

bushings.

3. Put one tool with one seal into the front of the car-

riage, and the other tool with the other seal into the

rearofthecarriage.

4. Insert the upper half of the headset press into the

frontofthecarriage.

5. Insert the lower half of the headset press into the

rearendofthecarriageandlockitintoplace.

6. Spin the headset press until it is snug against the

sealtool.Checkforthecorrectalignmentofthe

press,toolsandseals.Rotatethepresstopushthe

sealsintoplace.

7. Tightenthepressuntilyoufeelresistance.Onceyou

feelresistance,removethepressandtools.

8. Inspect the seals to verify that there is no gap be-

tweenthesealandthecarriage.

9. Soakthefoamringin10wtforkbathoil.

10. Installthefoamringintothefrontofthecarriage.

2021 E-Caliber Service Manual

18

Carriage wiper seals and bushings (continued)

Install the IsoStrut into the carriage

1. Removethecompressionsleeve.

2. Carefullypullouttheoilplugfromtheshock.

3. Place the foam blocks into the carriage and position

themagainstthesidesofthecarriage.Donotsoak

thefoamblocksinforkbathoilpriortoinstallation.

4. Lightlyoiltheinsideofthecarriageseals.

5. With the sag o-ring in place on the shock, insert the

shockintothecarriage.

Install the damper body hardware

See IsoStrut section on page 10.

Add oil to the carriage

1. UseasyringetolltheIsoStrutwith15ccof10wt

oil.

2. Firmly press the oil plug back into the aft end of the

shock.Makesurethattheplugistightlyseatedinthe

opening.

3. Install the compression sleeve intotheoilplug.

4. InstalltheIsoStrutrearaxleandendcapnut.Torque

theaxleto10Nm.

Tip: If the compression sleeve will not allow the rear

IsoStrut hardware to pass through, the oil plug is not

fullyseatedintotheshock.(Seestep2.)

5. InstallthefrontIsoStrutwashersandbolts.Torque

theboltsto5Nm.

6. WipeoffanyexcessoilfromtheIsoStrut.

2021 E-Caliber Service Manual

19

Fazua system

Service manual and parts

Bicycle retailers

Refertothe2021Domane+LTFazuasystemmanual.

Consumers

ContactyourlocalTrekretailerforassistance.

Table of contents

Other Trek Bicycle manuals

Trek

Trek DOMANE AL GEN 4 2024 User manual

Trek

Trek BOONE 2022 Operating manual

Trek

Trek MY22 Top Fuel User manual

Trek

Trek RIDE+ User manual

Trek

Trek 8 User manual

Trek

Trek Lync Owner's manual

Trek

Trek TOP FUEL 2022 Operating manual

Trek

Trek Rail 9.5 Gen 4 User manual

Trek

Trek FUEL EXE 2023 User manual

Trek

Trek Speed Concept 2014 Operating and installation instructions

Trek

Trek Powerfly Gen 3 FS 9 EQ User manual

Trek

Trek 2022 CHECKPOINT SL Operating manual

Trek

Trek Alloy Rail 5 Gen 3 User manual

Trek

Trek MADONE 2019 User manual

Trek

Trek Sport EQ 4 User manual

Trek

Trek DOMANE+AL 2023 User manual

Trek

Trek Fetch+ 4 User manual

Trek

Trek Madone 2016 User manual

Trek

Trek 2023 FX+ User manual

Trek

Trek Ride Plus User manual