5. Install the rear derailleur on the the rear derailleur

hanger. Tighten to the OEM torque spec.

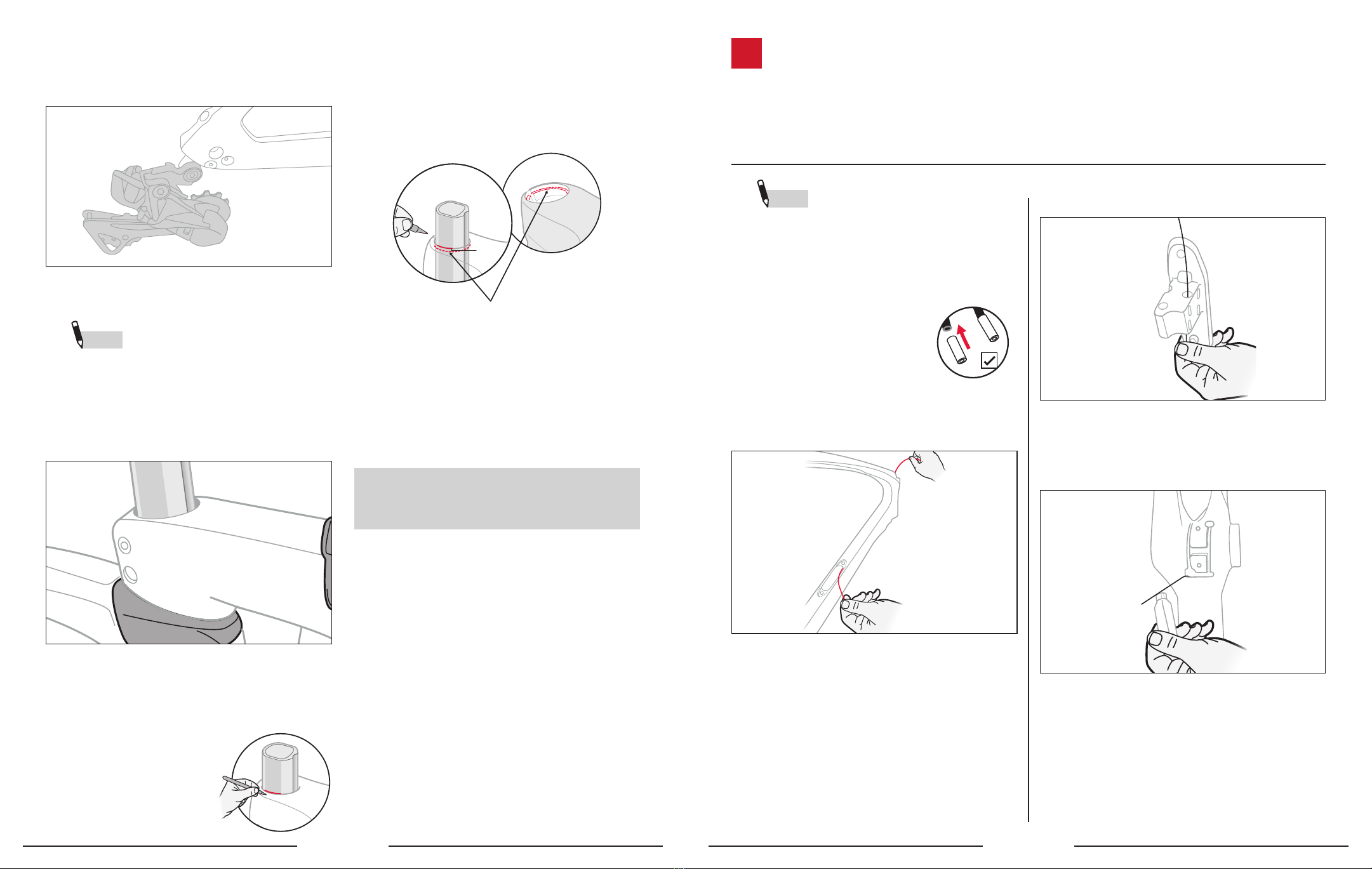

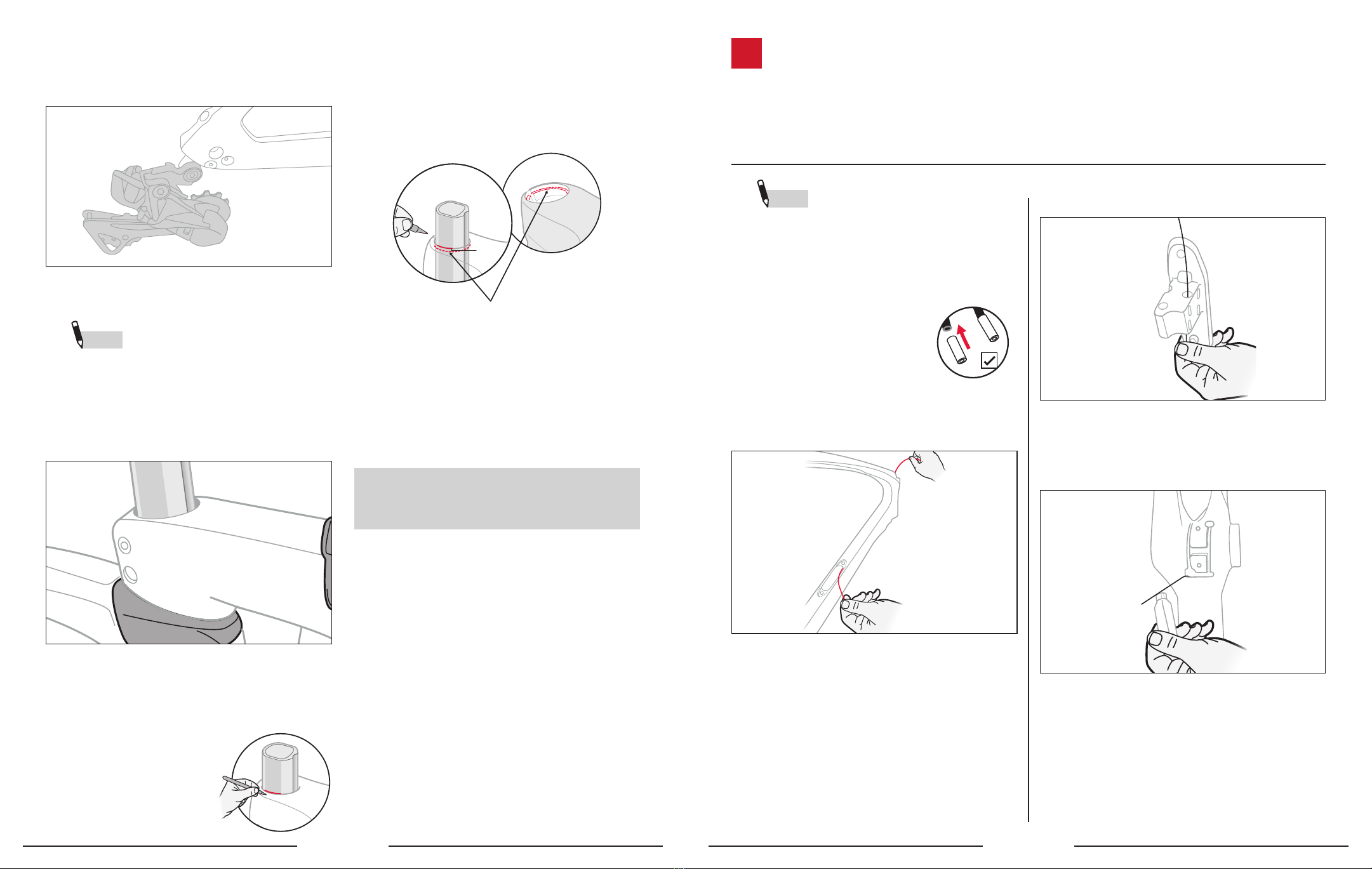

CUT THE FORK STEERER TUBE:

NOTE You will need to temporarily install the fork,

headset and stem together to get the correct location

for cutting the steerer tube.

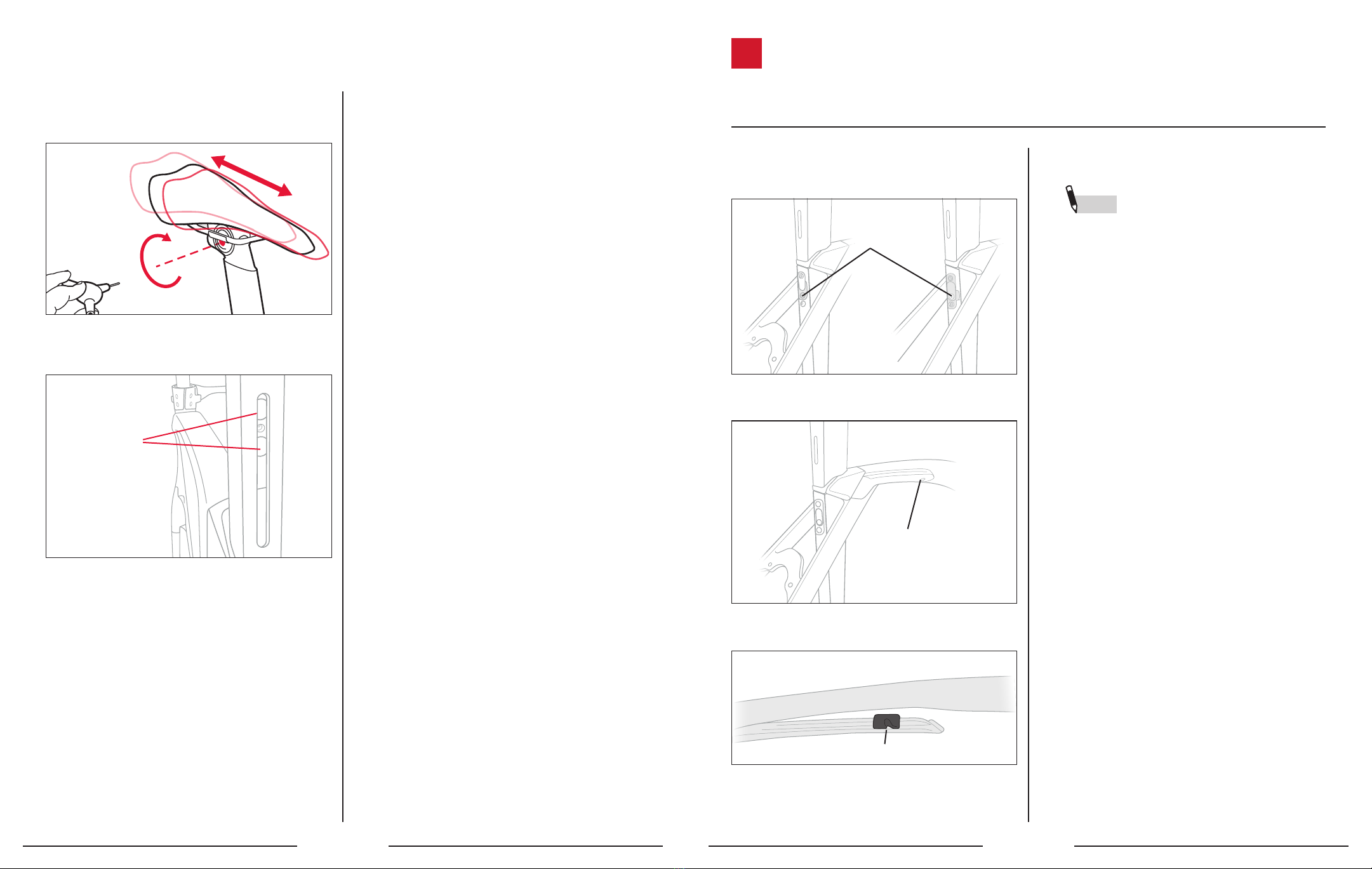

1. Holding the fork legs, slide the stem down the steerer

tube until it is firmly seated on top of the bearing top

cap or shaped spacers. Lightly tighten the stem

pinch bolts.

2. Determine the preferred cut length. Use additional

spacers above the stem until you are certain about the

desired stack height (handlebar height).

3. Mark a fine line on the flat side of the steerer tube

along the top edge of the

stem.

4. If you are planning to use the 5 mm spacer recessed

in the stem, your actual cutting line should be 5 mm

below the pencil mark made in the prior step. If you

are planning on using a 5 mm headset spacer above

the stem, cut on the line.

5 mm

5. IMPORTANT: There is a 5 mm spacer built into the

stem which allows you to install the stem top cap flush

with the stem.

6. Disassemble the stem and headset from the steerer

tube.

7. Proceed with cutting the steerer at the selected

location from Steps 3/4 using a standard carbon

steerer cutting process.

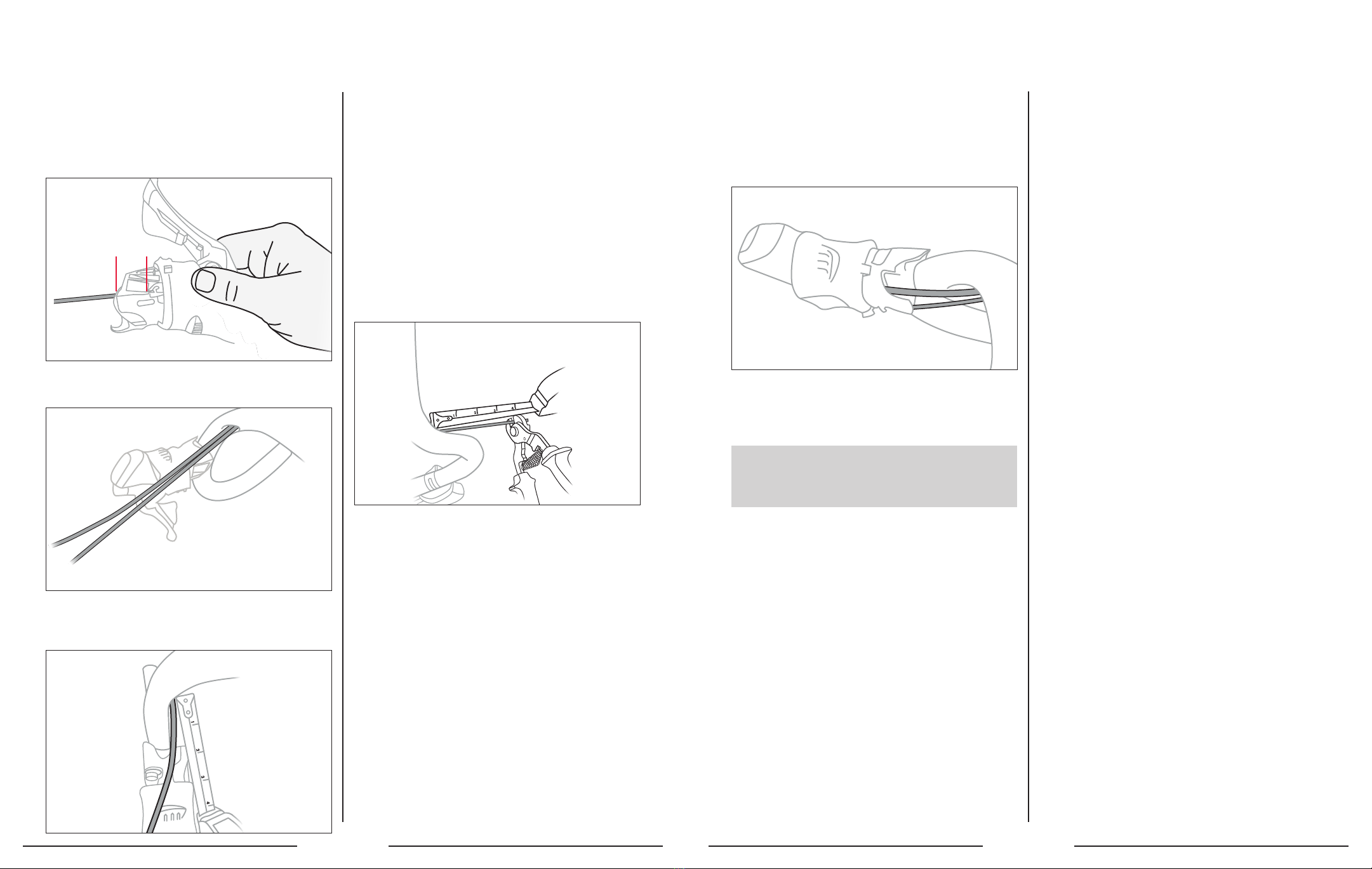

If you’re building a mechanical drivetrain, go to Step 2.

Install the Mechanical Control Centre on page 5.

If you’re building a Di2 drivetrain, go to Step 3. Install

the Di2 Cables and Housings on page 9.

NOTE There is plastic tubing inside the frame

to help with initial cable and wire routing. It is not

intended to be left in the frame.

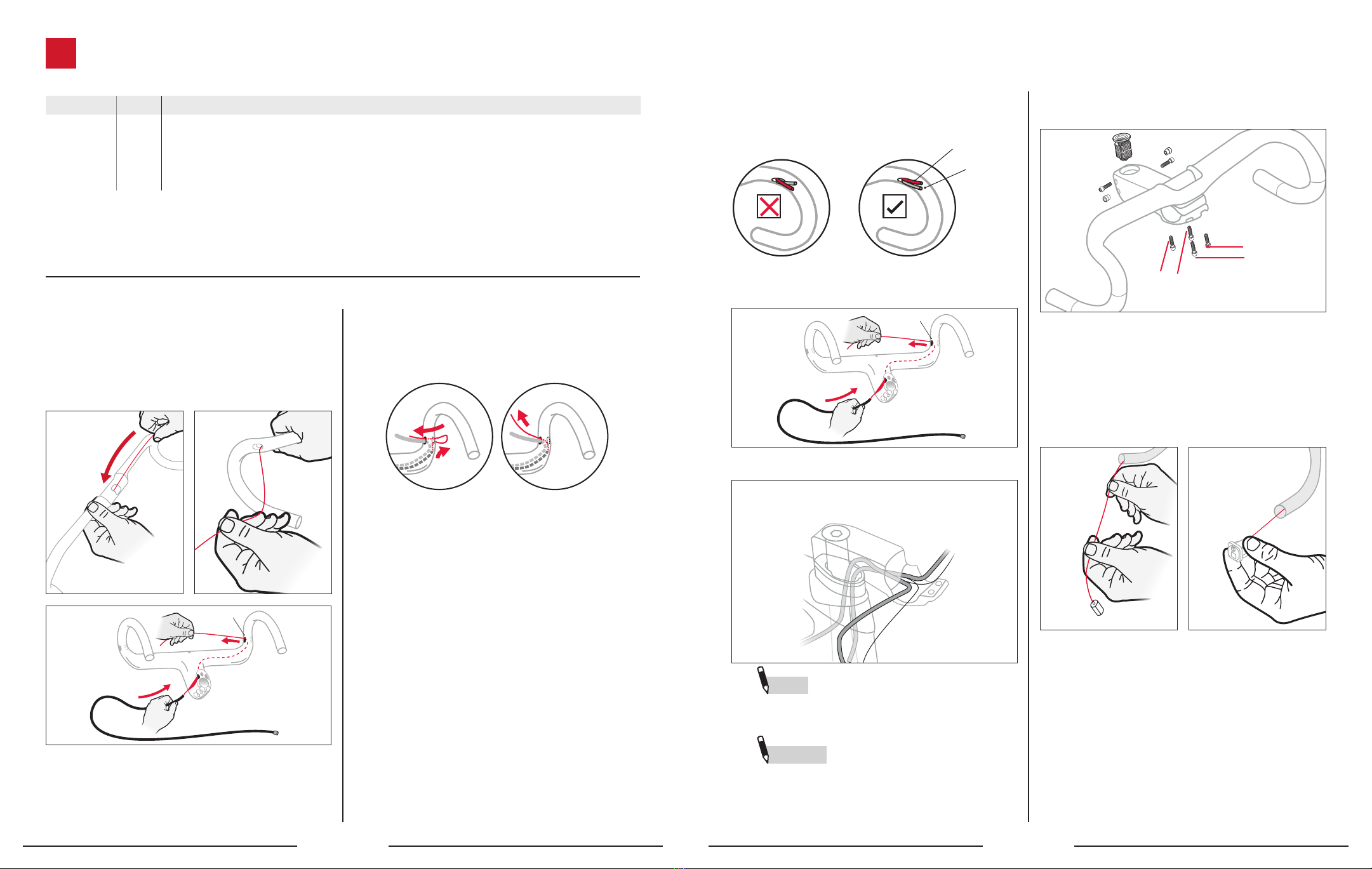

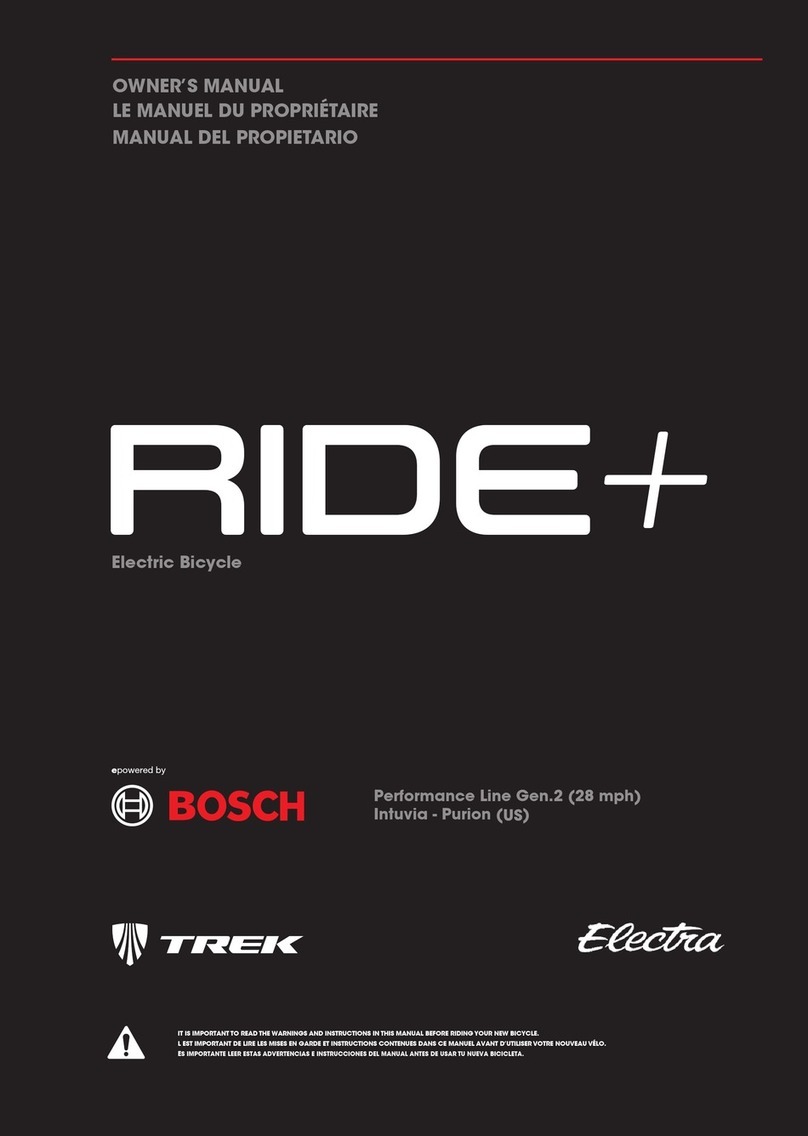

1. Refer to the table at the front of this manual to cut

the front and rear derailleur cable housings to the

appropriate lengths.

2. Attach ferrules to both ends of

the derailleur housings. Route the

cables into their housings.

3. Mark the FD housing with tape to

identify it.

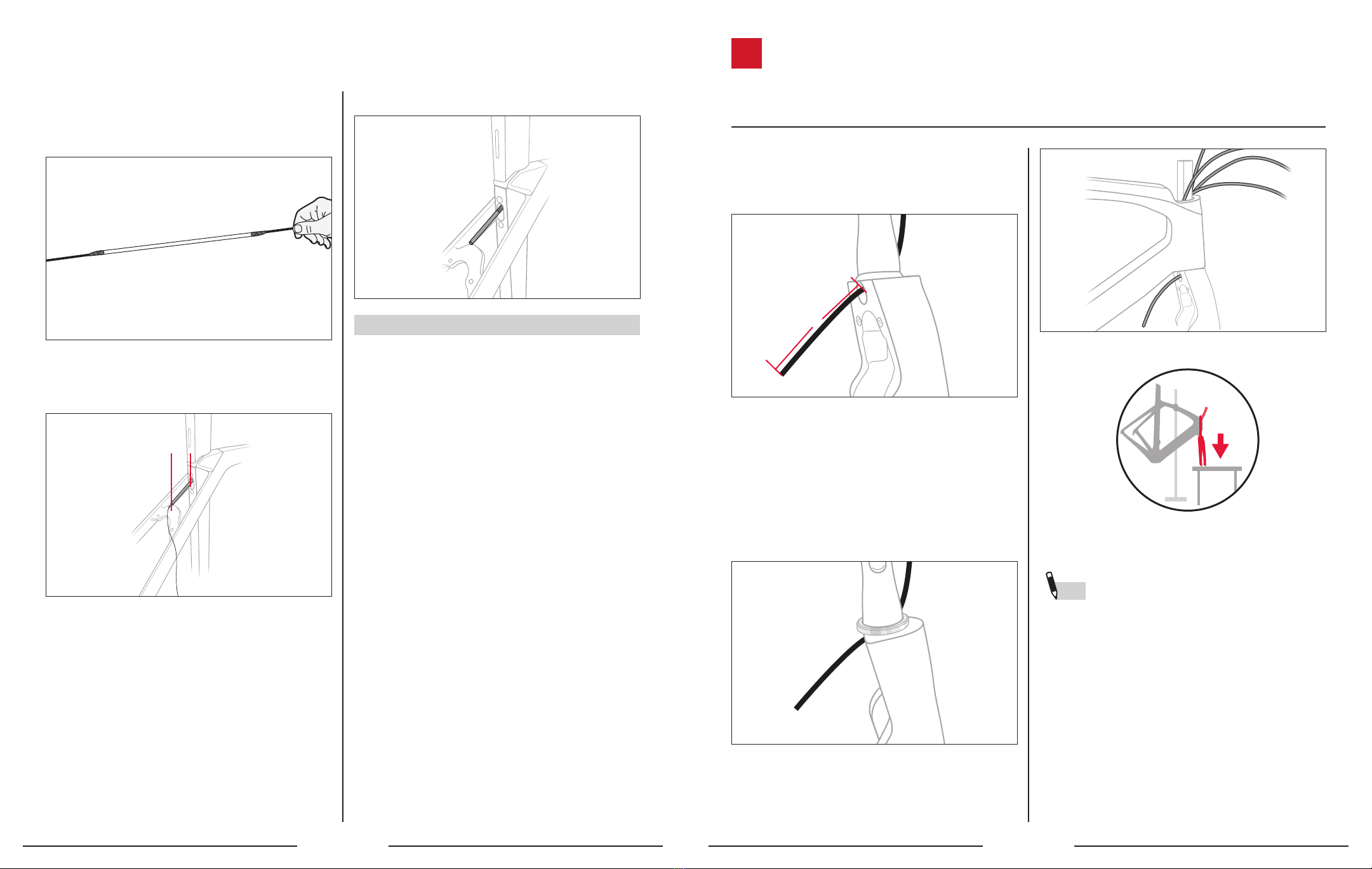

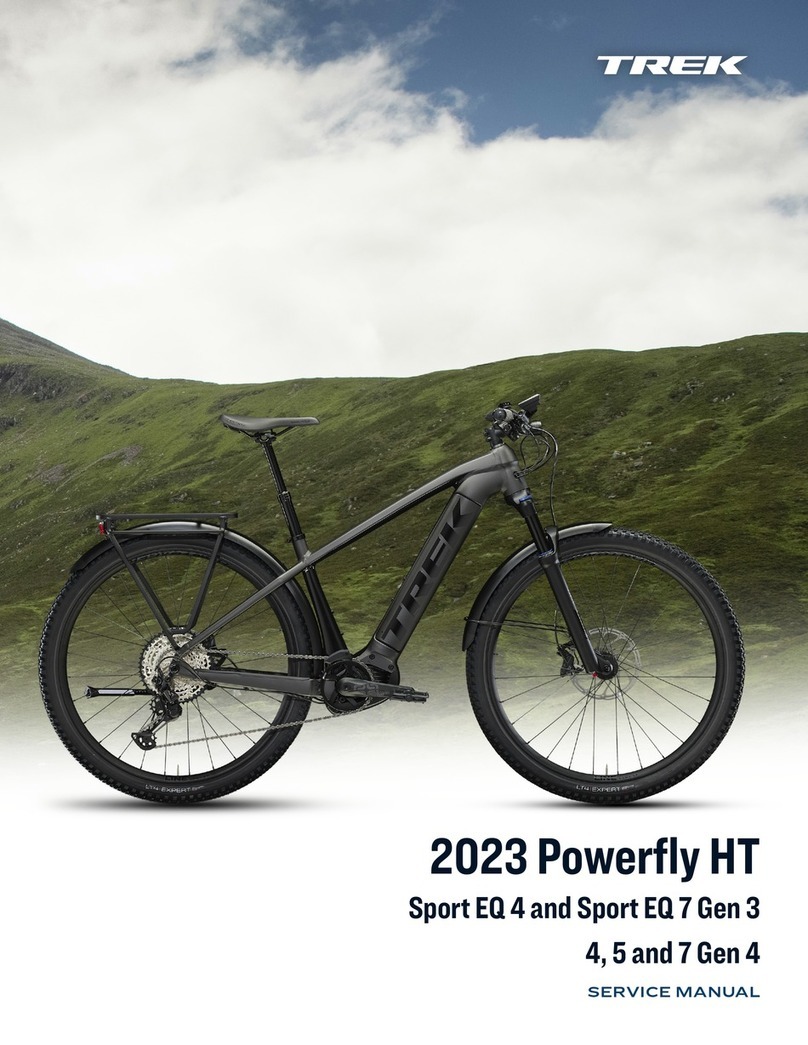

4. Route the FD cable/housing from the head tube to the

cutout in the downtube.

5. Pass the FD cable through the top hole of the

control centre.

6. Set the control centre loosely in the downtube cutout.

7. Route the FD cable down the downtube and push it

through the bottom bracket guide slot.

2INSTALL THE MECHANICAL CONTROL CENTRE

TOOLS AND MATERIALS REQUIRED

• Park Tool Routing Kit • Marker • Ferrules

• Mechanical control centre • Rear derailleur cable stop • Rear derailleur cable liner

• Cable cutter • Bottom bracket guide • Ruler

4 5