DJ300

SAFETY PRECAUTIONS

■Always switch off the power and unplug the

router when changing cutters or when making

adjustments.

■Always wear protective goggles when routing.

■Wear sound protective ear muffs when routing

for long periods of time.

■Always wear a dust mask or respirator. Use

dust extraction equipment whenever possible.

■Do not wear loose clothing. Make sure baggy

sleeves are rolled up and ties are removed.

■Always remove spanners and hex keys from

the workpiece before switching router on.

■Keep hands well clear of the router cutter

when routing.

■Avoid accidental starting of the router. Make

sure the power switch is in the ‘Off’ position

before plugging in and connecting to the

electrical supply.

■Never leave the router unattended when

running. Always wait until the router comes to

a complete stop before making any

adjustments.

■Do not switch the router on with the cutter

touching the workpiece.

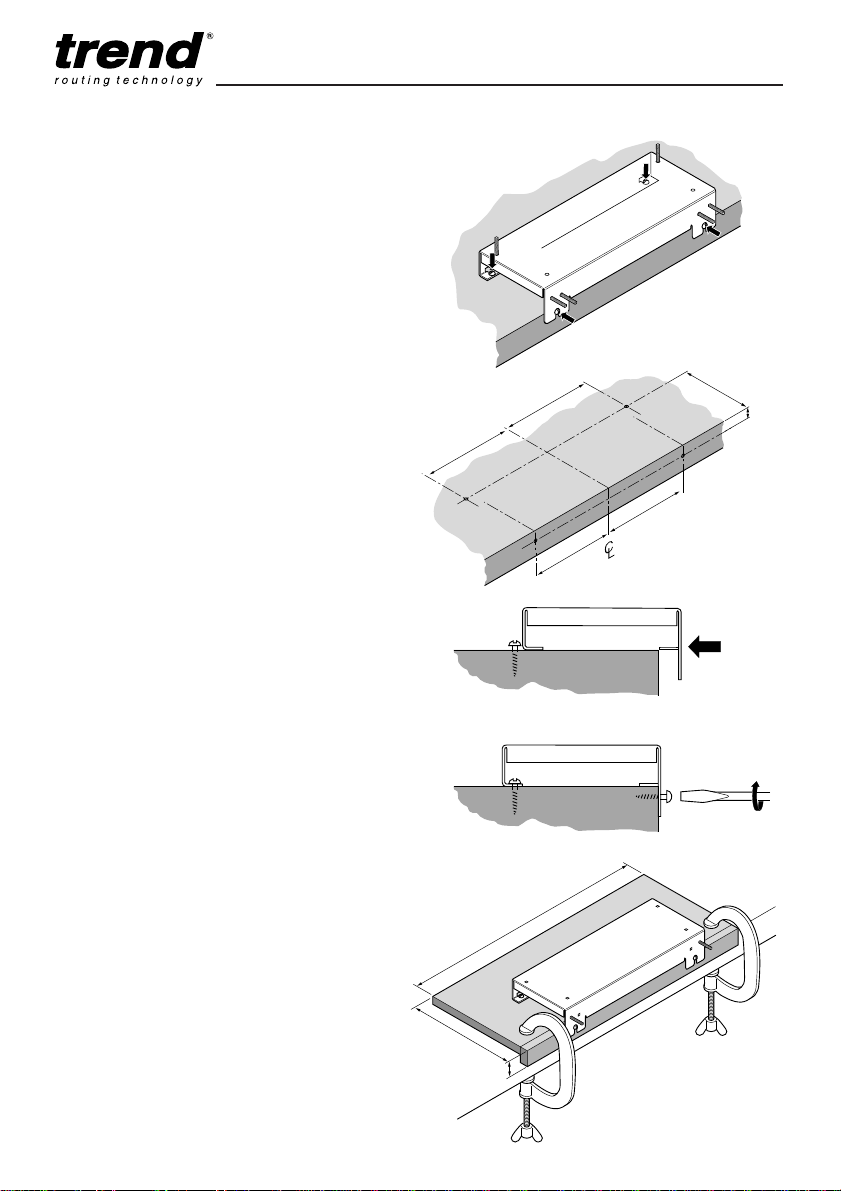

■Mount the Dovetail Jig securely to a work

bench or to a workboard fitted to a suitable

surface.

■Periodically check all nuts and bolts to make

sure they are tight and secure.

■Use dust extraction equipment.

Cutter Care

■Do not drop cutters or knock them against

hard objects.

■Cutters should be kept clean. Resin build-up

should be removed at regular intervals with

Resin Cleaner®. The use of a dry lubricant

will act as a preventative such as Trendicote®

PTFE spray.

■Cutter shanks should be inserted into the

collet at least 3/4of shank length to prevent

distortion. A distorted collet should be

discarded, as it can cause vibration and

damage the shank.

■Do not overtighten collet as this will score the

shank and create a weakness.

■It is also advisable to periodically check the

router collet nut for wear.

Useful Advice

■Judge your feed rate by the sound of the

motor. In time, the operator will acquire a

‘feel’ for the router and a feed speed relative

to the work will come naturally. Too slow a

feed will result in burning.

■Apply the normal precautions as with any

electric power tool.

■The main cause of routing machine failure is

the inclination for operators to overload them.

The motto is ‘Keep the revs up’. The drop in

revolutions should not exceed, if possible,

more than 20% of full running speed.

■The motor of a router is susceptible to the

accumulation of sawdust and wood chips and

should be blown out, or ‘vacuumed’,

frequently to prevent interference with normal

motor ventilation.

■Refer to the Instruction Manual supplied with

your router for full details of it’s features and

safety information.

■The use of a fine height adjuster is highly

recommended (if available for your router) for

accurately adjusting the height of the cutter

when dovetailing.

■Trial cuts should be made on waste material

before starting any project.

-3-