Installation

313444E 7

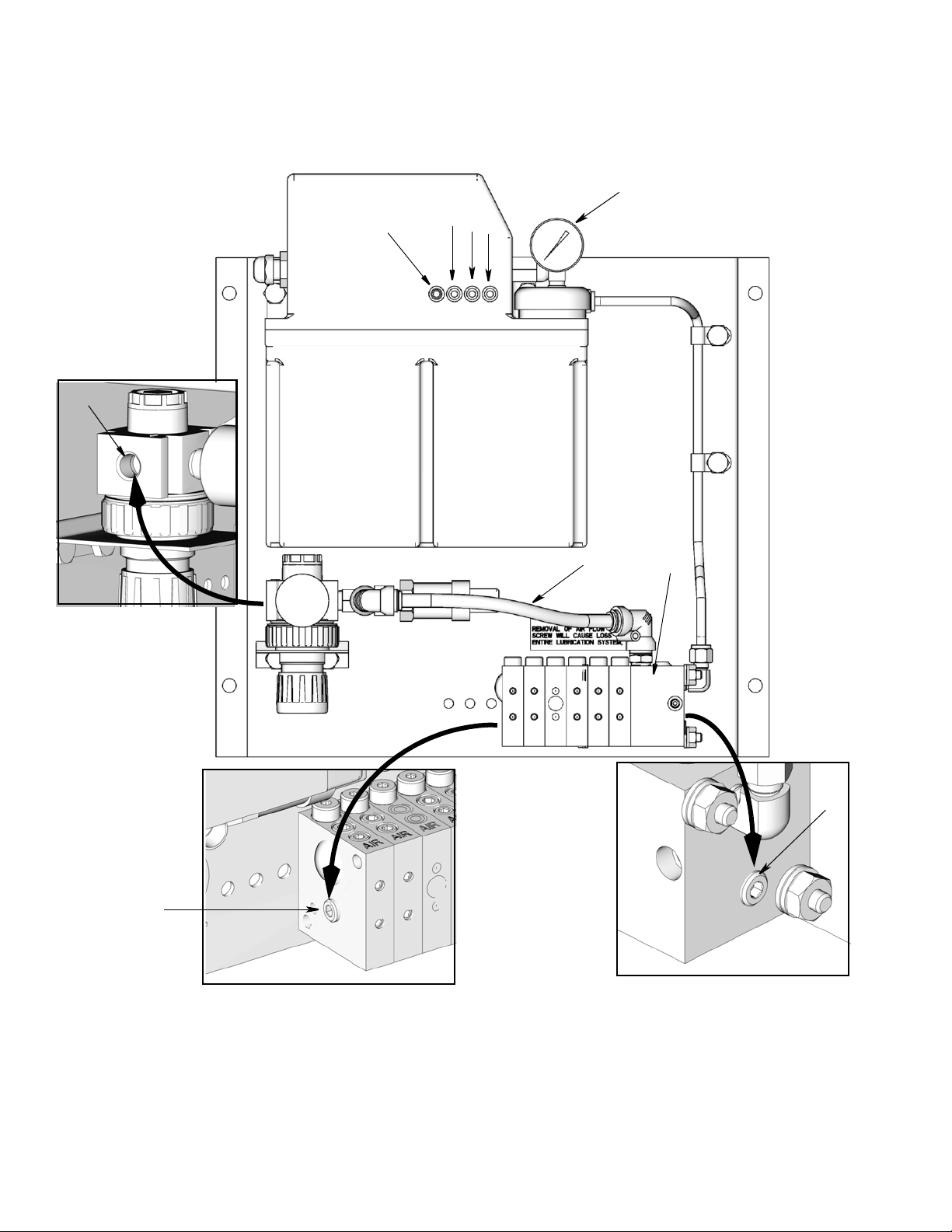

Setup

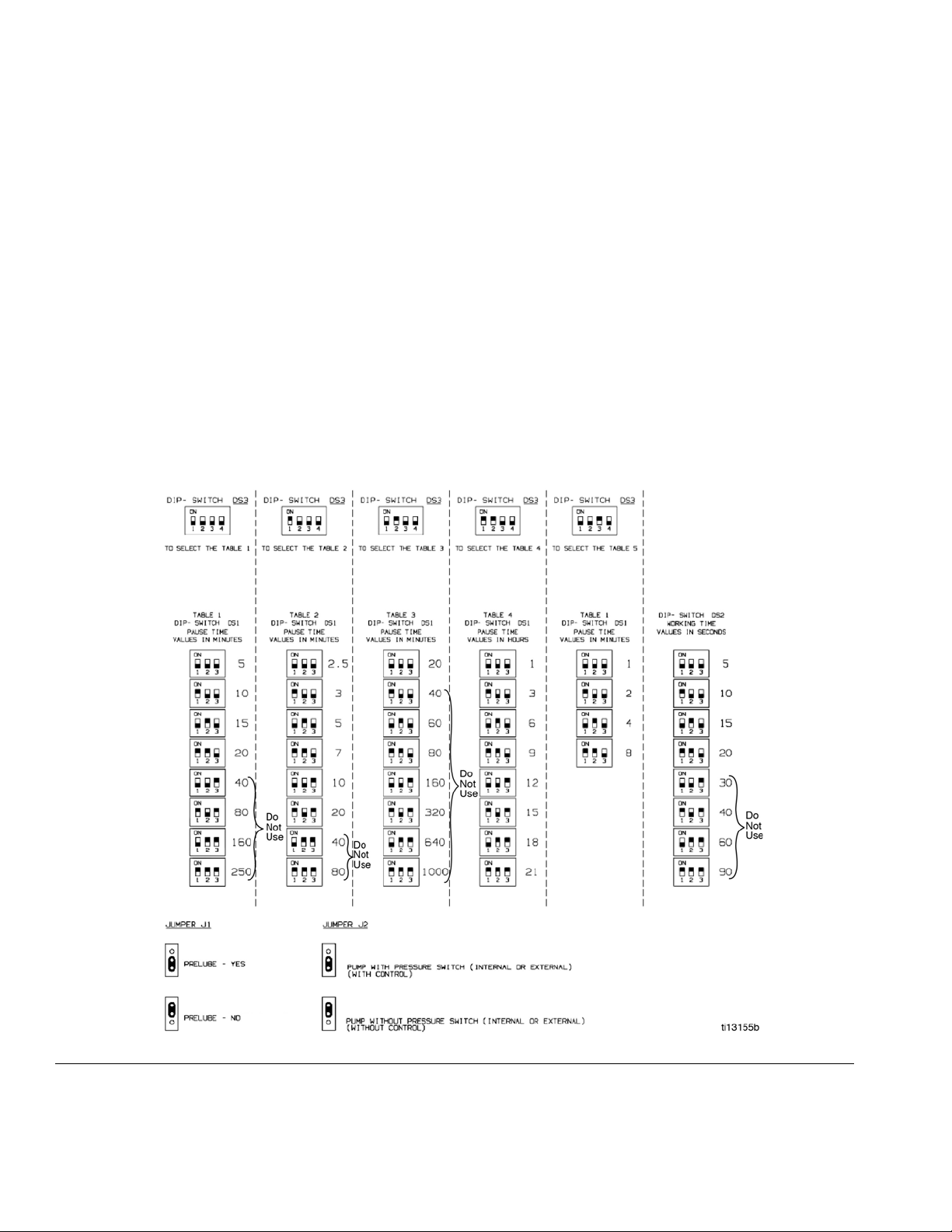

1. Set the desired Pause (off) and Work (on) Times for

your model using the 3 banks of dip switches (DS-1,

DS-2, DS-3) located under the electrical enclosure

cover on the top of the pump. (See Dip Switch Set-

tings, page 8.)

The possible time choices for both the Pause and

Work Times are shown on page 8.

NOTE:

• Pause (off) Time cannot exceed 20 minutes.

• Work (on) Time cannot exceed 20 seconds.

2. Adjust the air flow using the air flow adjustment

screw (H) located on the air/oil mixing blocks (K) by

turning the set screw counter-clockwise. When the

screw is flush with the surface of the block, the

blocks are full open.

To restrict the air flow, turn the adjustment screw

clockwise.

NOTE: Entirely removing the air flow adjustment

screw (H) will cause a loss of air pressure to the

entire lubrication system.

3. Set the pressure regulator for the air/oil mixing

blocks between 30 and 60 psi (0.20 MPa, 2.06 bar

and 0.41 MPa, 4.13 bar). Refer to Air Flow Chart,

page 6 for setting guidelines.

4. Air flow is supplied on a constant basis to the air-oil

mixing block. Adjust the air regulator to achieve the

required air pressure as follows.

a. Fill the reservoir with spindle oil.

b. Press the manual run button (B).

c. Loosen the purge plug (A) on the air/oil mixing

block assembly (K).

d. Press the manual run button (B) until oil flows

out of the port. As oil begins flowing out of the

purge port, quickly tighten the purge plug (A).

e. Press the manual run button (B) 10 additional

times (allowing approximately 5 seconds OFF

time). The pressure should build on the oil pres-

sure gauge (J) to 320 psi (2.21 MPa, 22.1 bar)

and drop to 0.0 psi (0 MPa, 0 bar).

f. If pressure is not established, repeat steps b - e.

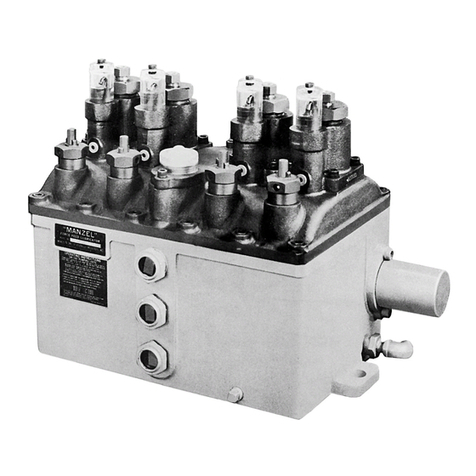

Adding a Lubrication Point

To add a point, the air/oil mixing assembly must be

removed from the panel. An additional mixing module

and new tie rod combination can then be added.

Plugging a Lubrication Point

To plug an air/oil outlet, Graco Plug Part No. 555456

must be installed in the piston distributor port on top of

the air/oil mixing block.