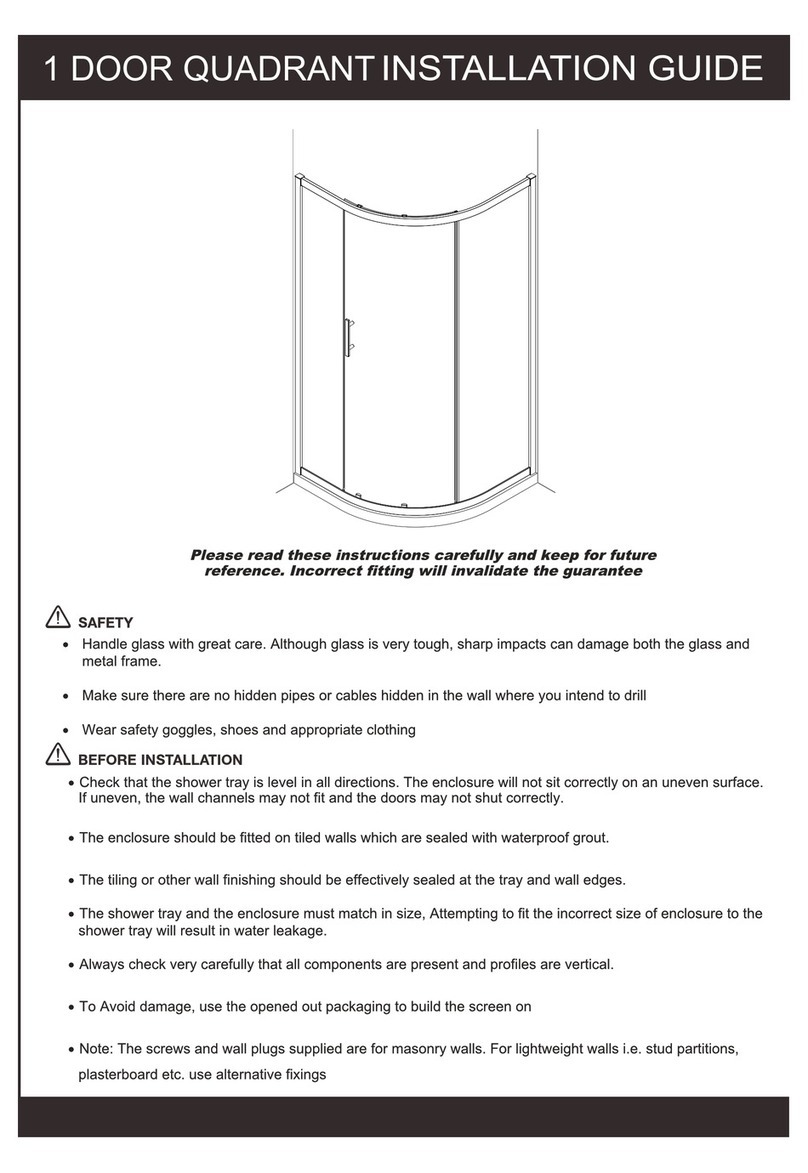

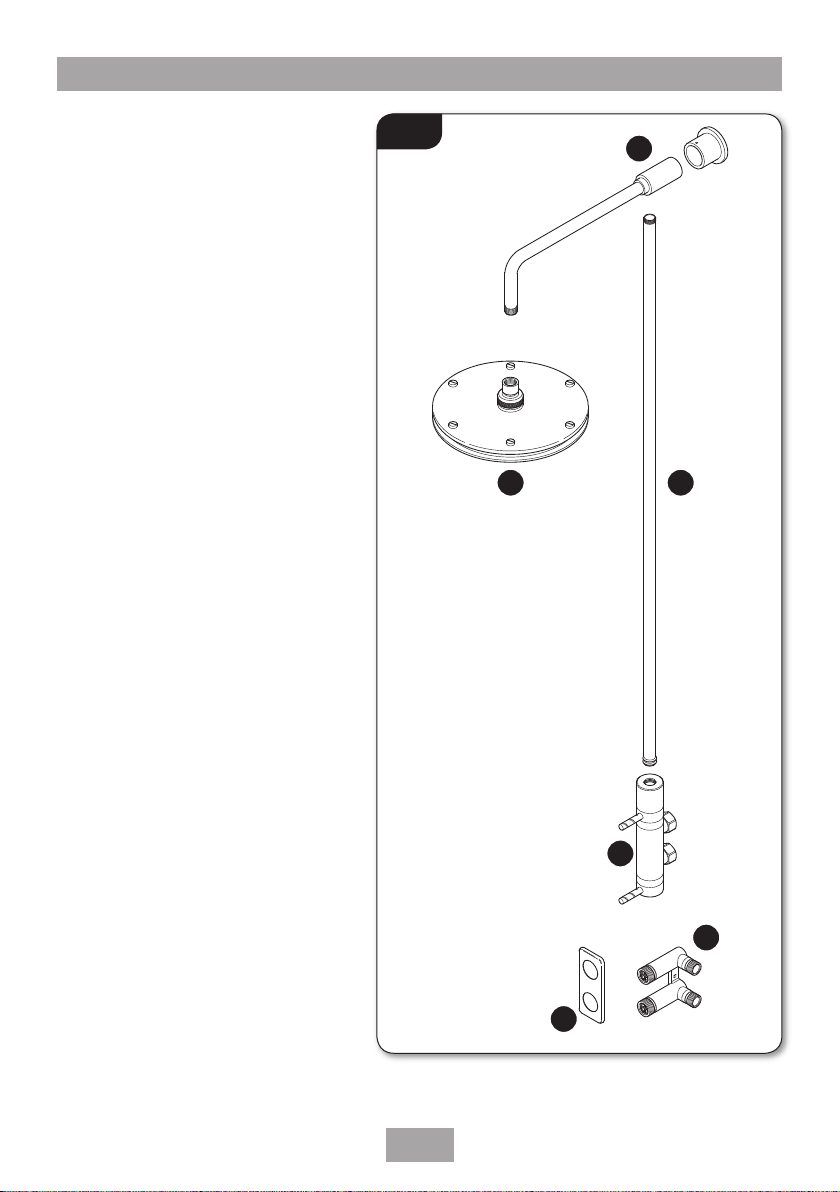

Vertical bar mixer shower

3

PLUMBING REQUIREMENTS

DO NOT use jointing compounds on any pipe

fittings for the installation.

DO NOT solder fittings near the mixer unit

as heat can transfer along the pipework and

damage the mixer valve.

IMPORTANT:

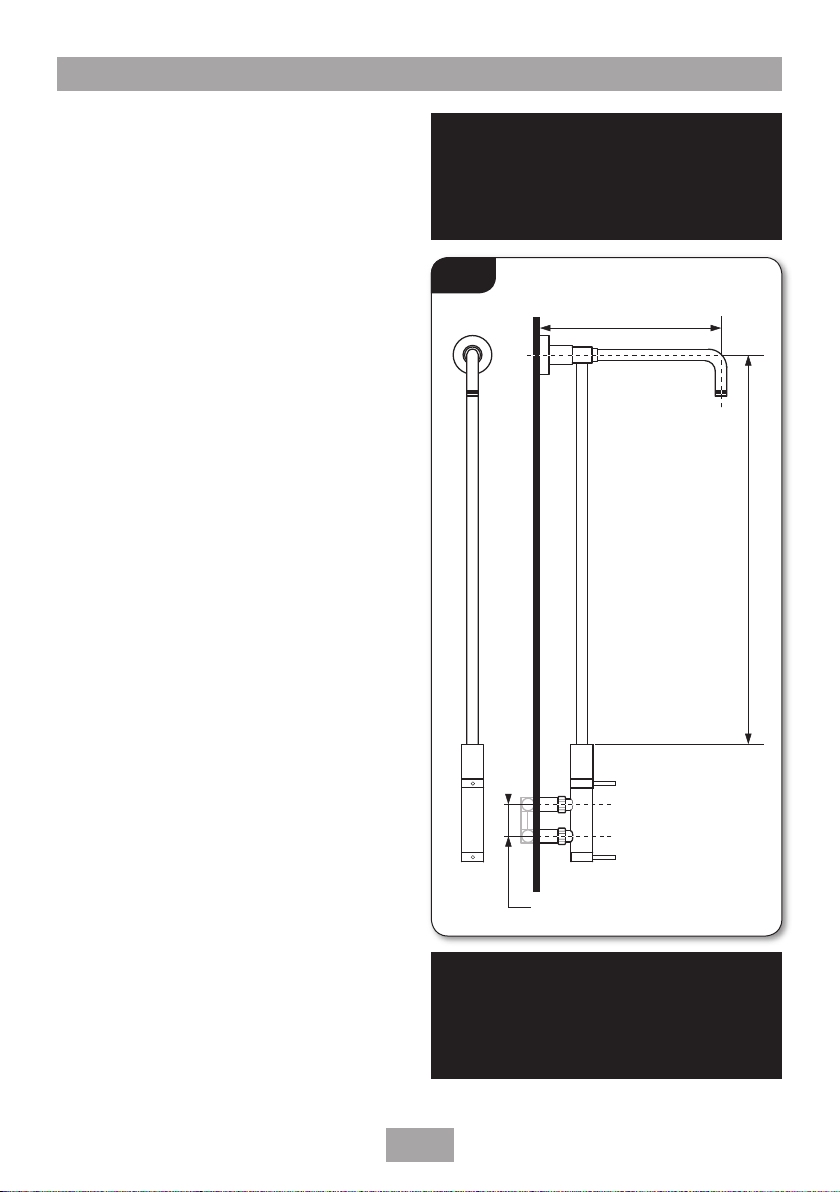

• The layout and sizing of pipework MUST

be such that nominally equal inlet supply

pressures are achieved and the effects of

other draw-offs are minimised.

• The pipe-work should be installed such

that other taps and appliances being

operated elsewhere on the premises do not

significantly affect the flow.

• When connecting pipe-work avoid using

tight 90° elbows; swept or formed bends will

give the best performance.

• The hot water pipe entry must be made to

inlet, marked HOT, ‘H’ or with a red/orange

label.

• Suitable isolating valves (complying with

Water Regulations and Bylaws) must be fitted

on the hot and cold water supplies to the

shower as an independent means of isolating

the water supplies should maintenance or

servicing be necessary.

• It is preferable to flush the pipe-work to clear

the system of debris and check for leaks

before connecting to the mixer.

• The mixer inlets contain removable filters

that may become blocked if debris is not

flushed through before fitting.

(Commercial applications)

• Triton recommends for all commercial

applications that, easily accessible, in-line

filters are used to aid maintenance.

Hard water areas

a. If it is intended to operate the shower

in areas of hard water (above 200-ppm

temporary hardness), a scale inhibitor may

have to be fitted. For advice on the Triton

scale inhibitor, please contact Customer

Service.

b. For best performance the showerhead MUST be

regularly cleaned to remove scale and debris.

WATER SYSTEM REQUIREMENTS

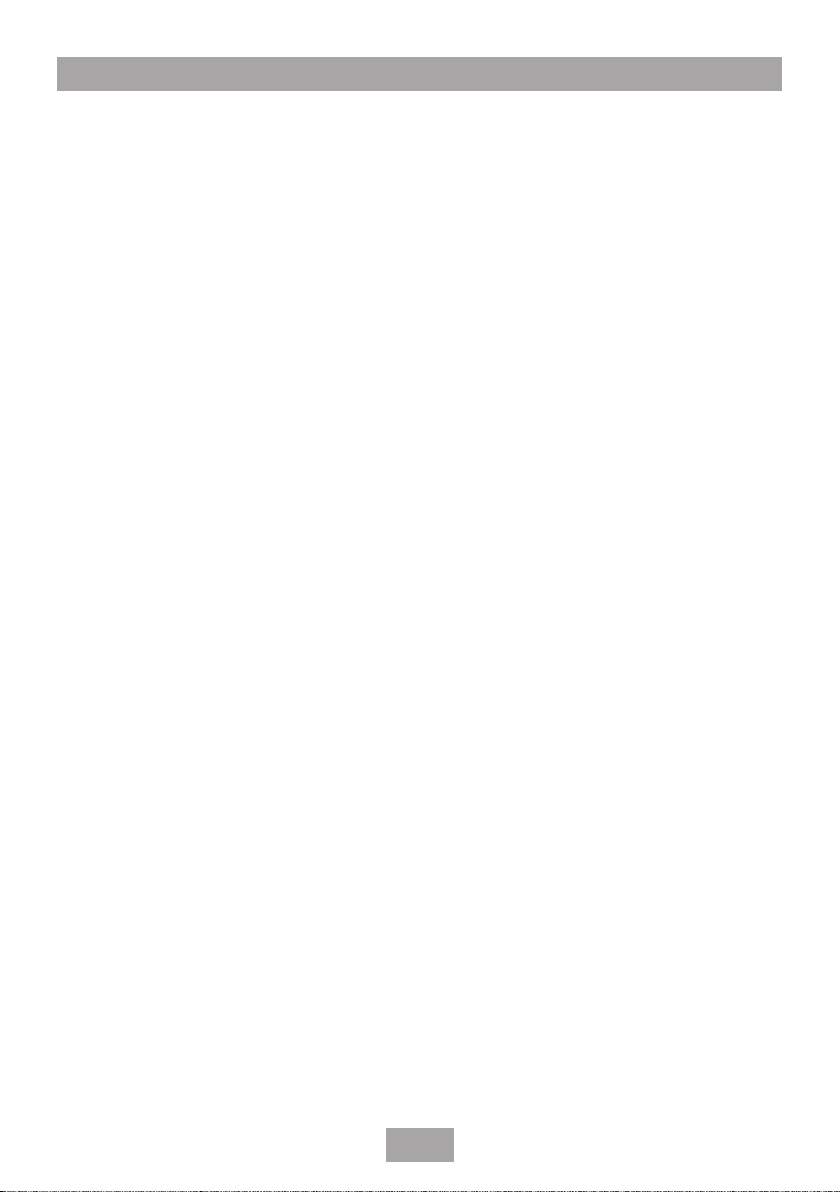

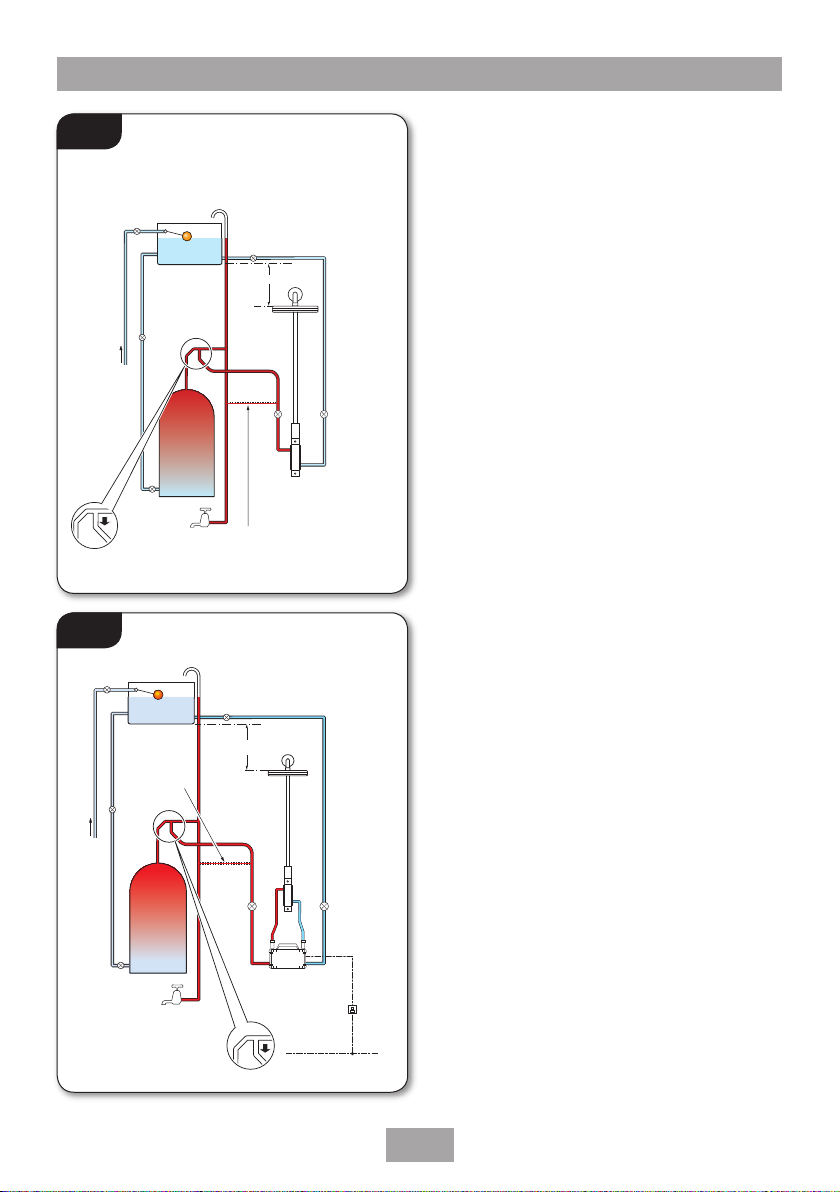

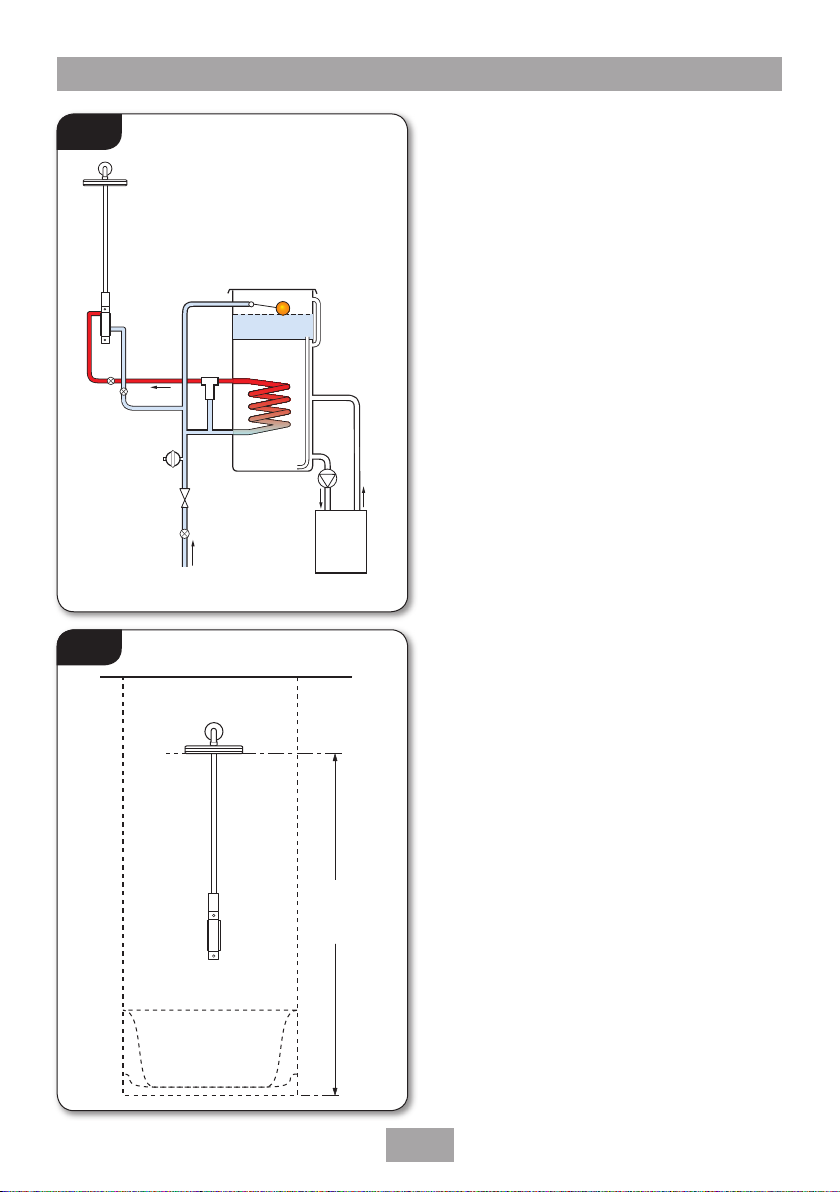

This mixer shower is suitable for: -

• Gravity systems.

• Pumped gravity systems.

• Fully modulating type combination boilers.

• Multi-point hot water heaters.

• Thermal storage.

• Unvented systems.

When installing this mixer with a Combination or

multi-point boiler, it may be necessary to install

flow regulation.

Check that the appliance is capable of delivering

hot water at a minimum switch-on flow rate

of 3 litres per minute. At flow rates between 3

and 8 litres per minute, the appliance must be

capable of raising the water temperature to 52°C

(minimum).

Water temperature at the inlet of the mixer valve

must remain relatively constant when flow rate

adjustments are made (refer to the appliance-

operating manual to confirm compatibility with

this mixer shower).

Where thermal store systems and instantaneous

gas water heaters are used, if excessive draw-

off take place the appliance may not be able to

maintain an adequate output temperature. This

could result in the shower temperature becoming

noticeably cooler.

Flow regulators can be fitted to the inlet

pipework with high-pressure water systems to

reduce flow rate and assist economy.

The hot supply temperature MUST remain a

minimum of 10°C hotter than the required blend

temperature for optimum performance.