FDMR - Fire damperPage 2 Version 2022-12-20

TPM 165/22

These technical specifications state a row of manufactured sizes and models of fire dampers FDMR.

It is valid for production, designing, ordering, delivery, maintenance and operation.

CONTENT

I. GENERAL.....................................................................................................................................................................................3

Description..............................................................................................................................................................................3

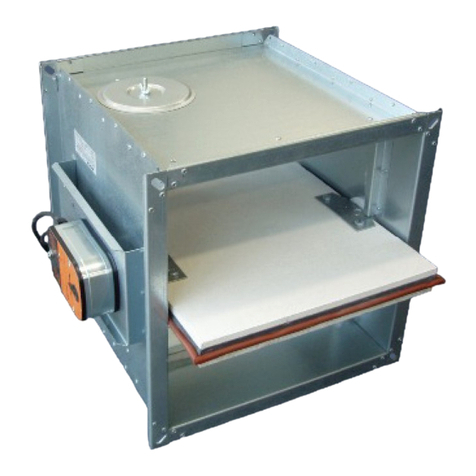

Design.....................................................................................................................................................................................4

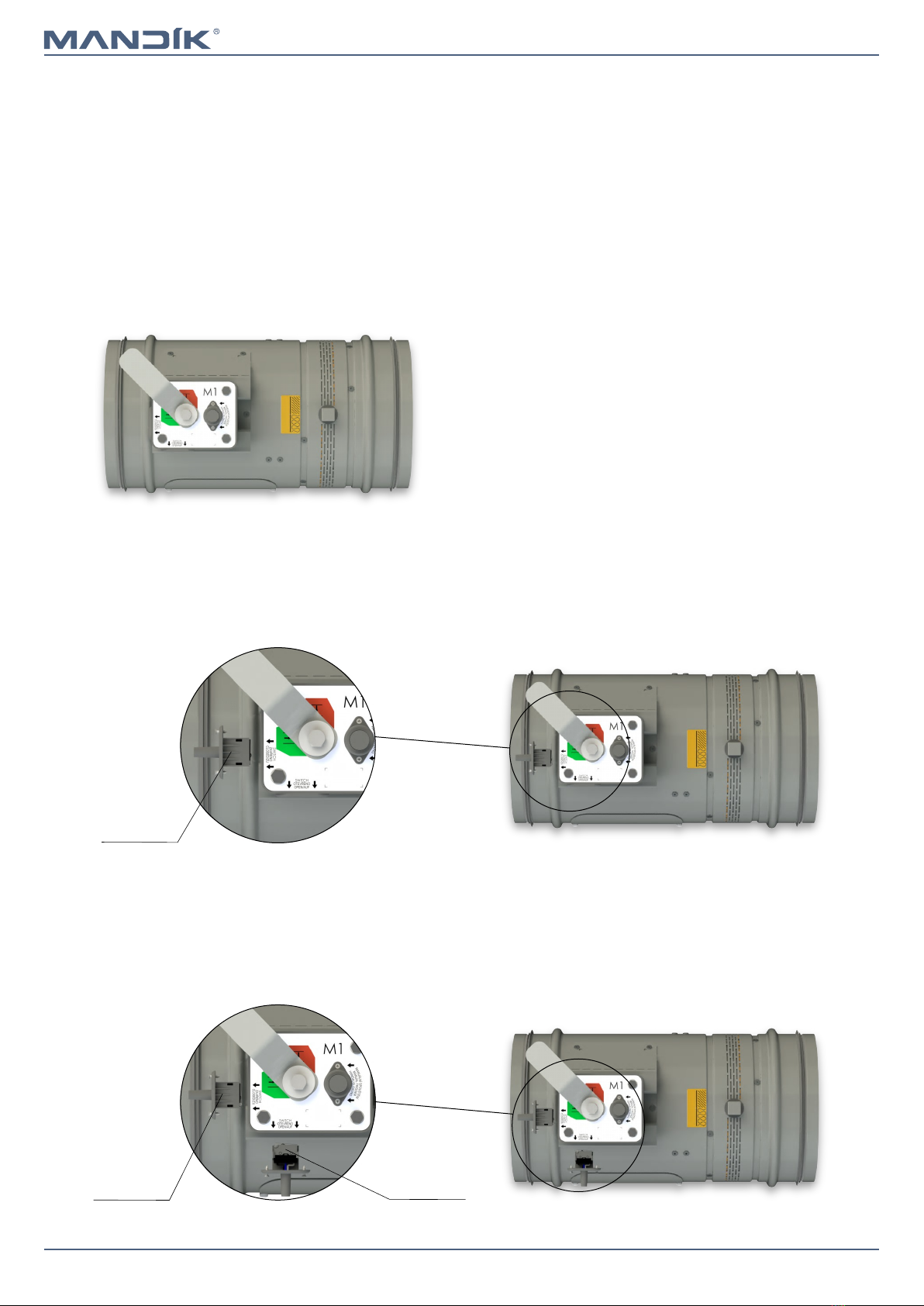

Design with mechanical control..........................................................................................................................................4

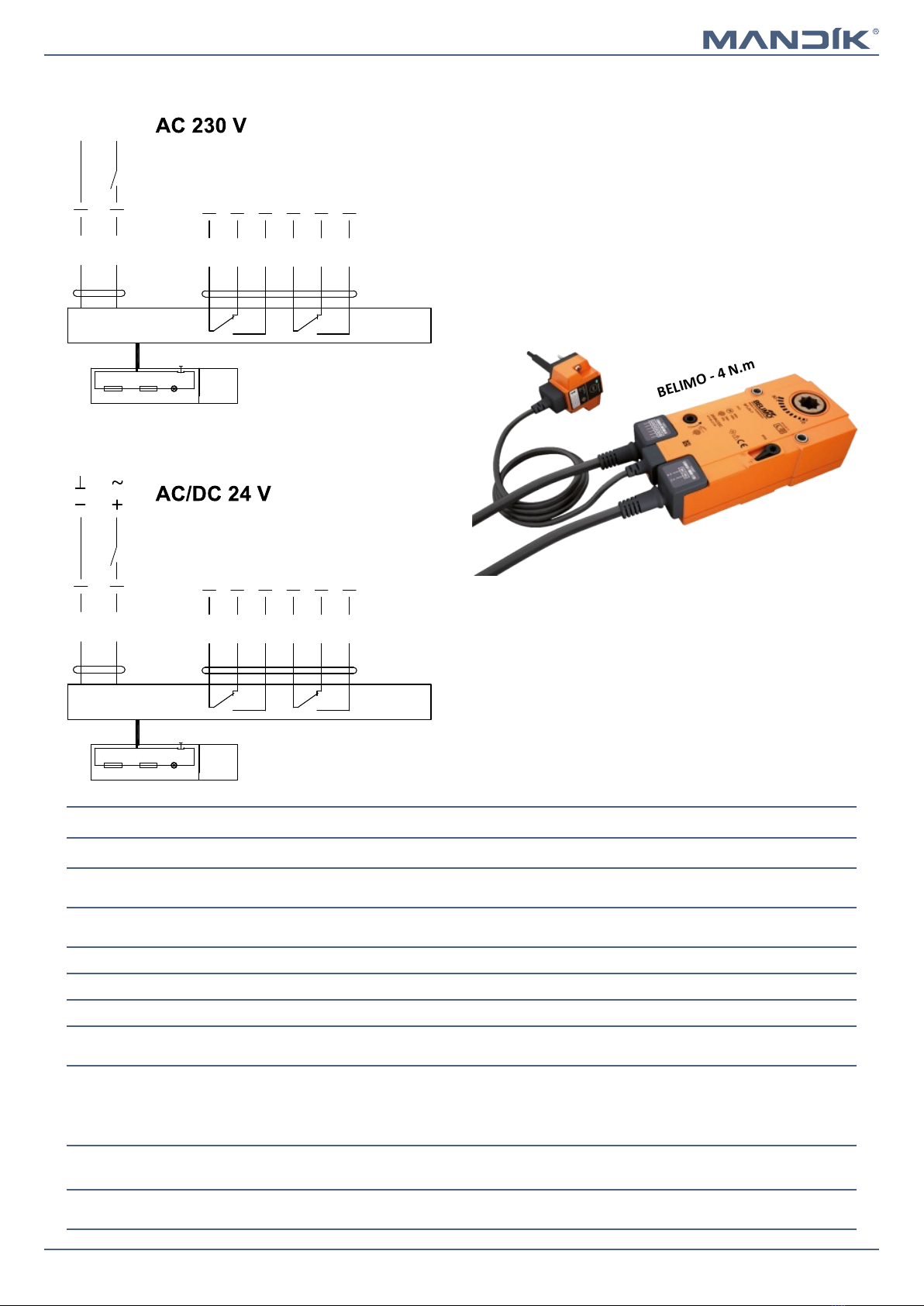

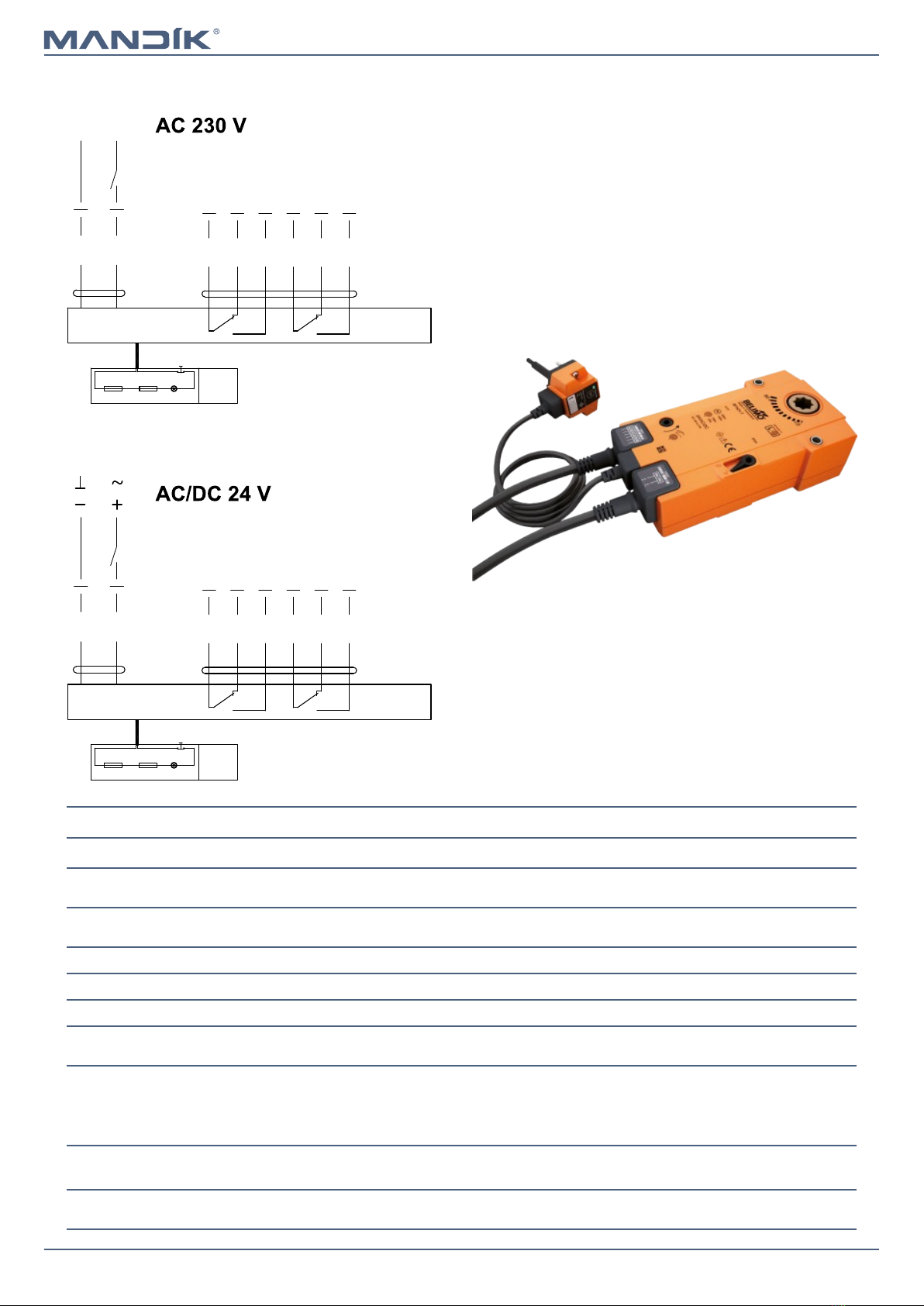

Design with actuating mechanism.......................................................................................................................................6

Communication and control module MDCM.....................................................................................................................11

Dimensions...........................................................................................................................................................................12

Technical parameters............................................................................................................................................................17

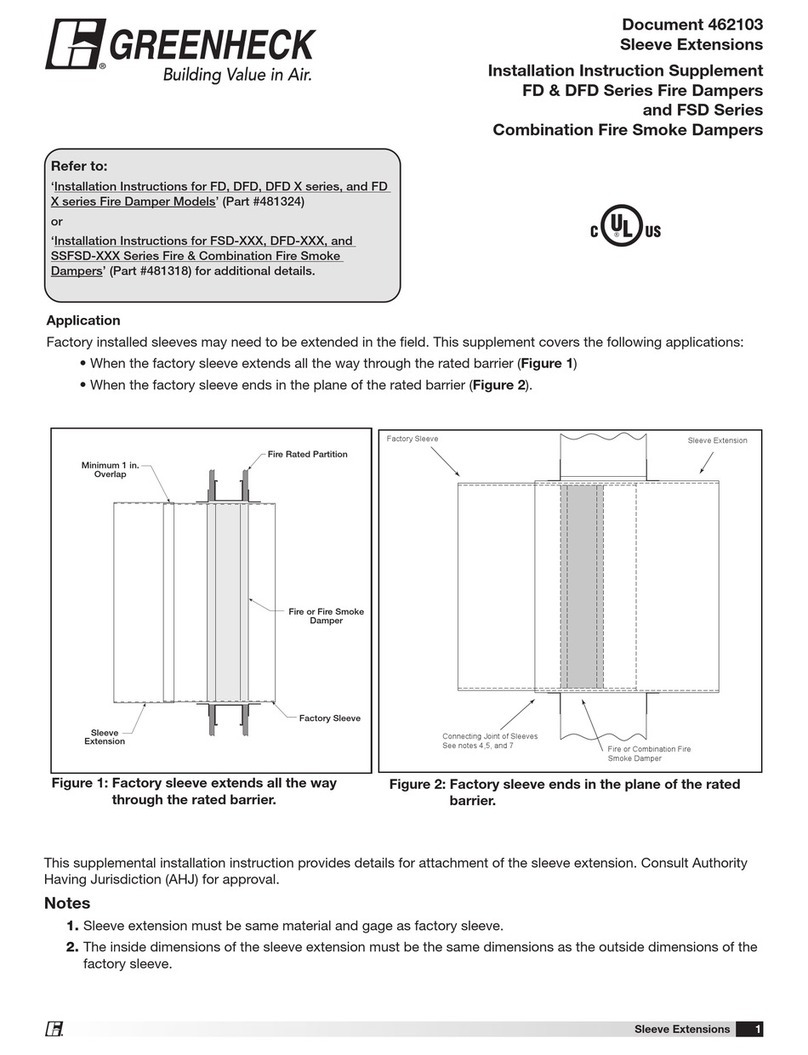

Placement and Assembly......................................................................................................................................................18

Statement of installations.....................................................................................................................................................20

Installation in solid wall construction................................................................................................................................21

Installation in gypsum wall construction...........................................................................................................................23

Installation in solid ceiling construction............................................................................................................................25

Suspension systems..............................................................................................................................................................26

Duct connection....................................................................................................................................................................28

II. TECHNICAL DATA.....................................................................................................................................................................29

Pressure loss.........................................................................................................................................................................29

Noise data.............................................................................................................................................................................30

III. MATERIAL, FINISHING.............................................................................................................................................................31

Material................................................................................................................................................................................31

IV. INSPECTION, TESTING.............................................................................................................................................................31

V. TRANSPORTATION AND STORAGE...........................................................................................................................................32

Logistic terms........................................................................................................................................................................32

VI. ASSEMBLY, ATTENDANCE AND MAINTENANCE......................................................................................................................32

Assembly...............................................................................................................................................................................32

Entry into service and revisions.........................................................................................................................................35

Spare parts.........................................................................................................................................................................36

VII. PRODUCT DATA.....................................................................................................................................................................37

Data label..............................................................................................................................................................................37

VIII. ORDERING INFORMATION....................................................................................................................................................37

Ordering key.........................................................................................................................................................................37