4Declaration of performance

L-06/2021CE_DoP_Rf-t_C11_EN

DECLARATION OF PERFORMANCE

Declarationofperformance

CE_DoP_Rf-t_C11_EN

L-06/2021

1. Unique identification code of the product-type: CR120

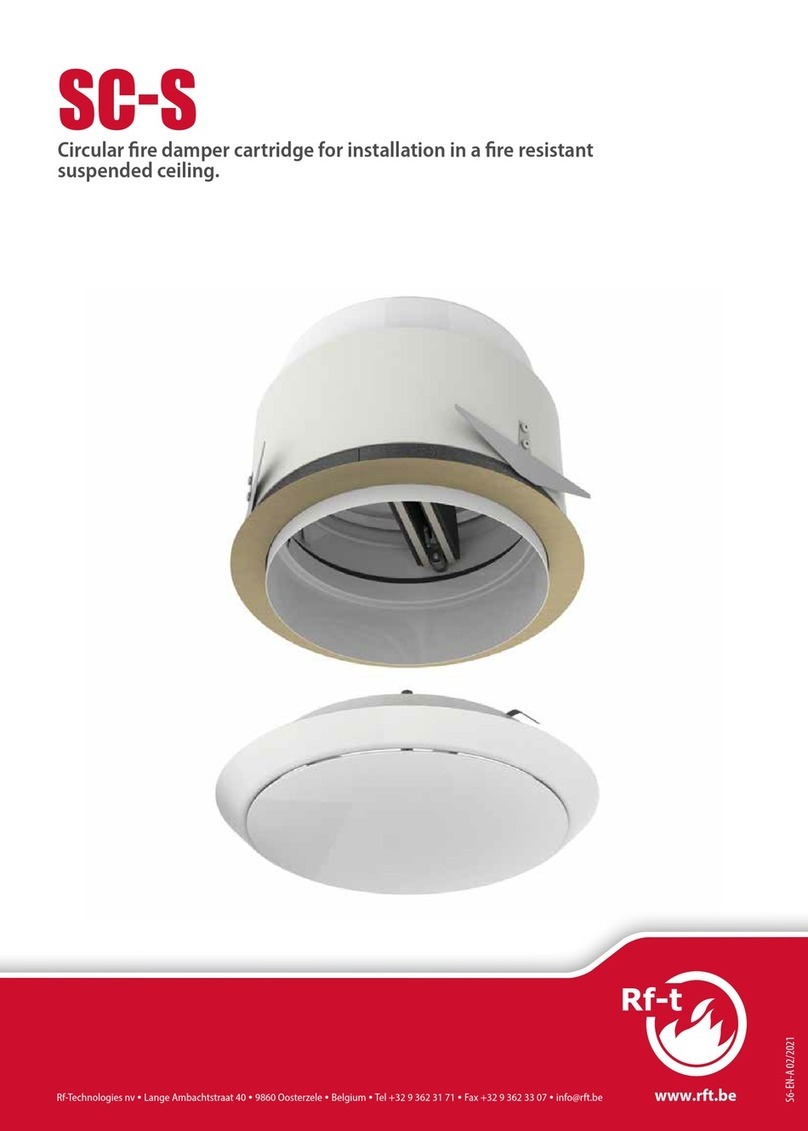

2. Intended use/es: Circular re damper to be used in conjunction with partitions to maintain re compartments in heating, ventilating and air conditioning installations.

3. Manufacturer: Rf-Technologies NV, Lange Ambachtstraat 40, B-9860 Oosterzele

4. System/s of AVCP: System 1

5. Harmonised standard / European Assessment Document; notified body / European Technical Assessment, Technical Assessment Body,

notified body; certificate of constancy of performance:

EN 15650:2010, BCCA with identication number 0749; BCCA-0749-CPR-BC1-606-0464-15650.02-2517

6. Declared performance according to EN 15650:2010 (Fire resistance according to EN 1366-2 and classications according to EN 13501-3)

Essential characteristics Performance

Range Wall type Wall Sealing Installation Classification

Ø 100-315 mm Rigid wall Reinforced concrete ≥ 110 mm Mortar / Gypsum 1 EI 120 (vei no) S - (500 Pa)

Aerated concrete ≥ 100 mm Gypsum 1 EI 120 (vei no) S - (500 Pa)

Mortar 1 EI 120 (vei no) S - (300 Pa)

Stone wool + coating ≥ 140 kg/m³ + coated casing 1 EI 120 (vei no) S - (300 Pa)

Stone wool + coating ≥ 140 kg/m³ 1 EI 90 (vei no) S - (300 Pa)

Stone wool Mulcol Multimastic SP + coating 1 EI 60 (vei no) S - (300 Pa)

Galvanised duct + stone wool + coating ≥ 140 kg/m³ 2x50 mm 2 EI 90 (vei no) S - (300 Pa)

Galvanised duct + stone wool + coating ≥ 140 kg/m³ 2x50 mm + mortar 2 EI 90 (vei no) S - (300 Pa)

Galvanised duct + GEOFLAM® F 45 mm + mortar 2 EI 120 (vei no) S - (500 Pa)

Galvanised duct + GEOFLAM® Light 35 mm + mortar 2 EI 120 (vei no) S - (500 Pa)

Rigid oor Reinforced concrete ≥ 150 mm Mortar 3 EI 120 (hoi no) S - (500 Pa)

Aerated concrete ≥ 100 mm Mortar 3 EI 90 (hoi no) S - (500 Pa)

Aerated concrete ≥ 150 mm Stone wool + coating ≥ 140 kg/m³ + coated casing 3 EI 120 (hoi no) S - (300 Pa)

Stone wool + coating ≥ 140 kg/m³ 3 EI 90 (hoi no) S - (300 Pa)

Flexible wall Metal studs gypsum plasterboard Type A (EN 520) ≥ 100 mm Gypsum 1 EI 60 (vei no) S - (500 Pa)

Stone wool + coating ≥ 140 kg/m³ 1 EI 60 (vei no) S - (300 Pa)

Metal studs gypsum plasterboard Type F (EN 520) ≥ 100 mm Gypsum 1 EI 90 (vei no) S - (500 Pa)

Mortar 1 EI 120 (vei no) S - (300 Pa)

Stone wool + coating ≥ 140 kg/m³ + coated casing 1 EI 120 (vei no) S - (300 Pa)

Stone wool + coating ≥ 140 kg/m³ 1 EI 90 (vei no) S - (300 Pa)

Metal studs gypsum plasterboard Type F (EN 520) ≥ 100 mm Stone wool Mulcol Multimastic SP + coating 1 EI 60 (vei no) S - (300 Pa)

Galvanised duct + stone wool + coating ≥ 140 kg/m³ 2x50 mm 2 EI 90 (vei no) S - (300 Pa)

Gypsum blocks ≥ 70 mm Block glue 1 EI 120 (vei no) S - (500 Pa)

Ø 100-250 mm Flexible wall Metal studs gypsum plasterboard Type A (EN 520) ≥ 100 mm Stone wool ≥ 40 kg/m³ + cover plates 1 EI 60 (vei no) S - (500 Pa)

CR120-1S Ø 100-315 mm Rigid wall Aerated concrete ≥ 100 mm Not applicable 4 EI 120 (vei no) S - (500 Pa)

Flexible wall Metal studs gypsum plasterboard Type F (EN 520) ≥ 100 - ≤ 125 mm Not applicable 4 EI 120 (vei no) S - (500 Pa)

1 Type of installation: built-in,

0-360°. Minimal distances autho-

rised with axis till 45°.

≥ 30 mm

≤ 45°360° ≥ 30 mm 2 Type of installation: remote from

the wall, 0/180°. Minimal distances

authorised.

≥ 30 mm ≥ 30 mm 3 Type of installation: built-in,

0-360°. Minimal distances

authorised.

360° ≥ 30 mm ≥ 30 mm

4 Type of installation: surface-

mounted, 0/180°. Minimal

distances authorised.

Nominal activation conditions/sensitivity: Pass

Response delay (response time): closure time Pass

Operational reliability: cycling MFUS - 50 cycles; MMAG - 300 cycles; B(L)F(T) - 10000 cycles; BFL(T) - 10000 cycles; ONE - 10000 cycles; ONE-X - 10000 cycles; UNIQ - 10000

cycles

Durability of response delay: Pass

Durability of operational reliability: Pass

Protection against corrosion according to EN 60068-2-52: Pass

Damper casing leakage according to EN 1751: ≥ class C

Harmonised standard

EN 15650:2010

The performance of the product identied above is in conformity with the set of declared performance/s.This declaration of

performance is issued, in accordance with Regulation (EU) No 305/2011, under the sole responsibility of the manufacturer identi-

ed above.

Signed for and on behalf of the manufacturer by:

Mathieu Steenland, Technical Manager

Oosterzele, 06/2021