2

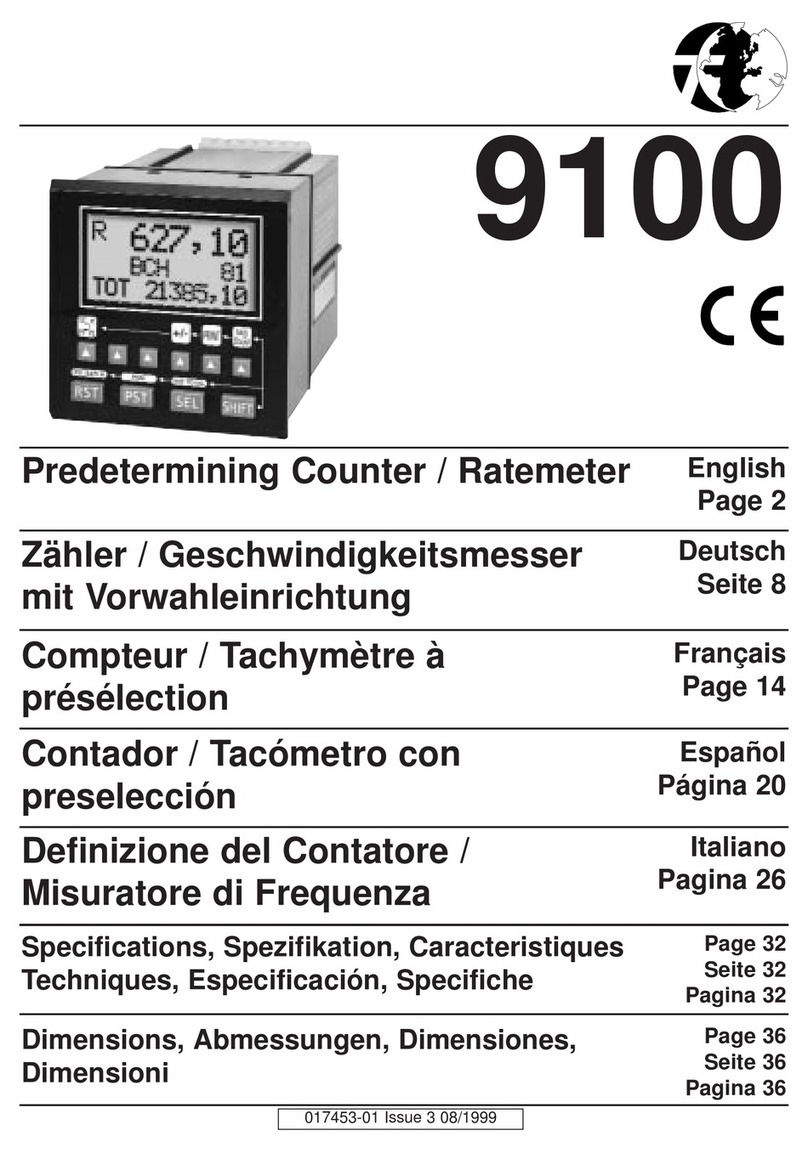

OVERVIEW

The 9100 is a versatile multi-function counter/ratemeter and

process controller. Features include:-

• LCD three-row dot matrix display with backlight;

• simultaneous display of instantaneous, batch and total

counts;

• seven count modes;

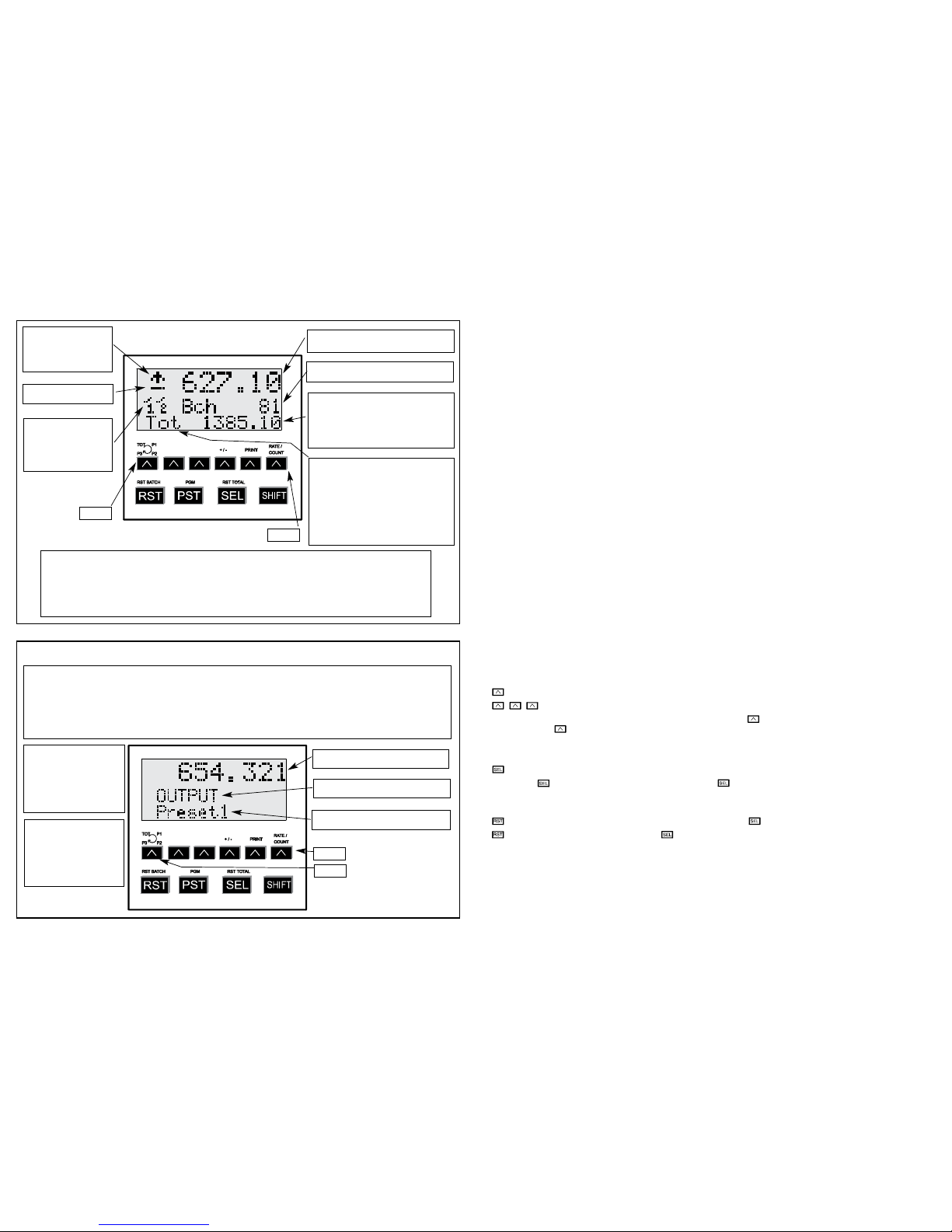

BASIC OPERATION

Inputs A and B receive count pulses. The 9100 counts these

and also measures the rate at which the pulses are arriving

on input A only (input B in quadrature x 1 mode).

The progress of the count or the rate is shown on the front

panel display according to the mode and the scale values

you program into the unit.

Outputs R1, R2 and R3 change state when the count or the

rate becomes equal to a preset value (P1, P2 or P3) which

you set for each output. Each of the three outputs can be

programmed to respond either to a count value or a rate

value, as required. Each output can be independently

programmed to remain in the changed state for an amount

of time which you can set (the ‘on time’) - this is called

Pulsed Mode - or to remain in the changed state until the

end of a complete count cycle - this is called Latched Mode.

The normal sequence for outputs, in count mode, is for P1

and P2 to be set between zero and P3, since the value of

P3 determines the end of a cycle of counting; outputs 1 and

2 will therefore change state at preset points within the

count cycle. If you have chosen ‘automatic reset’ mode,

then reaching the end of a count cycle resets all latched

outputs to their initial state. If you have chosen ‘manual

reset’ mode, then latched outputs remain latched until the

counter is reset from the front panel or by a pulse on the

External Reset input.

Output 1 can alternatively be set up as a batch counter,

which you can preset to operate when a certain number of

count cycles have been completed.

Output 2 can alternatively be set up as a ‘motion monitor’.

In this mode, if no count pulse has been received for 12.8

seconds (equivalent to 4.7 rpm when using a shaft

encoder), then relay R2 operates to provide an indication

that the process has stopped. When the next pulse is

received, R2 releases and timing starts again.

• comprehensive prescaling for direct display in units of

your choice;

• three fully programmable relay outputs for process

control;

• simple, straightforward visual programming;

• programming in any of four European languages.

COUNT TYPES

UNI + DIR

Count is incremented or decremented by input A. Direction

is determined by input B:-

Input B open - Increment

Input B closed - Decrement

A+B

Count is incremented by either input A or input B.

A-B

Count is incremented by input A and decremented by B.

A/B

Count is incremented by input A. Display is derived from

input A divided by input B. Manual reset (keyboard or

remote) is required to clear the B count value.

Quadrature Counting Modes

For all quadrature modes, the phase of input A must lag or

lead that of input B by 90 degrees.

For an incrementing count, A must lead B by 90 degrees.

For a decrementing count, A must lag B by 90 degrees.

Quadrature x1

Count is incremented or decremented on the rising edge of

input B.

Quadrature x2

Count is incremented or decremented on the rising and

falling edges of input A.

Quadrature x4

Count is incremented or decremented on the rising and

falling edges of both inputs.

Note: In the quadrature counting modes, use electronic

sensors because inputs A and B are not debounced.

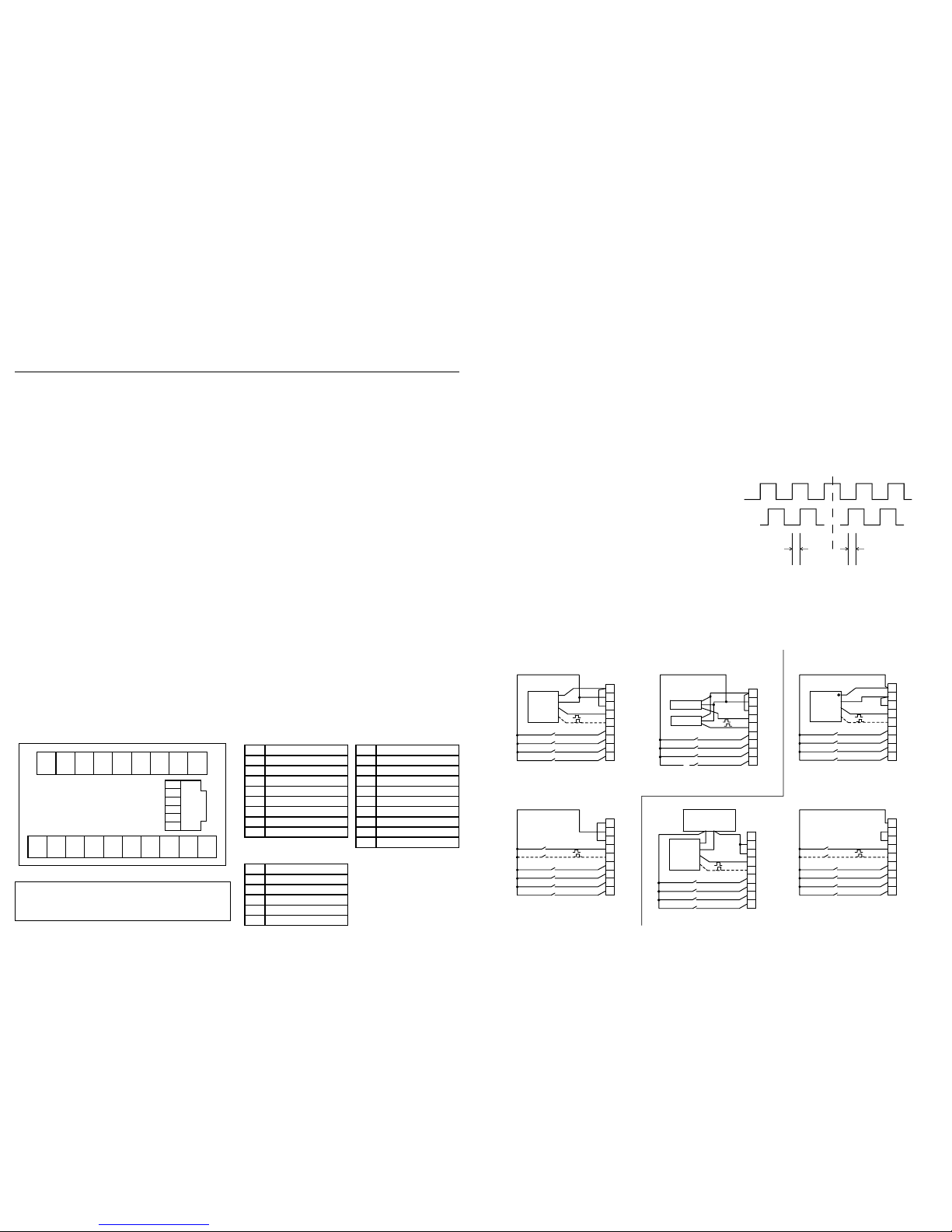

EXTERNAL CONNECTIONS

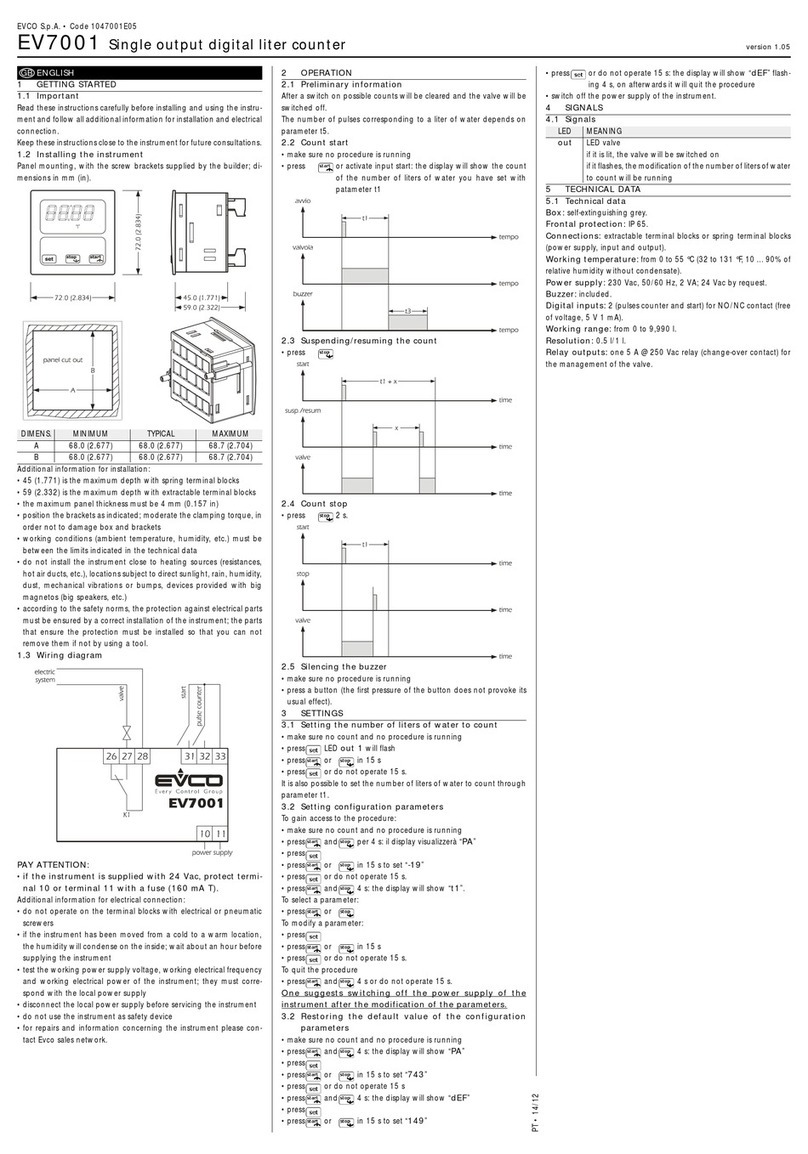

Two terminal blocks are provided at the back of the counter,

arranged as shown. The terminal strips may be unplugged

from the counter to facilitate easy wiring.

To ensure correct operation this unit must be installed in

accordance with the “Recommended Installation

Procedures for Micro-Processor Based Products” -

Trumeter product number 015580-01.

23456 7 89

1918

17

1615

14

13

1211

10

1

5

6

4

3

2

1

CN1

CN2

CN3

Connectors from rear

Connector CN1 Connector CN2

Connector CN3

1DC Output 12V

2DC Output 0V

3Signal Common

4Count Input A

5Count Input B

6External Reset

7Keyboard Disable

8Count Inhibit

9External Print

10 AC Mains L

11 AC Mains N

12 N.C.

13 Relay R1 Common

14 Relay R1 Contact

15 Relay R2 Common

16 Relay R2 Contact

17 Relay R3 Common

18 Relay R3 Contact

19 No Connection

1Receive (RX)

2Transmit (TX)

30V

4N.C.

5N.C.

6N.C.

Sink Mode Source Mode

1

2

3

4

5

6

7

8

9

Sensor 1

Sensor 2

+12v

0v

Signal (A)

(Sign al B)

External Reset

Keyboard Disable

Count Inhibit

External Print

Illustrating use of two sensors to provide

A and B signals (sink mode depicted).

1

3

4

5

6

7

8

9

Sensor

Signal (A)

(Sign al B)

+

v 0v

External Reset

Keyboard Disable

Count Inhibit

External Prin t

External Supply

10 to 30v dc

2

Illustrating use of external power supply

(source mode depicted).

+

1

2

3

4

5

6

7

8

9

Sensor

+12v

0v

Signal (A)

(Sign al B)

+

External Reset

Keyboard Disable

Count Inhibit

External Prin t

(NPN output devices)

1

2

3

4

5

6

7

8

9

+12v

0v

Signal (A)

(Sign al B)

External Reset

Keyboard Disable

Count Inhibit

External Print

Contact clos ure

device(s)

(Contact closure devices)

1

2

3

4

5

6

7

8

9

Sensor

+12v

0v

Signal (A)

(Sign al B)

External Reset

Keyboard Disable

Count Inhibit

External Print

(PNP output devices)

1

2

3

4

5

6

7

8

9

+12v

0v

Signal (A)

(Sign al B)

External Reset

Keyboard Disable

Count Inhibit

External Print

Contact closure

device(s)

(Contact closure devices)

3

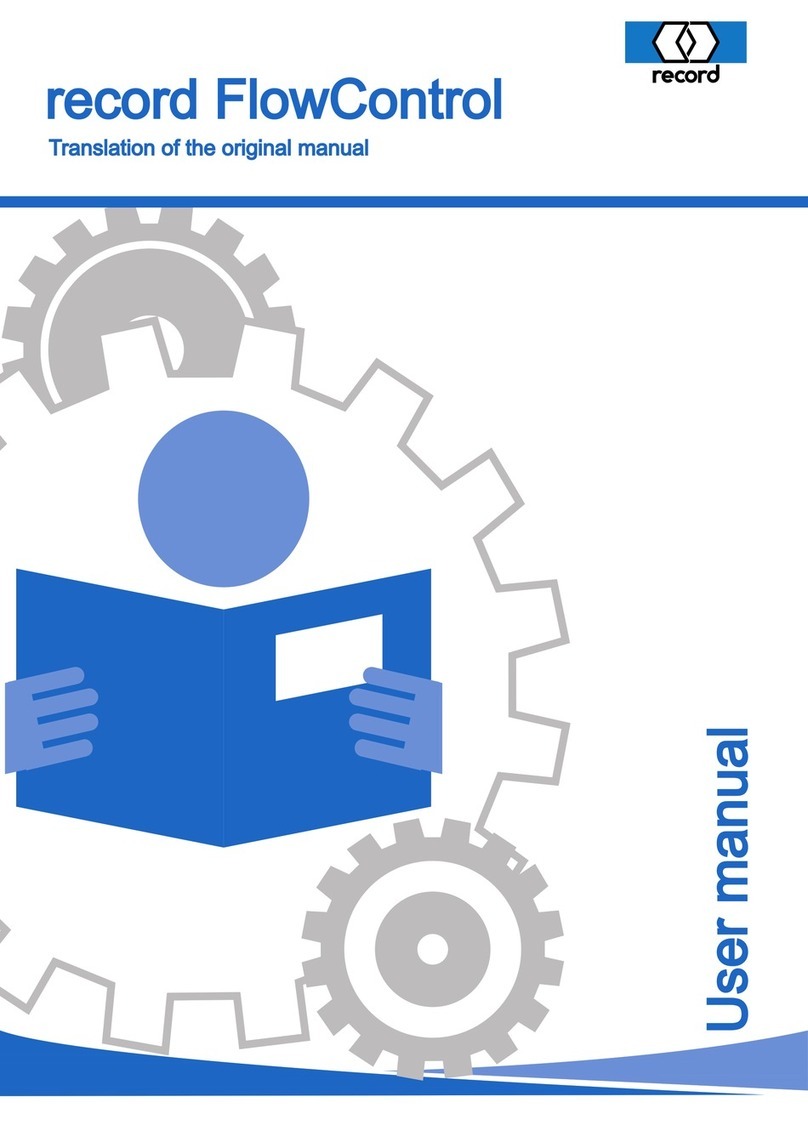

CONNECTION OF SENSORS

A “sensor” can be a 3-wire proximity switch, 3-wire photocell

or incremental shaft encoder etc.

3-wire devices should use input A as the single input for

unidirectional counting.

For bi-directional (quadrature) counting, input A and input B

must be 90° out of phase, lag or lead.

Two 3-wire devices connected to inputs A and B

respectively can provide signals for bi-directional counting

(either for quadrature or A-B modes).

When signal is generated by contact closure devices,

choose “contact cls” in programming. This ensures

adequate de-bouncing but limits the count rate to 30 counts

per second.

The external control inputs are permanently set in de-

bounce mode but may also be driven by electronic devices,

subject to the 30 count per second limitation.

TIMING DIAGRAM

The timing diagram below illustrates how the direction of

count is controlled in quadrature mode by the lead or lag of

the pulses on Input A with respect to Input B.

A

B

Count up Count down

90º Lead 90º Lag

COMMUNICATIONS PORT (CN3)

RS232-C communication is used to allow connection of the 9100 to a printer. Printouts of the user text (12 characters) and

count or rate value plus engineering units may be initiated from the keyboard or external printer input.

Baud rate, number of stop bits and number of print copies are selected in program mode.

If the printer type is set to IBM/Epson, a PC can be used to remotely execute a Print or Reset:Connect the PC’s serial port

transmit pin to the 9100’s RJ11 receive pin, and send an ASCII P (50 Hex) to execute a Print or an ASCII R (52 Hex) to

execute a Reset.

The data may be read into a PC by connecting the RJ11 transmit pin to the PC’s serial port receive pin, instead of a printer.

In Manual Reset mode only, the 9100 can be automatically reset as soon as a Print is executed (by the keyboard or

externally). This feature can be turned on or off using the Comms/Print menu (see page 6).

Please note:

Any signal cables connected to this device must not exceed

30 metres in length.

If any signal cables are installed that are routed outside the

building, it will be necessary to install additional surge

protection devices.

www.GlobalTestSupply.com

Find Quality Products Online at: sales@GlobalTestSupply.com