Trumpf TruTool S 250 User manual

Operator's manual

english

TruTool S 250 (1A1)

2 Safety E518EN_04.DOC

Table of contents

1. Safety ..................................................................................3

2. Description .........................................................................5

2.1 Correct use ..........................................................................6

2.2 Technical data TruTool S 250 .............................................7

3. Tool assembly....................................................................8

3.1 Selecting the blade ..............................................................8

3.2 Setting the cutting clearance ...............................................9

4. Operation..........................................................................10

4.1 Working with the TruTool S 250 ........................................10

5. Maintenance .....................................................................11

5.1 Changing the blade............................................................12

5.2 Replacing carbon brushes.................................................13

6. Original accessories and wearing parts........................14

Warranty

Replacement parts list

Addresses

E518EN_04.DOC Safety 3

1. Safety

¾Read the Operator's Manual and the general safety rules

(Material number 1239438, red document) in their entirety

before starting up the machine. Follow precisely the directions

contained therein.

¾Read the Operator's Manual and the safety instructions

(Material number 125699, red document) in their entirety

before starting up the machine. Follow precisely the directions

contained therein.

¾The safety regulations according to DIN VDE, CEE, AFNOR

and other regulations which are valid in individual countries

should be adhered to.

Danger

Lethal danger due to electric shock!

¾Remove the plug from the plug socket before undertaking any

maintenance work on the machine.

¾Check the plug, the cable and the machine for damage each

time before the appliance is used.

¾Keep the machine dry and do not operate in damp rooms.

¾When using the electric tool outside, connect the fault current

(FI) protective switch with a maximum breaking current of

30 mA.

Warning

Danger of injury possible due to improper handling!

¾When working with the machine, wear safety glasses, hearing

protection, protective gloves and work shoes.

¾Do not plug in the plug unless the machine has been

switched off. Pull out the mains plug after use.

Warning

Risk of injury to the hands!

¾Do not place your hand into the processing line.

¾Use both hands to hold the machine.

USA/CAN

Rest of the world

4 Safety E518EN_04.DOC

Caution

Damage to property possible due to improper handling!

The machine will be damaged or destroyed.

¾Do not use the power cord to carry the machine.

¾Always guide the electric cord away from the back of the

machine and do not pull it across sharp edges.

¾Arrange for start-ups and checks on manual electric tools to

be carried out by a trained specialist. Only used the original

accessories provided by TRUMPF.

Warning

Risk of injury from chip!

¾Use chip deflector.

E518EN_04.DOC Description 5

2. Description

5

15

19

20

23

21

24

20

25

127

5 Eccentric shaft

15 Ram

19 Adjusting screw

20 Upper blade and lower blade

21 Fixing screw for the upper blade

23 Fixing screw for the lower blade

24 Fixed blade carrier

25 Chip deflector

127 On/Off switch

TruTool S 250

Fig. 36728

6 Description E518EN_04.DOC

2.1 Correct use

Warning

Risk of injury!

¾For processing and materials, only use machines which are

named in "Correct use".

The TRUMPF portable shears TruTool S 250 are an electric hand

tool used for the following applications:

•Slitting of plate-shaped workpieces made of steel, aluminium,

non-ferrous heavy metal and plastic.

•Slitting straight or curved exterior and interior cutouts.

•Slitting along scribed lines.

E518EN_04.DOC Description 7

2.2 Technical data TruTool S 250

Rest of the world USA

Values Values Values Values

Voltage 230 V 120 V 110 V 120 V

Frequency 50/60 Hz 50/60 Hz 50 Hz 50/60 Hz

•Steel

400 N/mm²

•Steel

600 N/mm²

•Steel

800 N/mm²

•Aluminium

250 N/mm²

2.5 mm

2.0 mm

1.5 mm

3.0 mm

2.5 mm

2.0 mm

1.5 mm

3.0 mm

2.5 mm

2.0 mm

1.5 mm

3.0 mm

0.1 in

0.079 in

0.06 in

0.12 in

Working speed 4-7m/min 4-7m/min 4-7m/min 13-23 ft/min

Starting hole

diameter

28 mm 28 mm 28 mm 1.1 in

Nominal power

consumption

500 W 500 W 500 W 500 W

Stroke rate with

nominal load

1760/min 1600/min 1600/min 1600/min

Weight 2.2 kg 2.2 kg 2.2 kg 5.1 lbs

Smallest radius

with curved

cutouts

20 mm 20 mm 20 mm 0.787 in

Protective

insulation

Class II Class II Class II Class II

Technical data

Noise and vibration Measured values in accordance

with EN 60745

A-weighted sound level Typically 81 dB (A)

A-weighted acoustic power level Typically 85 dB (A)

Hand-arm vibration Typically 2.6 m/s²

Measured values for noise and vibration

Note

The measured values specified above may be exceeded while

working.

Tab. 1

Tab. 2

8 Tool assembly E518EN_04.DOC

3. Tool assembly

3.1 Selecting the blade

Caution

Damage to property can result from improper blade

selection!

The quality of the cut will be severely impaired and the

individual tools will be overloaded.

¾Use only appropriate tools.

The blade is notable for the following points:

•Moving cutter blade (upper blade) and fixed cutter blade (lower

blade) are identical in shape and can be used interchangeably

(above or below).

•All blades have four cutting edges.

•They are non-regrindable "4-way multi-edge, throw-away

cutters".

Notes

•Two different blade types can be selected for the machining

process, depending on the sheet thickness or the tensile

strength of the workpiece.

•Standard blades with a tensile strength of ≤400 N/mm² have no

special identification marking. Chromium steel blades are

marked with "Cr".

Blade type Sheet thickness

ranges

(mm)

Type of material

and

Tensile strength

Material No.

Standard 0.3-3.0 Aluminium

250 N/mm²

127911

Standard 0.3-2.5 Mild steel

400 N/mm²

127911

Cr 0.3-2.0 Stainless steel

600 N/mm²

919761

Cr 0.3-1.5 Stainless steel

800 N/mm²

919761

Tab. 3

E518EN_04.DOC Tool assembly 9

3.2 Setting the cutting clearance

The blade clearance "a" is factory-set to a sheet thickness of

2.0 mm when the machine is first delivered (see Fig. 10182, Pg.

12).

Set the following values to obtain optimum cutting results:

Sheet thickness [mm] Blade clearance [mm]

0.3-0.8 0.1

0.8-1.3 0.2

1.3-1.8 0.3

1.8-2.5 0.4

1. Push the On/Off switch several times until the moving cutter

blade has reached the lower dead point.

2. Loosen the lower blade.

3. Set the blade to the required clearance using the adjusting

screw (19).

4. Retighten the blade.

5. Tighten the adjusting screw (19) slightly.

6. Check clearance with the setting gauge.

Tab. 4

10 Operation E518EN_04.DOC

4. Operation

4.1 Working with the TruTool S 250

¾Move the On/Off switch to the front.

1. Do not move the machine towards the workpiece until full

speed has been reached.

2. Machine/process the material.

–Move the device forward at an angle of 80 to 90° to the

sheet surface.

Requirements for the cutting of radiuses

•Do not tilt the machine.

•Proceed with a low feed rate.

Requirements for cutting near the margin

¾Cut in upside-down position, meaning that the cutting table is

facing upwards.

Note

Do not burden the device to such an extent that it comes to a

standstill.

¾Move On/Off switch to the rear.

Switching on the

TruTool S 250

Working with the

TruTool S 250

Fig. 37872

Switching off the

TruTool S 250

E518EN_04.DOC Maintenance 11

5. Maintenance

Danger

Possible lethal danger due to electric shock!

¾Pull the plug out of the socket when carrying out tool changes

and before all maintenance work on the machine.

Caution

Damage to property possible due to blunt tools!

Overloading of the machine.

¾Check the cutting edge of the cutting tool hourly for wear.

Sharp blades provide good cutting performance and are

easier on the machine. Replace blades promptly.

Warning

Risk of possible injury due to improper repairs!

The machine does not function properly.

¾Repairs should be carried out only by a trained specialist.

Note

Check tools hourly for wear.

Maintenance point Procedure and time interval Recommended lubricants Order No.

Lubrication

agents

Moving cutter blade Check hourly - -

Fixed cutter blade Check hourly - -

Ram guide Every 20 operating hours Lubricating grease "G1" 0139440

Gearbox and

gear head (2)

After 300 operating hours, arrange

for a trained specialist to

relubricate or to replace the

lubricating grease

Lubricating grease "G1" 0139440

Fixed cutter blade Turn over as needed - -

Fixed cutter blade Replace as needed - -

Moving cutter blade Turn over as needed - -

Moving cutter blade Replace as needed - -

Ventilation slots Clean as needed - -

Maintenance table

Tab. 5

12 Maintenance E518EN_04.DOC

5.1 Changing the blade

Danger

Possible lethal danger due to electric shock!

¾Pull the plug out of the socket when carrying out tool changes

and before all maintenance work on the machine.

Upper and lower blades are identical. They each have 4 cutting

edges and can be used interchangeably.

In the event of insufficient cutting performance, rotate each of the

blades by 90° respectively or replace them.

1. Loosen the screw on the respective blade.

2. Rotate blade by 90°.

3. Tighten the screw.

Note

Take care to ensure that the adjusting screw (19) is up against the

lower blade.

15

20

20

23 19

a Blade clearance

15 Ram

19 Adjusting screw

20 Upper blade and lower blade

23 Fixing screw

Fig. 10182

E518EN_04.DOC Maintenance 13

5.2 Replacing carbon brushes

The motor comes to a standstill when the carbon brushes are worn

out.

¾Have the carbon brushes checked and replaced as needed by

a trained technician.

Note

Only use original replacement parts and observe the specifications

on the type plate.

14 Original accessories and wearing parts E518EN_04.DOC

6. Original accessories and wearing parts

Designation Original

acces-

sories

deli-

vered

Wea-

ring

parts

Optio-

nal

Material

-number

2 Standard blade for the machining

of mild steel

+ + 127911

2 Chromium steel blades for the

machining of high-tensile sheets

+ + 919761

Allen key DIN 911-4 + 023065

Allen key DIN 911-2.5 + 067822

Case + 971396

Lubricating grease "G1" (900 g) can + 0139440

Lubricating grease "G1" (25 g) tube + 0344969

Operator's manual + 1254078

Safety instructions (printed in red),

other countries

+ 125699

Safety instructions (printed in red),

USA

+ 1239438

Original accessories, wearing parts and optional items

Note

Moving cutter blade (upper blade) and fixed cutter blade (lower

blade) are identical in shape and can be used interchangeably

(above or below).

All blades have 4 cutting edges. They are non-regrindable "4-way

multi-edge, throw-away cutters".

To ensure fast delivery of the correct original and wearing parts:

1. Give the order number.

2. Enter further order data:

–Tension data

–Number of pieces

–Machine type

3. Give complete dispatch data:

–Correct address.

–Required delivery type (e.g. air mail, courier, express mail,

ordinary freight, parcel post).

4. Send the order to the TRUMPF representative office. For

TRUMPF service addresses, see the address list at the end of

the document.

Tab. 6

Ordering wearing parts

Table of contents

Other Trumpf Industrial Equipment manuals

Trumpf

Trumpf TruPlasma RF 1001 User manual

Trumpf

Trumpf PFO 33 User manual

Trumpf

Trumpf TC 2020R User manual

Trumpf

Trumpf F 300-2 Plus User manual

Trumpf

Trumpf OMLOX SATELLITE User manual

Trumpf

Trumpf TruTool TKA 500 User manual

Trumpf

Trumpf TRUPUNCH 5000 User manual

Trumpf

Trumpf BendMaster 60 User manual

Trumpf

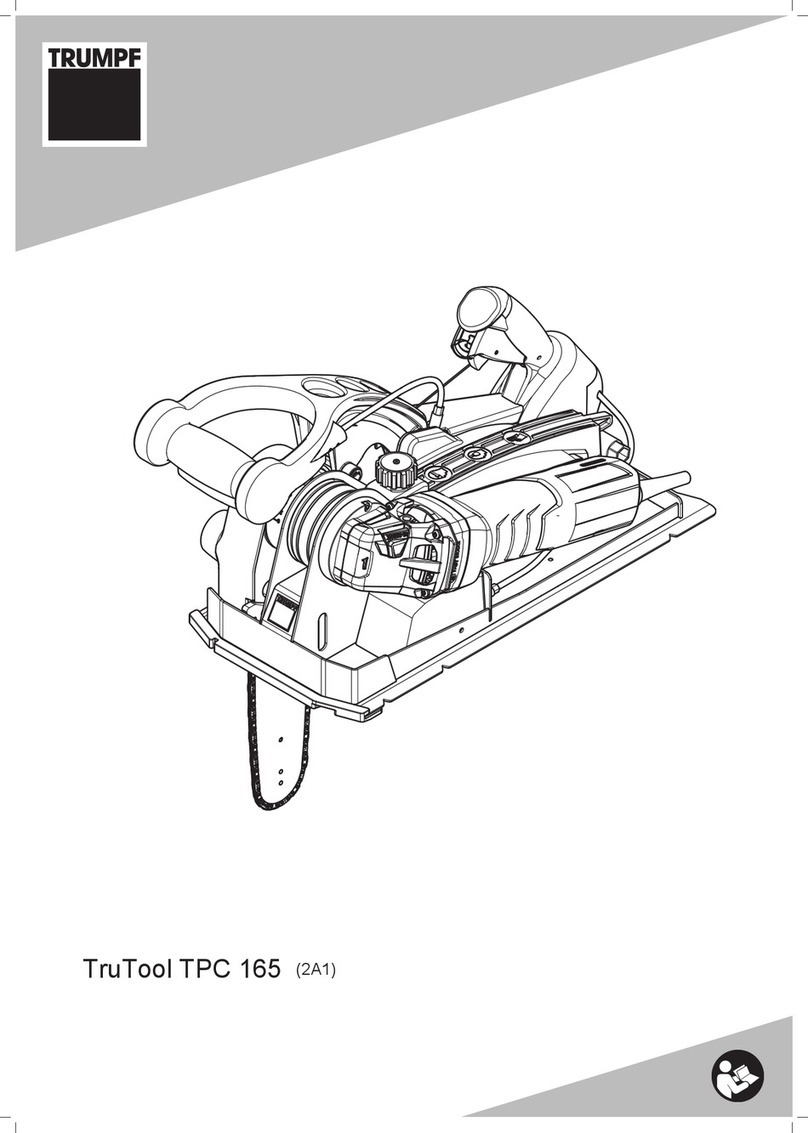

Trumpf TruTool TPC 165 (2A1) User manual

Trumpf

Trumpf Track&Trace User manual