Trumpf TRUPUNCH 5000 User manual

Operator's manual

TruPunch 5000

Operator's manual

TruPunch 5000

Original operator's manual

Edition: 2008-11-01

Ordering information Please specify the following when ordering this document:

Operator's manual

TruPunch 5000

Edition 2008-11-01

Document number B380

Ordering address TRUMPF Werkzeugmaschinen GmbH + Co. KG

Technische Dokumentation

Johann-Maus-Straße 2

D-71254 Ditzingen

Tel.: +49 7156 303 - 0

Fax: +49 7156 303 - 30540

Internet: http://www.trumpf.com

For "partly completed machinery" in accordance with the EC Machinery

Directive, this document corresponds to the assembly instructions.

© TRUMPF Werkzeugmaschinen GmbH + Co. KG

0-6 Contents B380EN00_OHNE FELDF.DOC

Contents

Chapter 1 Safety

1. For your safety............................................................... 1-3

2. Terminology ................................................................... 1-4

3. Operational safety ......................................................... 1-5

3.1 Intended use of the system.............................................. 1-5

3.2 Measures to be taken by the user/operator..................... 1-7

Danger signs and warnings........................................ 1-7

Symbols...................................................................... 1-7

Signaling words .......................................................... 1-8

Information on the source and type and how

to avoid the danger..................................................... 1-8

Instructing personnel .................................................. 1-9

Duty of care when handling the system ..................... 1-9

Eliminating malfunctions during operation................ 1-12

Using designated spare parts and

operating materials................................................... 1-12

Water protection ....................................................... 1-13

3.3 Measures taken by the manufacturer............................ 1-14

Securing of the danger zone of the system..............1-14

4. Laser safety.................................................................. 1-16

5. Danger due to magnetic fields ................................... 1-17

6. Overview of residual risks.......................................... 1-18

B380EN00_OHNE FELDF.DOC Contents 0-7

Chapter 2 TruPunch 5000 Installation Conditions

Responsibilities.......................................................................... 2-3

1. Planning aid ................................................................... 2-4

2. Installation site............................................................... 2-6

2.1 Space requirements......................................................... 2-6

2.2 Floor requirements........................................................... 2-6

2.3 Load indications............................................................... 2-8

2.4 Ambient conditions ........................................................ 2-11

2.5 Air purity......................................................................... 2-11

3. Electrical supply .......................................................... 2-12

3.1 Power supply ................................................................. 2-12

Isolating transformer................................................. 2-13

3.2 Connected loads/fuse protection................................... 2-15

3.3 Remote diagnostics ....................................................... 2-15

3.4 Network connection....................................................... 2-16

4. Compressed air supply...............................................2-17

5. Operating materials..................................................... 2-20

5.1 Operating materials for the hydraulic system................ 2-20

5.2 Cooling water for the cooling unit.................................. 2-21

5.3 Materials ........................................................................ 2-21

5.4 Pallets for SheetMaster (optional) ................................. 2-23

5.5 Older tool cartridges ...................................................... 2-23

5.6 New MultiTools and tapping tools.................................. 2-25

6. Transport...................................................................... 2-26

6.1 Measures to be taken by the customer .........................2-27

Machine delivery....................................................... 2-27

Unloading the machine from the truck...................... 2-28

Transporting the machine to the installation site......2-31

Installing the machine............................................... 2-32

0-8 Contents B380EN00_OHNE FELDF.DOC

Chapter 3 Description

1. The machine concept.................................................... 3-4

2. Technical data................................................................ 3-7

3. The most important assemblies................................... 3-8

3.1 Machine frame................................................................. 3-9

3.2 Punching head............................................................... 3-10

3.3 Coordinate guide with linear magazine ......................... 3-11

3.4 Drives............................................................................. 3-12

3.5 Part removal .................................................................. 3-13

4. Tools ............................................................................. 3-14

4.1 The tool system ............................................................. 3-14

4.2 Components of a tool set............................................... 3-16

Punch........................................................................ 3-16

Punch selection ........................................................ 3-18

Alignment ring........................................................... 3-20

Die ............................................................................ 3-20

Stripper..................................................................... 3-22

4.3 Stripper selection........................................................... 3-23

Table 1: Short, flat punch ......................................... 3-26

Table 2: Long, flat punch.......................................... 3-27

Continuation of table 2.............................................. 3-28

Table 3: Angle-sheared punch ................................. 3-29

Stripper selection examples ..................................... 3-30

4.4 Tool innovations............................................................. 3-33

Roller tools................................................................ 3-33

Roller deburring tool and deburring MultiTool.......... 3-35

TRUMPF MultiTools ................................................. 3-36

Tapping tools............................................................ 3-41

Clean cutting with TRUMPF MultiShear................... 3-43

Press brake bending with the

TRUMPF MultiBend.................................................. 3-44

Quick beading........................................................... 3-45

Engraving.................................................................. 3-45

Adaptive stroke calibration ....................................... 3-46

5. Maximum output tables............................................... 3-48

5.1 Calculation formulae...................................................... 3-48

5.2 Influencing factors.......................................................... 3-49

5.3 Punch............................................................................. 3-51

5.4 Dies................................................................................ 3-51

5.5 Table overview............................................................... 3-53

B380EN00_OHNE FELDF.DOC Contents 0-9

6. Stroke rate tables......................................................... 3-56

6.1 Influencing factors.......................................................... 3-56

6.2 Table overview: TruPunch 5000 (medium format)........3-57

Standard tool ............................................................ 3-57

Whisper tool.............................................................. 3-59

Standard tool with active presser foot...................... 3-60

Long standard tool with active presser foot..............3-61

MultiTool................................................................... 3-62

Forming tool.............................................................. 3-63

6.3 Table overview: TruPunch 5000 (large format)............. 3-64

Standard tool ............................................................ 3-64

Whisper tool.............................................................. 3-66

Standard tool with active presser foot...................... 3-67

Long standard tool with active presser foot..............3-68

MultiTool................................................................... 3-69

Forming tool.............................................................. 3-70

7. Technical information: Automation........................... 3-71

7.1 Automation made to measure ....................................... 3-71

7.2 Overview of automation................................................. 3-72

7.3 Simple automation......................................................... 3-73

SheetMaster ............................................................. 3-74

Loading table (TruPunch 5000 only)........................3-78

GripMaster................................................................ 3-79

ShearMaster (not TruPunch 3000)........................... 3-81

7.4 Flexible manufacturing cell............................................ 3-83

ToolMaster (only TruPunch 3000 and

TruMatic 6000).......................................................... 3-84

Cart systems with travel rails.................................... 3-87

Cart system with toothed belt drive .......................... 3-89

Characteristic features.............................................. 3-90

SortMaster Box......................................................... 3-91

SortMaster Pallet...................................................... 3-92

7.5 Flexible manufacturing cell with TRUMPF

compact store ................................................................ 3-94

7.6 Flexible sheet machining system................................... 3-96

7.7 Control system and administration for connection

to storage....................................................................... 3-97

8. Control system technology ........................................ 3-98

9. Programming ............................................................. 3-100

9.1 Directly at the machine................................................ 3-100

9.2 In the office .................................................................. 3-101

Defining machining: What is done

automatically?......................................................... 3-102

0-10 Contents B380EN00_OHNE FELDF.DOC

10. The most important options..................................... 3-103

10.1 Active die ..................................................................... 3-104

10.2 Die spray lubrication.................................................... 3-105

10.3 Brush tables with loading and unloading aid...............3-106

10.4 Height-adjustable clamps ............................................ 3-107

Chapter 4 Operation

Part 1: Control elements ........................................................... 4-7

1. Control elements: Overview......................................... 4-7

2. Control panel with color display.................................. 4-9

2.1 Operating elements of the machine............................... 4-10

2.2 Operating elements of the control system..................... 4-14

3. Keyboard ...................................................................... 4-18

4. USB connection........................................................... 4-19

Part 2: User interface............................................................... 4-20

1. Structure of the user interface ................................... 4-20

1.1 Menu bar........................................................................ 4-21

1.2 Status line...................................................................... 4-21

1.3 Message bar.................................................................. 4-22

1.4 Softkey bar..................................................................... 4-22

1.5 Display area................................................................... 4-22

2. Machine submodes ..................................................... 4-23

2.1 AUTOMATIC submode.................................................. 4-23

2.2 MDA submode............................................................... 4-24

2.3 JOG submode................................................................ 4-24

3. Control areas................................................................ 4-25

4. Diagnostics .................................................................. 4-26

5. PRODUCTION Operation............................................. 4-27

5.1 PRODUCTION Single job.............................................. 4-27

Layout of graphics .................................................... 4-27

B380EN00_OHNE FELDF.DOC Contents 0-11

5.2 PRODUCTION Production plan .................................... 4-30

5.3 NC program management in the NCU .......................... 4-32

5.4 PRODUCING machine components ............................. 4-33

5.5 PRODUCTION Program options................................... 4-34

5.6 PRODUCTION Switch elements ................................... 4-35

Operating the switch elements................................. 4-35

General switch elements .......................................... 4-36

Z axis calibration (optional)....................................... 4-38

Switch elements H+L diagnostics page 1................. 4-39

Switch elements H+L diagnostics page 2................. 4-39

Switch elements H+L diagnostics page 3................. 4-39

Switch elements H+L diagnostics page 4................. 4-39

SortMaster Box switch elements (optional).............. 4-40

GripMaster switch elements (optional)..................... 4-40

SheetMaster axis switch elements (optional)........... 4-40

SheetMaster General switch elements (optional)..... 4-41

5.7 PRODUCTION: Tables.................................................. 4-42

Loading sheets ......................................................... 4-43

Sheet unloading........................................................ 4-46

Sheet technology...................................................... 4-54

Workpiece removal................................................... 4-55

Repositioning............................................................ 4-60

Tool technology – Tapping (optional)....................... 4-61

Tool technology – Engraving (optional).................... 4-62

Tool technology – Tapping (optional)....................... 4-63

Tool technology – Punching/general........................ 4-64

Tool technology – Quick beading (optional)............. 4-67

Tool technology – Multishear (optional) ................... 4-67

Tool technology – Roller tool (optional).................... 4-69

Tool technology – Engraving (optional).................... 4-71

6. SETUP Operation......................................................... 4-72

6.1 SET-UP Switch elements .............................................. 4-72

General switch elements .......................................... 4-72

Punching switch elements........................................ 4-73

Switch elements H+L diagnostics page 1................. 4-73

Switch elements H+L diagnostics page 2................. 4-74

Switch elements H+L diagnostics page 3................. 4-74

Switch elements H+L diagnostics page 4................. 4-74

SortMaster Box switch elements (optional).............. 4-74

GripMaster switch elements (optional)..................... 4-75

Support table switch elements (optional) .................4-75

SheetMaster switch elements (optional) .................. 4-76

Stripper unit switch elements (optional) ................... 4-77

ToolMaster switch element (optional)....................... 4-77

Loading table switch elements (optional)................. 4-78

0-12 Contents B380EN00_OHNE FELDF.DOC

6.2 SET UP Jog mode......................................................... 4-79

6.3 MDA SET-UP................................................................. 4-80

7. PROGRAMMING Operation......................................... 4-81

7.1 NC Editor ....................................................................... 4-81

7.2 PROGRAMMING NC program management................ 4-81

7.3 PROGRAMMING File management.............................. 4-83

7.4 Sending NC programs from the program manager....... 4-86

8. TOOLING Operation .................................................... 4-87

8.1 TOOLING Tool table (autom.) ....................................... 4-87

8.2 TOOLING Tool table (manual) ...................................... 4-87

Setting up rails.......................................................... 4-87

Setting up the ToolMaster (optional) ........................ 4-87

Set up rail/tool (optional)........................................... 4-89

8.3 Selecting NC programs.................................................. 4-90

8.4 TOOLING Rail allocation............................................... 4-91

8.5 TOOLING tool allocation................................................ 4-91

8.6 TOOLING Tools............................................................. 4-93

Required tools........................................................... 4-93

Tool change list......................................................... 4-93

General tool data...................................................... 4-94

Tool master data/status data.................................... 4-95

8.7 Explanation of the tool data........................................... 4-97

9. MAINTENANCE/START-UP Operation..................... 4-102

9.1 Maintenance/start-up Data backup..............................4-102

Changing the configuration for a partial backup.....4-104

Starting a partial backup manually .........................4-104

Starting a complete backup.................................... 4-105

9.2 MAINTENANCE/START-UP Display...........................4-105

10. DIAGNOSTICS Operation.......................................... 4-106

10.1 DIAGNOSTICS Fault diagnostics................................ 4-106

10.2 DIAGNOSTICS I/O diagnostics...................................4-107

10.3 DIAGNOSTICS Remote diagnostics...........................4-107

10.4 DIAGNOSTICS Display original position..................... 4-108

11. Integrated MDR Operation (optional)....................... 4-109

11.1 MDR Message text......................................................4-109

11.2 MDR Creating and modifying message texts..............4-110

11.3 MDR Displaying and editing machine data..................4-112

11.4 MDR Creating and changing interruptions ..................4-114

11.5 MDR Evaluating machine data....................................4-115

11.6 MDR Displaying the times in list form.......................... 4-116

11.7 MDR Changing the time ..............................................4-116

B380EN00_OHNE FELDF.DOC Contents 0-13

Part 3: Operating the machine.............................................. 4-117

1. Switching the machine on and off...........................4-118

1.1 Switching on the machine............................................4-118

1.2 Switching off the machine in the event of

malfunctions or emergencies.......................................4-119

1.3 Switching off the machine............................................ 4-119

2. Executing a program................................................. 4-120

2.1 Executing a program automatically ............................. 4-120

2.2 Executing a program with the softpunch (optional).....4-121

2.3 Triggering a single stroke ............................................ 4-122

2.4 Changing the forming depth ........................................ 4-123

2.5 Program stop during execution.................................... 4-124

2.6 Stopping programs ......................................................4-124

2.7 Reentry into a program................................................ 4-125

3. Working with the production plan ........................... 4-127

3.1 Creating a production plan...........................................4-127

3.2 Executing a production plan ........................................ 4-128

3.3 Restarting the execution of the production plan

after a program interruption.........................................4-129

4. Moving the axes manually........................................ 4-130

5. Releasing the drive brakes....................................... 4-131

5.1 Releasing the X and Y axis drive brakes.....................4-131

6. Manual execution of the lubrication cycle.............. 4-132

7. Diagnostic functions ................................................. 4-133

7.1 Fault diagnostics.......................................................... 4-133

7.2 Displaying machine inputs and outputs....................... 4-134

7.3 Remote diagnosis via pcANYWHERE......................... 4-135

7.4 Querying the software version..................................... 4-135

8. Managing master files............................................... 4-136

8.1 Uploading NC programs from the USB interface ........ 4-136

8.2 Uploading NC programs from the hard disk................ 4-137

8.3 Output of NC programs via USB ainterface................. 4-138

8.4 NC program output on the hard disk drive...................4-139

8.5 Program part output via USB interface........................4-140

8.6 Deleting NC programs from the program manager..... 4-141

0-14 Contents B380EN00_OHNE FELDF.DOC

9. NC program management......................................... 4-142

9.1 Displaying NC text.......................................................4-142

9.2 Editing NC text............................................................. 4-143

Searching for a block in the NC text....................... 4-143

Searching for a function in the NC text................... 4-144

Searching for and replacing a function in the

NC text....................................................................4-144

Inserting an additional line......................................4-146

Copying and inserting text passages ..................... 4-147

Deleting text passages...........................................4-148

10. Editing tables based on NC text............................... 4-148

11. TOOLING..................................................................... 4-150

11.1 Creating an automatic tool table and loading the

tool rail .........................................................................4-150

11.2 Manually loading/unloading tools ................................ 4-151

11.3 Loading a tool from the rail onto the ToolMaster

(optional)...................................................................... 4-152

11.3 Correcting clamp positions .......................................... 4-153

11.4 Removing an active tool .............................................. 4-154

11.5 Unloading all tools ....................................................... 4-154

12. Operating the integrated MDR.................................. 4-154

12.1 Creating a message text..............................................4-155

12.2 Assigning a message text............................................4-155

12.3 Splitting up an interruption period................................ 4-156

12.4 Evaluating machine data ............................................. 4-157

13. Adjusting the pressure foot pressure ..................... 4-158

14. If problems arise........................................................ 4-159

14.1 Removing stripper from stripper adapter..................... 4-159

14.2 Removing the punch from the punching head............. 4-161

14.3 Removing the die from the die holder..........................4-164

14.4 Replacing the stripper segment................................... 4-165

15. Using ShearMaster (optional)................................... 4-166

15.1 Starting and stopping ShearMaster manually..............4-166

15.2 Change scrap container............................................... 4-167

15.3 Use ShearMaster in stacking mode.............................4-167

15.4 Technical notes............................................................4-168

15.5 Correcting malfunctions............................................... 4-168

Release tilted scrap skeleton..................................4-168

Release tilted scrap from the chute........................ 4-169

B380EN00_OHNE FELDF.DOC Contents 0-15

16. Using height-adjustable clamps .............................. 4-170

16.1 Moving height-adjustable clamps ................................ 4-170

16.2 Utilizing height-adjustable clamps............................... 4-171

16.3 Help if problem arises................................................. 4-171

Chapter 5 Maintenance of the machine

1. General guidelines......................................................... 5-4

2. Maintenance overview................................................... 5-5

3. Lubrication ..................................................................... 5-8

3.1 Overview.......................................................................... 5-8

3.2 Maintenance instructions............................................... 5-11

Longitudinal and transverse guides.......................... 5-11

Transverse carrier and table support bearings......... 5-13

Central lubrication..................................................... 5-14

Hydraulics................................................................. 5-15

Zero stop sensor (only TruPunch 5000

with automation) ....................................................... 5-20

Punch spray lubrication............................................5-21

Die spray lubrication (optional)................................. 5-24

Tapping lubrication unit (optional) ............................ 5-26

Die clamping piston clamp........................................ 5-30

Rail transverse carrier and table support .................5-31

Punch holder............................................................. 5-32

Active die (optional).................................................. 5-32

4. Hydraulic system......................................................... 5-34

4.1 Overview........................................................................ 5-34

4.2 Depressurizing the accumulator system........................ 5-35

4.3 Maintenance instructions............................................... 5-37

Hydraulic accumulator.............................................. 5-37

Hydraulics hose lines................................................ 5-41

Hydraulic unit............................................................ 5-43

5. Pneumatic system....................................................... 5-46

5.1 Overview........................................................................ 5-46

5.2 Maintenance instructions............................................... 5-47

Air cushions (optional).............................................. 5-47

Punch spray lubrication............................................5-48

0-16 Contents B380EN00_OHNE FELDF.DOC

6. Mechanical elements................................................... 5-50

6.1 Overview........................................................................ 5-50

6.2 Maintenance instructions............................................... 5-51

Punching tool adapter............................................... 5-51

Chip vacuum system: side channel blower.............. 5-52

Chip vacuum system: vacuum pipe..........................5-54

Chip vacuum system: chip flap.................................5-55

Chip vacuum system, complete................................ 5-57

Tool cartridge support slat........................................ 5-59

Clamps...................................................................... 5-60

Racks and guide rails ............................................... 5-61

Index pin(s)............................................................... 5-61

Brush field segment tables, parts flap and brush

tables (optional)........................................................ 5-62

Brush field segment tables....................................... 5-64

Compressed air maintenance unit............................ 5-67

Control panel ............................................................ 5-68

7. Electrics........................................................................ 5-69

7.1 Overview........................................................................ 5-69

7.2 Maintenance instructions............................................... 5-70

Switch cabinet: connectors and clamping screw

connections............................................................... 5-70

Switch cabinet: external air circuit............................ 5-70

Switch cabinet: NCU battery..................................... 5-71

Buffer battery box PC ............................................... 5-73

Safety light barrier and light barrier parts flap

(optional)................................................................... 5-76

Inductive proximity switch......................................... 5-77

Sensor system - stripper sensor............................... 5-78

8. Cooling unit.................................................................. 5-82

8.1 Maintenance instructions............................................... 5-82

9. Procedure after a collision ......................................... 5-87

10. Handling the setting device........................................ 5-88

10.1 Assigning the punch and alignment ring........................ 5-88

10.2 Determining the tool length............................................ 5-90

11. Regrinding tools .......................................................... 5-91

11.1 Compensating the regrind amount ................................ 5-92

B380EN00_OHNE FELDF.DOC Contents 0-17

Chapter 6 Maintenance of the automation

1. General guidelines......................................................... 6-5

2. Maintenance overview................................................... 6-6

2.1 SheetMaster and GripMaster

maintenance overview..................................................... 6-6

2.2 ToolMaster maintenance overview (40/70) ..................... 6-7

2.3 SortMaster Box maintenance overview........................... 6-7

2.4 SortMaster Pallet maintenance overview........................ 6-7

2.5 Maintenance overview Double cart with guide rails......... 6-8

2.6 Maintenance overview for double cart with toothed

belt drive .......................................................................... 6-9

2.7 ShearMaster maintenance overview ............................... 6-9

3. Lubrication ................................................................... 6-11

3.1 Lubrication chart for SheetMaster with GripMaster....... 6-11

3.2 Lubricant........................................................................ 6-12

3.3 Maintenance instructions............................................... 6-13

X axis guide strip at the SheetMaster....................... 6-13

Pick-up columns of the carrier cups at the

SheetMaster ............................................................. 6-14

Stripper unit (optional) guide rod on the

SheetMaster ............................................................. 6-15

Safety device of the suction frame at the

SheetMaster ............................................................. 6-16

Guide rods of the sheet thickness gauge at the

SheetMaster ............................................................. 6-17

Central lubrication on the SheetMaster.................... 6-18

X axis feedgear at the SheetMaster......................... 6-19

Z axis feedgear at the SheetMaster ......................... 6-19

Y axis feedgear at the SheetMaster (optional)......... 6-19

Guide rails at the GripMaster.................................... 6-20

Stop pins on the movable GripMaster......................6-20

Grippers on the GripMaster...................................... 6-21

3.4 Lubrication chart for ToolMaster (40/70) ....................... 6-22

3.5 Lubricant........................................................................ 6-23

3.6 Maintenance instructions............................................... 6-24

Lifting device bearing................................................ 6-24

Indexing.................................................................... 6-25

Shifting unit (ToolMaster (70)).................................. 6-26

Rotary table .............................................................. 6-27

Central lubrication..................................................... 6-27

Drive motor gearbox................................................. 6-28

0-18 Contents B380EN00_OHNE FELDF.DOC

3.7 Lubrication chart for SortMaster Box............................. 6-29

3.8 Lubricant........................................................................ 6-30

3.9 Maintenance instructions............................................... 6-30

Rolling elements of the four-point bearing................ 6-30

Inner toothing of slewing ring.................................... 6-32

3.10 Lubrication chart for SortMaster Pallet .......................... 6-33

3.11 Lubricant........................................................................ 6-34

3.12 Maintenance instructions............................................... 6-34

Cam .......................................................................... 6-34

Flange bearing unit................................................... 6-35

Roller chains and chain wheels................................ 6-35

Flat gearbox.............................................................. 6-35

Screw joints .............................................................. 6-36

Weld joints................................................................ 6-36

3.13 Lubrication chart for double unloading cart ................... 6-37

3.14 Lubricant........................................................................ 6-38

3.15 Maintenance instructions............................................... 6-38

Track rollers.............................................................. 6-38

Ball bearings............................................................. 6-39

Flange bearing unit................................................... 6-39

Roller chains and chain wheels................................ 6-40

Flat gearbox.............................................................. 6-40

Screw joints .............................................................. 6-41

Weld joints................................................................ 6-41

3.16 Lubrication chart for double cart with toothed

belt drive ........................................................................ 6-43

3.17 Lubricant........................................................................ 6-44

Running surfaces...................................................... 6-44

Track rollers.............................................................. 6-44

Ball bearings............................................................. 6-45

Flange bearing unit................................................... 6-46

Roller chains and chain wheels................................ 6-46

Flat gearbox.............................................................. 6-47

Screw joints .............................................................. 6-47

Weld joints................................................................ 6-48

3.18 Lubrication chart for ShearMaster ................................. 6-49

3.19 Lubricant........................................................................ 6-49

3.20 Maintenance instructions............................................... 6-50

4. Pneumatic components.............................................. 6-57

4.1 Pneumatic components on the SheetMaster and

scissor table................................................................... 6-57

4.2 Overview........................................................................ 6-57

4.3 Maintenance instructions............................................... 6-58

Pressure regulator.................................................... 6-58

Vacuum hoses in the suction frame ......................... 6-60

B380EN00_OHNE FELDF.DOC Contents 0-19

Filters in the suction cup vacuum connections.........6-61

Pneumatic bellows cylinder at the scissor table....... 6-62

Pneumatic hoses at the scissor table....................... 6-62

5. Mechanical components............................................. 6-63

5.1 Mechanical components at the SheetMaster and

GripMaster..................................................................... 6-63

5.2 Overview........................................................................ 6-63

5.3 Maintenance instructions............................................... 6-64

Dowelling of SheetMaster, GripMaster and

support table with movable GripMaster.................... 6-64

Vacuum cups on the SheetMaster ........................... 6-65

X axis, Z axis, and Y axis (optional) cable tow

chains at the SheetMaster........................................ 6-68

5.4 Mechanical components on the ShearMaster............... 6-69

Scrap container......................................................... 6-69

Conveyor belt............................................................ 6-70

6. Electrical components ................................................ 6-71

6.1 Maintenance of the electrical components at the

SheetMaster and scissor table ...................................... 6-71

6.2 Maintenance instructions............................................... 6-71

Switch cabinet of the SheetMaster: TASC 100

control system battery .............................................. 6-71

Light barriers at the scissor table.............................. 6-72

Chapter 7 Test certificate - Noise level TruPunch 5000

1. Test certificate ............................................................... 7-2

2. Measurement result....................................................... 7-3

3. Reference workpiece..................................................... 7-4

4. Position of the measuring points................................. 7-5

0-20 Contents B380EN00_OHNE FELDF.DOC

Chapter 8 Aligning MSL safety light barrier

1. Additional equipment for the alignment

procedure ....................................................................... 8-2

2. Set-up example .............................................................. 8-3

3. Alignment procedure..................................................... 8-4

Table of contents

Other Trumpf Industrial Equipment manuals

Trumpf

Trumpf TC 2020R User manual

Trumpf

Trumpf TruTool TKA 500 User manual

Trumpf

Trumpf PFO 33 User manual

Trumpf

Trumpf TruTool S 250 User manual

Trumpf

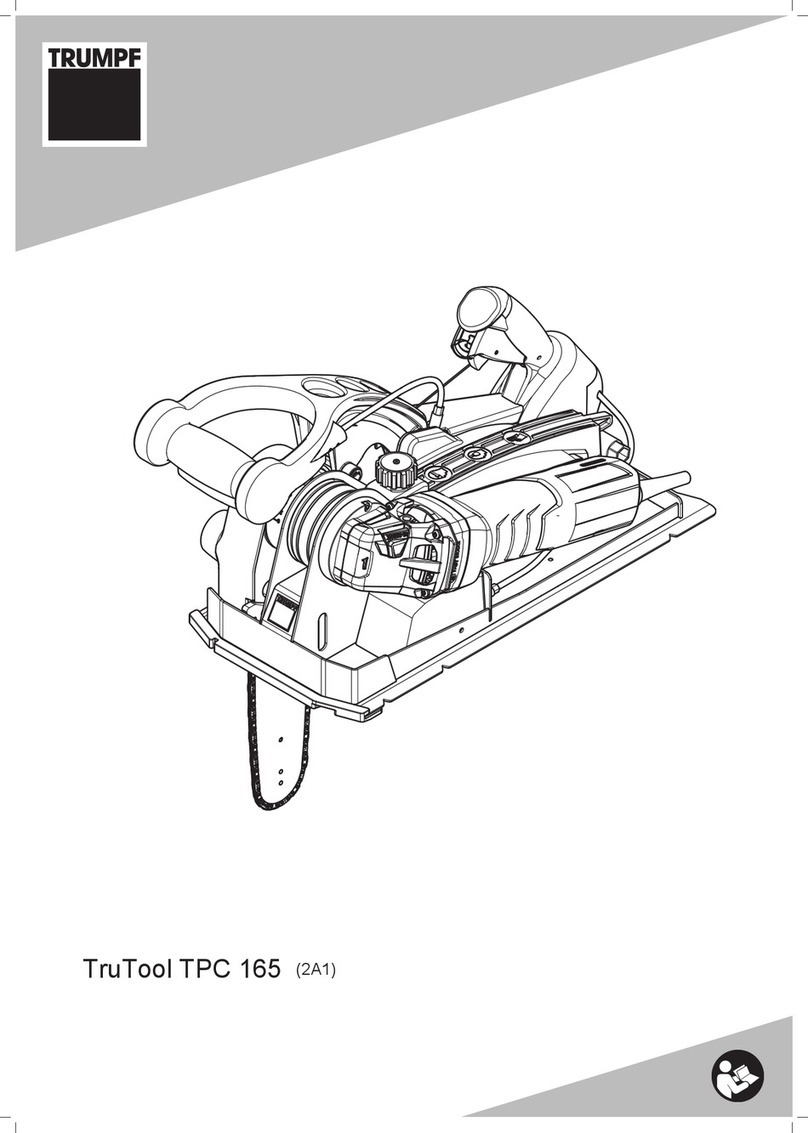

Trumpf TruTool TPC 165 (2A1) User manual

Trumpf

Trumpf F 300-2 Plus User manual

Trumpf

Trumpf Track&Trace User manual

Trumpf

Trumpf BendMaster 60 User manual

Trumpf

Trumpf TruPlasma RF 1001 User manual

Trumpf

Trumpf TruHeat HF 1000 Series User manual