Table of Contents

1. FUNDAMENTALS ABOUT THE SYSTEM ..................................................................1

1.1 Features of the TTP/TDP-244 Plus ............................................................................1

1.2 Model Naming Syntax............................................................................................1

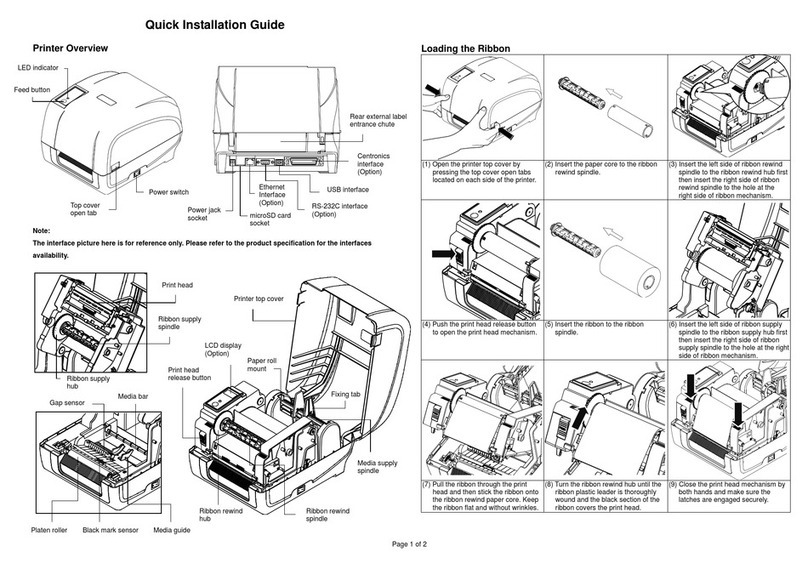

1.3 Overview ....................................................................................................................2

1.3.1 Front View...........................................................................................................2

1.3.2 Rear View...........................................................................................................3

1.4 Basic Specifications....................................................................................................4

1.5 Effective Print Area.....................................................................................................5

1.6 Available Bar Codes...................................................................................................5

1.7 Various Sensors.........................................................................................................6

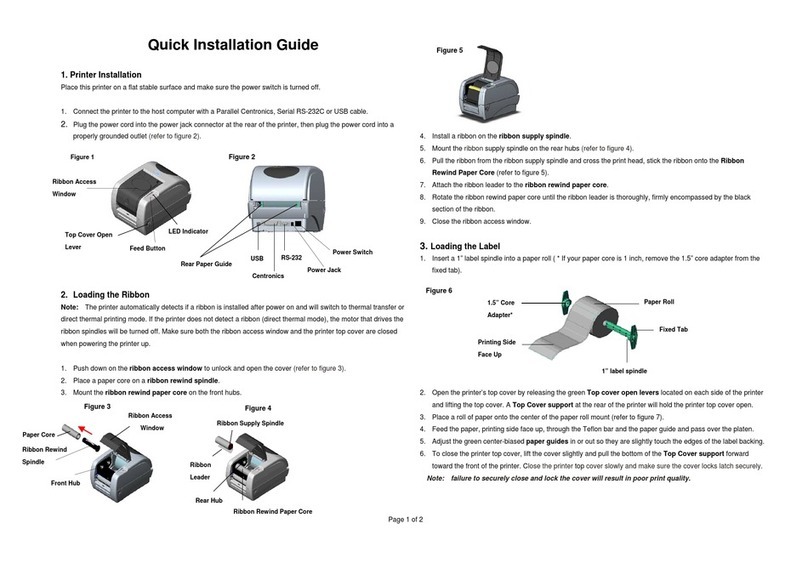

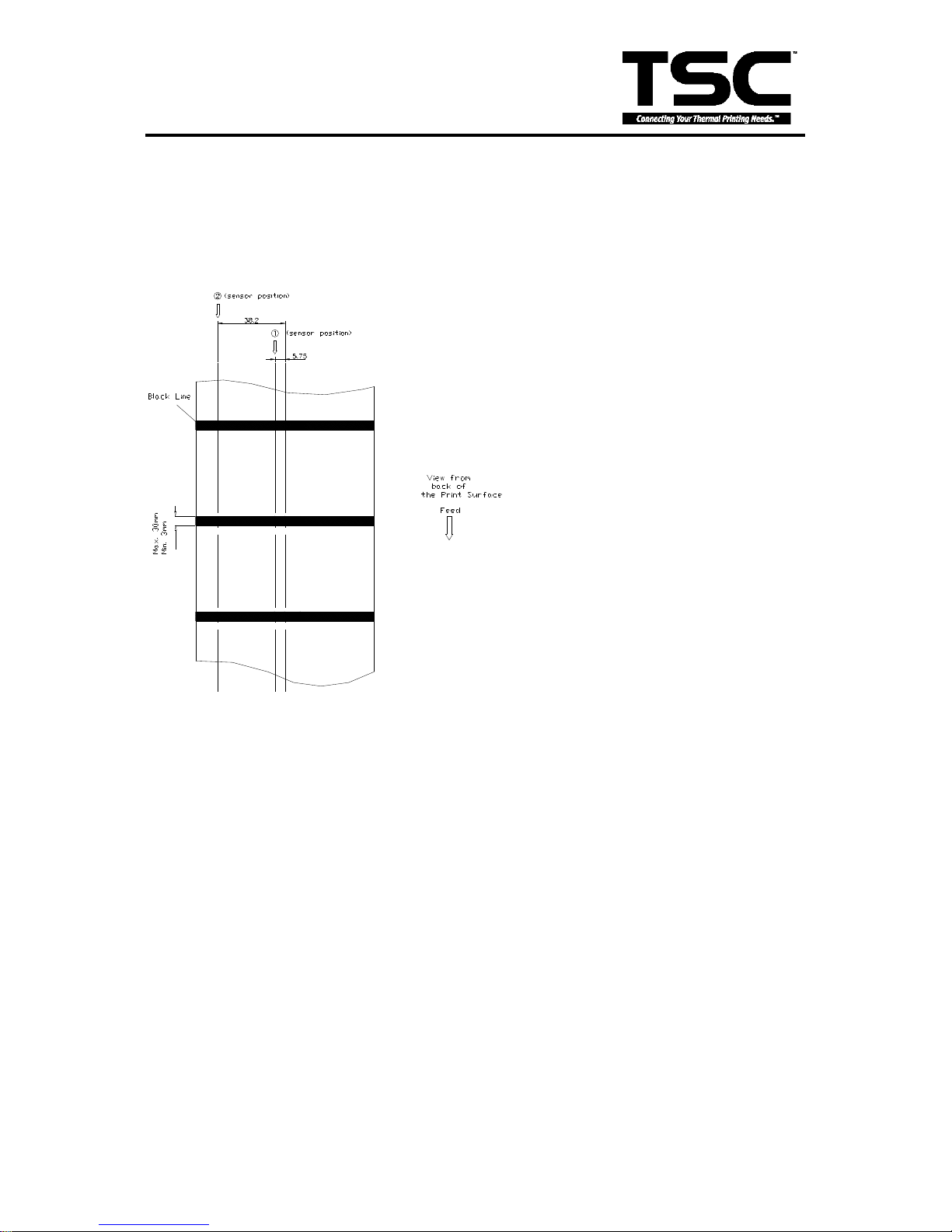

2. SUPPLY SPECIFICATIONS.............................................................................................8

2.1 Types of Paper...........................................................................................................8

2.2 Specifications.............................................................................................................8

2.3 Ribbon Sizes and Shapes ........................................................................................10

3. ELECTRONICS ..............................................................................................................11

3.1 Summary of Board Connectors ................................................................................11

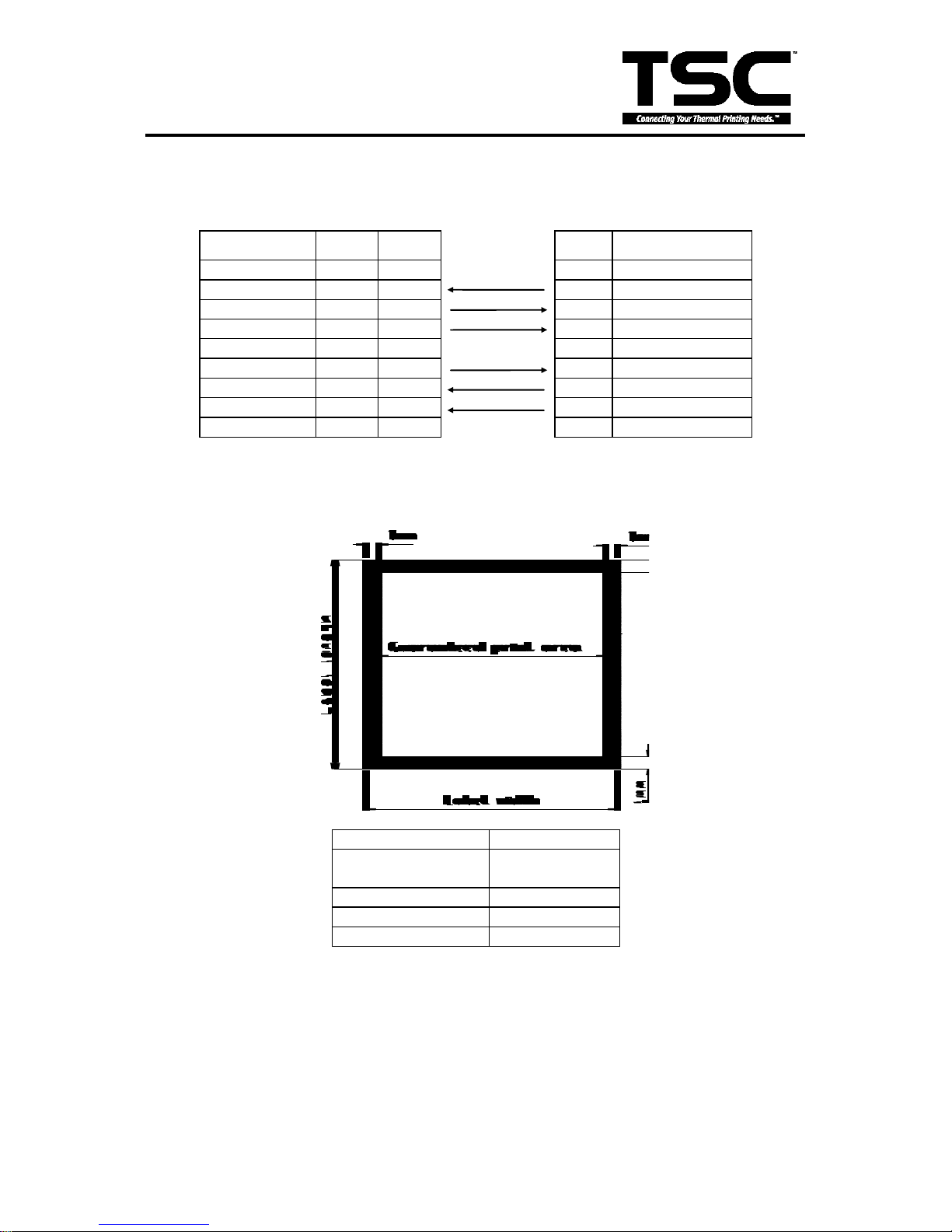

3.2 Pin Configuration......................................................................................................13

4. MECHANISM..................................................................................................................15

4.1 Mainboard Replacement...........................................................................................15

4.2 DC Motor Replacement............................................................................................17

4.3 Print Head Replacement ..........................................................................................21

4.4 Ribbon Rewind Spindle Encoder Replacement ........................................................23

4.5 Felt Fabric Replacement ..........................................................................................24

4.6 Stepping Motor Replacement...................................................................................26

4.7 Black Mark Sensor / Gap Sensor (Receiver) Replacement ......................................27

4.8 Ribbon Sensor (Receiver) Replacement...................................................................28

4.9 Ribbon Sensor (Transmitter) / Gap Sensor (Transmitter) Replacement ...................30