TSUBAKI E&M CO.

- 1 -

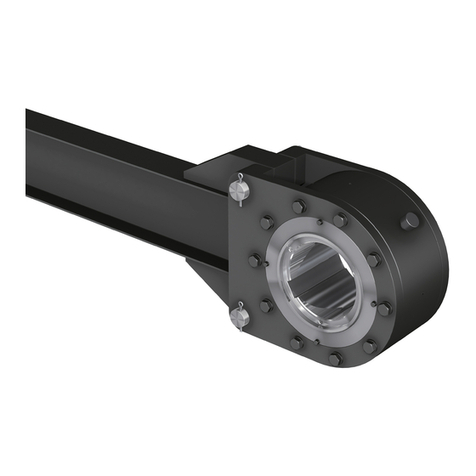

Cam Clutch Installation and Maintenance Instruction

MZEU Series

MZEU30(K),MZEU35(K), MZEU40(K) ,MZEU45(K),MZEU50(K) MZEU60(K),MZEU70(K),

MZEU80(K),MZEU90(K), MZEU100(K), MZEU130(K),MZEU150(K)

ThankyouforchoosingTsubakiE&M products.

Beforeinstallingor workingontheproduct,confirmitisthecorrect sizebycheckingitslabelandmakesure youhavethecompletesetof

arts.Ifanypartis missing, contact yourdistributor immediately.

This manual shouldbe considered an essential partoftheunitand remain withtheunit whenredistributed.

SAFETY

YourCamClutchisahighquality,sophisticatedunitwhichshouldbehandledbyexperiencedengineersonly.

For safetypurposes,make surethismanual iseasilyaccessiblebytheuser atalltimes.

Toensuresafetyand optimal performance, carefullyread this instruction manual in itsentirety.

Death or serious injury may resultfrom misuse, improper installationand/or improper maintenance of

this product. Please refer to the detailed instructions provided in this manual for installation and

maintenancespecifications.

USE CARE TO PREVENT INJURY

COMPLYWITH THE FOLLOWING TO

AVOIDSERIOUS PERSONAL INJURY:

1.Guardsmust beprovidedonallchain andsprocketinstallations in

accordancewithprovisions ofANSI/ASME B15.1-2000

“Safety Standards for Mechanical Power Transmission Apparatus,” and

ANSI/ASMEB20.1- 2012 “Safety Standards for Conveyors and Related

Equipment,” or other applicable safety standards. Whenrevisionsof

thesestandardsarepublished, theupdated editionshallapply.

2.Always lock outthepower switchbeforeinstalling, removing, lubricating

orservicingasystemwhichuses PTUCproduct.

3.Whenconnecting or disconnectingPTUCproducts,eyeprotectionisrequired.

Wearsafety glasses, protectiveclothing,gloves andsafetyshoes.

4.Improperinstallationor mounting,as wellas operatingconditionsand maintenance,

can affect the performanceofacamclutch.Thecamclutchshould be inspectedregularly.

“PTUC is used by U.S. Tsubaki to designate “Power Transmission Unit Components.”

PTUCproductsincludeCamClutchDISCO,POWER-LOCK

Ⓡ

,Shock Relay,Gearmotor,

HFDrive,Shock Damper,PowercylinderTM ,Couplings,SCRvariablespeed motorand

other likeproducts manufactured by/for Tsubaki.