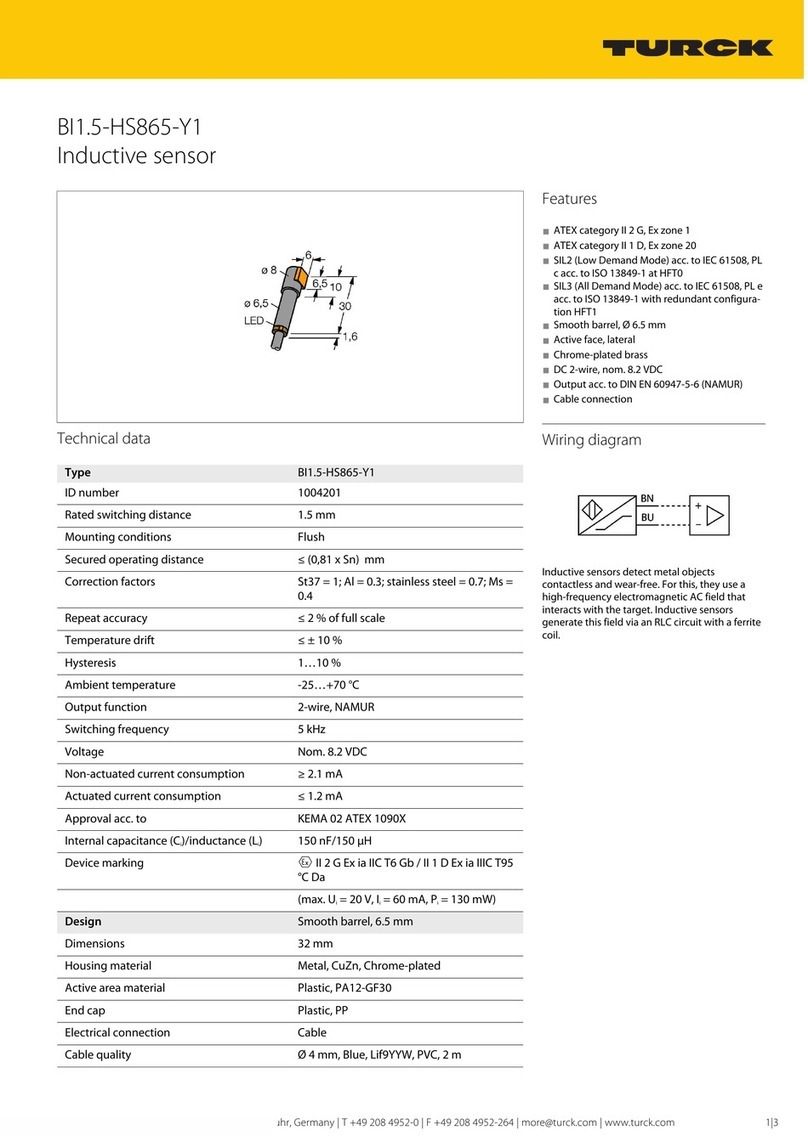

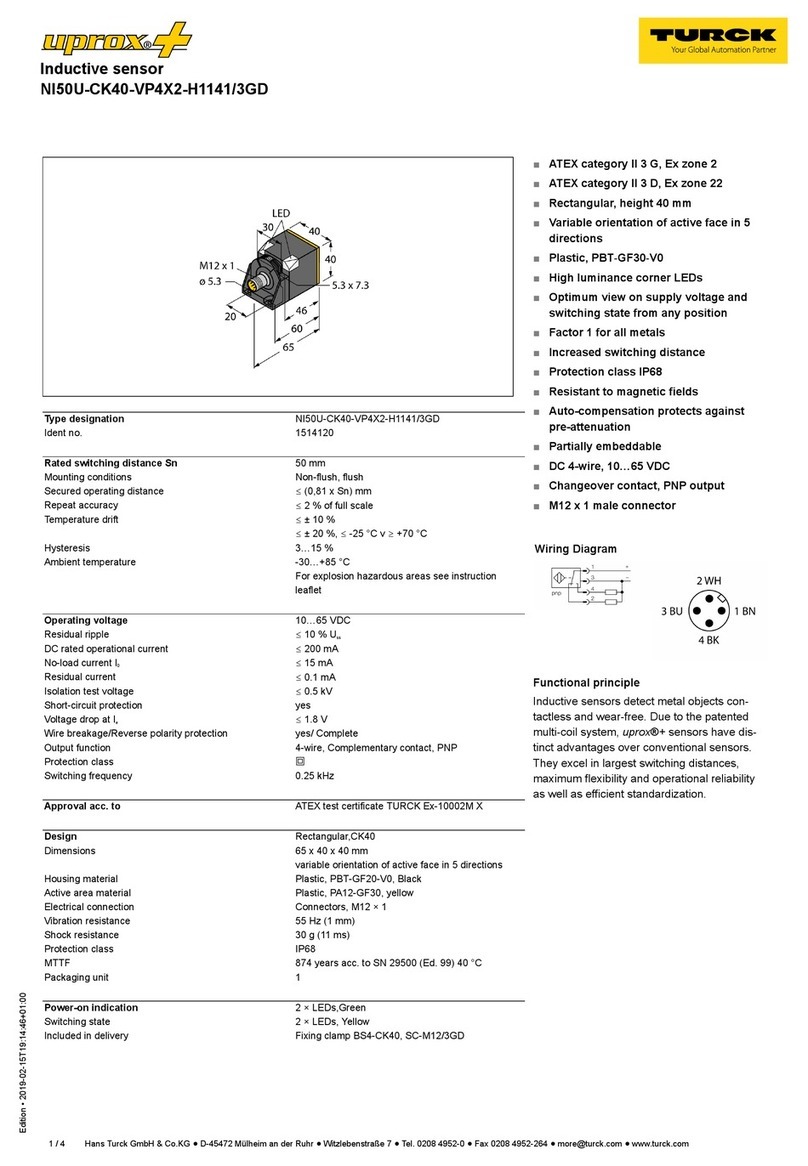

Inductive sensor

For the food industry

BI15U-EM30WD-AP6X-H1141/3GD

Edition • 2016-05-14T08:17:29+02:00

1 / 4

Hans Turck GmbH & Co.KG

ñ D-45472 Mülheim an der Ruhr

ñ Witzlebenstraße 7

ñ T

el. 0208 4952-0

ñ Fax 0208 4952-264

ñ [email protected] ñ www

.turck.com

Type code BI15U-EM30WD-AP6X-H1141/3GD

Ident no. 1634855

Rated switching distance Sn 15 mm

Mounting conditions flush

Assured switching distance ð (0,81 x Sn) mm

Repeatability ð 2 % of full scale

Temperature drift ð ± 10 %

ð ± 20 %, ð -25 °C , ï +70 °C

Hysteresis 3…15 %

Ambient temperature -40…+100 °C

in the explosion hazardous area see instruction

leaflet

Operating voltage 10… 30VDC

Residual ripple ð 10 % Uss

DC rated operational current ð 200 mA

No-load current I0ð 20 mA

Residual current ð 0.1 mA

Rated insulation voltage ð 0.5 kV

Short-circuit protection yes/ cyclic

Voltage drop at Ieð 1.8 V

Wire breakage / Reverse polarity protection yes/ complete

Output function 3-wire, NO contact, PNP

Protective insulation ÷

Switching frequency 0.75 kHz

Approval acc. to ATEX test certificate TURCK Ex-10002M X

Device designation É II 3 G Ex nA IIC T4 Gc/II 3 D Ex tc IIIC T110°C

Dc

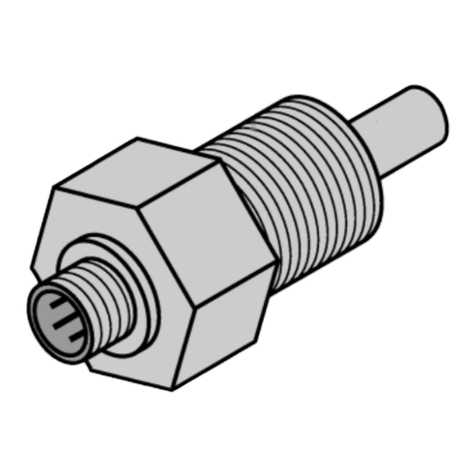

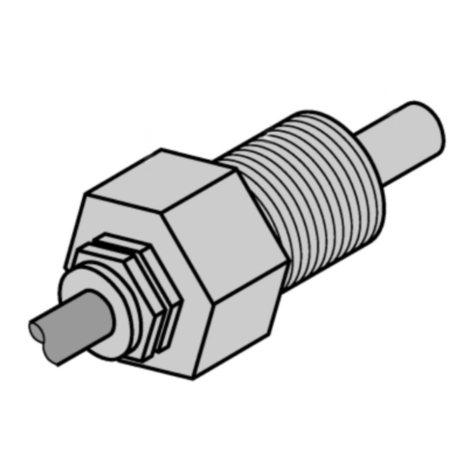

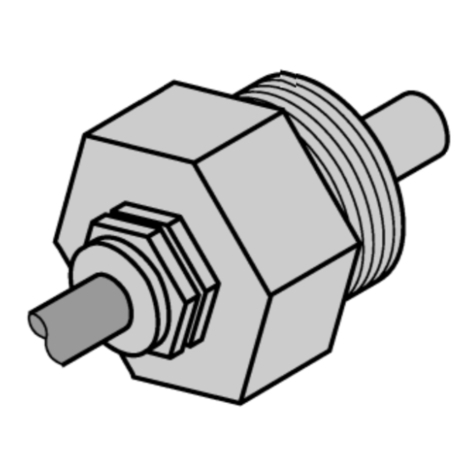

Construction Threaded barrel, M30 x 1.5

Dimensions 62 mm

Housing material Stainless steel, V4A (1.4404)

Active area material Plastic, LCP

Connector housing plastic, PP

Admissible pressure on front cap ð 10 bar

Max. tightening torque housing nut 75 Nm

Connection Flange connector, M12 x 1

Vibration resistance 55 Hz (1 mm)

Shock resistance 30 g (11 ms)

Protection class IP68 / IP69K

MTTF 874 years acc. to SN 29500 (Ed. 99) 40 °C

Switching state LED yellow

■ATEX category II 3 G, Ex Zone 2

■ATEX category II 3 D, Ex Zone 22

■Threaded barrel, M30 x 1.5

■Stainless steel, 1.4404

■Front cap made of liquid crystal poly-

mer

■Factor 1 for all metals

■Resistant to magnetic fields

■Temperatures -40 °C … +100 °C

■High protection class IP69K, for harsh

environments

■Special double-lip seal

■Protection against all common acid and

alkaline cleaning agents

■Laser engraved label, permanently legi-

ble

■DC 3-wire, 10…30 VDC

■NO contact, PNP output

■M12 x 1 male connector

Wiring Diagram

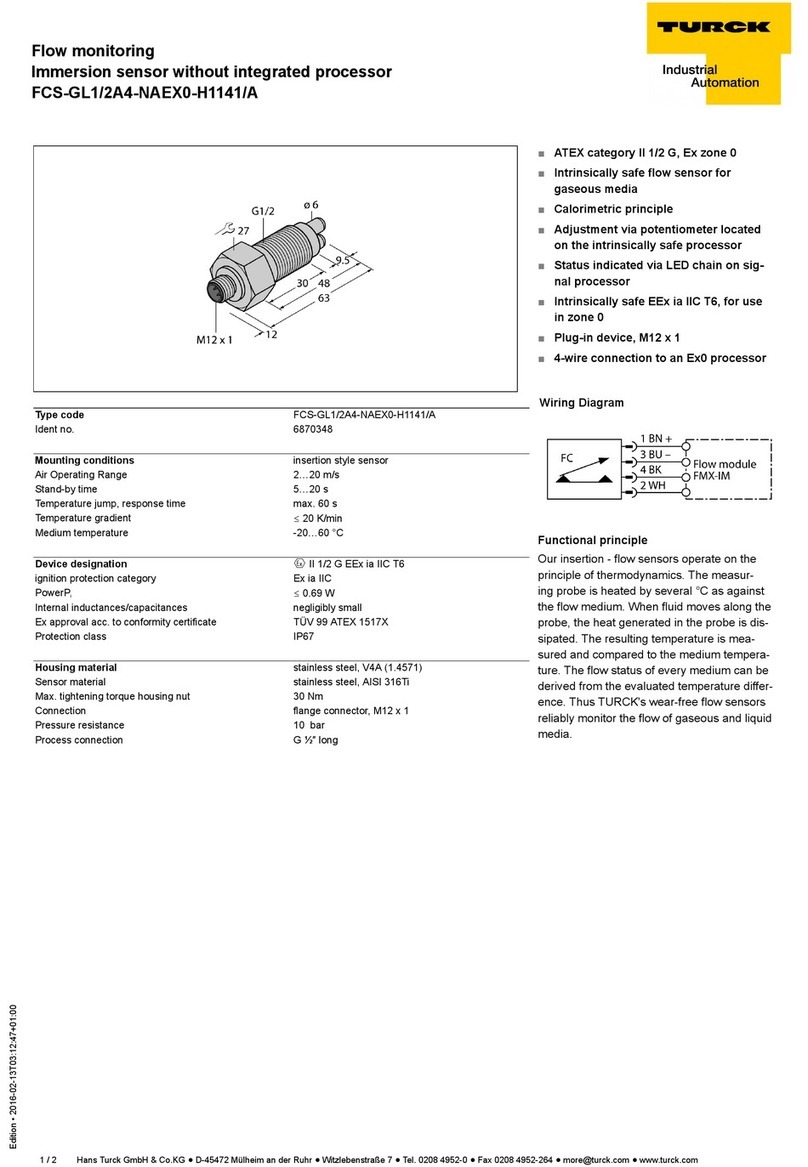

Functional principle

The inductive sensors for the food industry

are absolutely tight and resistant to cleaning

agents and disinfectants,thanks to the LCP

front cap and the stainless steel housing.

Derating curve