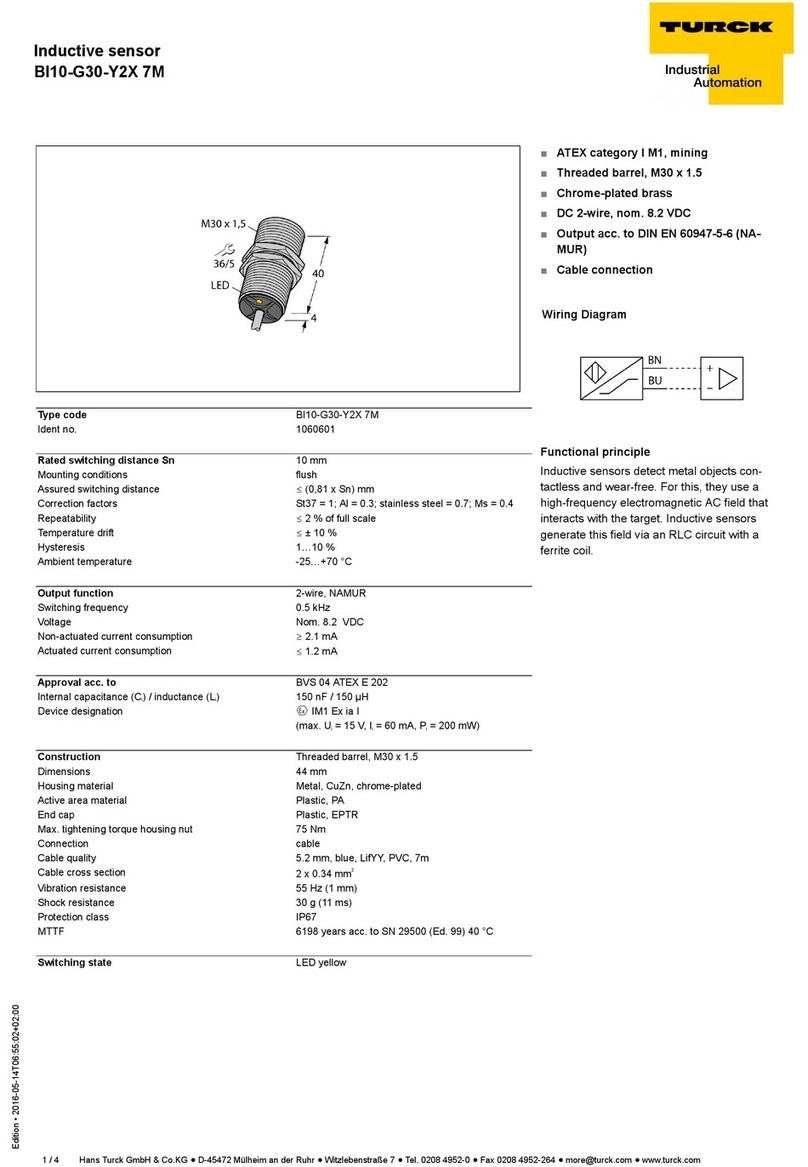

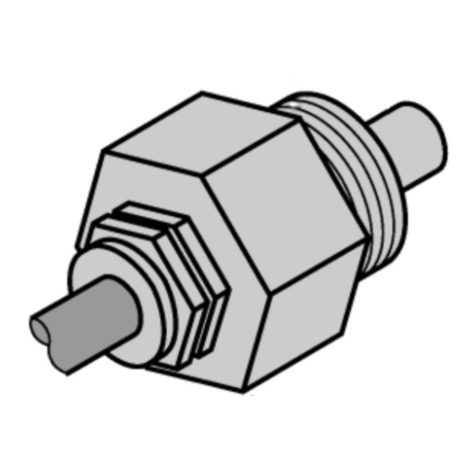

Inductive sensor

NI50U-CK40-VP4X2-H1141/3GD

Edition • 2019-02-15T19:14:46+01:00

1 / 4

Hans Turck GmbH & Co.KG

ñ D-45472 Mülheim an der Ruhr

ñ Witzlebenstraße 7

ñ T

el. 0208 4952-0

ñ Fax 0208 4952-264

ñ [email protected] ñ www

.turck.com

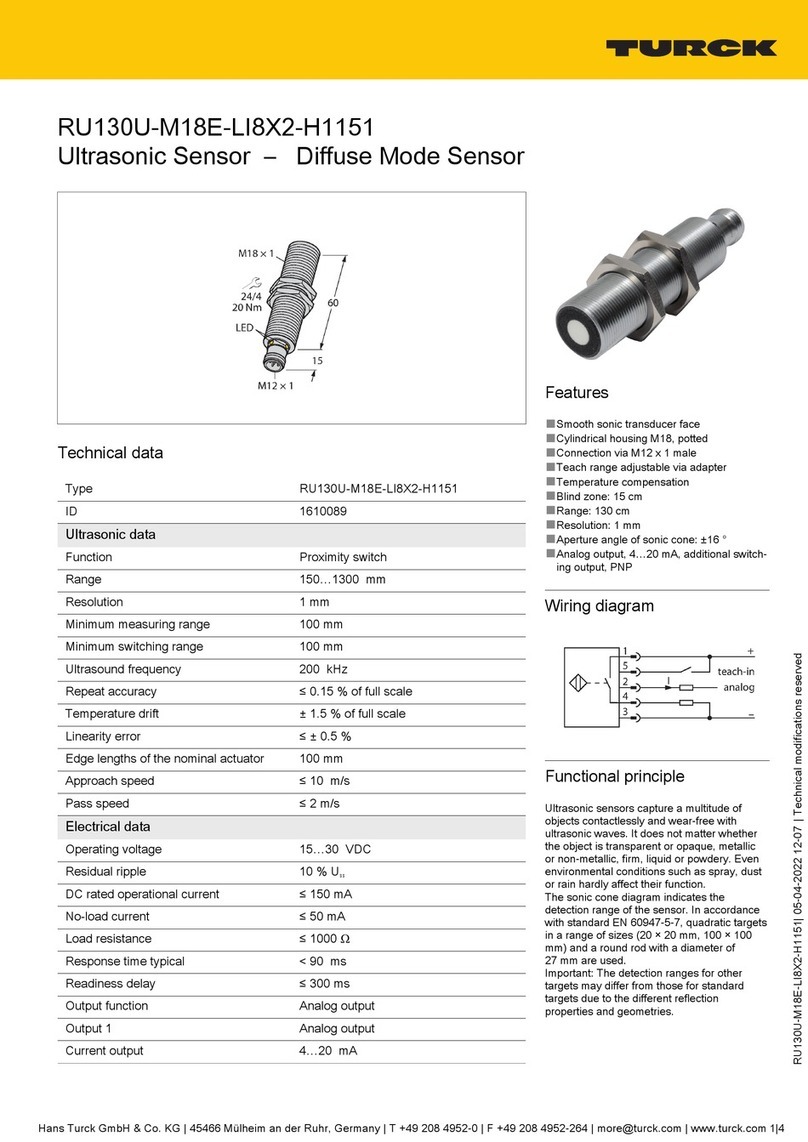

Type designation NI50U-CK40-VP4X2-H1141/3GD

Ident no. 1514120

Rated switching distance Sn 50 mm

Mounting conditions Non-flush, flush

Secured operating distance ð (0,81 x Sn) mm

Repeat accuracy ð 2 % of full scale

Temperature drift ð ± 10 %

ð ± 20 %, ð -25 °C v ï +70 °C

Hysteresis 3…15 %

Ambient temperature -30…+85 °C

For explosion hazardous areas see instruction

leaflet

Operating voltage 10…65 VDC

Residual ripple ð 10 % Uss

DC rated operational current ð 200 mA

No-load current I0ð 15 mA

Residual current ð 0.1 mA

Isolation test voltage ð 0.5 kV

Short-circuit protection yes

Voltage drop at Ieð 1.8 V

Wire breakage/Reverse polarity protection yes/ Complete

Output function 4-wire, Complementary contact, PNP

Protection class ÷

Switching frequency 0.25 kHz

Approval acc. to ATEX test certificate TURCK Ex-10002M X

Design Rectangular,CK40

Dimensions 65 x 40 x 40 mm

variable orientation of active face in 5 directions

Housing material Plastic, PBT-GF20-V0, Black

Active area material Plastic, PA12-GF30, yellow

Electrical connection Connectors, M12 × 1

Vibration resistance 55 Hz (1 mm)

Shock resistance 30 g (11 ms)

Protection class IP68

MTTF 874 years acc. to SN 29500 (Ed. 99) 40 °C

Packaging unit 1

Power-on indication 2 × LEDs,Green

Switching state 2 × LEDs, Yellow

Included in delivery Fixing clamp BS4-CK40, SC-M12/3GD

■ATEX category II 3 G, Ex zone 2

■ATEX category II 3 D, Ex zone 22

■Rectangular, height 40 mm

■Variable orientation of active face in 5

directions

■Plastic, PBT-GF30-V0

■High luminance corner LEDs

■Optimum view on supply voltage and

switching state from any position

■Factor 1 for all metals

■Increased switching distance

■Protection class IP68

■Resistant to magnetic fields

■Auto-compensation protects against

pre-attenuation

■Partially embeddable

■DC 4-wire, 10…65 VDC

■Changeover contact, PNP output

■M12 x 1 male connector

Wiring Diagram

Functional principle

Inductive sensors detect metal objects con-

tactless and wear-free. Due to the patented

multi-coil system, uprox®+ sensors have dis-

tinct advantages over conventional sensors.

They excel in largest switching distances,

maximum flexibility and operational reliability

as well as efficient standardization.