turck FCS-GL1/2T-NAEX-H1141 User manual

Other turck Accessories manuals

turck

turck LTX Series User manual

turck

turck PK01VR N Series User manual

turck

turck FCS-GL1/2TN-NAEX-H1141 User manual

turck

turck FCS-G1/2HC4-NAEX/L065/D100 User manual

turck

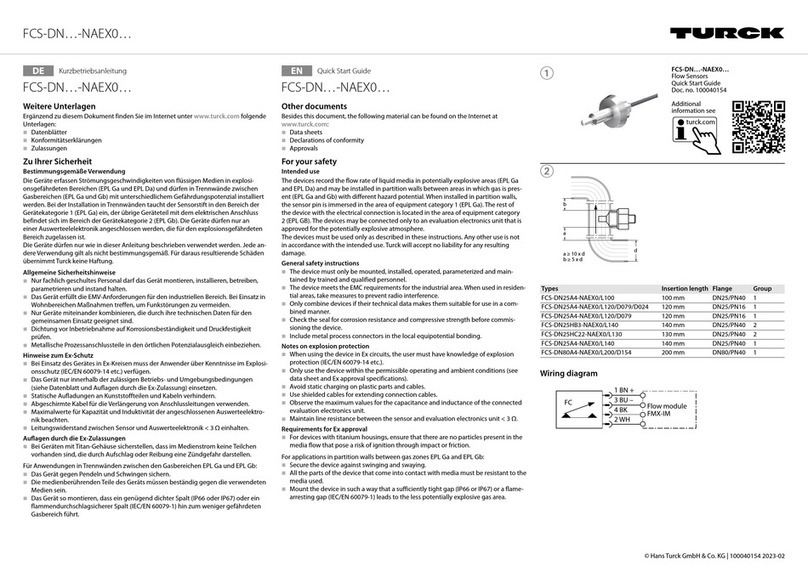

turck FCS-DN NAEX0 Series User manual

turck

turck RU100-CP40 Series User manual

turck

turck IM18-CCM40 User manual

turck

turck Li-Q25LxE Series User manual

turck

turck FCS-G1/2A4-NAEX-H1141 User manual

turck

turck FCS-G1/2A4-NAEX0-H1141/L065 User manual

turck

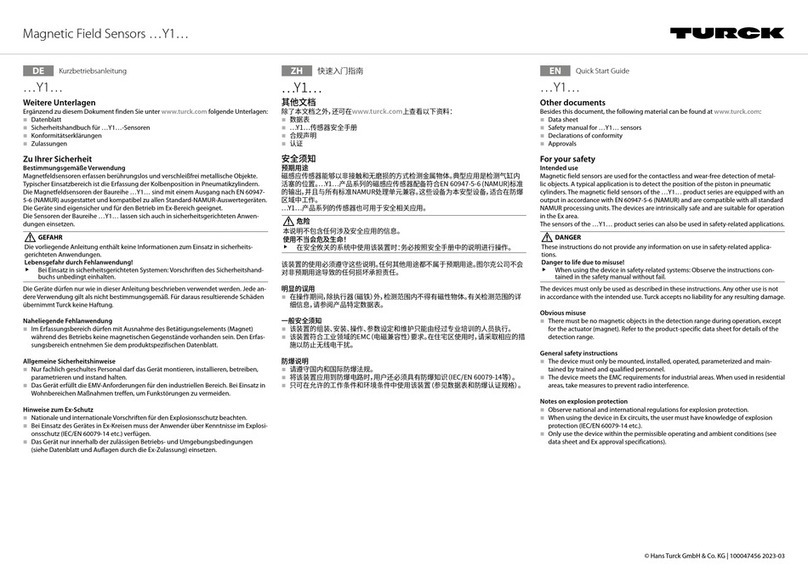

turck Y1 Series User manual

turck

turck B1N360V-Q20L60-2LU3-H1151/3GD User manual

turck

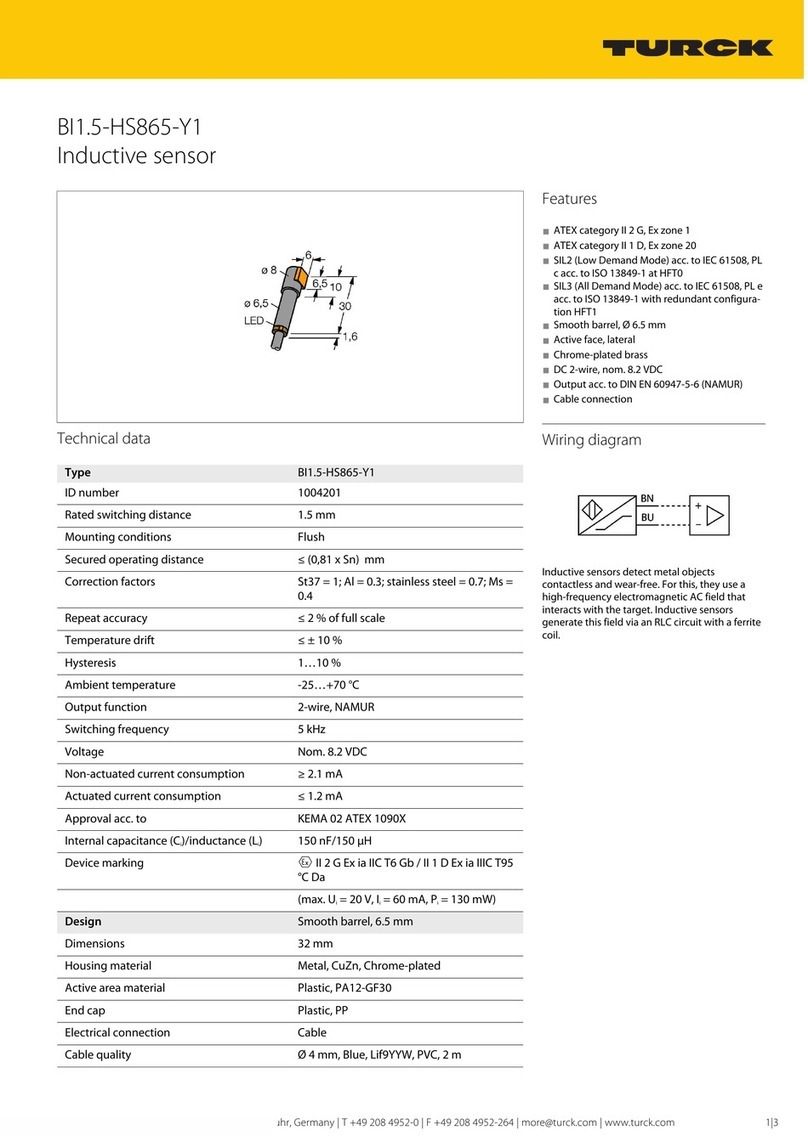

turck BI1.5-HS865-Y1 User manual

turck

turck FCS-G1/2A4-NAEX/D100 User manual

turck

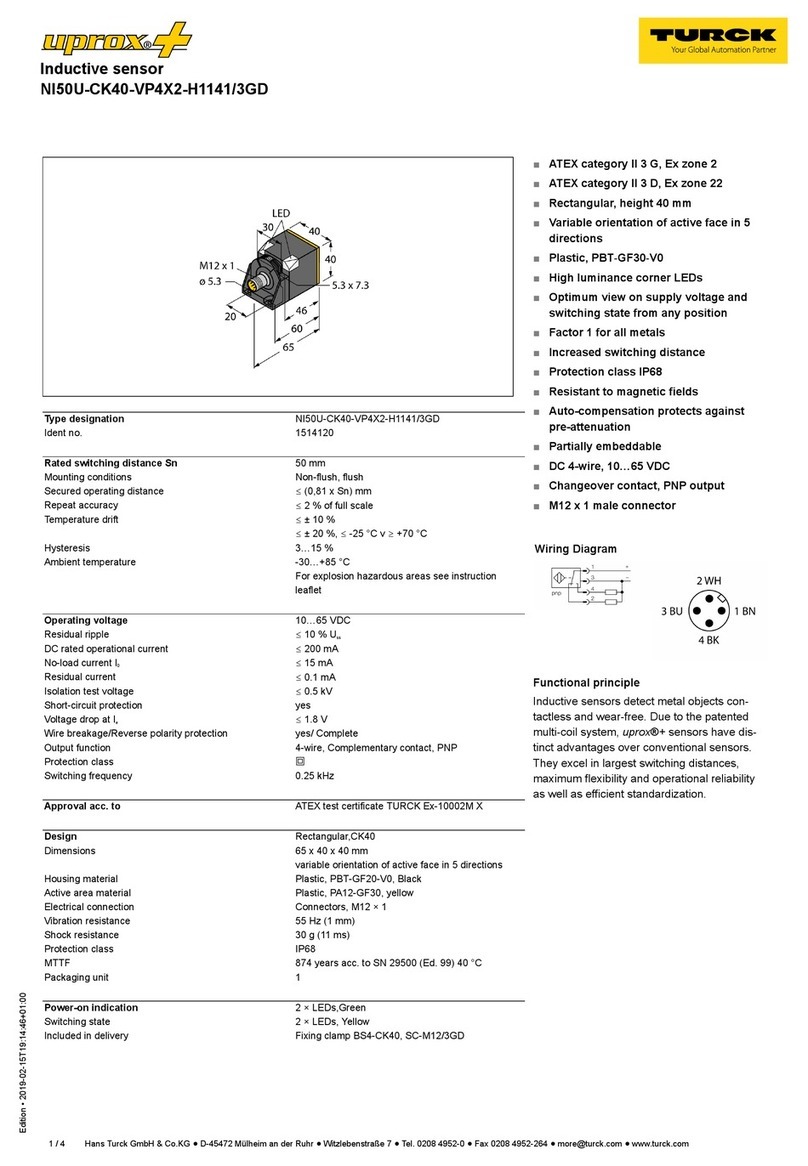

turck Uprox+ NI50U-CK40-VP4X2-H1141/3GD User manual

turck

turck CMTH Series User manual

turck

turck FCS-G1/2A4-NAEX0 User manual

turck

turck RU10 M08 Series User manual

turck

turck RU600 Series User manual

turck

turck LTX-R10 Series User manual