Design Requirements — Light Hazard Extended Coverage Applications

Density .1 GPM/ft2- NFPA 13 All Editions

Design

Data

All Central Model ELO LH Re-

cessed Pendent and Pendent Auto-

matic Sprinklers must be installed

according to the current NFPA 13

Standard and these installation

instructions. Deviations from these

requirements and standards or any

alteration to the sprinkler itself will

void any warranty made by Central

Sprinkler Company. In addition,

installation must also meet local

government provisions, codes, and

standards as applicable.

The system piping must be properly

sized to ensure the minimum required

flow rate at the sprinkler. Check for

the proper model, style, orifice size,

and temperature rating prior to

installation. Install sprinklers after the

piping is in place to avoid mechanical

damage; replace any damaged units.

Wet pipe systems must be

protected from freezing.

Upon completion of the installation,

the system must be tested per

recognized standards.

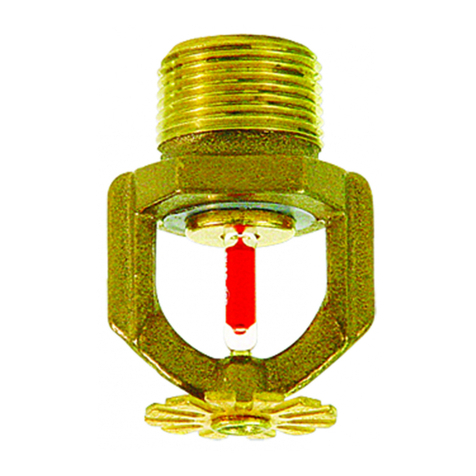

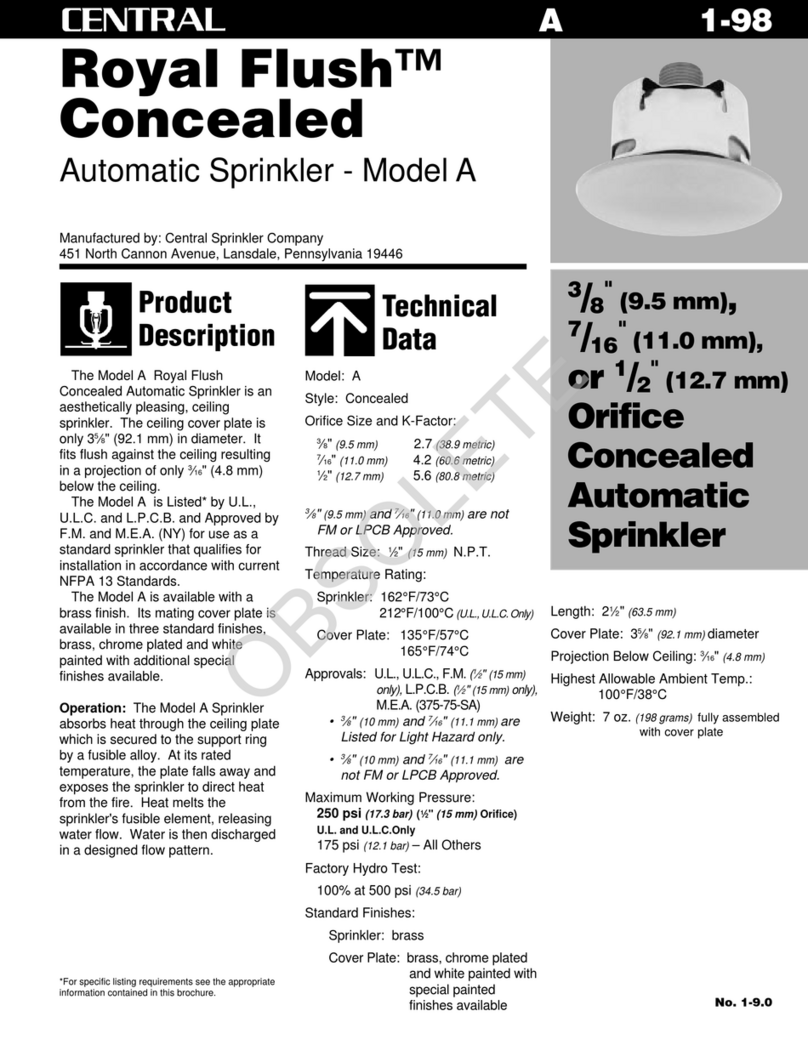

The Model ELO LH incorporates the latest in heat-responsive glass bulb

technology. The operating mechanism consists of a 3 mm (76.2 mm)

liquid-filled frangible capsule that is only 20 mm in length.

Operation: The glass bulb capsule operating mechanism contains a

heat-sensitive liquid that expands upon application of heat. At the rated

temperature, the frangible capsule ruptures, thereby releasing the orifice

seal. The sprinkler then discharges water in a pre-designed spray pattern

to control the fire.

In the event of a thread leak,

remove the unit, apply new pipe joint

compound or tape, and reinstall.

Installation Sequence

Step 1. For Pendent and Recessed

Pendent sprinklers, the face of the

sprinkler fitting should be installed a

nominal 3⁄4" (±3⁄8") (20 mm (±9.5 mm))

behind the ceiling line. Adjustments

are made via the push-on escutcheon.

Step 2. Use only a non-hardening

pipe joint compound or Teflon* tape.

Apply only to the male threads.

Step 3. Hand tighten the sprinkler into

the fitting. Use a Central Sprinkler

Wrench, to tighten the unit into the

fitting. A leak-tight joint requires only

7 to 14 ft.-lbs. (9.5 to 19.0 Nm) of

torque; a tangential force of 14 to 28

lbs. (62.3 to 124.5 N) delivered through

a 6" (150 mm) handle will deliver

adequate torque. Torque levels over

21 ft.-lbs. (28.6 Nm) may distort the

orifice seal, resulting in leakage.

Installation

Care &

Maintenance

Sprinklers must be handled care-

fully. They must not be transported

or stored where ambient temperature

may exceed 100°F/38°C. For best

results, store them in a dry, cool loca-

tion in the original shipping package.

Do not install sprinklers that have

been dropped or visibly damaged.

Sprinklers must never be painted,

coated, plated, or altered in any other

way from manufactured condition or

they may not function properly. Any

sprinklers altered in such manner

must be replaced.

The owner is responsible for the

proper operating condition of all fire

protection devices and accessories.

The NFPA standard 25 entitled,

“Inspection, Testing and Maintenance

of Water-Based Fire Protection

Systems”

, contains guidelines and

minimum maintenance requirements.

Furthermore, the local

Authority

Having Jurisdiction

may have addi-

tional regulations and requirements

for maintenance, testing, and inspec-

tion that must be obeyed.

It is advisable to have sprinkler

systems inspected regularly by a

qualified inspection service. Length of

time between such inspections can

vary due to accessibility, ambient

atmosphere, water supply, and site

activity.

Do not attempt to reassemble or

otherwise reuse a sprinkler that has

operated. Replace any sprinkler

Caution: Minimum spacing between pendent and recessed

pendent sprinklers is 11'-0" (3.3 m).

*Teflon is a trademark of the DuPont Corp.

Spacing Flow/Pressure Pendent Sensitivity Recessed PendentSensitivity

135°F 155°F, 200°F, & 250°F 135°F 155°F, 200°F, 250°F

(57°C) (68°C), (93°C), & (121°C) (57°C) (68°C), (93°C), & (121°C)

16' X 16' 30.2 gpm/7.0 psi QR QR QR* QR

(4.9 x 4.9) (114.5 Lpm / 0.5 bar)

18’x18' 33 gpm/8.4 psi QR QR QR* STD

(5.5 x 5.5) (125.1 Lpm / 0.6 bar)

20’x20' 40.0 gpm/12.3 psi QR STD QR* STD

(6.1 x 6.1) (151.6 Lpm / 0.8 bar)

* Use ELO vented support cup assembly, Part #4111 Brass, #4110 Chrome, #4112 White