sign. When installed properly, the Institutional Escutch-

eon is held fast to the mounting surface by the tightening

of the sprinkler assembly into the sprinkler fitting. In order

to accomplish a proper installation, the sprinkler fitting

must be properly located with respect to distance from

the face of the sprinkler fitting to the face of the mounting

surface (Ref. Figure 2); the sprinkler fitting being rigidly

secured and held immobile; and, the centerline of the

sprinkler fitting being perpendicular to the mounting sur-

face to assure that the escutcheon sits squarely against

the mounting surface around the entire perimeter of the

Institutional Escutcheon.

INSTALLATION

The 5.6 K-Factor, StarMax S100 Sprinklers must be in-

stalled in accordance with the following instructions:

NOTES

Refer to the Design Criteria section for important informa-

tion regarding the piping installation design and its affect

on maintaining the integrity of the tamper resistant design

of the Institutional Escutcheons.

If the bulb within the linkage mechanism is cracked or

there is a loss of liquid from the bulb, do not install the

sprinkler. With the bulb in the horizontal position, an air

bubble of approximately 1/16 inch (1,6 mm) diameter

should be present.

A leak tight 1/2 inch NPT sprinkler joint should be ob-

tained with a torque of 7 to 14 ft.lbs. (9,5 to 19,0 Nm). A

maximum of 21 ft.lbs. (28,5 Nm) of torque is to be used to

install these sprinklers. Higher levels of torque may dis-

tort the sprinkler inlet with consequent leakage or impair-

ment of the sprinkler.

Do not attempt to compensate for improper location of

the sprinkler fitting by under- or over-tightening the Sprin-

kler. Readjust the position of the sprinkler fitting to suit, or

increase or decrease the number of #1752 Spacers, as

applicable.

After the installation is complete, make certain that the In-

stitutional Escutcheon is held fast to the mounting sur-

face and that it sits squarely against the ceiling around its

entire perimeter.

1. The S100 Sprinklers must be installed pendent and with

the centerline of their waterway perpendicular to the ceil-

ing.

2. With the Institutional Escutcheon in place and with pipe

thread sealant applied to the pipe threads, hand tighten

the sprinkler into the sprinkler fitting.

3. Wrench tighten the Sprinkler using only the #1509-1 or

#1509-3 Sprinkler Wrench (Ref. Figure 4). The wrench-

ing teeth of the Sprinkler Wrench are to be applied to

the sprinkler wrenching notch areas (Ref. Figure 1).

4 After the installation is complete, make certain that the

Institutional Escutcheon is held fast to the mounting sur-

face and that it sits squarely against the ceiling around

its entire perimeter.

CARE AND MAINTENANCE

The 5.6 K-Factor, StarMax S100 Sprinklers must be main-

tained and serviced in accordance with the following in-

structions:

NOTES

Service inspections should be made on a regular basis to

detect possible damage or alterations to the sprinkler and

escutcheon. Inspections should include making certain

that the Institutional Escutcheon is held fast to the mount-

ing surface. Damaged or altered sprinklers are to be re-

placed immediately to avoid personal injury and to pre-

vent use for causing personal injury, as well as to

maintain the sprinkler system in an operative condition.

Before closing a fire protection system main control valve

for maintenance work on the fire protection system which

it controls, permission to shut down the affected fire pro-

tection systems must be obtained from the proper authori-

ties and all personnel who may be affected by this action

must be notified.

Sprinklers which are found to be leaking or exhibiting vis-

ible signs of corrosion must be replaced.

Automatic sprinklers must never be shipped or stored

where their temperatures will exceed 100°F/38°C and

they must never be painted, plated, coated, or otherwise

altered after leaving the factory. Modified or over-heated

sprinklers must be replaced.

Care must be exercised to avoid damage to the sprinklers

- before, during, and after installation. Sprinklers dam-

aged by dropping, striking, wrench twist/slippage, or the

like, must be replaced. Also, replace any sprinkler that

has a cracked bulb or that has lost liquid from its bulb

(ref. Installation Section).

The owner is responsible for the inspection, testing, and

STAR SPRINKLER

Page 2 1-5.2.11

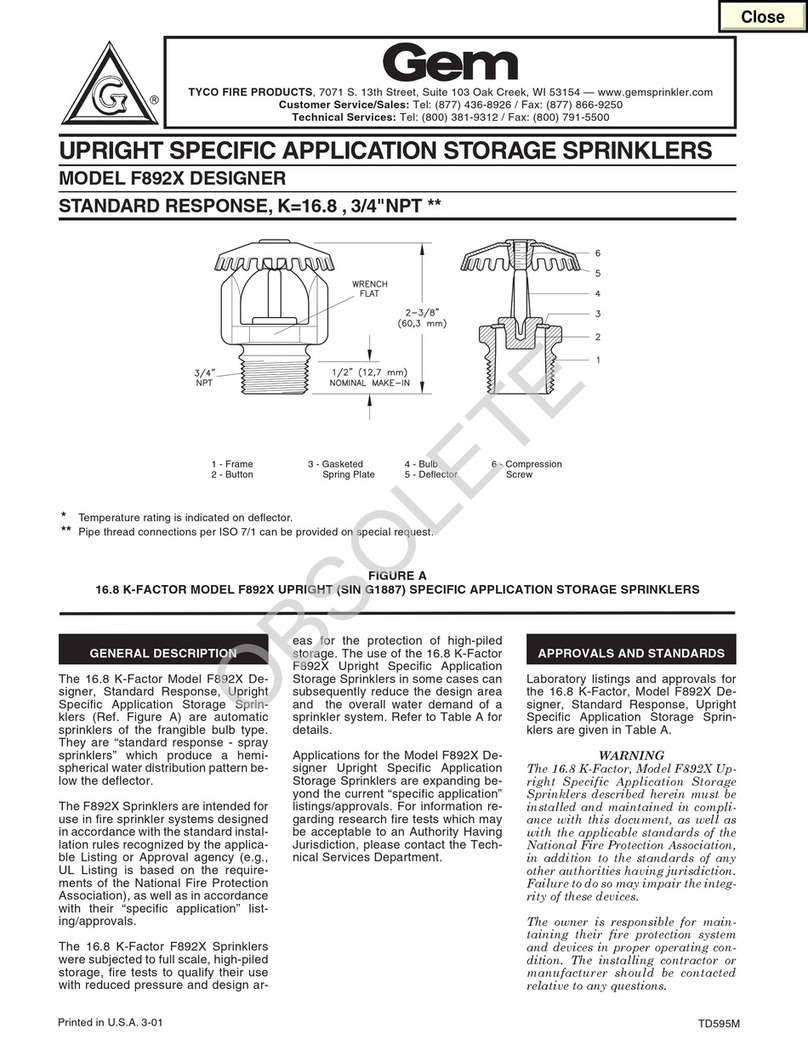

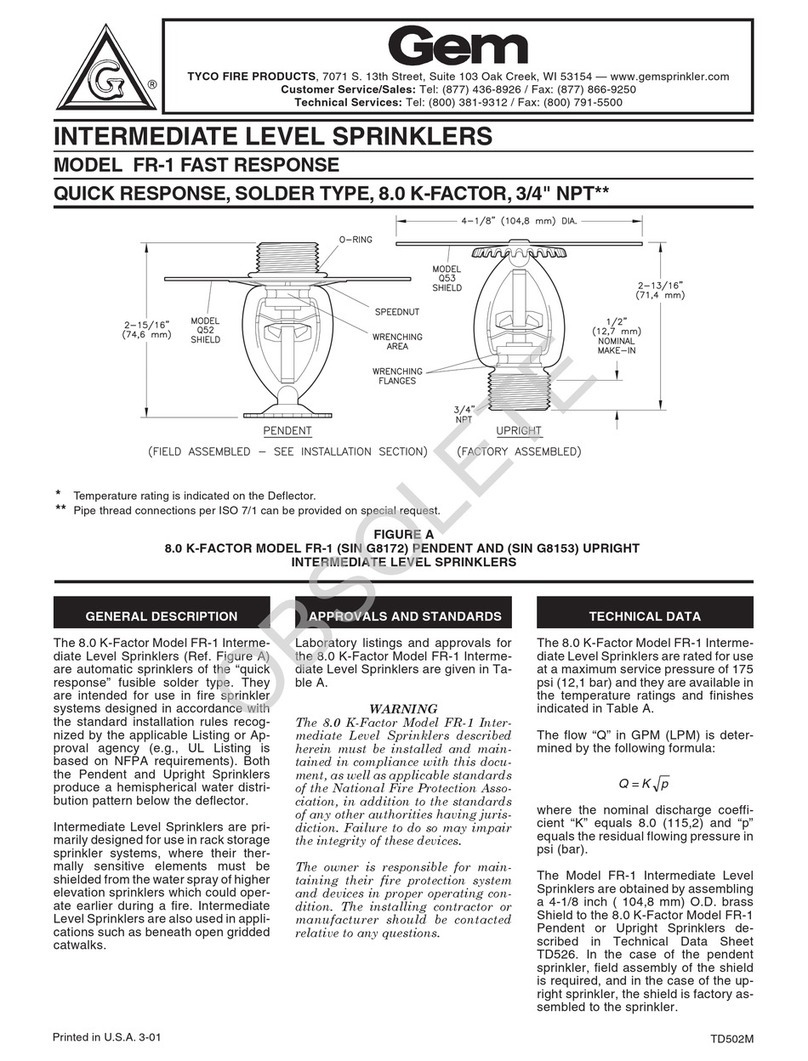

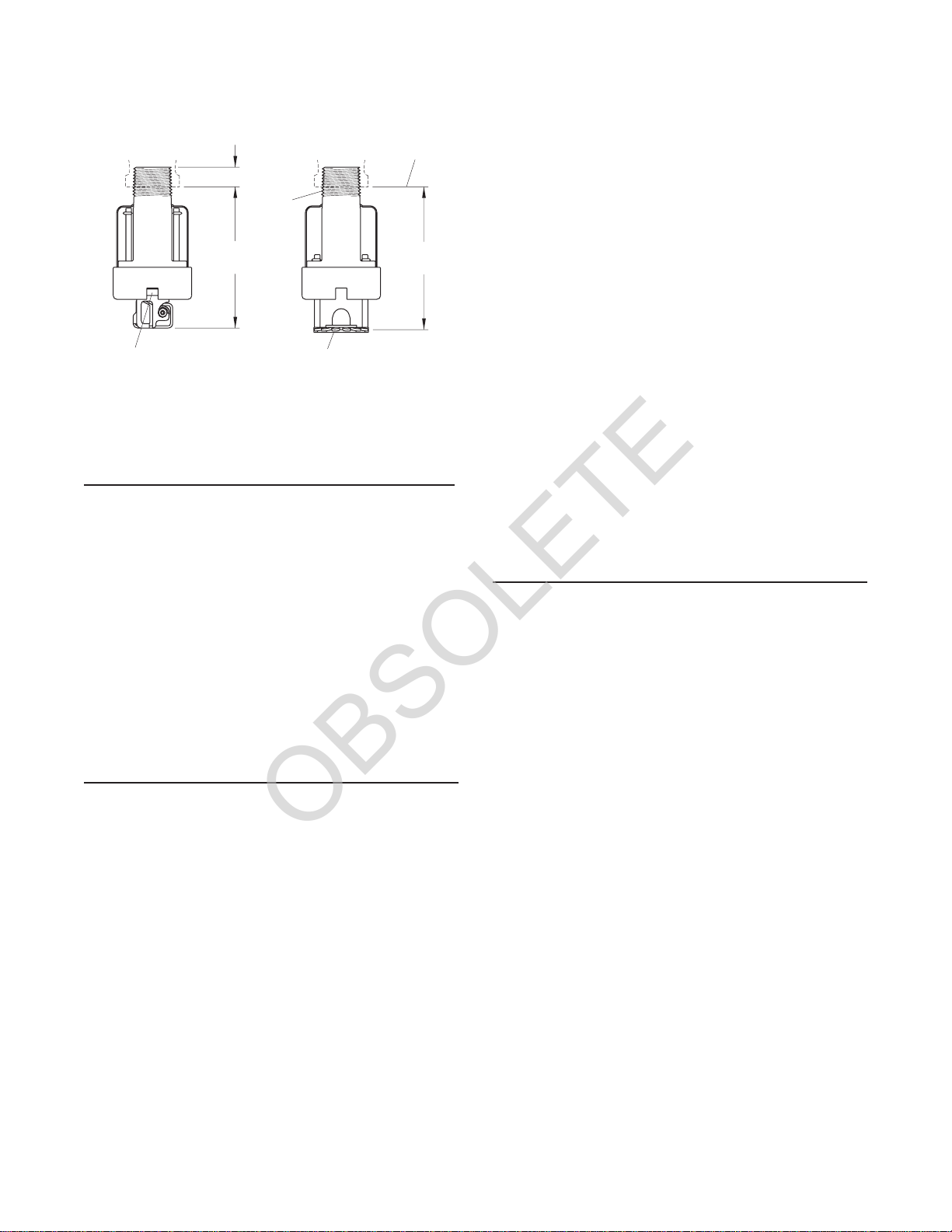

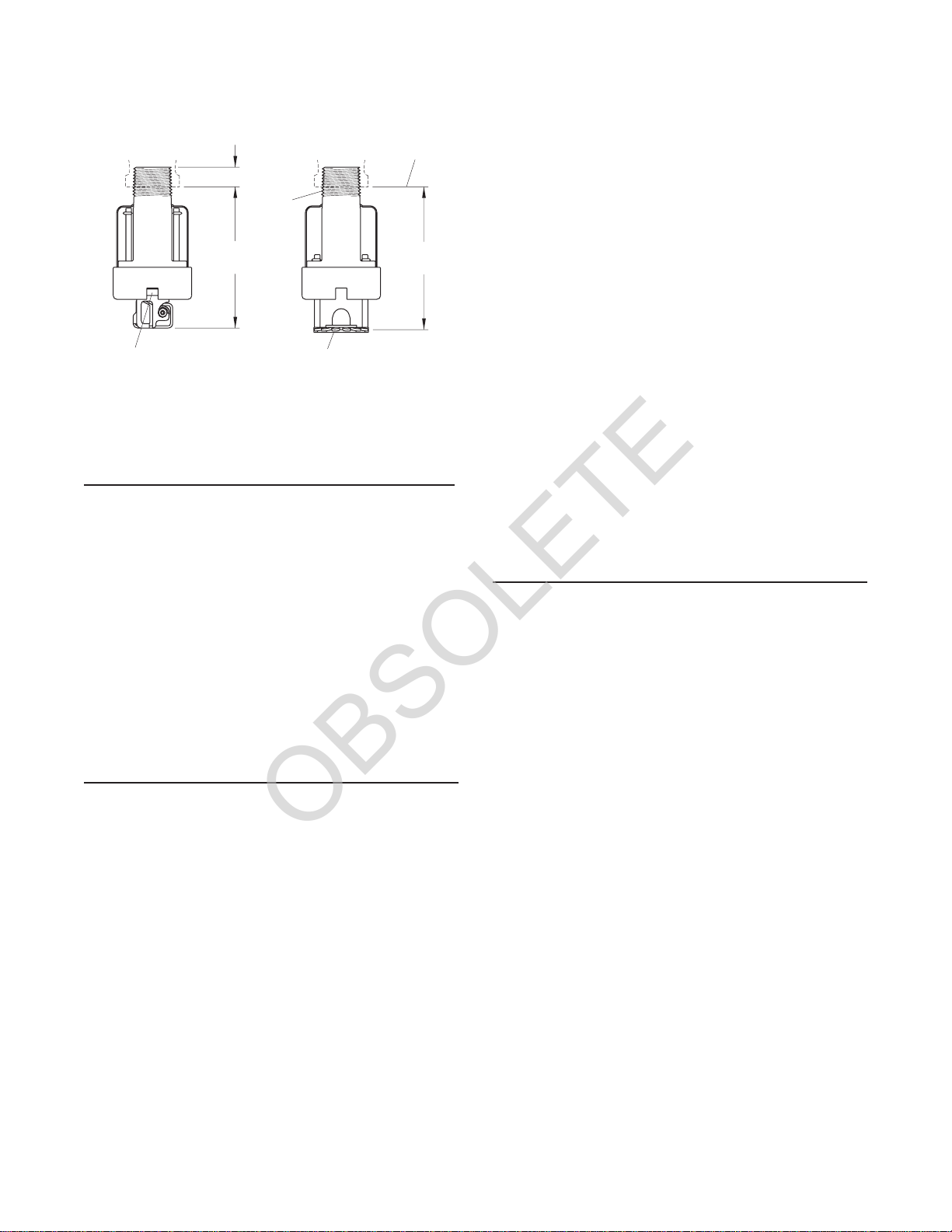

FIGURE 1

5.6 K-FACTOR, STARMAX S100 QUICK RESPONSE

INSTITUTIONAL PENDENT SPRINKLER

3.18"

(80.8 mm)

FITTING

FA

E

F

SPRINKLER

SPRINKLER

NOTCH (2)

WRENCHING IN OPERATED

DEFLECTOR

POSITION

(80.0 mm)

NPT

3.15"

1/2"

7

16"

11.1 mm

NOMINAL MAKE-IN