TFP110

Page 3 of 6

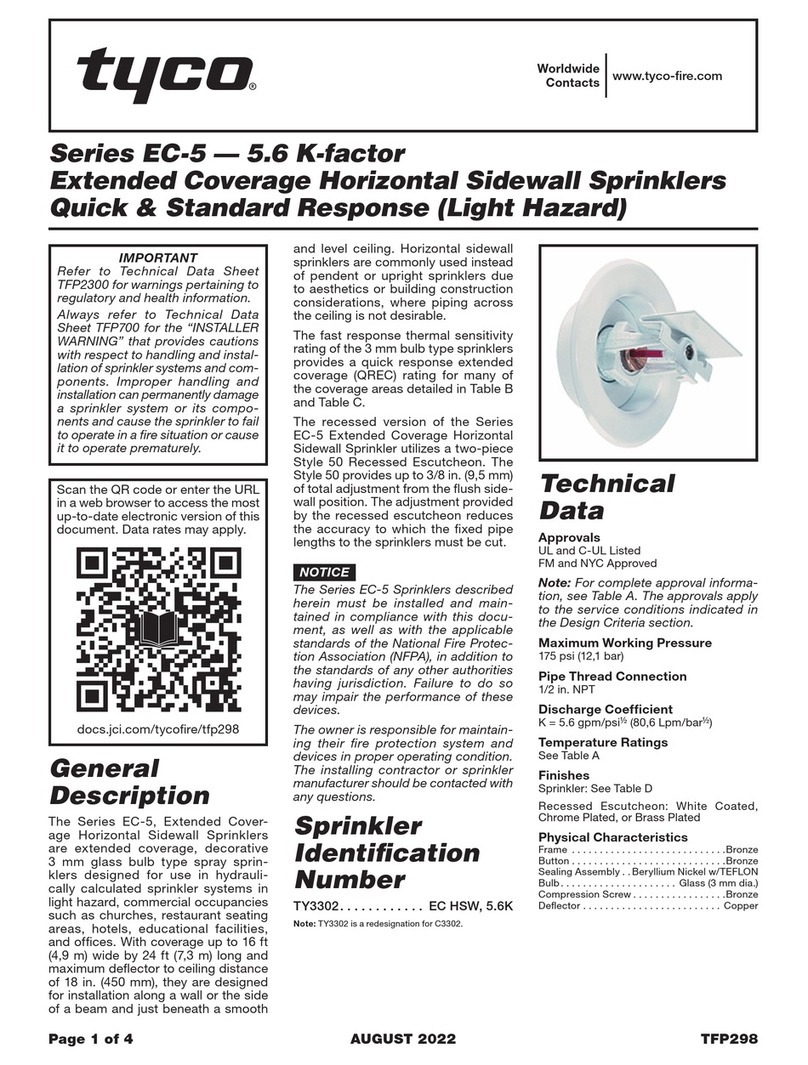

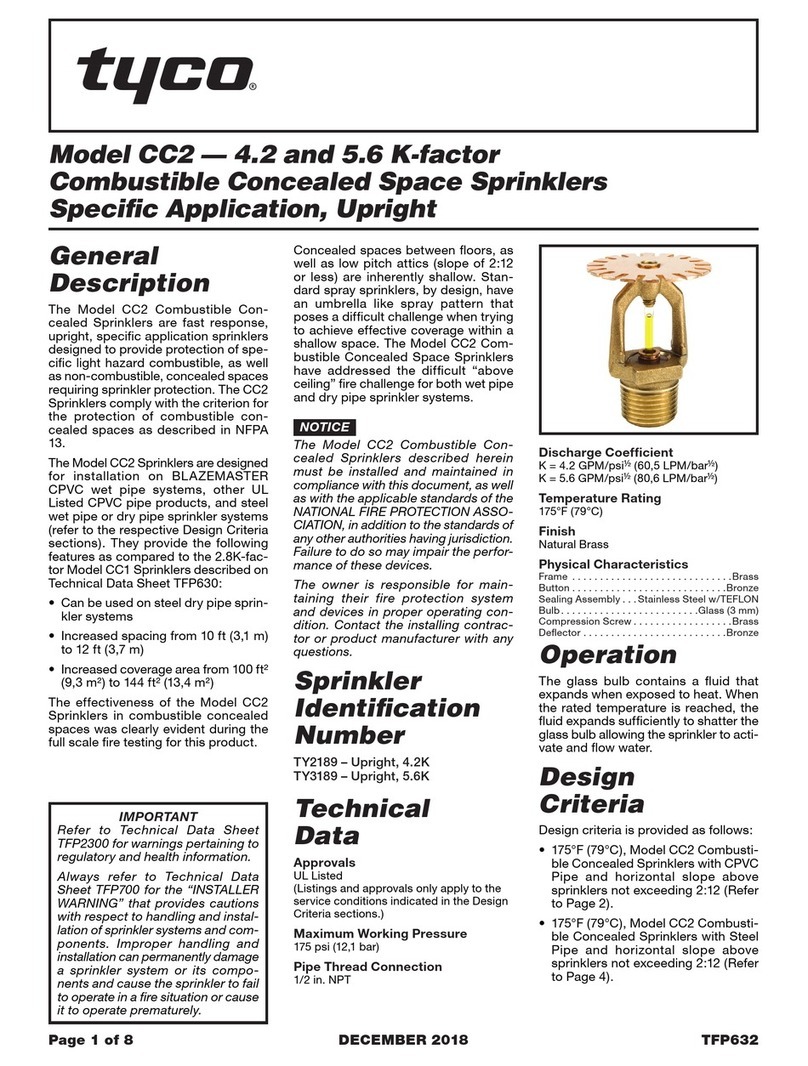

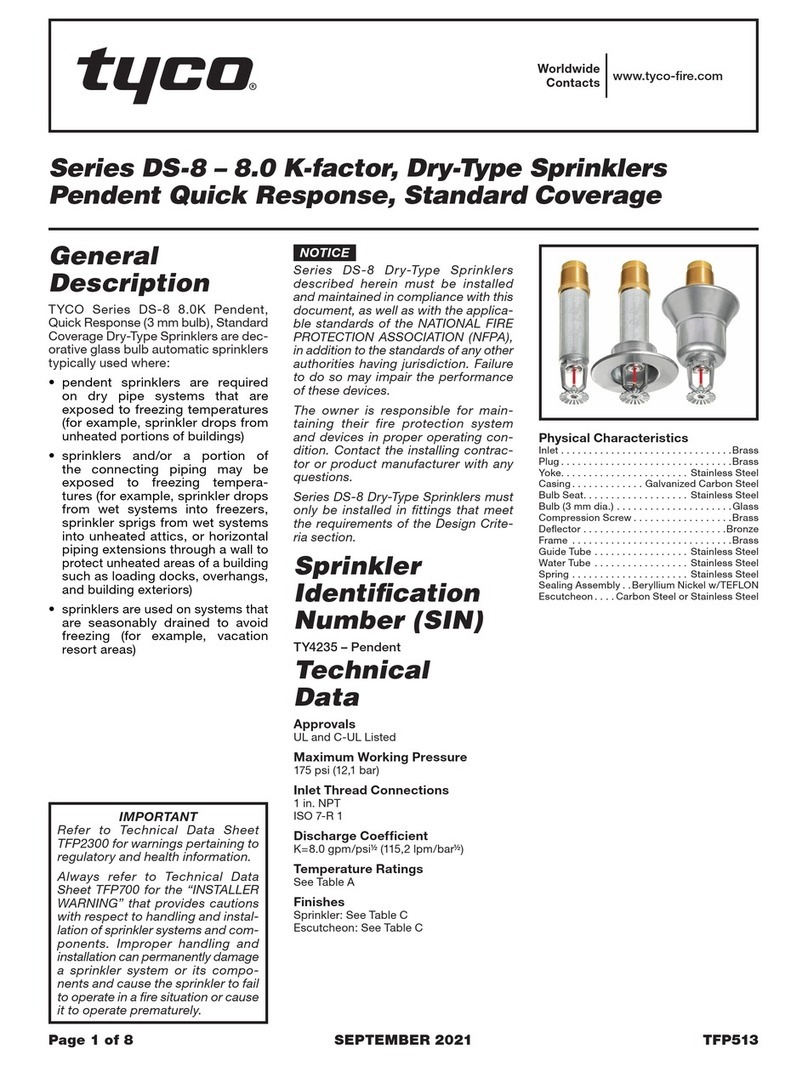

Technical

Data

Approvals

UL and C-UL Listed. FM, and LPCB

Approved. (Refer to Table A for complete

approval information including corrosion

resistant status.)

Maximum Working Pressure

175 psi (12,1 bar)

Discharge Coefficient

K=5.6 GPM/psi½(80,6 LPM/bar½)

K=8.0 GPM/psi½(115,2 LPM/bar½)

Temperature Ratings

Refer to Table A

Finishes

Sprinkler: Refer to Table A Recessed

Escutcheon: White Coated, Chrome

Plated, or Brass Plated

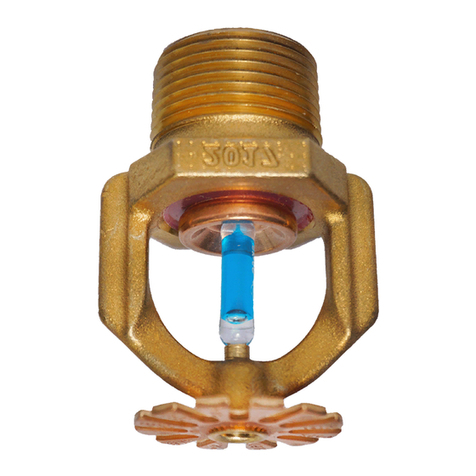

Physical Characteristics

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . .Brass

Sealing Button . . . . . . . . . . . Bronze w/TEFLON

Ejection Spring . . . . . . . . . . . . . . Stainless Steel

Strut . . . . . . . . . . . . . . . . . . . . . . . . . . . . MONEL

Hook ..................... Bronze/MONEL

Deflector . . . . . . . . . . . . . . . . . . . . . . . . . .Bronze

Fusible Element. . . . . . . . . . . . . .Solder, Copper,

Stainless Steel

Operation

A copper tube sealed by two stainless

steel balls holds a fusible alloy. When

the rated temperature is reached, the

alloy melts, the balls are forced toward

each other releasing the tension mech-

anism, allowing the sprinkler to operate.

Design

Criteria

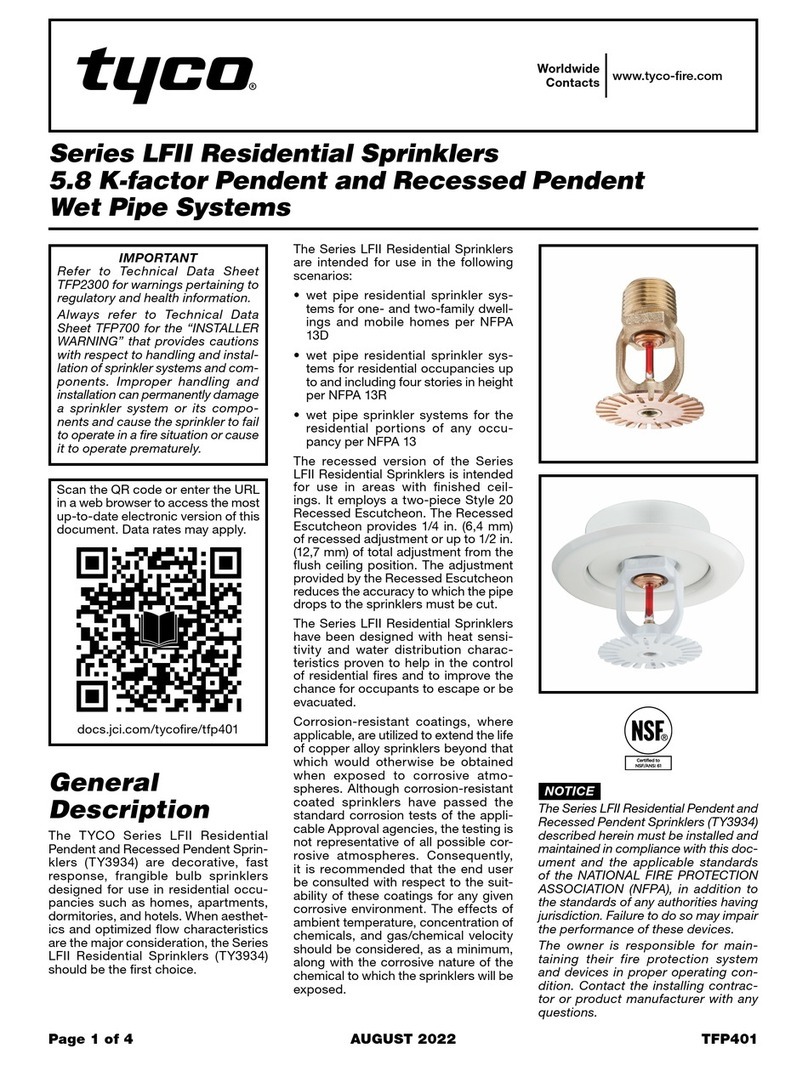

The TYCO Series TY-L, 5.6 and

8.0 K-factor, Upright, Pendent, and

Recessed Pendent Sprinklers are

intended for fire protection systems

designed in accordance with the stan-

dard installation rules recognized by the

applicable Listing or Approval agency

(e.g., UL Listing is based on the require-

ments of NFPA 13, and FM Approval

is based on the requirements of FM’s

Loss Prevention Data Sheets). Only

the Style 20 or 30 Recessed Escutch-

eon, as applicable, are to be used for

recessed pendent installations.

Installation

The TYCO Series TY-L, 5.6 and

8.0 K-factor, Upright, Pendent, and

Recessed Pendent Sprinklers must

be installed in accordance with this

section:

A leak tight 1/2 inch NPT sprinkler joint

should be obtained with a torque of 7

to 14 ft.-lbs. (9,5 to 19,0 Nm). A leak

tight 3/4 inch NPT sprinkler joint should

be obtained with a torque of 10 to 20

ft.-lbs. (13,4 to 26,8 Nm). Higher levels

of torque may distort the sprinkler inlet

and cause leakage or impairment of the

sprinkler.

Do not attempt to make-up for insuf-

ficient adjustment in the escutcheon

plate by under- or over-tightening the

sprinkler. Readjust the position of the

sprinkler fitting to suit.

Series TY-L Pendent and Upright

Sprinkler Installation

The Series TY-L Pendent and Upright

Sprinklers must be installed in accor-

dance with this section.

Pendent sprinklers are to be installed

in the pendent position, and upright

sprinklers are to be installed in the

upright position.

Step 1. With pipe thread sealant

applied to the pipe threads, hand

tighten the sprinkler into the sprinkler

fitting.

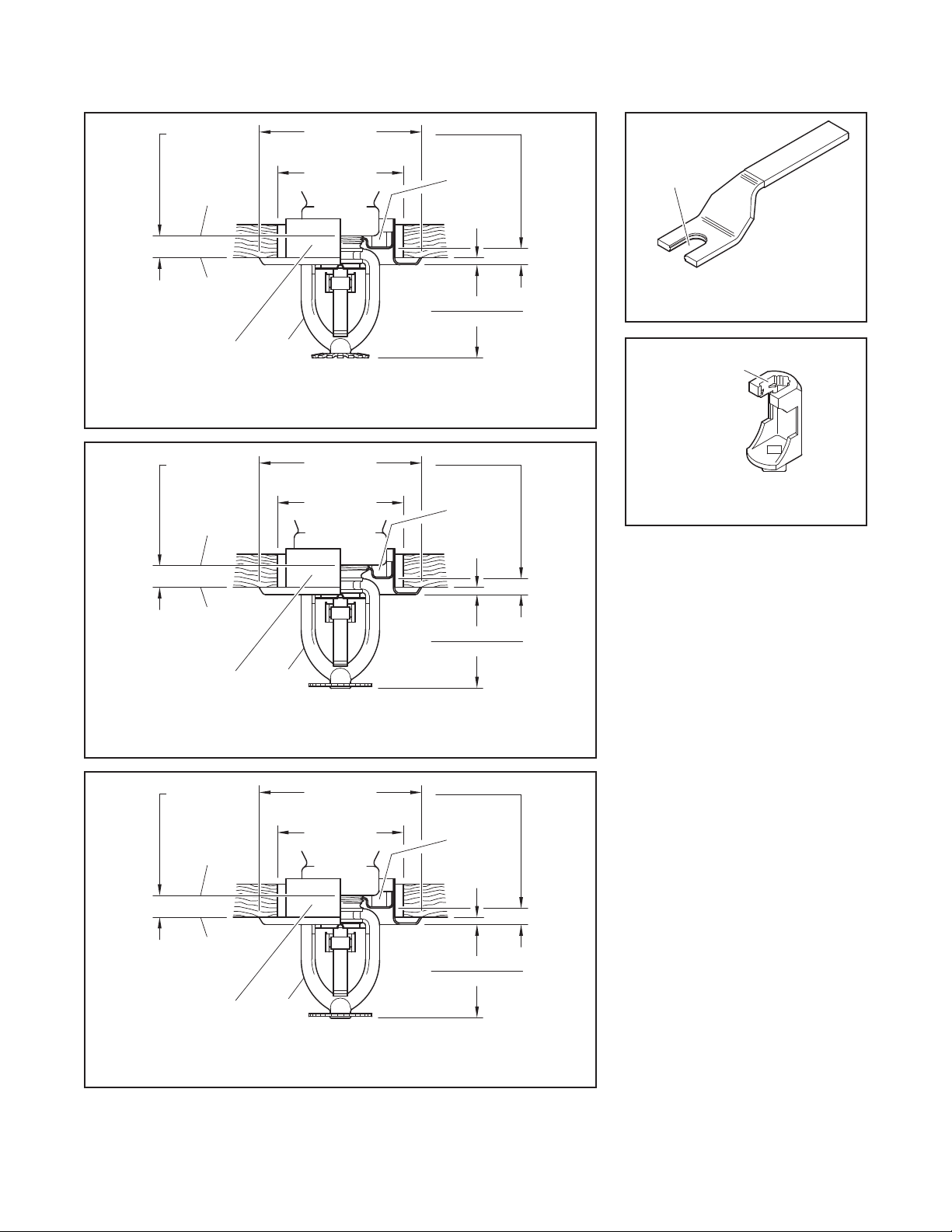

Step 2. Tighten the sprinkler into the

sprinkler fitting using only the W-Type

9 Sprinkler Wrench (Ref. Figure 7),

except that an 8 or 10 inch adjust-

able Crescent wrench is to be used

for wax coated sprinklers. With refer-

ence to Figures 1, 2, and 3, the W-Type

9 Sprinkler Wrench is to be applied to

the wrench area, or as applicable, the

adjustable Crescent wrench is to be

applied to the wrenching flanges.

When installing wax coated sprinklers

with the adjustable Crescent wrench,

additional care needs to be exercised

to prevent damage to the wax coating

on the sprinkler wrench flats or frame

arms and, consequently, exposure of

bare metal to the corrosive environ-

ment. The jaws of the wrench should be

opened sufficiently wide to pass over

the wrench flats without damaging the

wax coating. Before wrench tightening

the sprinkler, the jaws of the wrench are

to be adjusted to just contact the sprin-

kler wrench flats. After wrench tight-

ening the sprinkler, loosen the wrench

jaws before removing the wrench.

**

*

*

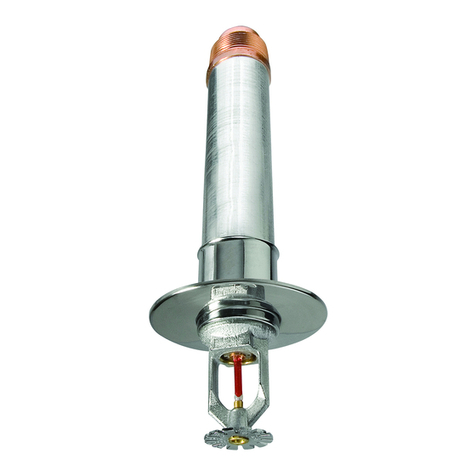

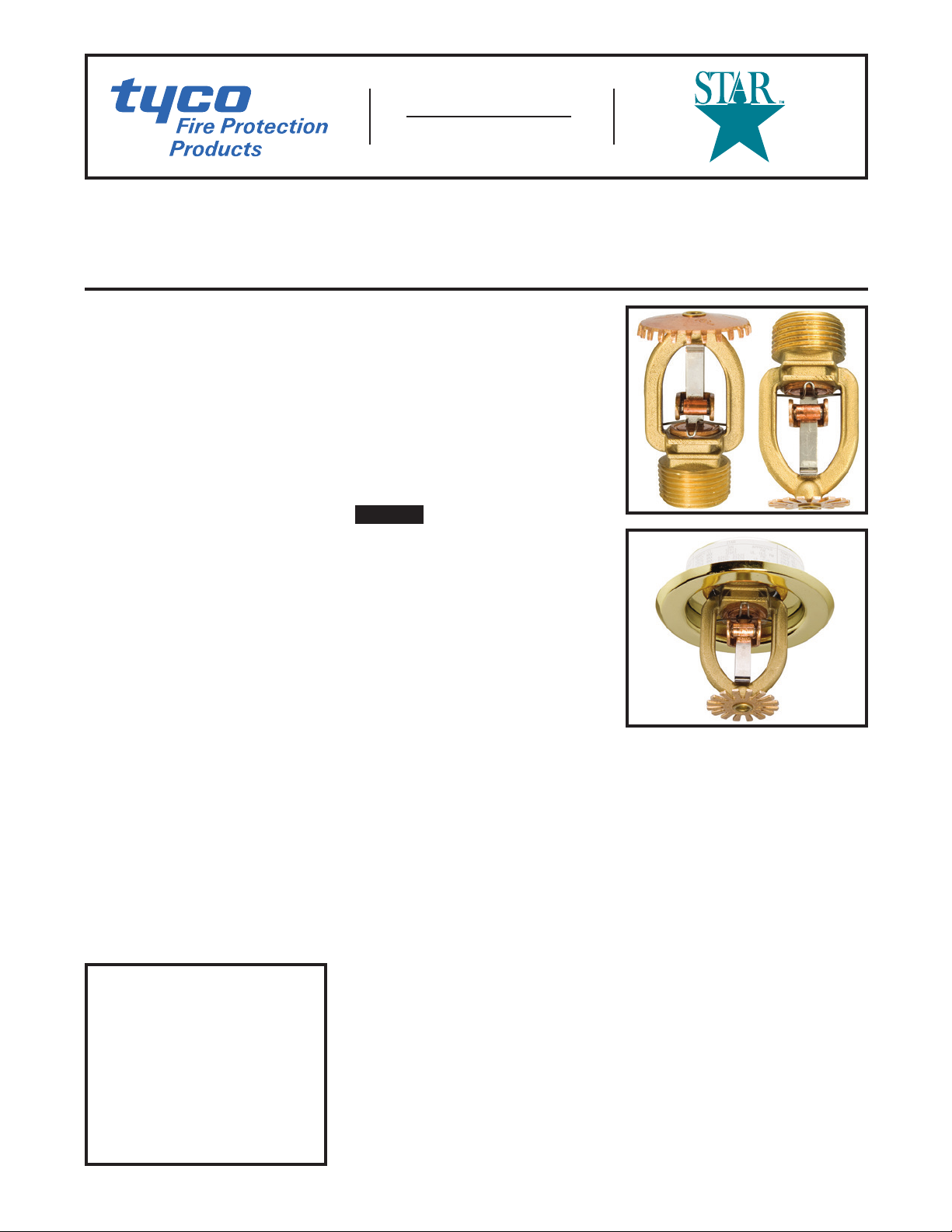

UPRIGHT PENDENT CROSS SECTIONRECESSED PENDENT

2-5/8"

(66,7 mm)

7/16"

(11,1 mm)

NOMINAL

MAKE-IN

2-5/8"

(66,7 mm)

2"

(50,8 mm)

WRENCH

FLANGES

ESCUTCHEON

PLATE SEATING

SURFACE

2-7/8" (73,0 mm) DIA.

WRENCH

AREA

3

STYLE 20

RECESSED

ESCUTCHEON

7

5

6

4

2

1

Pipe thread connections per

ISO 7-1 can be provided on

special request.

is indicated on

Deector.

2 Sealing

Button

-

Fusible

Element

-

4

Spring Hook

7-Deector

-

6

1/2" NPT

FIGURE 3

STANDARD RESPONSE SERIES TY-L UPRIGHT (TY4811) AND PENDENT (TY4911) SPRINKLERS

8.0 K-FACTOR, 1/2 INCH NPT