General

Description

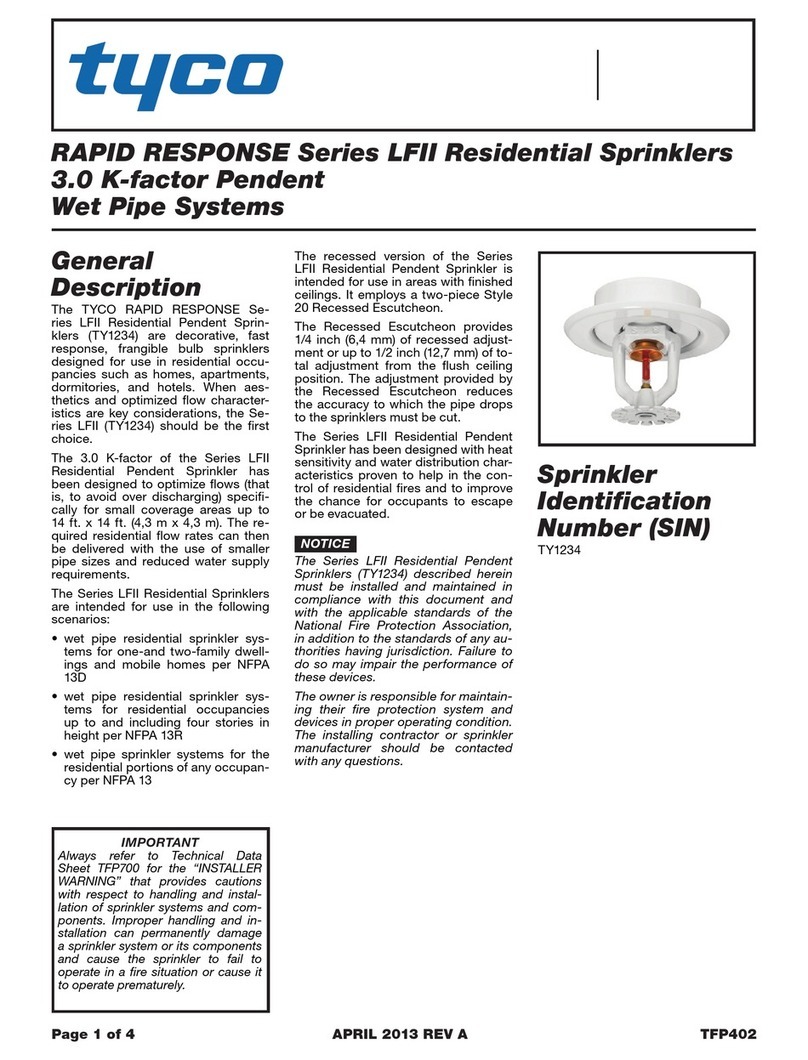

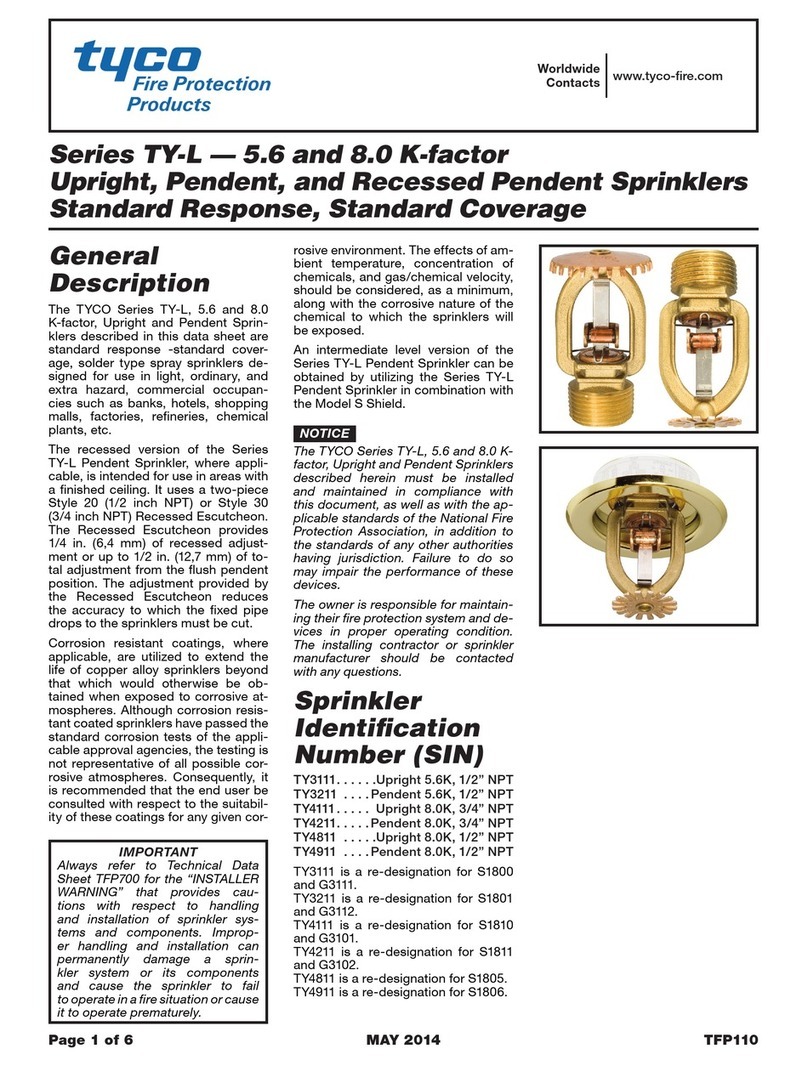

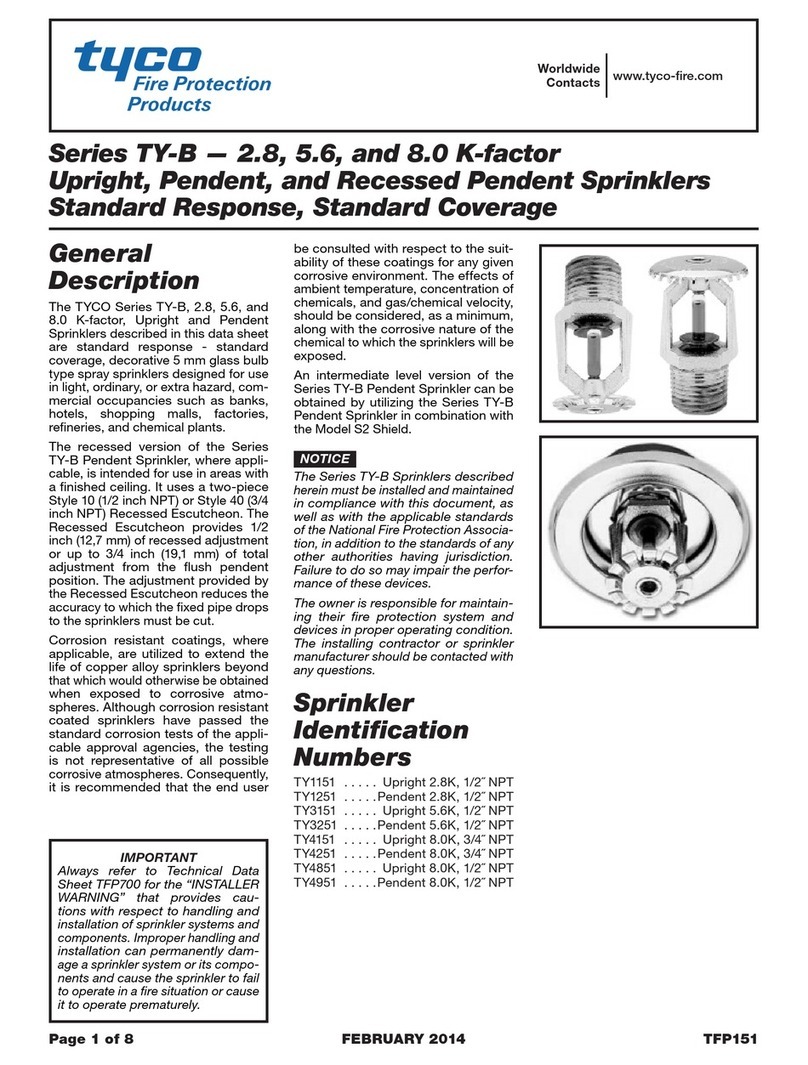

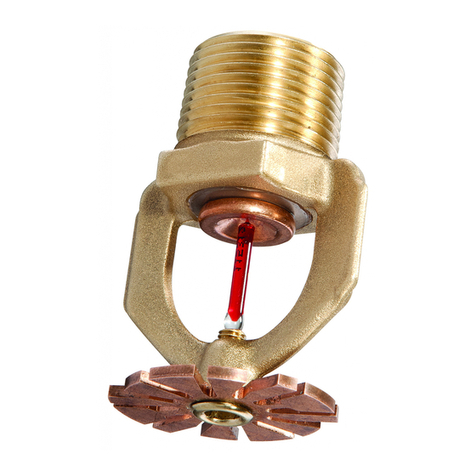

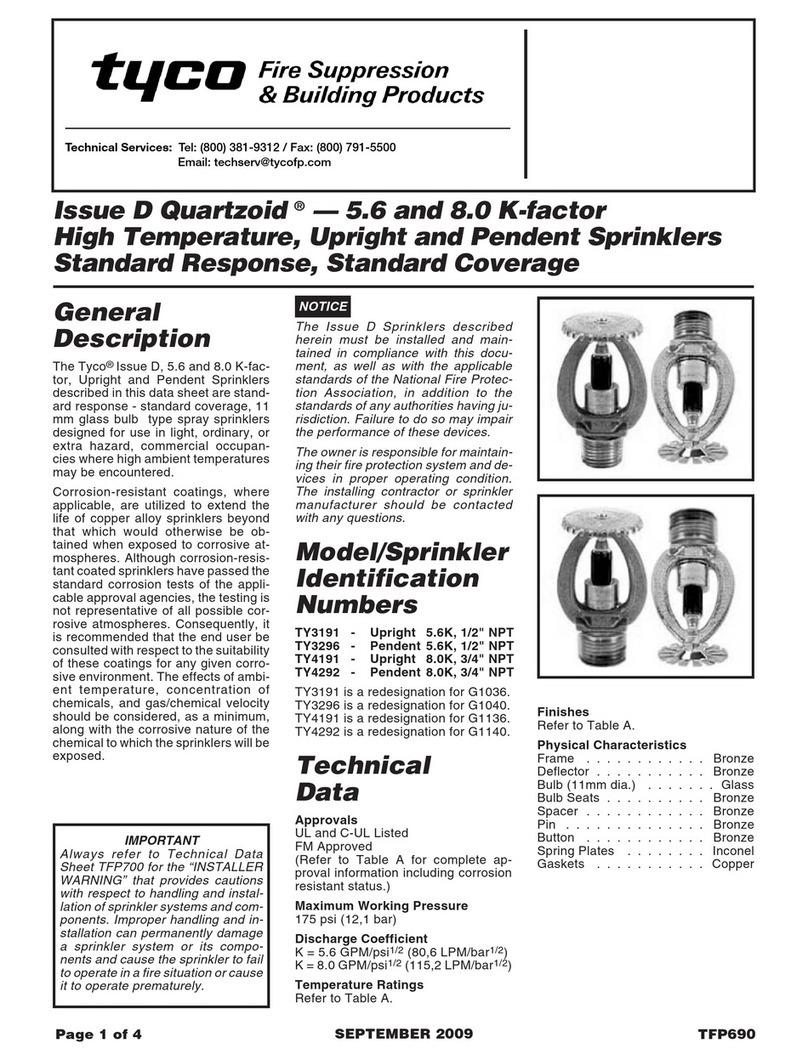

The Series TY-FRB, 5.6 and 8.0 K-fac-

tor, Conventional Sprinklers described

in this data sheet are quick response -

standard coverage, decorative 3 mm

glass bulb type spray sprinklers.

These sprinklers are intended to be

installed either pendent or upright, and

in either position, they produce a

spherical water discharge pattern with

approximately 50% of the discharge

directed upwards and approximately

50% of the discharge directed down-

wards.

Conventional sprinklers are generally

used with Ordinary and Extra High

Hazard Class Systems, as defined by

the automatic sprinkler system instal-

lation rules of the country and authority

having jurisdiction. The NFPA permits

the use of “Old Style Sprinklers” where

special construction features require a

unique water distribution; for the pro-

tection of fur vaults; or, the replace-

ment of similar sprinklers that had

been installed prior to 1955.

Corrosion resistant coatings, where

applicable, are utilized to extend the

life of copper alloy sprinklers beyond

that which would otherwise be ob-

tained when exposed to corrosive at-

mospheres. Although corrosion resis-

tant coated sprinklers have passed the

standard corrosion tests of the appli-

cable approval agencies, the testing is

not representative of all possible cor-

rosive atmospheres. Consequently, it

is recommended that the end user be

consulted with respect to the suitability

of these coatings for any given corro-

sive environment. The effects of ambi-

ent temperature, concentration of

chemicals, and gas/chemical velocity,

should be considered, as a minimum,

along with the corrosive nature of the

chemical to which the sprinklers will be

exposed.

WARNINGS

The Series TY-FRB Sprinklers de-

scribed herein must be installed and

maintained in compliance with this

document, as well as with the applica-

ble standards of the National Fire Pro-

tection Association, in addition to the

standards of any other authorities hav-

ing jurisdiction. Failuretodosomay

impair the performance of these de-

vices.

The owner is responsible for maintain-

ing their fire protection system and de-

vices in proper operating condition.

The installing contractor or sprinkler

manufacturer should be contacted

with any questions.

Model/Sprinkler

Identification

Numbers

TY3631 - 5.6K, 1/2"NPT

TY4631 - 8.0K, 3/4"NPT

Technical

Data

Approvals

UL and C-UL Listed.

LPCB, VdS and NYC Approved.

(Refer to Table A for complete approval

information including corrosion resis-

tant status.)

Maximum Working Pressure

175 psi (12,1 bar)

Discharge Coefficient

K=5.6GPM/psi

1/2 (80,6 LPM/bar1/2)

K=8.0GPM/psi

1/2 (115,2 LPM/bar1/2)

Temperature Ratings

RefertoTableA

Finishes

Sprinkler: Refer to Table A

Physical Characteristics

Frame ............ Bronze

Button ........ Brass/Copper

SealingAssembly ..........

. . . . . . Beryllium Nickel w/Teflon†

Bulb .............. Glass

Compression Screw . . . . . Bronze

Deflector........... Copper

† DuPont Registered Trademark

Series TY-FRB — 5.6 and 8.0 K-factor

Conventional (Old Style) Sprinklers

Quick Response

Page 1 of 4 TFP666

JULY, 2004

Technical Services: Tel: (800) 381-9312 / Fax: (800) 791-5500

IMPORTANT

Always refer to Technical Data

Sheet TFP700 for the “INSTALLER

WARNING” that provides cautions

with respect to handling and instal-

lation of sprinkler systems and com-

ponents. Improper handling and in-

stallation can permanently damage

a sprinkler system or its compo-

nents and cause the sprinkler to fail

to operate in a fire situation or cause

it to operate prematurely.