Design Criteria

ULandC-ULListing

Requirements

The Tyco®Ultra K17 (TY7153) Sprin-

klers with a 200°F/93°C temperature

rating may be installed in accordance

with NFPA 13 “Specific Application

Control Mode Sprinkler (for Storage

Use)” requirements to provide ceiling

only protection (i.e., no in-rack sprin-

klers) for high piled storage occupan-

cies (Solid-piled, palletized and rack

storage including but not limited to

Class I-IV and Group A plastics) using

the following criteria:

•astorageheightofupto25feet(7,6

m);

•a maximum ceiling height of 30 feet

(9,1 m);

•a minimum aisle width of 8 feet (2,4

m) for rack storage of Group A plas-

tic commodity stored from 20 feet to

25 feet (6,1to 7,6 m) and with ceiling

heights to 30 feet (9,1 m);

•a minimum deflector to top of stor-

age clearance of 36 inches (0,9m);

•a maximum coverage area of 100 ft2

(9,1 m2);

•a minimum coverage area of 80 ft2

(7,3 m2);

•NFPA spacing criteria for large drop

sprinklers, i.e.

12 feet (3,6 m) maximum for unob-

structed construction,

10 feet (3,0 m) maximum for rack

storage applications,

10 feet (3,0 m) maximum for ob-

structed construction, and

8feet(2,4m)minimum;

•NFPA deflector-to-ceiling distances

for large drop sprinklers;

•NFPA obstruction criteria for large

drop sprinklers;

•no additional column protection is

required;

•a hydraulic design of:

15 sprinklers at 10 psi (0,7 bar) for

Class I & II commodities, or

15 sprinklers at 22 psi (1,5 bar) for

Class III, IV, and cartoned or uncar-

toned unexpanded Group A and B

plastics; and,

•wet systems only (including preac-

tion systems that qualify as wet-pipe

systems)

FM Approval Requirements

TheTyco®16.8 K-factor, Ultra K17

(TY7153) Sprinklers may be installed

with the applicable “specific applica-

tion control mode” guidelines provided

byFactoryMutual.(FMguidelinesmay

differ from UL and C-UL Listing crite-

ria.)

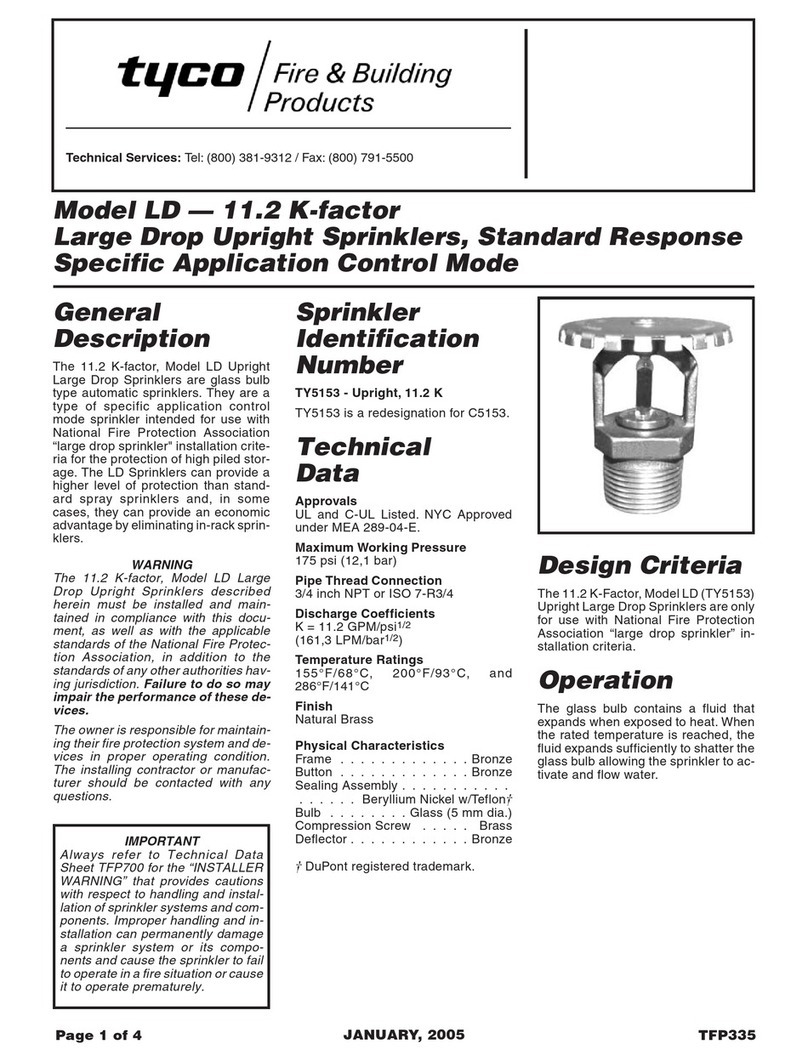

Operation

The glass bulb contains a fluid that

expands when exposed to heat. When

the rated temperature is reached, the

fluid expands sufficiently to shatter the

glass bulb, allowing the sprinkler to

activate and flow water.

Installation

NOTICE

Do not install any bulb type sprinkler if

the bulb is cracked or there is a loss of

liquid from the bulb. With the sprinkler

held horizontal, a small air bubble

should be present.The diameter of the

air bubble is approximately 1/16 inch

(1,6 mm).

The Ultra K17 Sprinklers must be in-

stalled in accordance with the follow-

ing instructions:

Step 1. With pipe thread sealant ap-

plied to the pipe threads, hand tighten

the Ultra K17 Sprinkler into the sprin-

kler fitting.

Step 2. Using the W-Type 8 Sprinkler

Wrench (Ref. Fig. 2) applied to the

sprinkler Wrench Flats (Ref. Fig. 1),

tighten the Ultra K17 Sprinkler into the

sprinkler fitting.

NOTICE

A leak tight 3/4 inch NPTsprinkler joint

should be obtained with a minimum to

maximum torque of 10 to 20 ft.lbs.

(13,4 to 26,8 Nm). Higher levels of

torque may distort the sprinkler with

consequent leakage or impairment of

the sprinkler.

Page2of4 TFP330

TYPE TEMP. BULB

LIQUID NATURAL BRASS

w/ CHROME DEFLECTOR

SPRINKLER FINISH

Red

Green

155°F/68°C

200°F/93°C

NOTES:

1. Listed by Underwriters Laboratories, Inc. (UL Listed).

2. Listed by Underwriters Laboratories, Inc. for use in Canada (C-UL Listed).

3. Approved by Factory Mutual Research Corporation (FM Approved).

4. Approved by the City of New York under MEA 177-03-E.

TABLE A

LABORATORY LISTINGS AND APPROVALS

(Refer to the Design Criteria Section)

3, 4UPRIGHT

K=16.8 (TY7153) 1, 2, 3, 4