Installation

NOTE

Do not install any bulb type sprinkler if

the bulb is cracked or there is a loss of

liquid from the bulb. With the sprinkler

held horizontal, a small air bubble

should be present. The diameter of the

air bubble is approximately 1/16 inch

(1,6 mm) for the 155°F/68°C to 3/32

inch (2,4 mm) for the 286°F/141°C rat-

ing.

The Model LD Sprinklers must be in-

stalled in accordance with the follow-

ing instructions:

Step 1. With pipe thread sealant ap-

plied to the pipe threads, hand tighten

the Model LD Sprinkler into the sprin-

kler fitting.

Step 2. UsingtheW-Type3(EndB)

Sprinkler Wrench (Ref. Fig. 2) applied

to the sprinkler Wrench Flats (Ref. Fig.

1), tighten the Model LD Sprinkler into

the sprinkler fitting.

NOTE

A leak tight 3/4 inch NPT sprinkler joint

should be obtained with a torque of 10

to 20 ft.lbs. (13,4 to 26,8 Nm). Higher

levels of torque may distort the sprin-

kler inlet with consequent leakage or

impairment of the sprinkler.

Care and

Maintenance

The Model LD Sprinklers must be

maintained and serviced in accord-

ance with the following instructions:

NOTE

Before closing a fire protection system

main control valve for maintenance

work on the fire protection system that

it controls, permission to shut down the

affected fire protection systems must

be obtained from the proper authori-

ties and all personnel who may be

affected by this action must be notified.

Sprinklers that are found to be leaking

or exhibiting visible signs of corrosion

must be replaced.

Automatic sprinklers must never be

painted, plated, coated, or otherwise

altered after leaving the factory. Modi-

fied sprinklers must be replaced.

Sprinklers that have been exposed to

corrosive products of combustion, but

have not operated, should be replaced

if they cannot be completely cleaned

by wiping the sprinkler with a cloth or

by brushing it with a soft bristle brush.

Care must be exercised to avoid dam-

age to the sprinklers - before, during,

and after installation. Sprinklers dam-

aged by dropping, striking, wrench

twist/slippage, or the like, must be re-

placed. Also, replace any sprinkler that

has a cracked bulb or that has lost

liquid from its bulb. (Ref. Installation

Section).

The owner is responsible for the in-

spection, testing, and maintenance of

their fire protection system and de-

vices in compliance with this docu-

ment, as well as with the applicable

standards of the National Fire Protec-

tion Association (e.g., NFPA 25), in

addition to the standards of any other

authorities having jurisdiction. The in-

stalling contractor or sprinkler manu-

facturer should be contacted relative to

any questions.

It is recommended that automatic

sprinkler systems be inspected,

tested, and maintained by a qualified

Inspection Service in accordance with

local requirements and/or national

codes.

Page2of4 TFP335

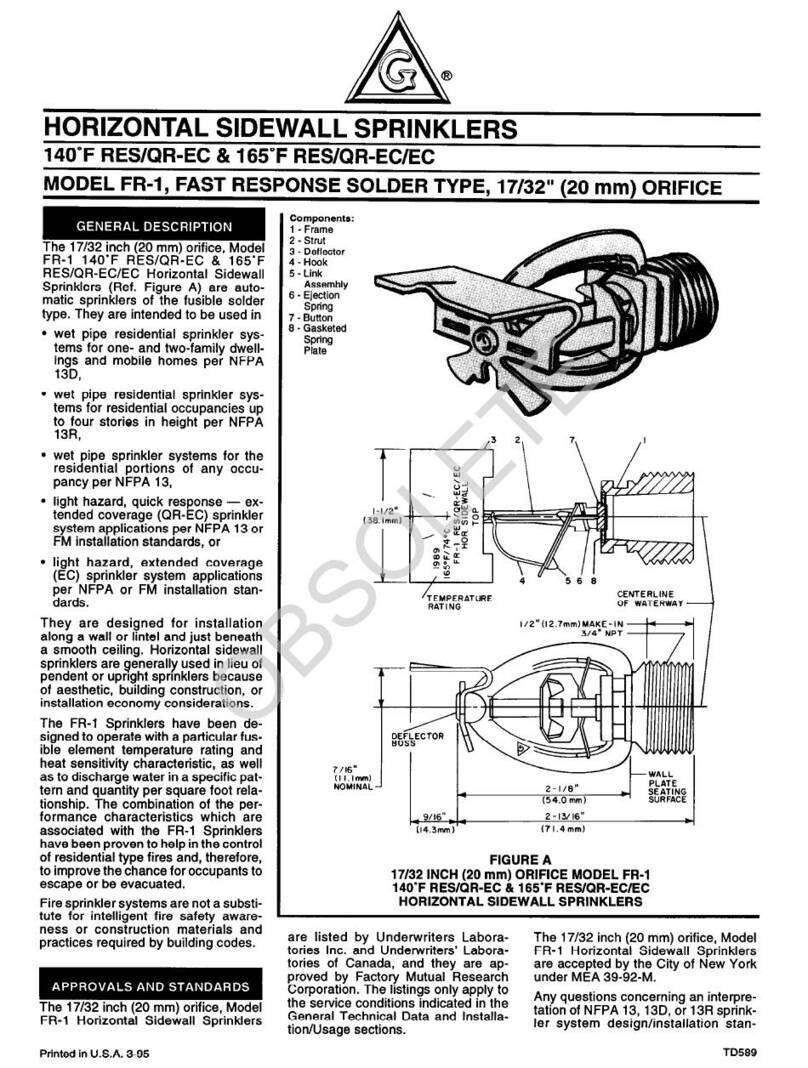

1-Frame

2 - Bulb

3 - Compression Screw

* Temperature rating is

indicated on deflector.

4 - Sealing Assembly

5-Button

6-Deflector*

** Pipe thread connections per ISO 7/1 can be provided on special request.

FIGURE 2

W-TYPE 3 SPRINKLER

WRENCH

4

5

WRENCH

FLAT

NOMINAL MAKE-IN

1/2" (12,7 mm)

2-3/8"

(60,3 mm)

SECTION

CROSS

UPRIGHT

*

3/4"

NPT **

2

1

36

FIGURE 1, MODEL LD (TY5153) UPRIGHT LARGE DROP SPRINKLERS

APPLY

SHOWN

WRENCH AS

RECESS

WRENCH

(END "B")