TFP319

Page 3 of 4

Care and

Maintenance

TYCO Model ESFR-14, 14.0 K-factor,

Pendent Sprinklers (TY6236) must

be maintained and serviced in accor-

dance with this section.

Before closing a re protection system

main control valve for maintenance

work on the re protection system that

it controls, obtain permission to shut

down the affected re protection sys-

tems from the proper authorities and

notify all personnel who may be af-

fected by this action.

Sprinklers which are found to be leak-

ing or exhibiting visible signs of corro-

sion must be replaced.

Automatic sprinklers must never be

painted, plated, coated, or other-

wise altered after leaving the factory.

Modied sprinklers must be replaced.

Sprinklers that have been exposed to

corrosive products of combustion, but

have not operated, should be replaced

if they cannot be completely cleaned

by wiping the sprinkler with a cloth or

by brushing it with a soft bristle brush.

Care must be exercised to avoid dam-

age to the sprinklers before, during,

and after installation. Sprinklers dam-

aged by dropping, striking, wrench

twist/slippage, or the like, must be

replaced. Also, replace any sprinkler

that has a cracked bulb or that has

lost liquid from its bulb. (Refer to In-

stallation Section.)

The owner is responsible for the in-

spection, testing, and maintenance of

their re protection system and devic-

es in compliance with this document,

as well as with the applicable stan-

dards of the National Fire Protection

Association (e.g., NFPA 25), in addition

to the standards of any other authori-

ties having jurisdiction. Contact the

installing contractor or product manu-

facturer with any questions.

Automatic sprinkler systems are rec-

ommended to be inspected, tested,

and maintained by a qualied Inspec-

tion Service in accordance with local

requirements and/or national codes.

Limited

Warranty

For warranty terms and conditions,

visit www.tyco-re.com.

Ordering

Procedure

Contact your local distributor for avail-

ability. When placing an order, indi-

cate the full product name and Part

Number (P/N).

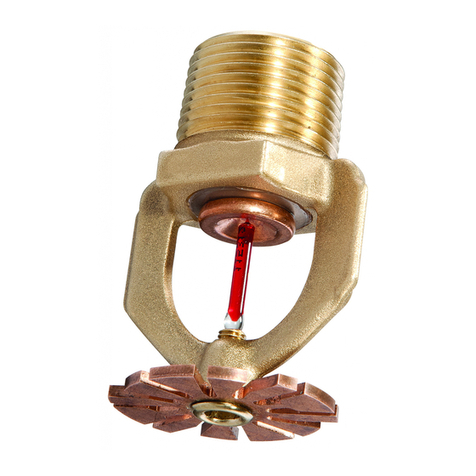

Sprinkler Assemblies

Specify: Model ESFR-14 (TY6236),

K=14.0, Pendent Sprinkler with (spec-

ify) temperature rating, Natural Brass,

P/N (specify):

155°F (68°C) .............. P/N 58-449-1-155

200°F (93°C).............. P/N 58-449-1-200

Special Order

Sprinkler Assemblies with

ISO 7/1 Thread Connections

Specify: Model ESFR-14 (TY6236),

K=14.0, Early Suppression, Fast Re-

sponse Pendent Sprinkler with ISO

7/1 Thread Connection, (specify) tem-

perature rating, Natural Brass, P/N

(specify):

155°F (68°C) .............. P/N 58-443-1-155

200°F (93°C).............. P/N 58-443-1-200

Sprinkler Wrenches

Specify: W-Type 2 Sprinkler Wrench,

P/N 56-872-1-001

Specify: W-Type 30 Sprinkler Wrench,

P/N 56-001-0-688

Storage Type NFPA FM Global

Open Frame (i.e., no solid shelves)

Single, Double, Multiple-Row, or Portable Rack Storage

of Class I-IV and Group A or B Plastics

Refer to NFPA 13,

Chapters 16 and 17

Refer to FM Global

2-0 and 8-9

Solid Pile or Palletized Storage

of Class I-IV and Group A or B Plastics

Refer to NFPA 13,

Chapters 14 and 15

Refer to FM Global

2-0 and 8-9

Idle Pallet Storage Refer to NFPA 13,

Chapter 12

Refer to FM Global

2-0, 8-9, and 8-24

Rubber Tire Storage Refer to NFPA 13,

Chapter 18

Refer to FM Global

2-0 and 8-9

Rolled Paper Storage

(Refer to the standard)

Refer to NFPA 13,

Chapter 19

Refer to FM Global

8-21

Flammable Liquid Storage

(Refer to the standard) Refer to NFPA 30 Refer to FM Global

7-29

Aerosol Storage

(Refer to the standard) Refer to NFPA 30B Refer to FM Global

7-31

Automotive Components in Portable Racks

(Control mode only, refer to the standard) N/A N/A

N/A – Not Applicable

TABLE A

MODEL ESFR-14 PENDENT SPRINKLERS

COMMODITY SELECTION AND DESIGN CRITERIA OVERVIEW