PAGE 2 OF 39 0920 IH-8184

SAFETY

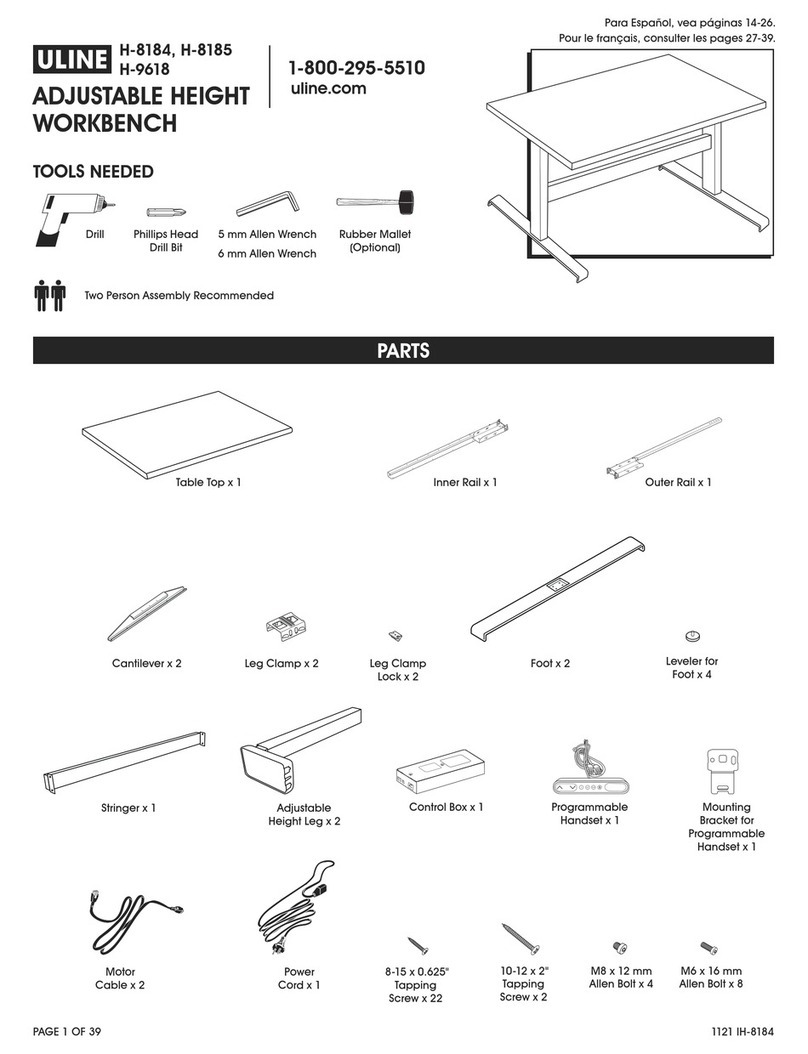

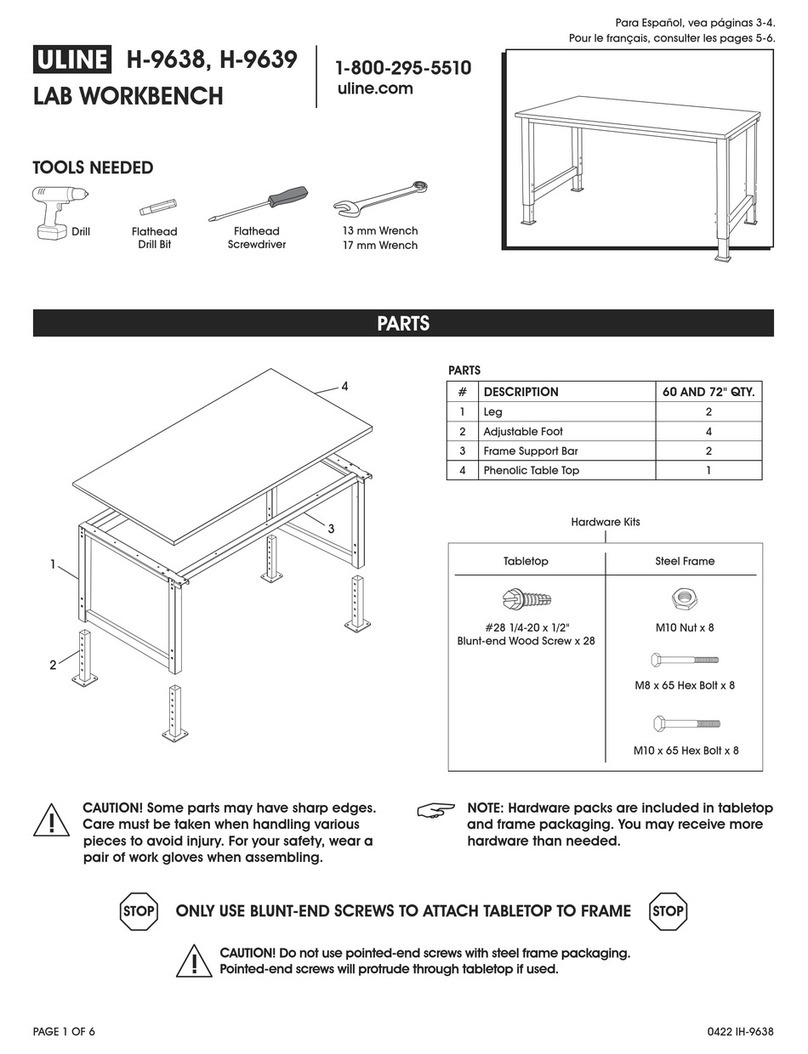

NOTE: Count and inspect all pieces before

disposing of any carton or packing materials.

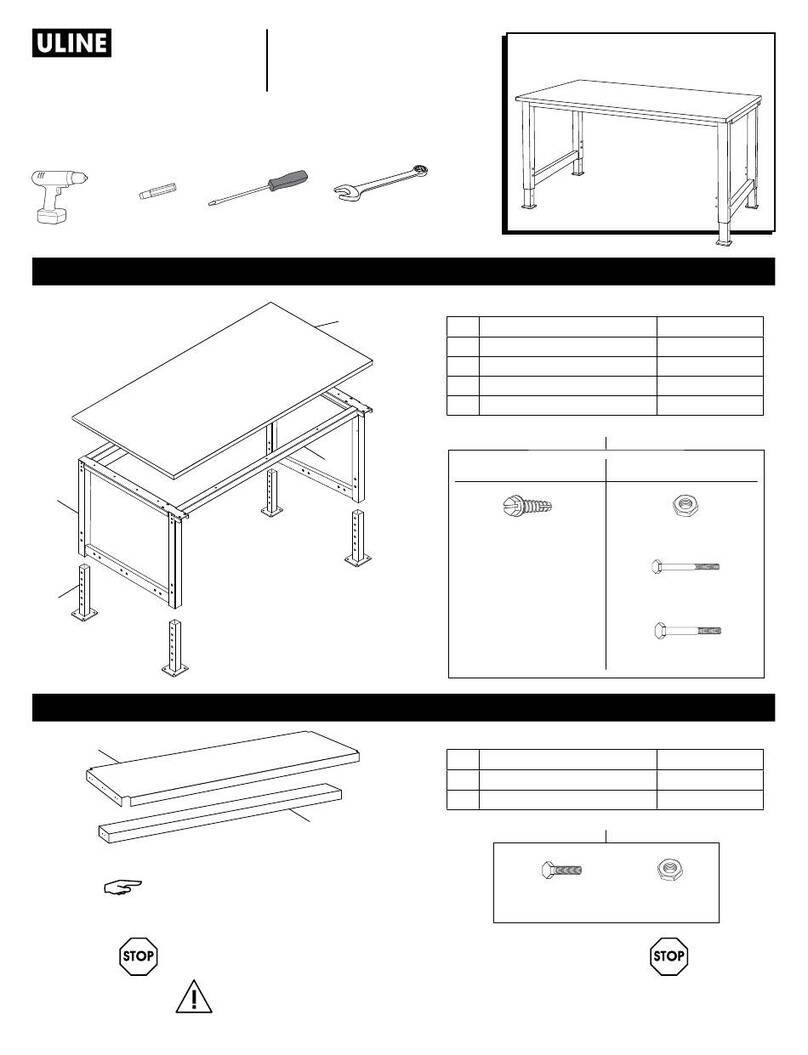

CAUTION! Adjustable legs are heavy and care

should be used when moving them during

assembly.

WARNING! Failure to comply with these

instructions may result in accidents involving

serious personal injury.

NOTE: Failing to follow these instructions can

result in the product being damaged or being

destroyed.

Safe use of the system is possible only when the

operating instructions are read completely and the

instructions are strictly observed.

CAUTION! It is important for everyone

connecting, installing or using the product to

have the necessary information and access

to these instructions. Follow the instructions

for mounting – there is a risk of injury if these

instructions are not followed.

CAUTION! The product is not intended for use

by young children or infirm persons without

supervision.

CAUTION! If there is visible damage to the

product, do not install it.

CAUTION! During construction of applications

in which the actuator is to be fitted, there must

be no possibility of personal injury, for example

squeezing of fingers or arms.

NOTE: Ensure free space for movement of the

product in both directions to avoid blockades.

CAUTION! Persons who do not have the

necessary experience or knowledge of the

product/products must not use the product/

products.

CAUTION! Persons with reduced physical,

sensory or mental abilities must not use the

product/products, unless they are under

surveillance or they have been thoroughly

instructed in the use of the apparatus by a

person who is responsible for the safety of

these persons.

CAUTION! Children must be supervised.

CAUTION! It is the operator's responsibility

before operating to ensure that there is free

space for the application to move without risk

for the operator or bystanders.

CAUTION! Do not overload the actuators – this

can cause personal injury and damage to the

system.

CAUTION! Do not use the workbench for lifting

persons. Do not sit or stand on a table while

operating.

CAUTION! Do not use the system in

environments other than the intended indoor

use.

BEFORE INSTALLATION, RE-INSTALLATION

OR TROUBLESHOOTING

• Stop the columns.

• Switch off the power supply and pull out the power

plug.

• Relieve the columns of any loads, which may be

released during the work.

BEFORE START-UP

• Make sure that the system has been installed as

instructed in these instructions.

• Make sure that the voltage of the control box is

correct before connecting the system to the power

supply.

• The individual parts must be connected before

connecting the control box to the power.

DURING OPERATION

• If the control box makes unusual noise or smells,

remove the power plug immediately.

• Ensure the cables are not damaged.

• Unplug the power cable on mobile equipment

before moving it.