0413 IH-2585PAGE 3 OF 3

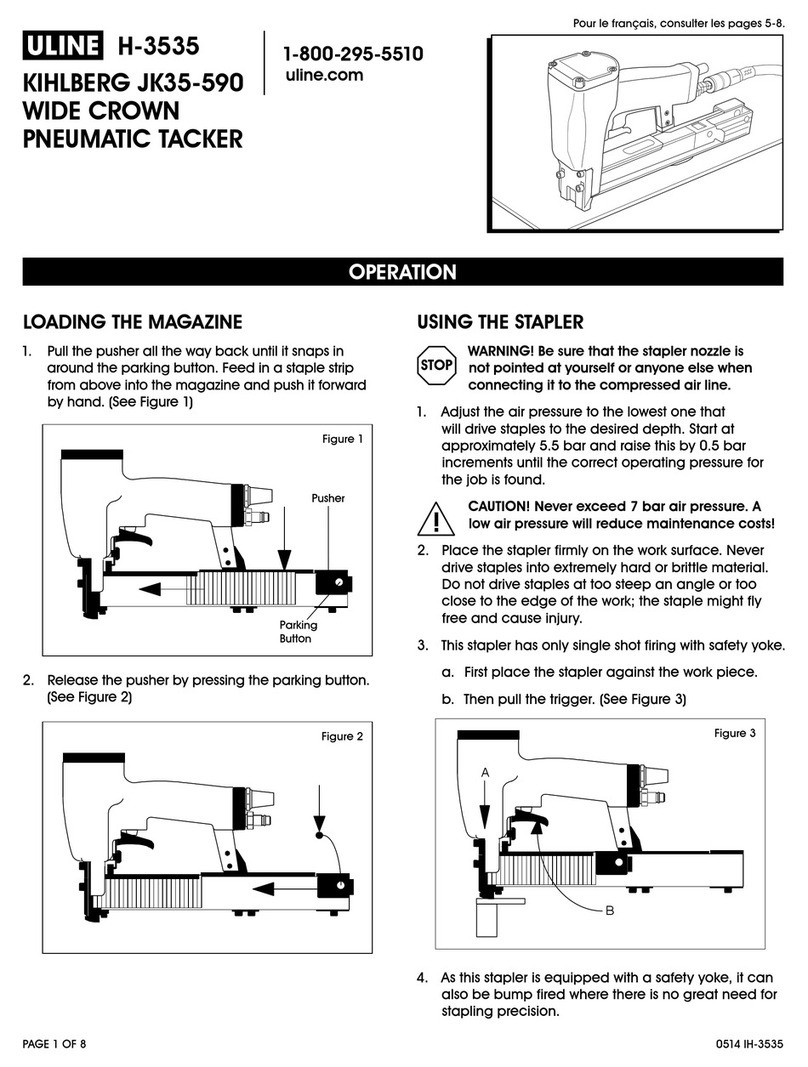

FOR ON TOP OF LOAD

1. Bring tensioning handle upward, allowing the

gripper to contact the lower strap.

Rotate the tensioning handle

back and forth to take up

slack in the strap.

When strap is snug,

the operator should

kneel perpendicular to the

strap and apply the final tension

using short tensioning strokes.

2. Open sealer fully and center sealer jaws of sealer

over each seal. Crimp or notch each seal the

proper number of times by

bringing the top handle

downward as far as it will

go. Consult your sealer

manual for the proper

number of crimps or

notches needed for

your application.

3. Release tensioner from strap by

bringing handle down until the

gripper release cam locks

in tensioning handle pin.

Remove tensioner by

twisting drum slot out

of strap curl and sliding

tool away from strap.

FOR ON SIDE OF LOAD (VERTICAL)

1. Bring tensioning handle downward,

allowing the gripper to contact

the lower strap. Rotate tensioning

handle back and forth to take up

slack in strap. When strap is snug,

the operator should stand to the

side of the tool and apply the

final tension using short

tensioning strokes.

2. Open sealer fully and

center sealing jaws of

sealer over each seal.

Crimp or notch each

seal the proper number of

times by bringing the top

handle downward as

far as it will go. Consult

your sealer manual for the proper

number of crimps or notches

needed for your application.

3. Release tensioner from strap by

rotating handle until it contacts

and locks into the gripper release

cam. Remove tensioner by twisting

drum slot out of strap curl and

sliding tool away from strap.

WARNING! While tensioning strap, do not rotate the tensioning

handle to the point where it will contact the gripper release cam.

This will result in a sudden loss of strap tension. Be careful when

applying final tension, as excessive tension could cause strap

breakage. Position yourself in such a manner than strap breakage

or hands slipping off the handle will not cause a loss of balance.

Never increase the length of the tensioning handle by any means,

such as slipping a pipe over the handle to extend its length.

OPERATING INSTRUCTIONS

RECOMMENDED

OPERATING

RANGE

GRIPPER

RELEASE

CAM

GRIPPER

RELEASE

CAM

GRIPPER

RELEASE

CAM

GRIPPER

RELEASE

CAM

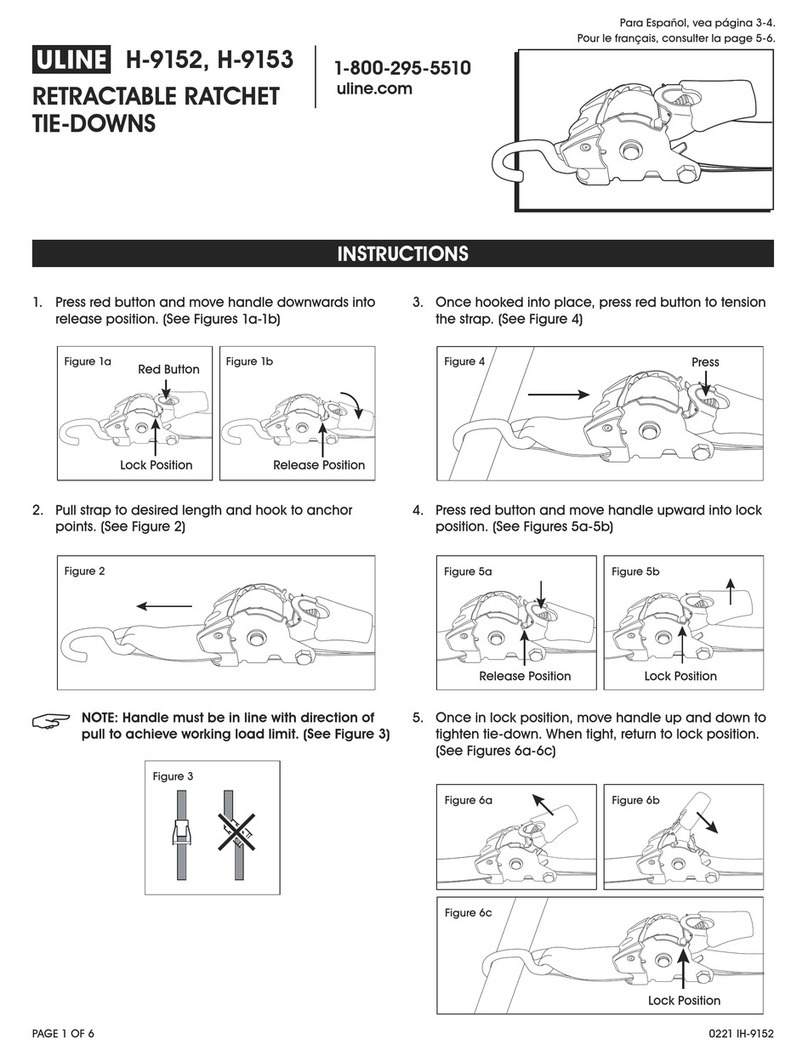

FOR WALL ANCHORED OR SIDE (HORIZONTAL) LOADS

The positioning of the tensioner on the strap for horizontal use

is the same as on top of load operation. After the slack strap is

taken up, final tension is applied by short push type strokes, as

illustrated at left. Note that a tensioner is used on each strap to

ensure equal tension. The sealing operation is also the same as

for top of load use (Refer to top of load instructions).

π CHICAGO • ATLANTA • DALLAS • LOS ANGELES • MINNEAPOLIS • NYC/PHILA • SEATTLE • MEXICO • CANADA

1-800 -295-5510

uline.com