Ulvac CRYOPUMP CRYO-U Series User manual

Other Ulvac Water Pump manuals

Ulvac

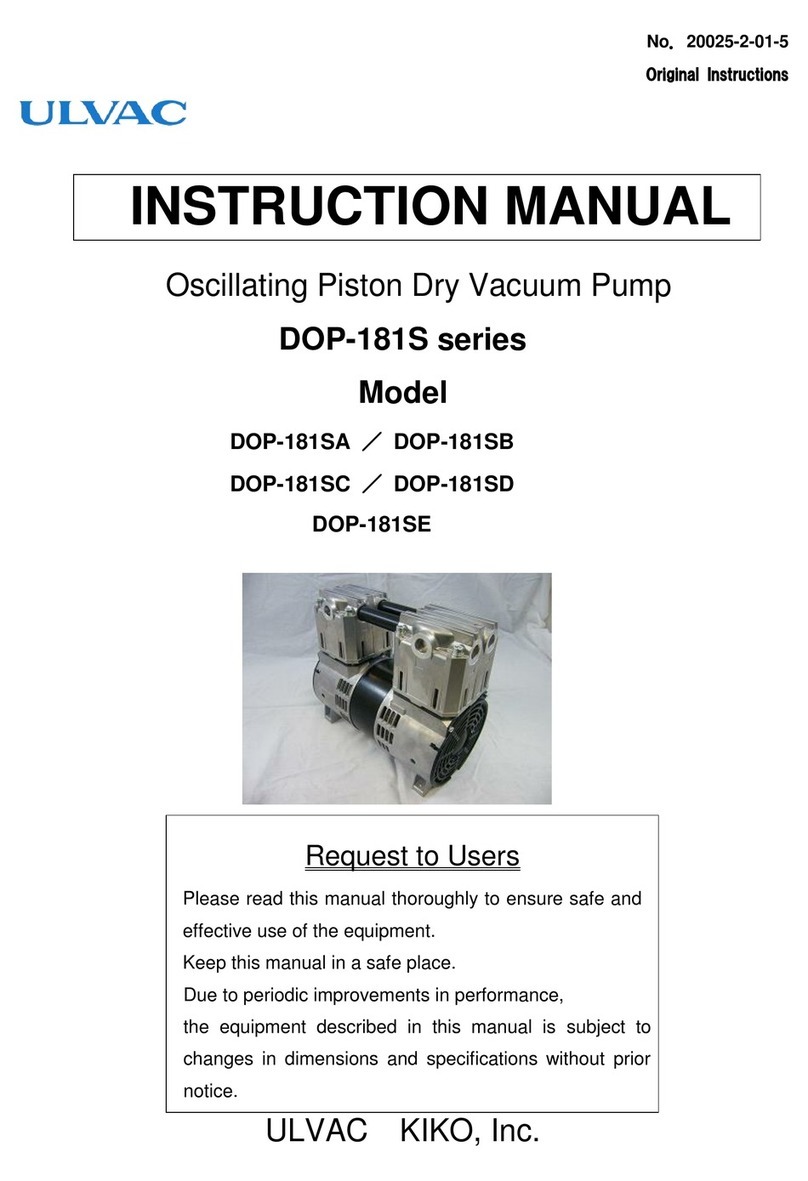

Ulvac DOP-181S Series User manual

Ulvac

Ulvac DISL-102 User manual

Ulvac

Ulvac CRYO-U12H User manual

Ulvac

Ulvac ULK-10A User manual

Ulvac

Ulvac DA-41D User manual

Ulvac

Ulvac PRC-003A User manual

Ulvac

Ulvac DAU-100 User manual

Ulvac

Ulvac PMB-040C User manual

Ulvac

Ulvac DIS-251 User manual

Ulvac

Ulvac G-5DA User manual

Ulvac

Ulvac DIS-90 User manual

Ulvac

Ulvac VD151 User manual

Ulvac

Ulvac DTC-41 User manual

Ulvac

Ulvac UTM3400 Series User manual

Ulvac

Ulvac ULK-04A User manual

Ulvac

Ulvac DTC-22 User manual

Ulvac

Ulvac UTM-MS Series User manual

Ulvac

Ulvac G-20DA User manual

Ulvac

Ulvac MBS-053 User manual

Ulvac

Ulvac UTM300B User manual

Popular Water Pump manuals by other brands

DUROMAX

DUROMAX XP WX Series user manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Xylem

Xylem e-1532 Series instruction manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual