i

YO20-0938-DI-001-00

Before Use of This machine

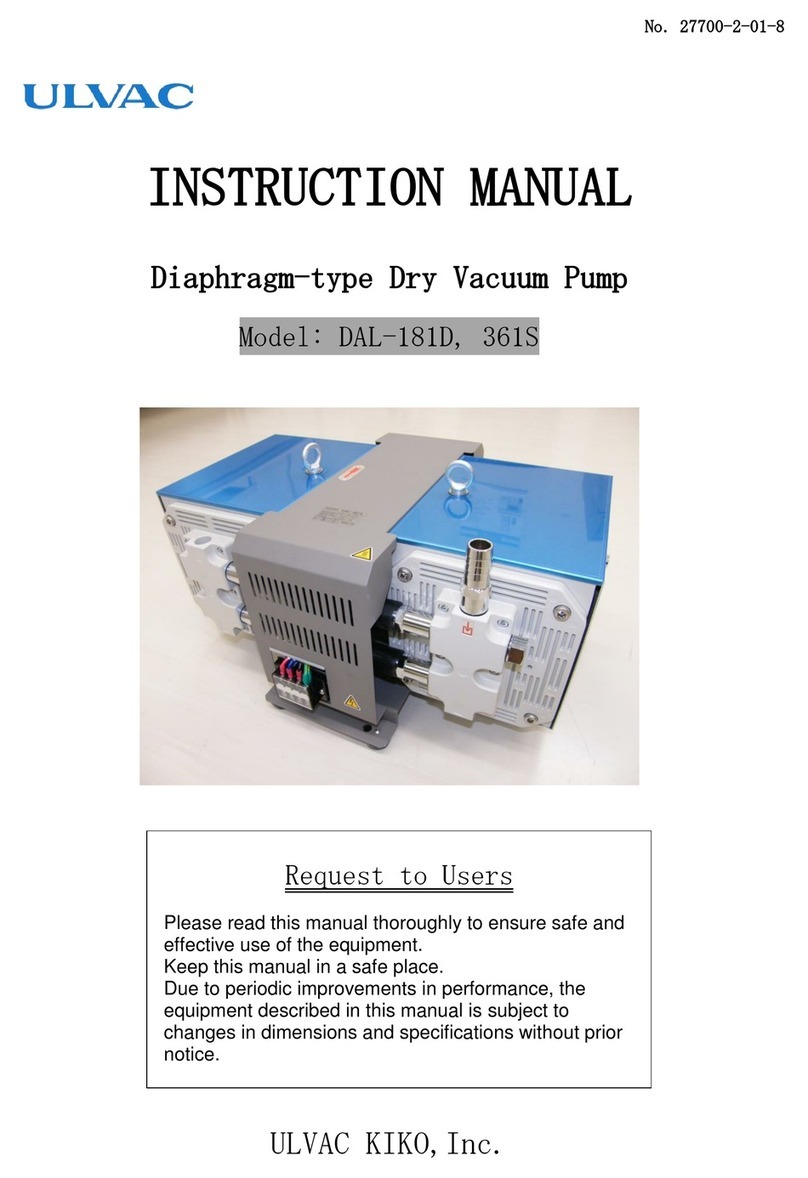

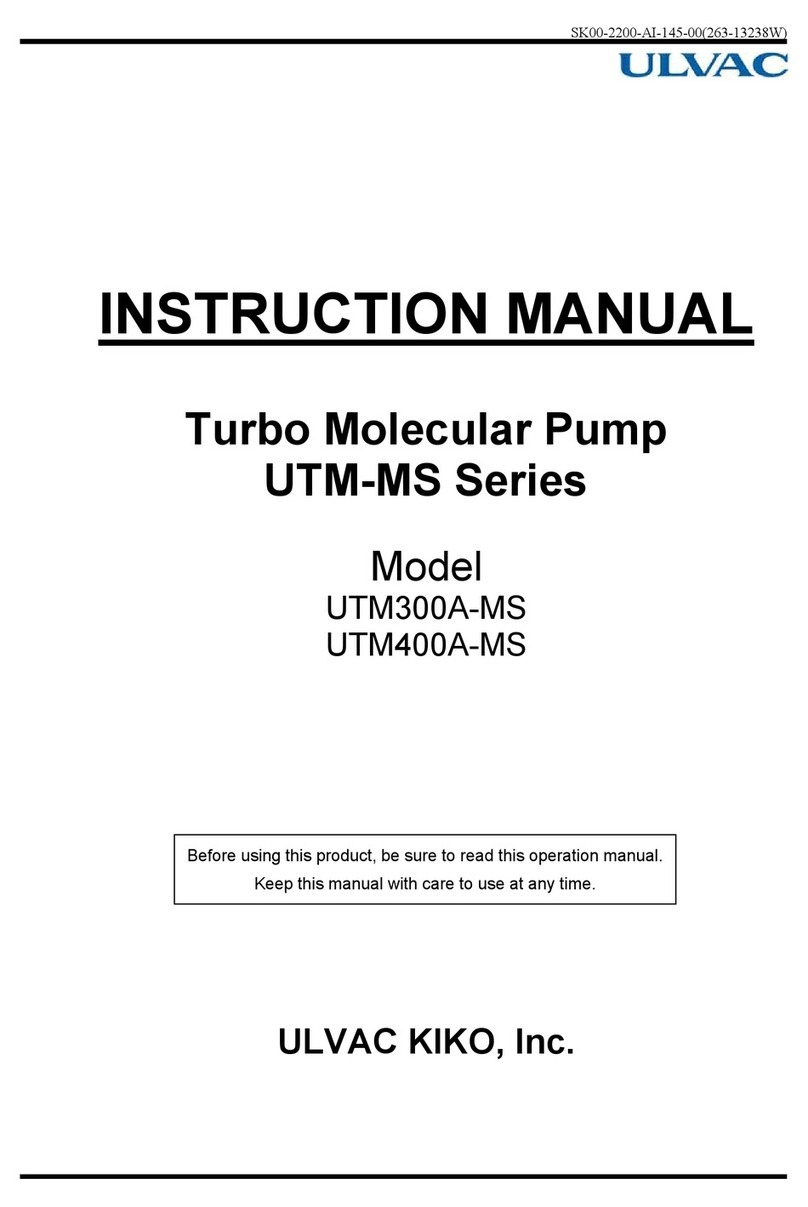

Dry Pumps from ULVAC, Inc. (hereinafter referred to as "Our Company"): MS series (hereinafter referred to as

"this machine")

Upon receipt of the machine, please confirm the contents included are the same as you ordered and check the

machine for any damage attributed to transportation etc. just in case.

This instruction manual (hereinafter, "this manual") describes appropriate handling and maintenance

procedures to safely use this pump and to maximize its performance. Read this document in advance to

properly use this pump.

Install and operate this machine according to the local and national safety laws and regulations (such as fire

laws and electric wiring code). It is required to take a training for general safety of the country and the local area

where this machine will be used. Do not use this machine without any training.

The operator is required to have taken such trainings. In addition, the operator must have expertise, skills,

qualifications in electrics, mechanics, cargo handling, vacuum, etc.

This pump has been designed to conform to the rules in place when this document was created. Conformity is

not guaranteed because the applicable standards may change in the future.

Performance and safety may not be ensured if equipment connected to this pump does not conform to the

same rules or if the pump is altered. In such cases, we cannot guarantee (take responsibility for) performance

or safety. Product alterations made by the customer are not covered by the warranty, and we cannot take

responsibility for them.

Before installing or removing this machine, separate all energy sources (including power and cooling water)

from the product.

None of this pump's parts may continue to be used permanently while maintaining the performance upon

delivery. Performance inevitably degrades after a certain amount of time elapses, thus increasing the likelihood

of product problems even in assumed common usage scenarios. We ask that our customers perform preventive

maintenance to avoid problems in accordance with their usage scenarios. By performing preventive

maintenance measures, you can lower the probability of problems with this pump due to parts failures caused

by parts becoming worn out as well as the probability of other risks, such as downtime caused by pump

problems, fire, or effects on other processes. From the viewpoint of preventive maintenance, we also ask our

customers to prepare maintenance and inspection plans and to replace parts and perform overhauls according

to such plans.

If you have any questions about handling or other matters, please contact our nearest sales office or dealer.