MANUAL - UG2000DM SERIES SPRAY GUN CLEANERS REVISED 2018-12

Prevent Solvent From Entering the Air Passage of Spray Gun:

insert the plastic plug into the air tting as in the photo

below . Positive air will ow through the passage way

to the cap during cleaning. If the air passage way has

a a male tting attach the knurled female nut to

prevent sovlent from entering the air passage way.

This tting is located on the chain with the

trigger clamp.

• Close the lid of the spray tank

and turn the "Auto Wash Timer"

clockwise as in photo below

to initiate cleaning. The wash

cycle takes about 60 seconds.

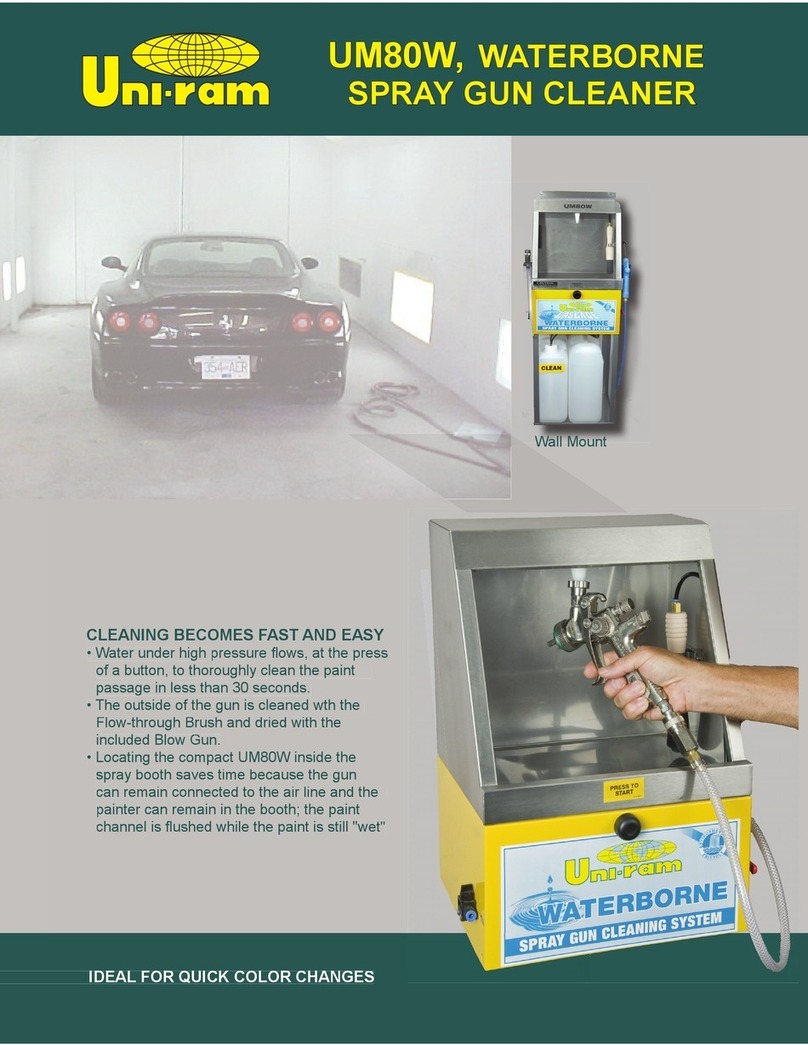

• MANUAL WASH

Open the lid and remove brush from its holder on the back wall of the wash tank.

Step on the foot pedal. A dedicated pump delivers wash solvent through the brush, left photo below.

To control the flow of solvent through the Brush, adjust the Flow Control, also on the front of the

unit, right photo.

•The spray gun can be washed with the brush before or after "Auto" wash.

• Dry the spray gun thoroughly.

REPLACING SOLVENT:

• Replace the solvent when the solvent has lost its cleaning

eectiveness or after approximately 100 cleanings.

• Close the drain valve (horizontal position).

• Remove the pail of used solvent. Dispose of the used solvent

in a manner compliant with the laws in the municipality.

Return the pail to the cabinet and install the suction hose and

drain hose to the pail. Pour 5 gallons of new clean solvent into the

cleaning tank to drain to the pail in the cabinet.

Plastic Plug insterted into the air

passage way of the spray gun

Drain Valve in

Closed Position