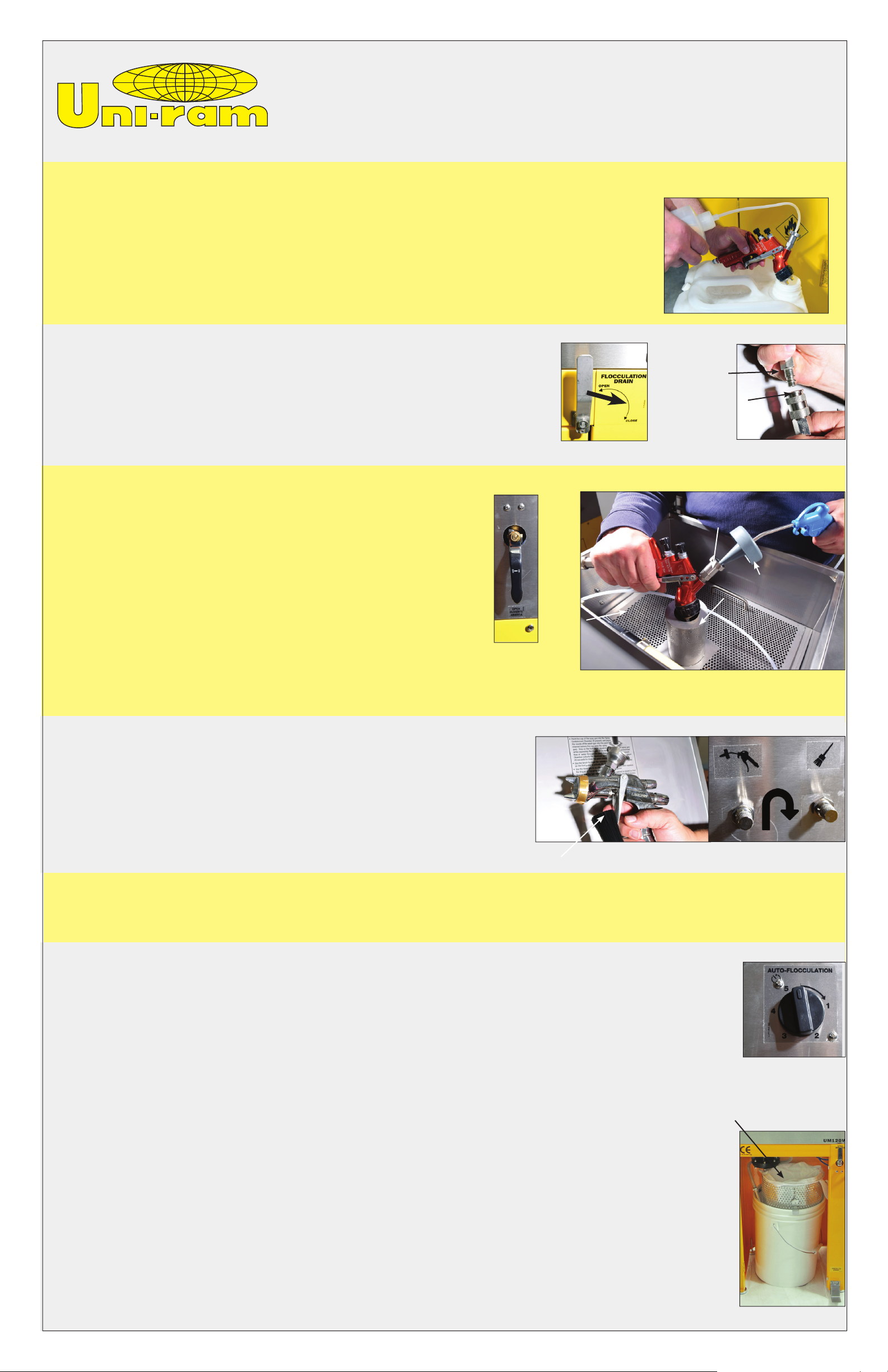

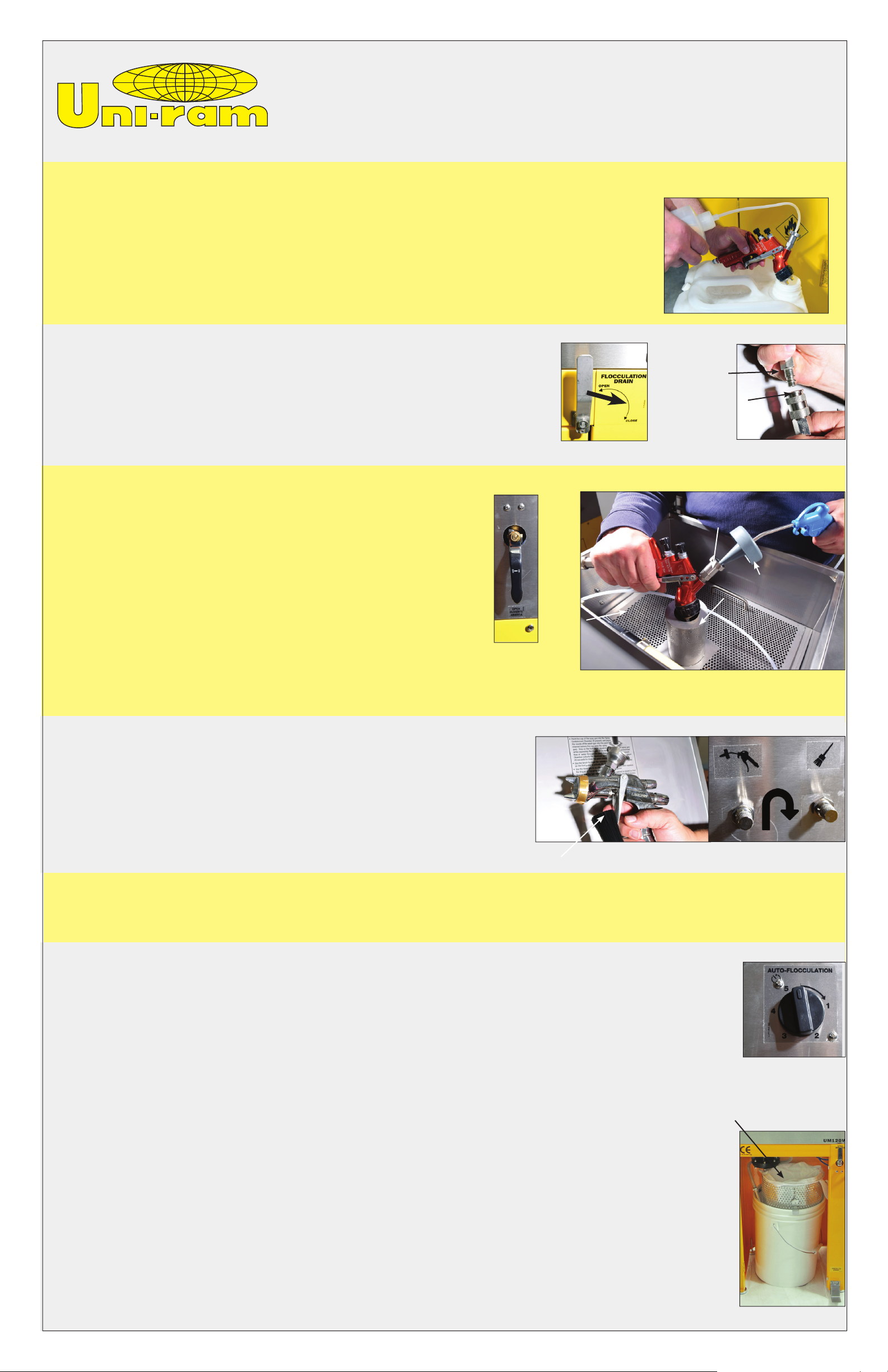

USE WATER GUN TO FLUSH THE PAINT CHANNEL:

• Move the handle of the Selector Valve to the Wash Gun position.

See photo on right.

• Step on the foot pedal, squeeze the trigger of the spray gun and

Wash Gun to send a pressurized flow of water through the paint

channel. The Spray Containment Chamber contains the spray.

• Allow water to flow for about 20 seconds to clean the

paint channel. See photo on far right.

• Use the Wash Gun Flow Control to adjust the water volume.

See photo on the far right in next section.

PREPARE FOR CLEANING:

• Move the handle of the drain flocculation valve to the closed position.

See photo on right.

• Connect the quick connect of the whip line to the air fitting of the spray

gun. See photo on far right.

DRY SPRAY GUN:

• Squeeze the trigger of the spray gun and use the blow gun to dry the paint channel and then the outside of the spray gun.

PRE-CLEAN:

• Disconnect the spray gun from the air line and remove the

cup.

• Squirt water into the disposable cup adapter, pull the trigger and

allow waste water to drain into a waste container (not supplied).

See photo on right.

UG5000W - WATER TANK

STANDARD OPERATING PROCEDURES

Wash

Gun

Fluid Passage of

Spray gun

USE THE FLOW-THROUGH BRUSH TO WASH THE SPRAY GUN:

• Move the handle of selector valve to the horizontal position and step on

the foot pedal to send a pressurized flow of water through the Brush.

• Use the Brush Flow Control to adjust the water volume.

See photo on the far right. To increase flow, loosen the locking nut,

rotate the dial anti-clock wise, and tighten the locking nut.

Spray Containment

Chamber

Air fitting of

spray gun

Coupler of the

whip line

Flow-through Brush

Selector

Valve

Flow Control

Flocculation Timer

Primary Filter

Water Pail

BrushWash Gun

WATER RECLAIM:

When no water remains in the water pail under the cleaning tank it is time to reclaim the dirty water.

• Remove the Work Screen. Sprinkle 2 full scoops of the flocculant, COAG-KLEEN,

evenly over the dirty water. Close the lid and turn the Flocculation Timer fully. When the Timer is

finished wait 2 minutes and turn the timer a second time to the one minute mark.

• Note: As the flocculation proceeds, the water will become clear below the surface. Open the

Flocculation drain valve to drain and filter the dirty water. Clean the tank with the wash gun, wipe

off the work screen, reinsert it and then close the drain valve. Ensure that the Air Agitator in the bottom

of the tank lies flat.

• Remove the two filters containing the debris and set aside for about 20 minutes to “dry”. When the

debris is “dry”, it should have an "oatmeal like" consistency. Dispose of the debris according to local

environmental regulations.

• If the filtered water is not clean, see the Troubleshooting section in the manual.

• The treated water can be reused until it becomes "silky" to the touch and then it should be disposed of

according to local environmental regulations. When adding fresh water, refill until the water reaches

the bottom of the filter holder.

• Reuse the filters and replace as required.

SOP-UG5 JULY 2020