2

MANUAL - UG4000 SERIES SPRAY GUN CLEANERS REVISED 2019-02

INTRODUCTION

Uni-ram holds many patents on designs used in its innovative products. Every machine is tested

for compliance with Quality Assurance standards. Follow the directions in this manual under Setup,

Operation and Maintenance in order to operate this machine safely and effectively. Not following these

instruction can lead to malfunction or damage to the machine. Ensure that the manual is readily available

for the operator at all times. If you have any questions about the operation of this machine, call Uni-Ram

Service Engineer at 1-800-417- 9133.

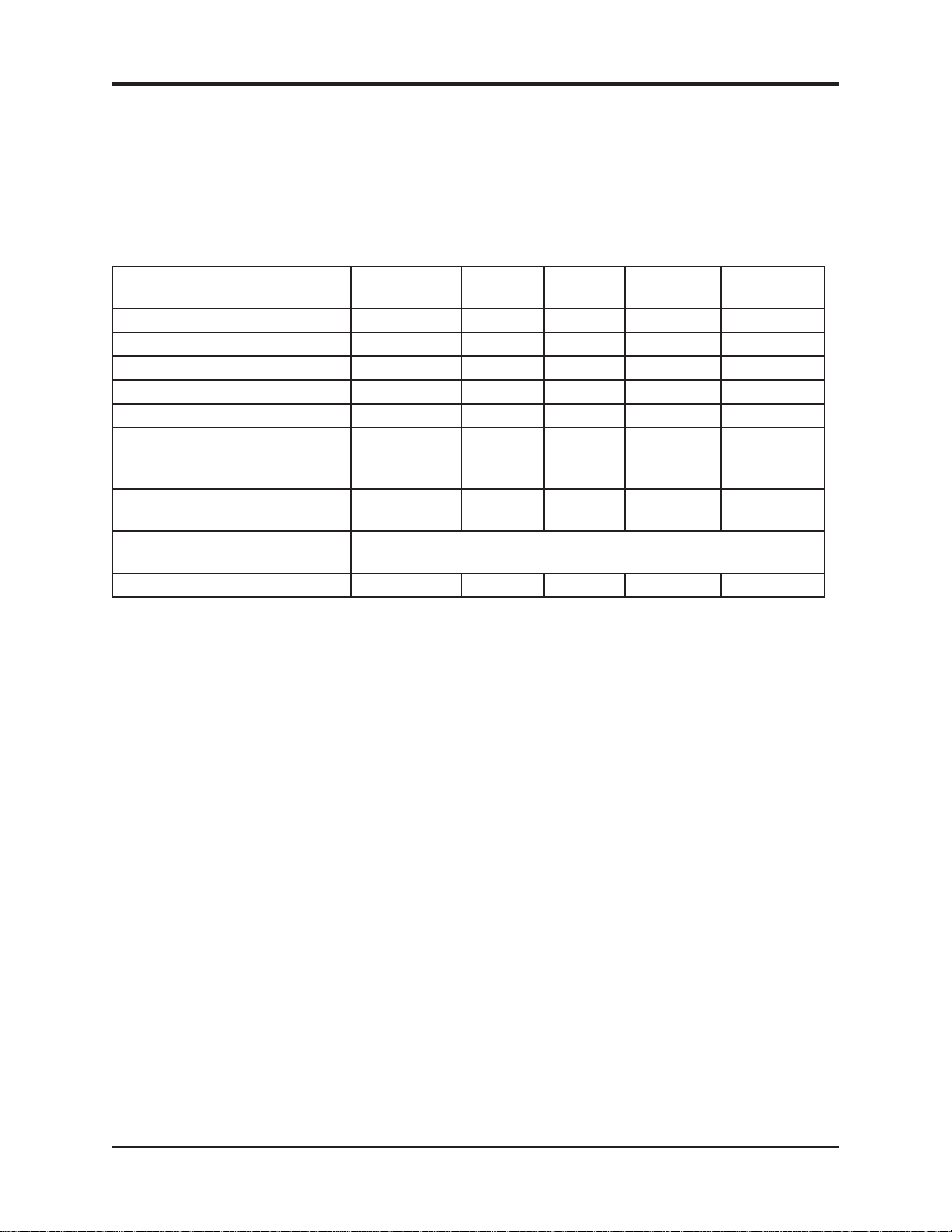

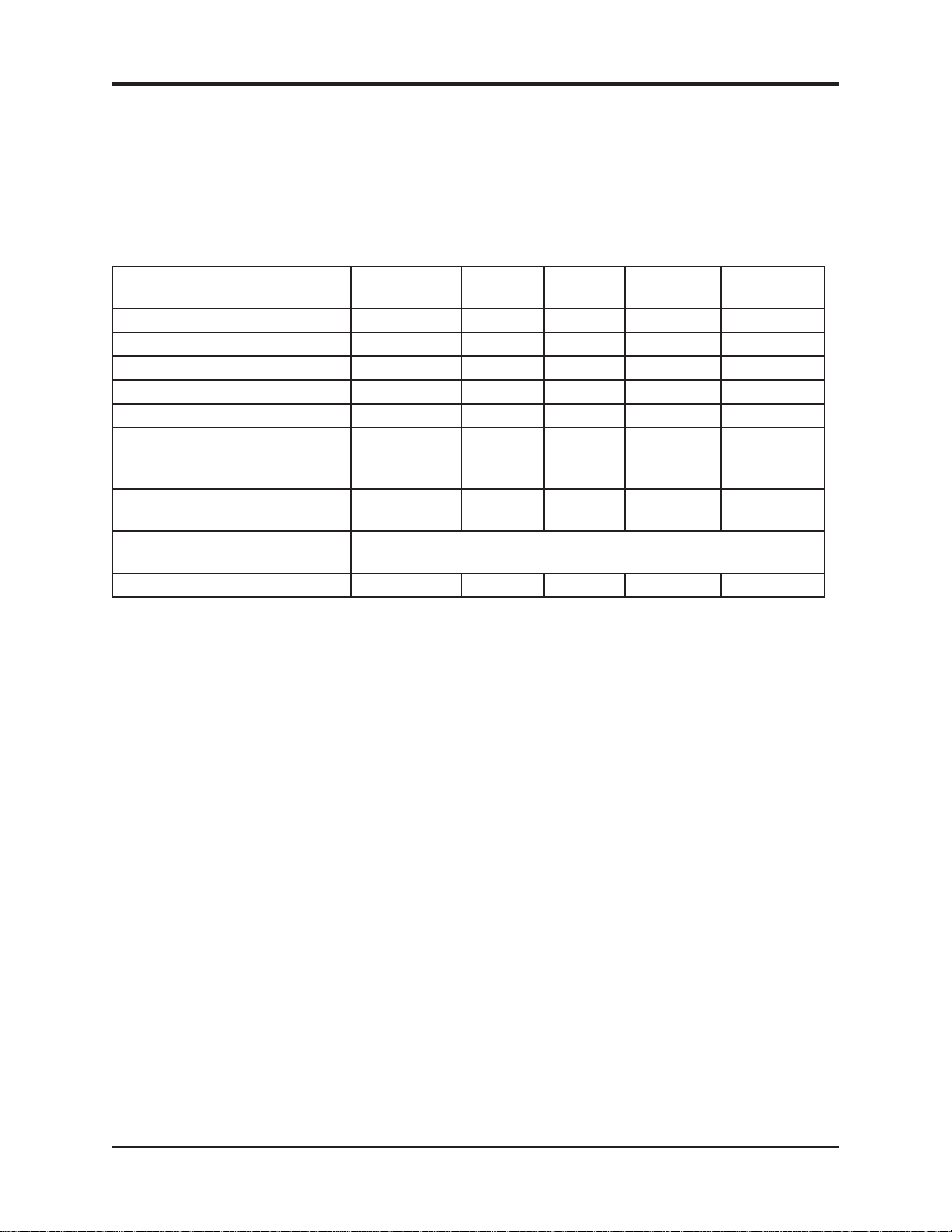

MODEL UG4000D UG4000E UG4500E UG4000FS UG4000DVM

HOSE CLEANING YES

MANUAL WASH SPIGOT

MANUAL RINSE WITH SPIGOT YES

COMBO READY YES YES YES

WASH SOLVENT PAIL INCL INCL INCL INCL INC

RINSE SOLVENT PAIL REQUIRED,

NOT IN-

CLUDED INCL INCL INCL REQUIRED,

NOT IN-

CLUDED

OVERFLOW TUBE AND RISER NOT RE-

QUIRED INCL NOT RE-

QUIRED

SHIPPING SIZE (WDH) 28 X 17 X 45 inches

71 X 43 X 114 cm

SHIPPING WEIGHT (LB / KG) 90 / 41 90 / 41 90 / 41 90 / 41

COMMON FEATURES

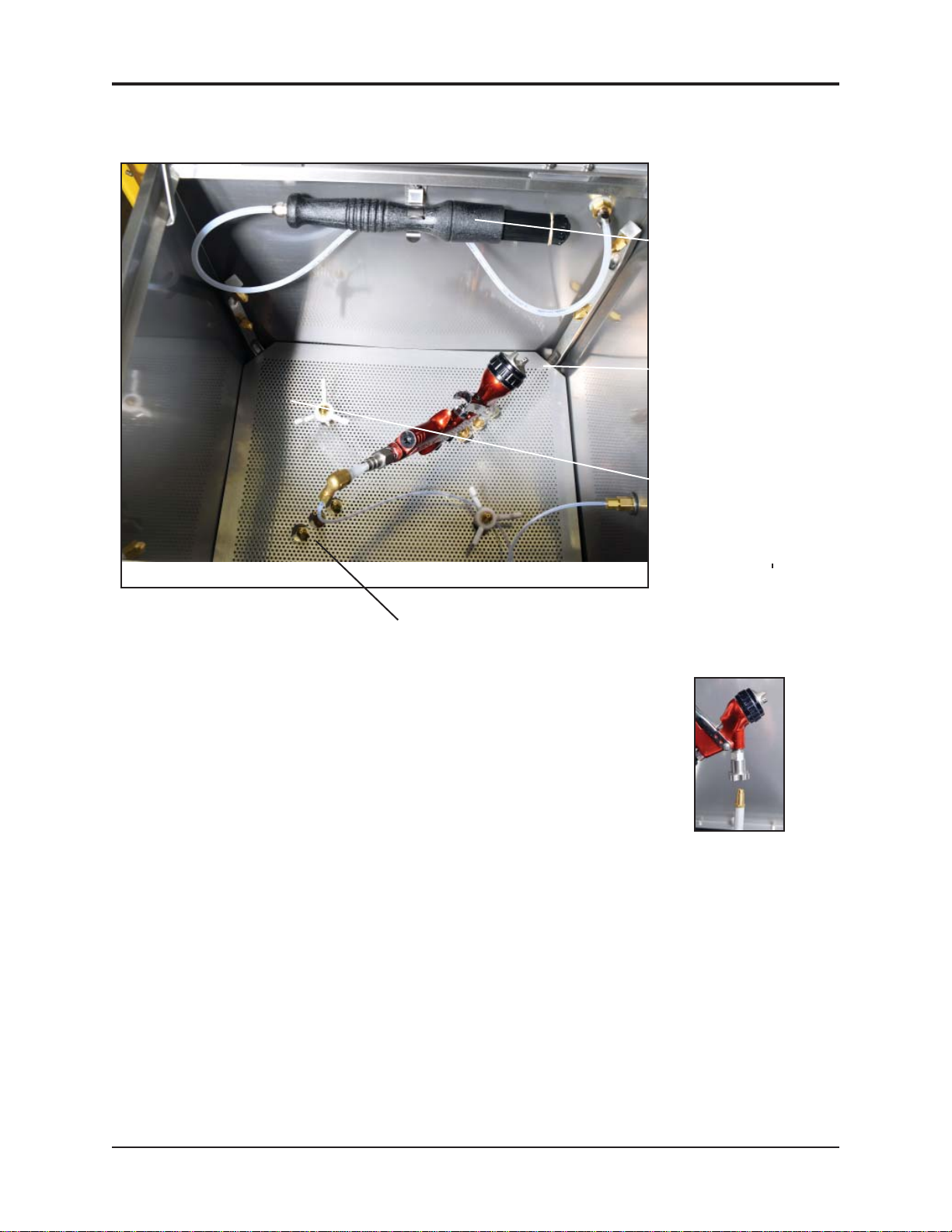

• Automatic Wash, Automatic Air Flush, Automatic Solvent Rinse.

• Flow-through Brush for manual washing. Flow Control.

• Clean 2 Spray Guns and 2 Pots at the same time.

• Stainless steel inlet filter, located at the end of the suction hose, prevents debris from reaching the

pump and wash pail.

• 14 Cleaning Jets with swirl action.

• Shipping Size and Weight: 28" W x 17" D x 42" H, 91 LBS 41 KG.

CAUTIONS AND WARNINGS

• Always disconnect this machine from power sources before performing maintenance.

• Do not smoke or use near open flames, sparks or heat.

• Make sure all ground wires are connected and that unit itself is grounded properly.

SAFETY EQUIPMENT

• Wear safety eyeware, respiratory protection and protective clothing.

• Wear deluxe extended length neoprene gloves; SAS PN 6588 or Thicksters PN 6602-20 through

6605-20.